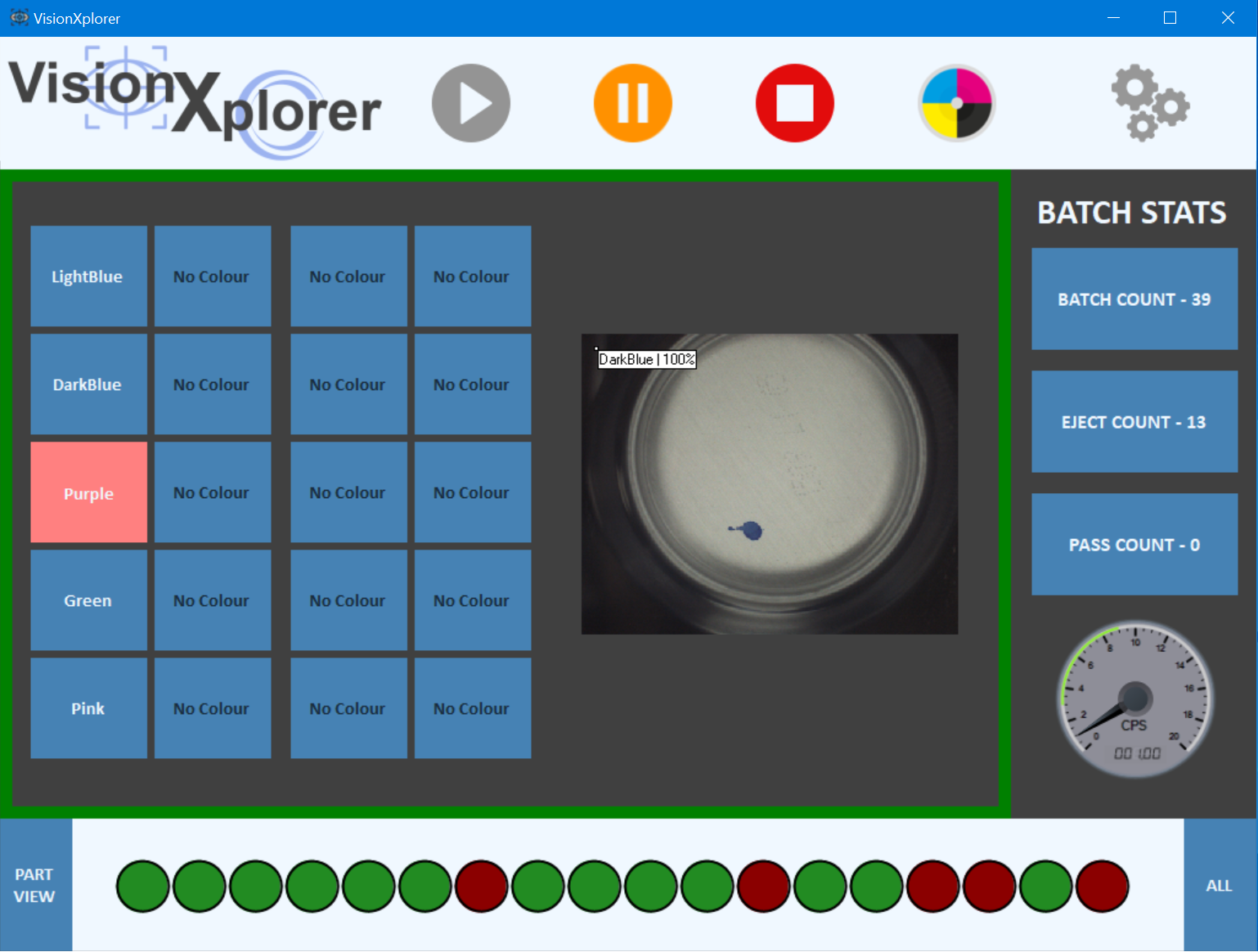

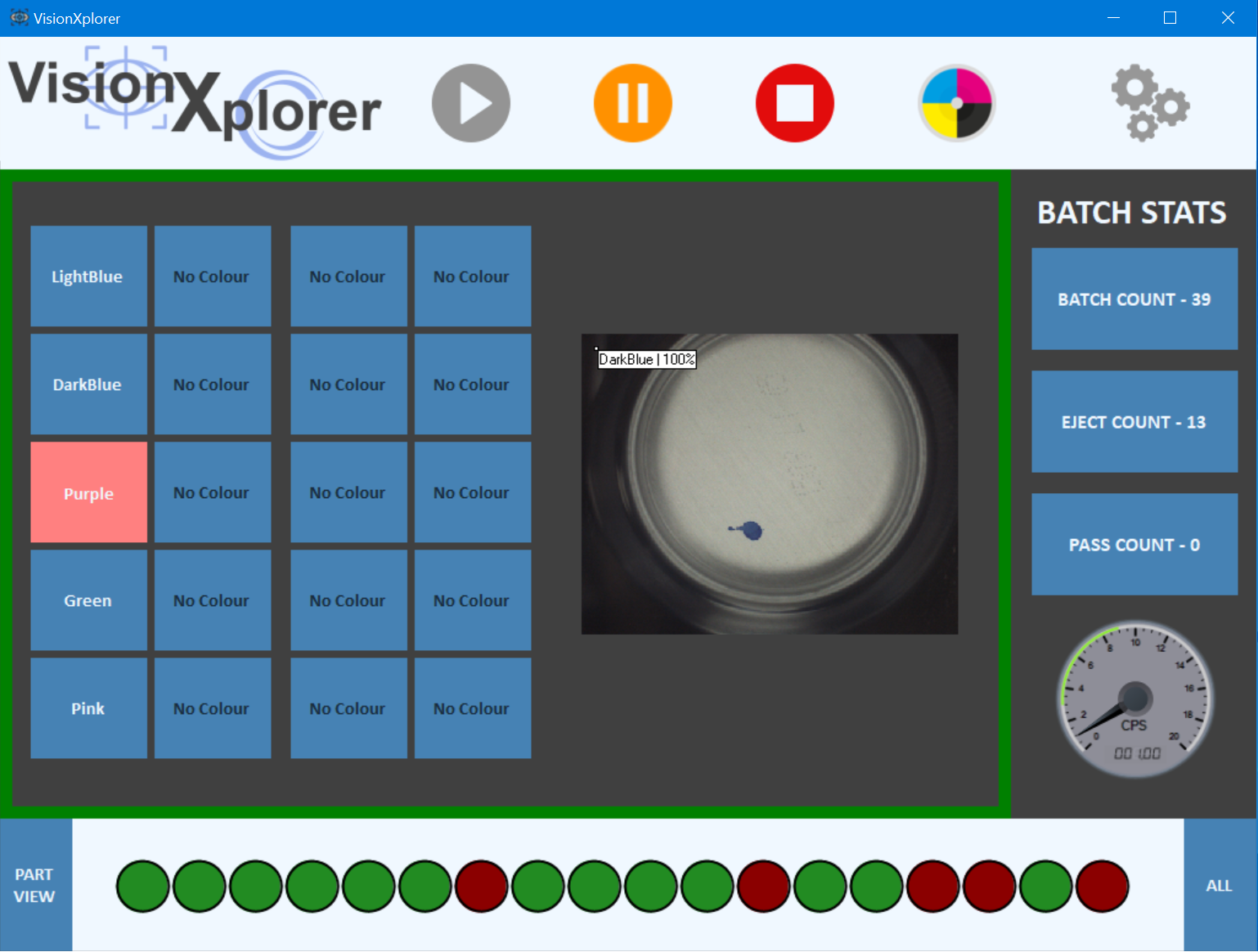

The Z701 Vision Sorting System has been developed specifically to meet customer end of line sorting requirements to facilitate sorting of HFI (Hold for Inspection) pallets to reduce manual work.

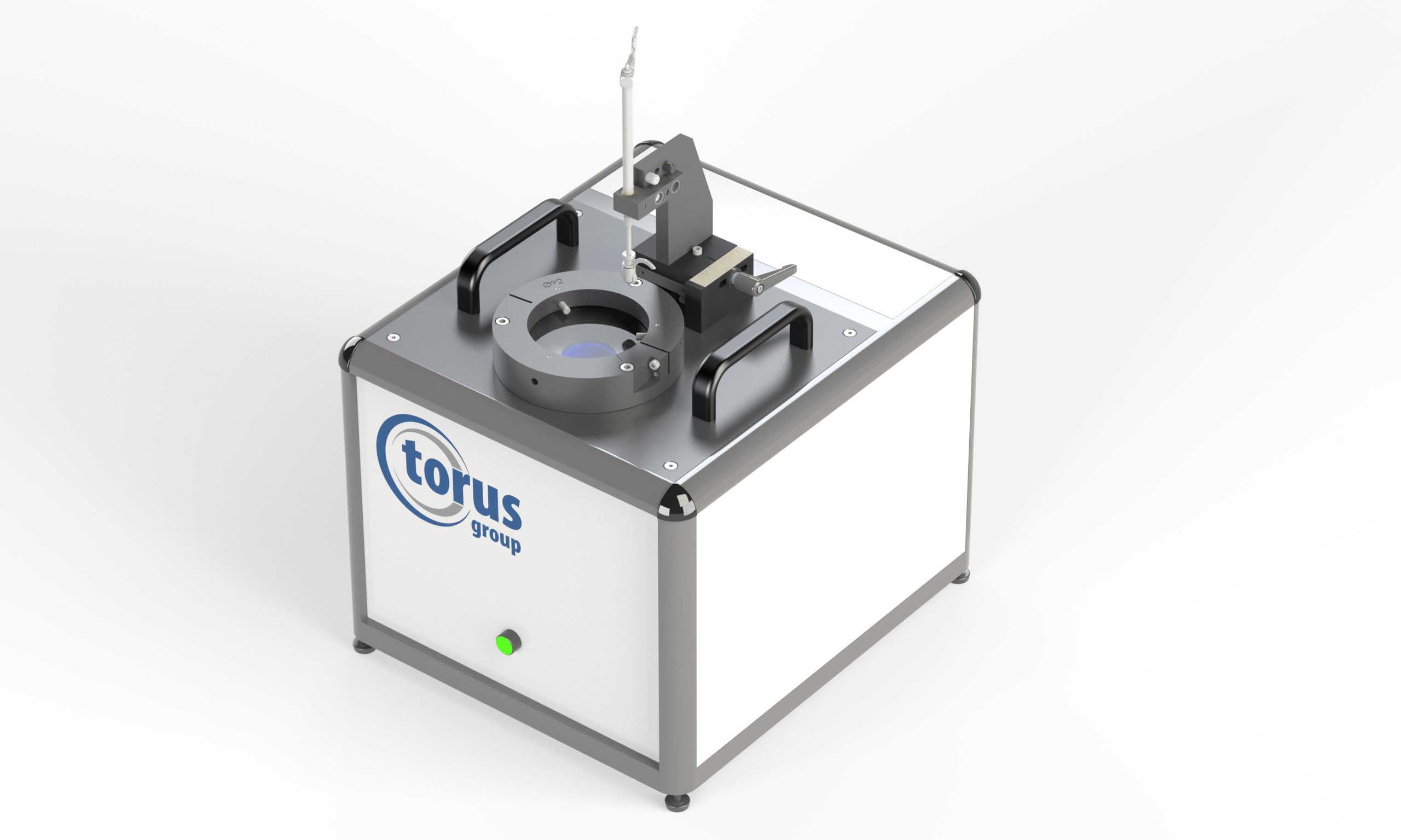

Torus Beverage Can Gauging

Measurement Features

Key Features

The Z701 integrates directly into an existing end of line sorter with minimal adjustments required. The system can be integrated into an existing or new sorter – Torus work closely with the customer’s chosen integrator to ensure a successful installation. A site survey is carried out by both parties to agree the suggested location for the integration.

The camera will be located on your existing sorting line

The Vision System can be positioned up to 10m away from the camera

The 2nd monitor can be positioned up to 10m away from the Vision System, enabling the user to measure results from elsewhere in the facility

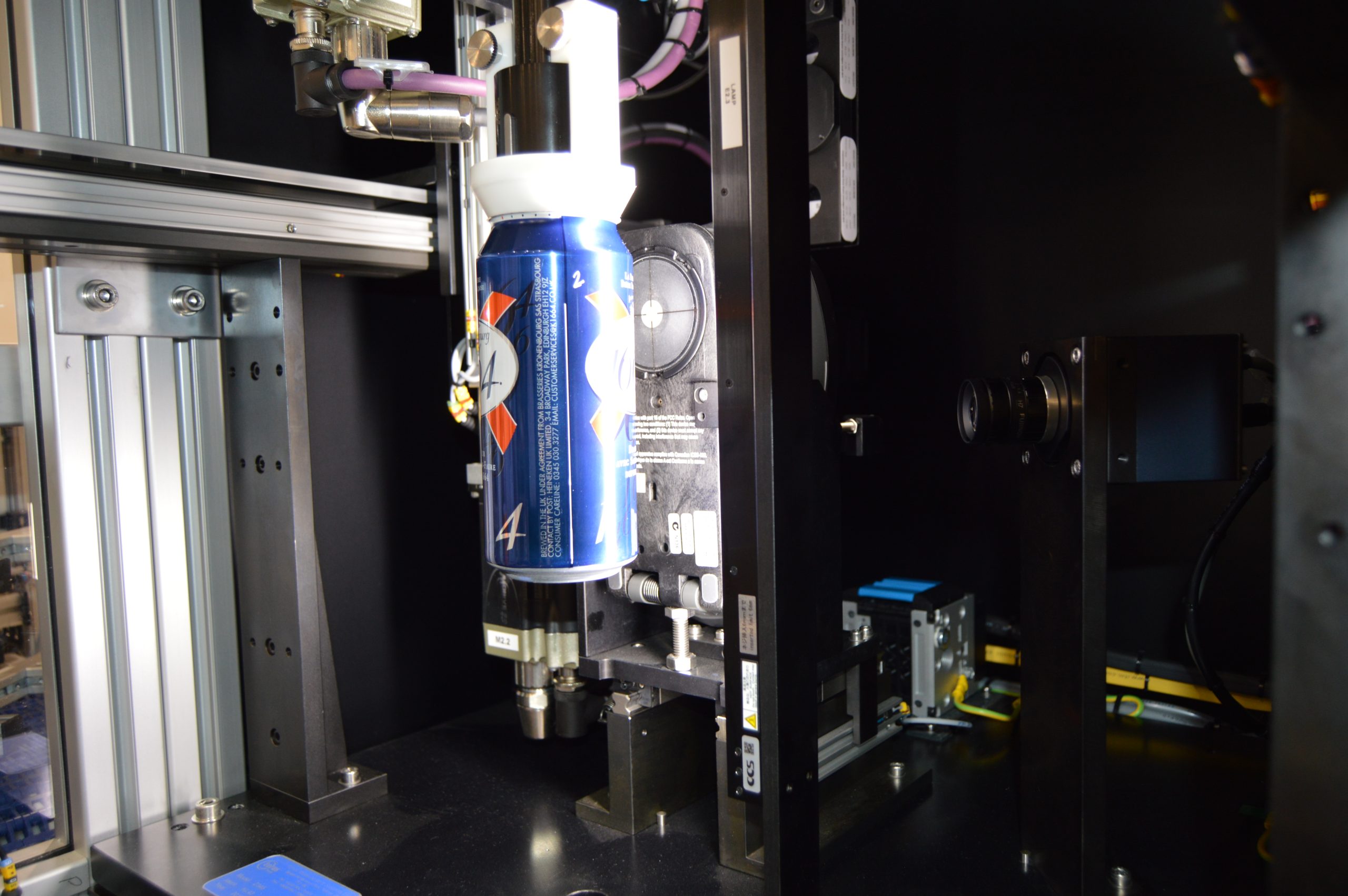

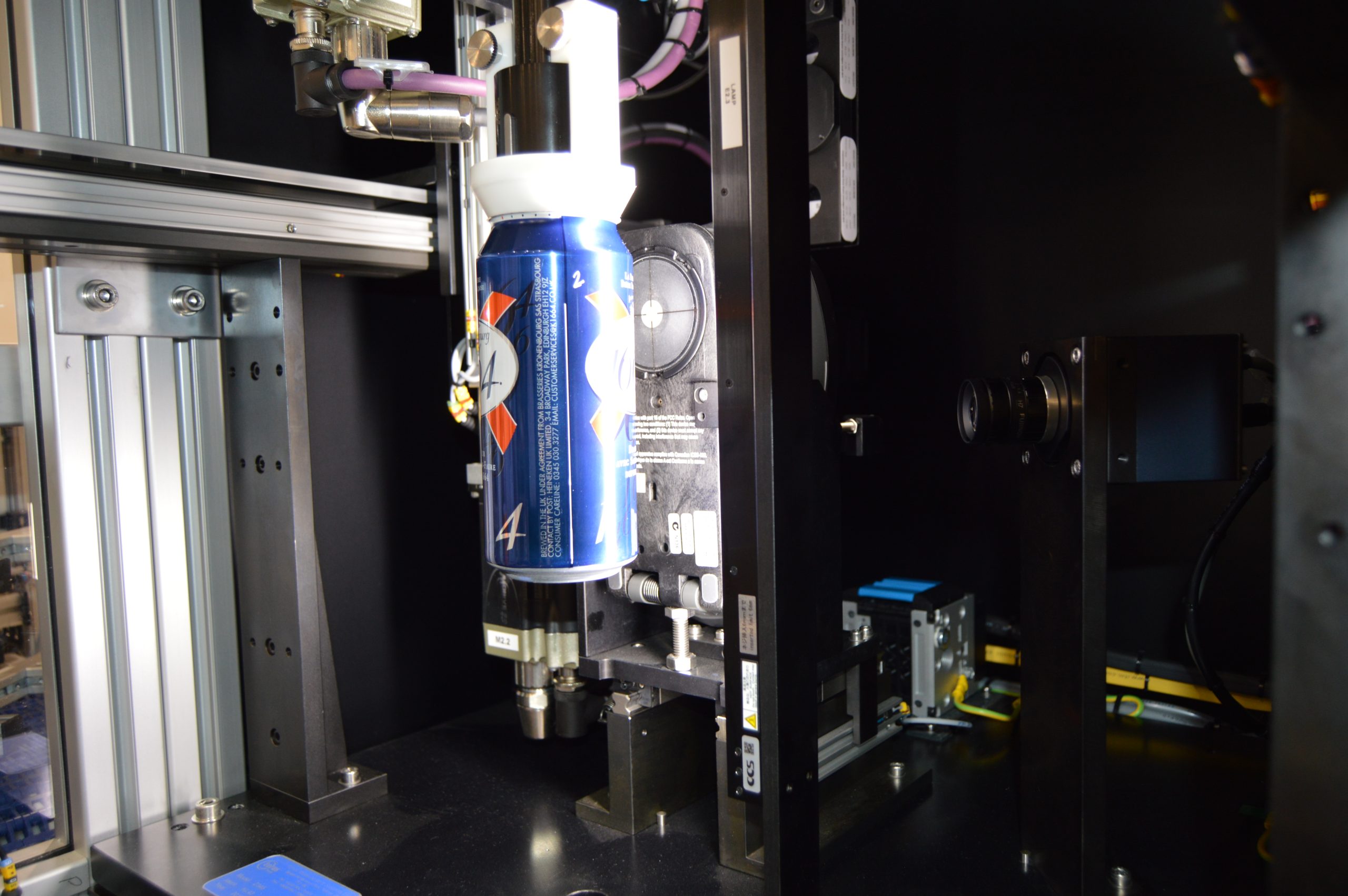

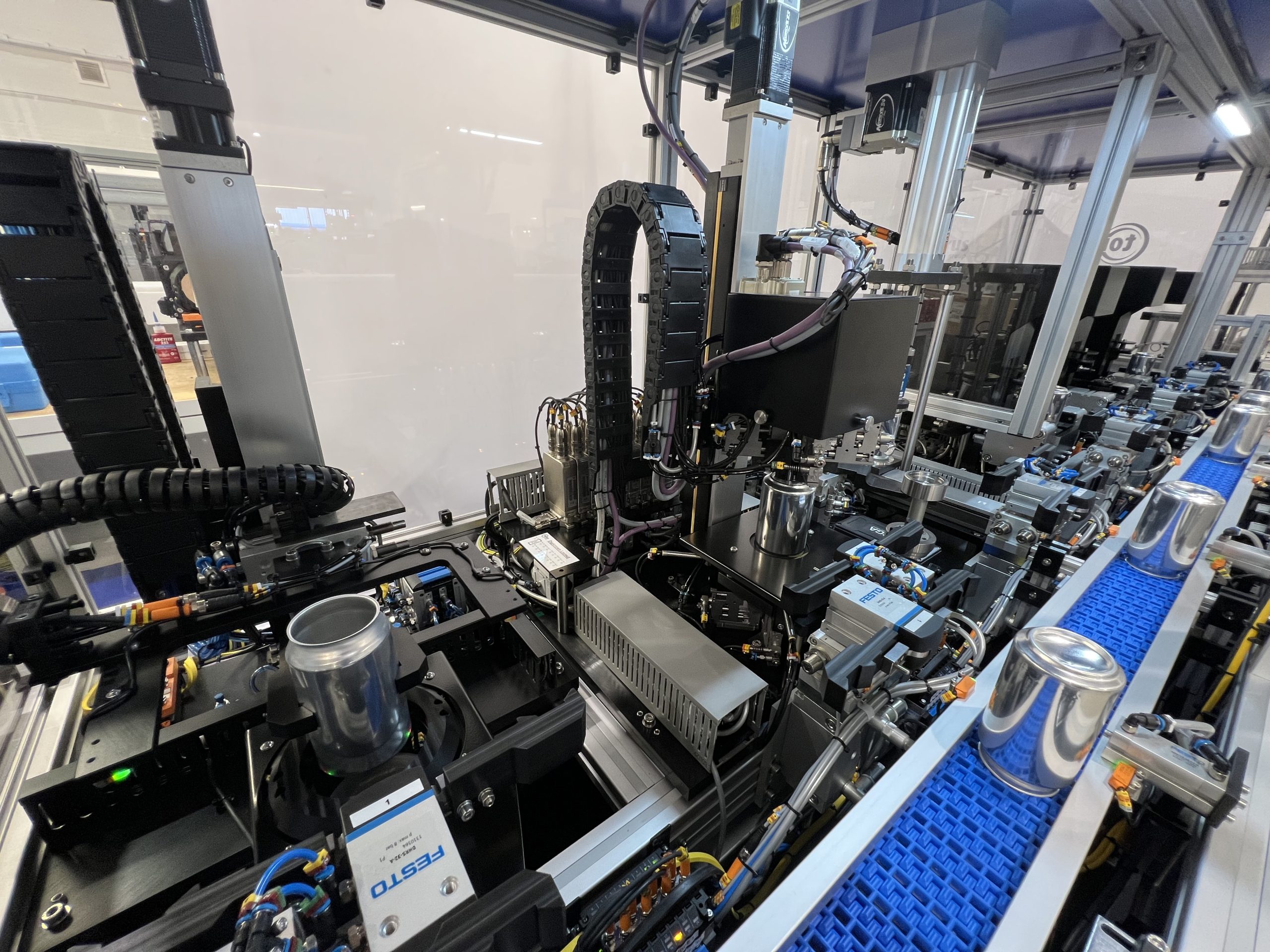

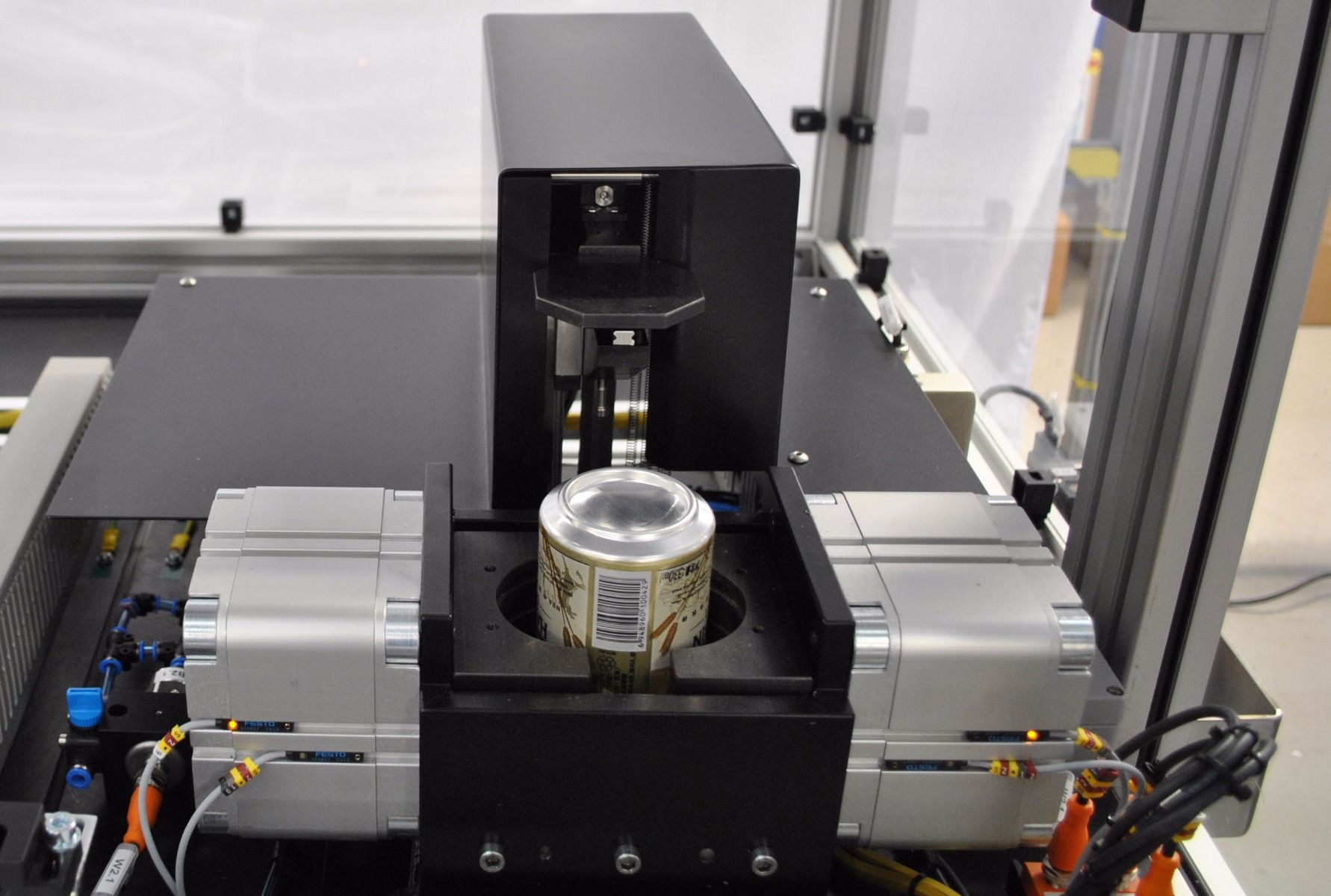

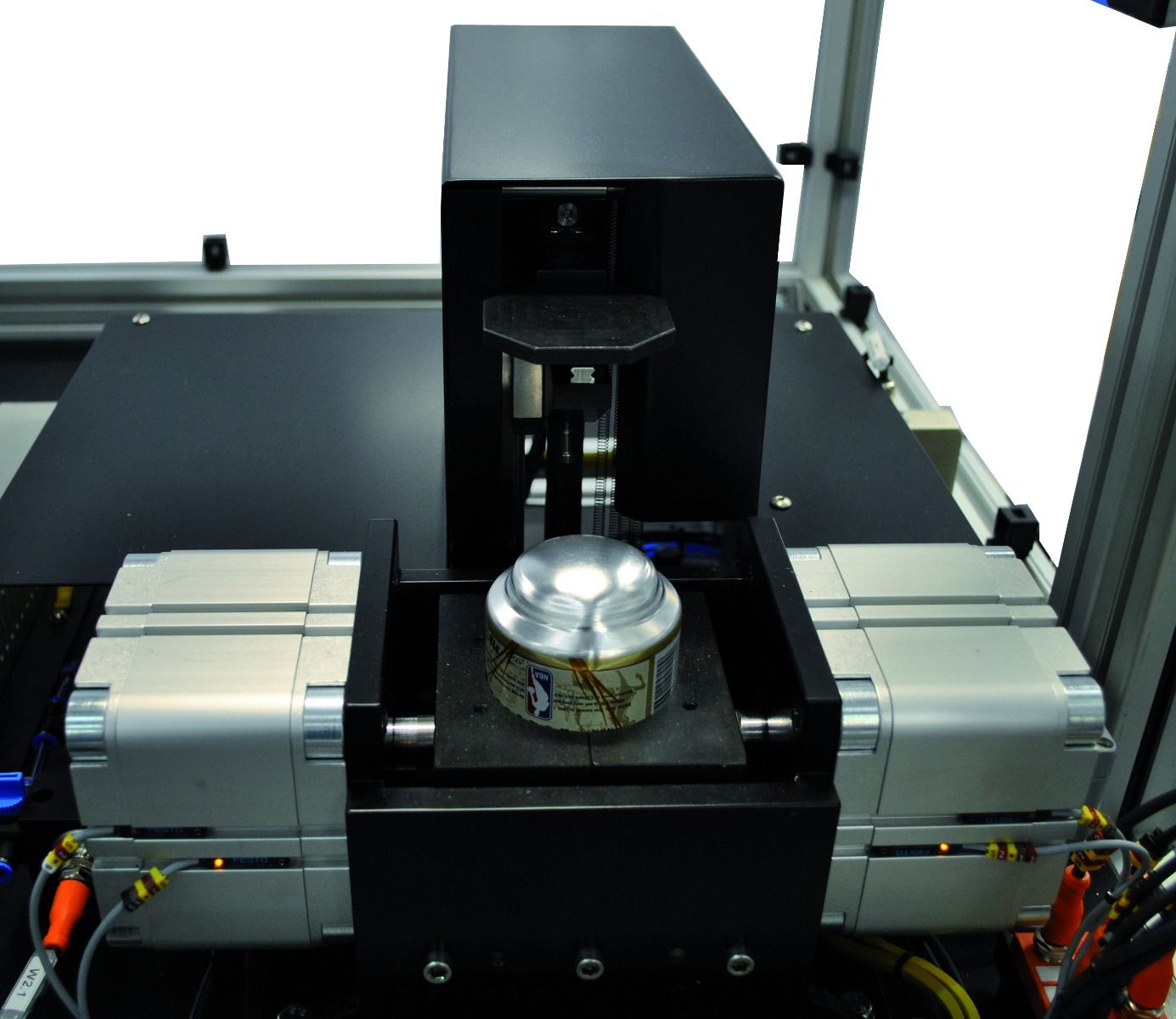

The Z346 is capable of inspecting 202-300 body diameter, straight walled and finished cans with minimal change parts. Providing direct correlation to Torus’ Z345 Automatic Colour Inspection System, the Z346 boasts an easy to use platform for the inspection of multiple decorations, giving you direct data transfer into your chosen SPC package.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

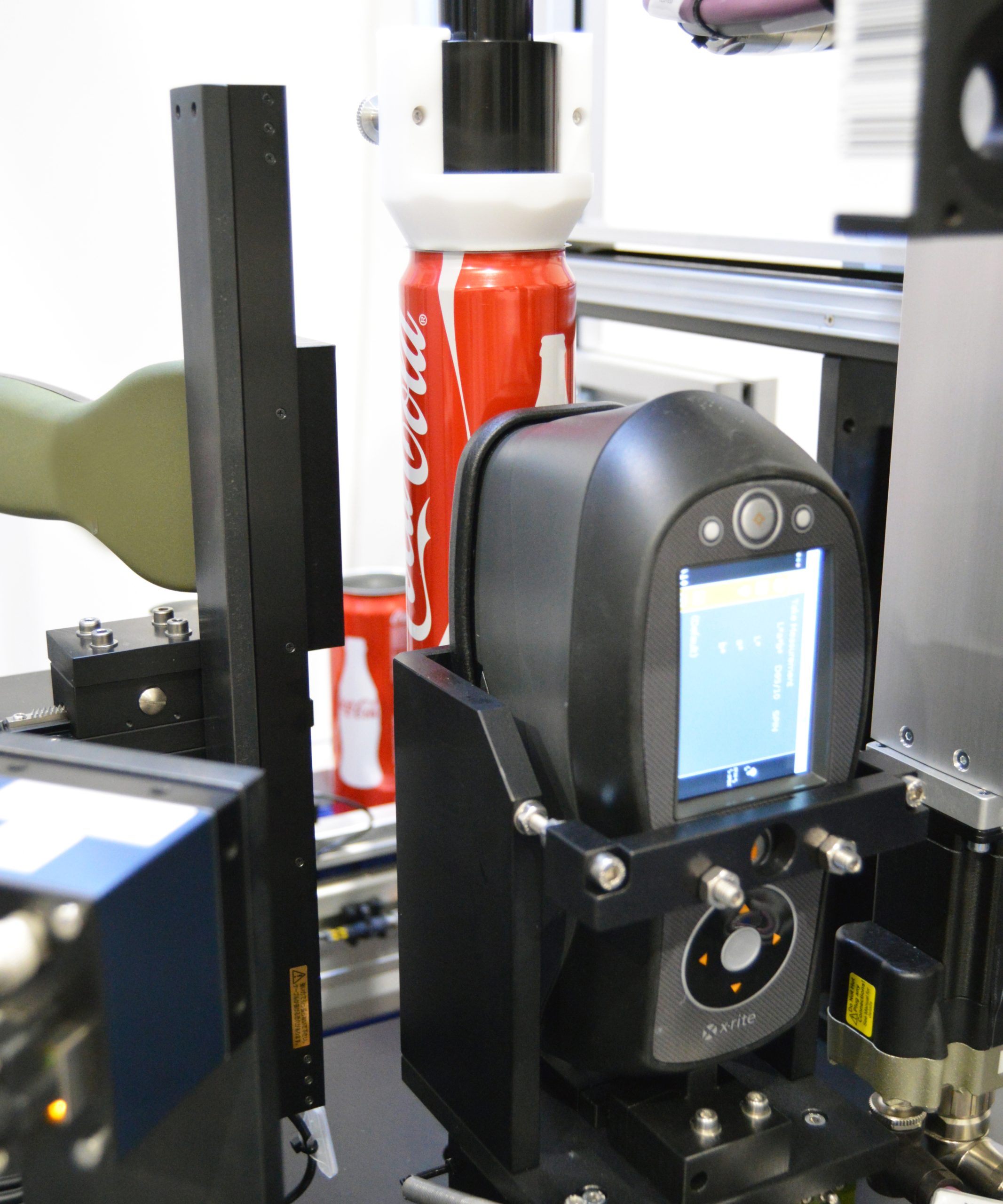

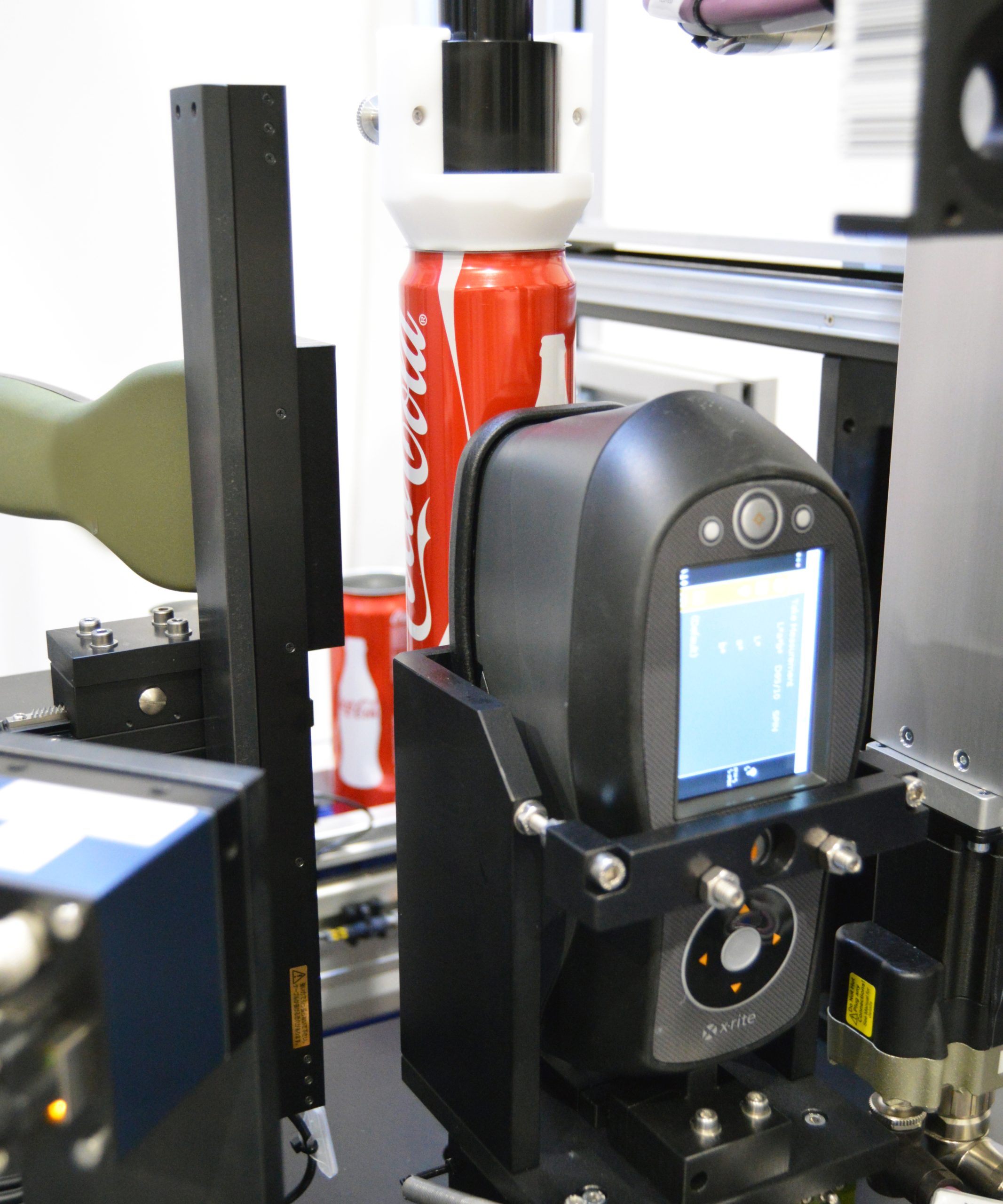

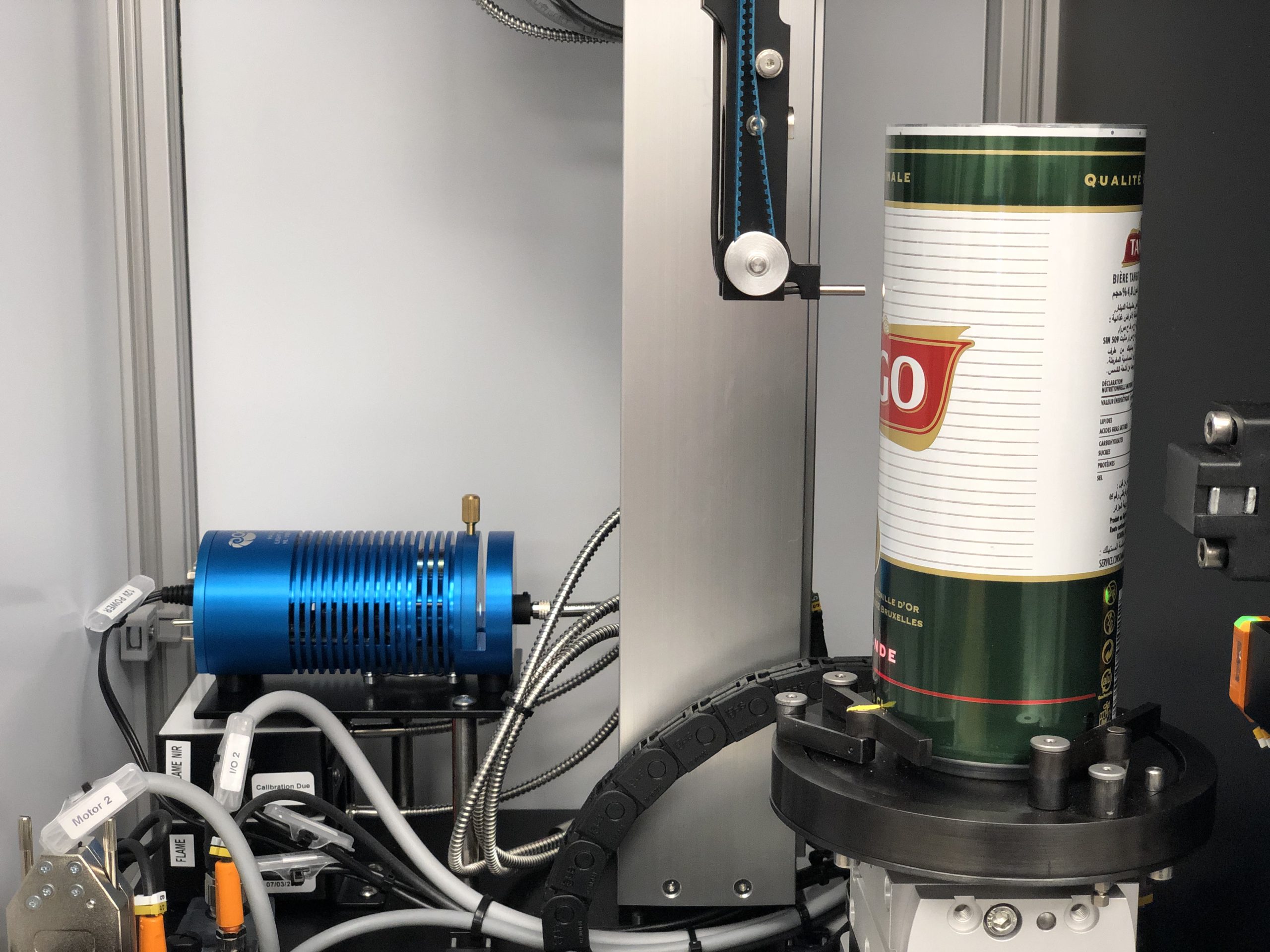

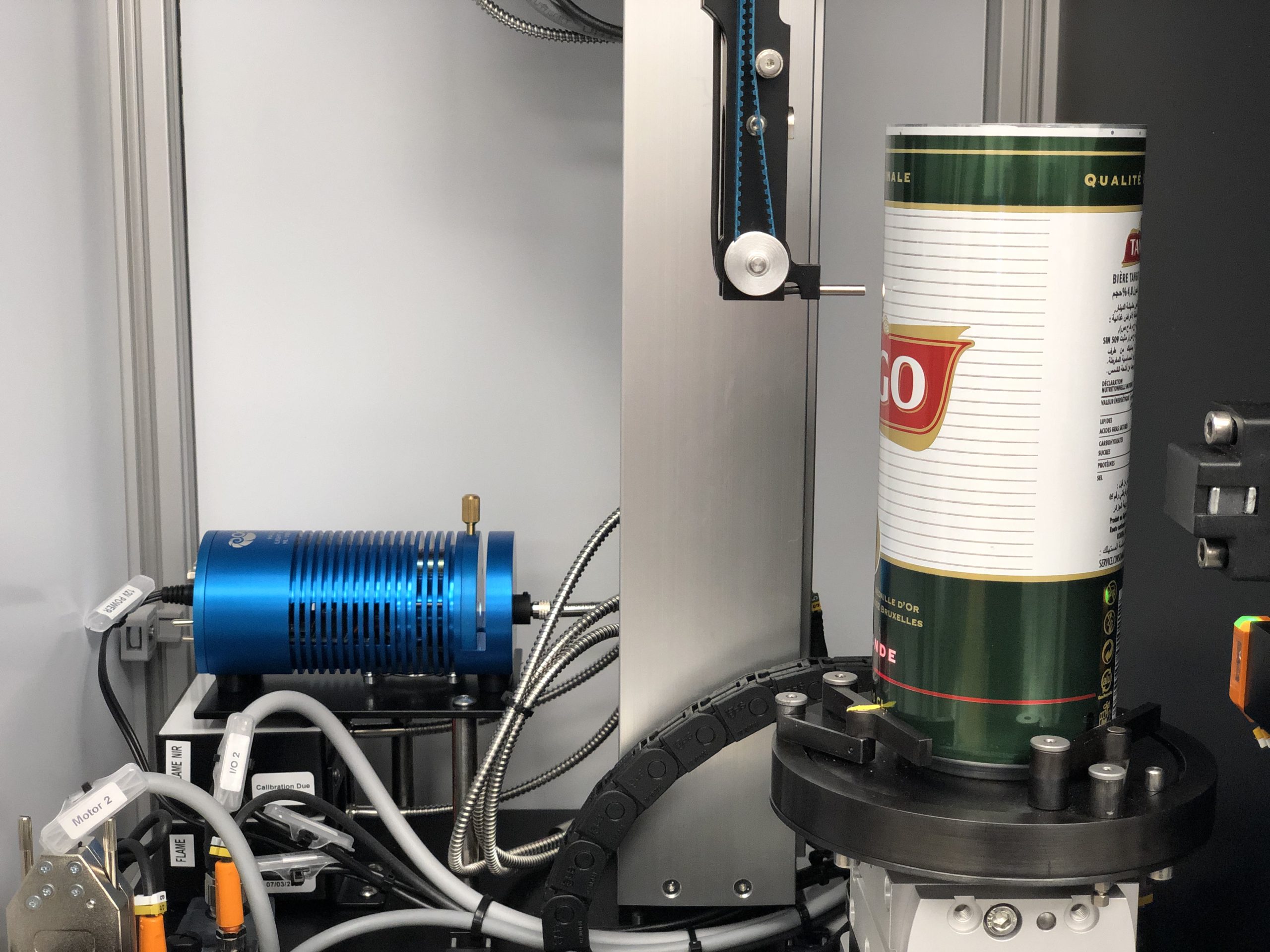

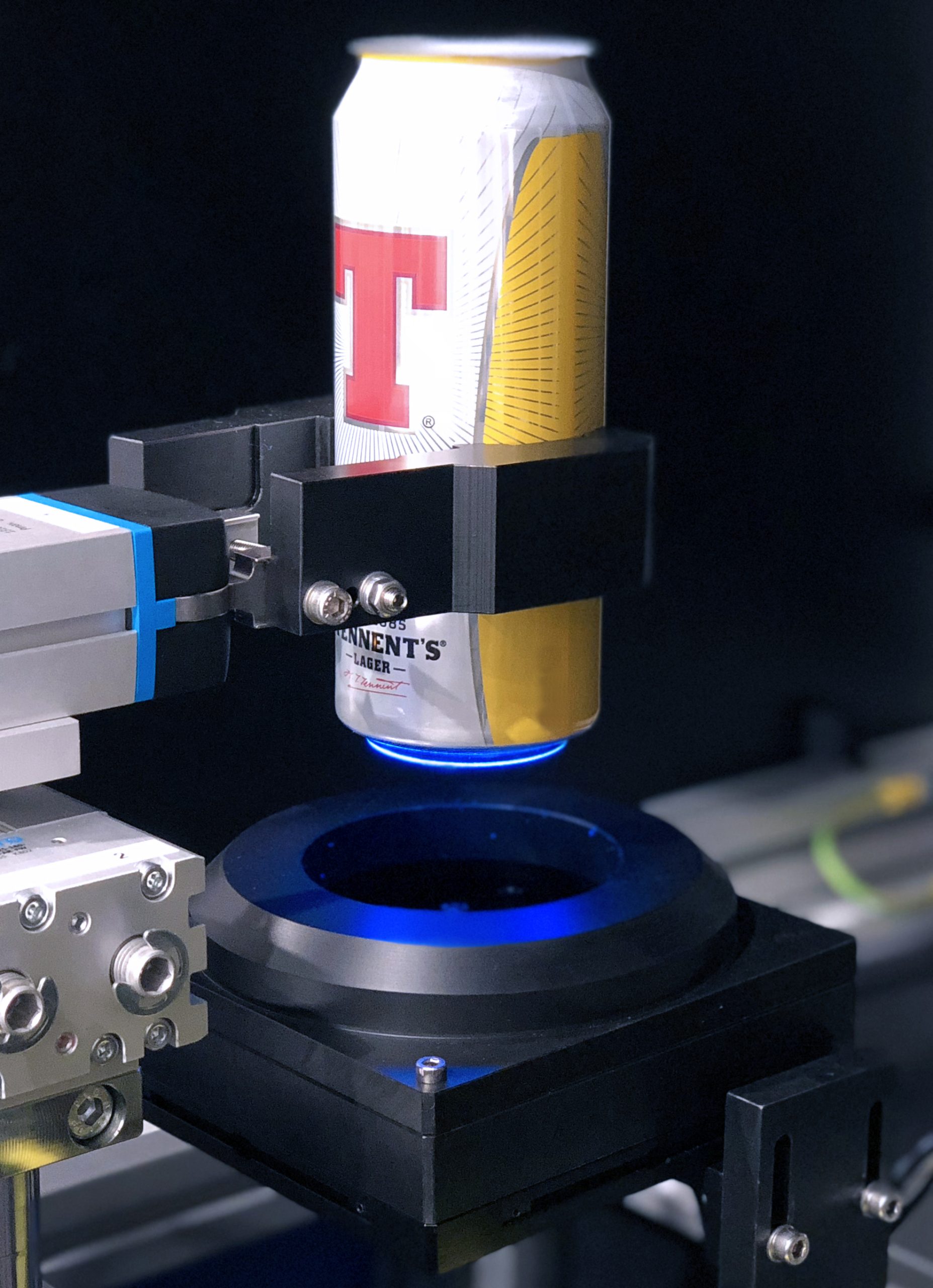

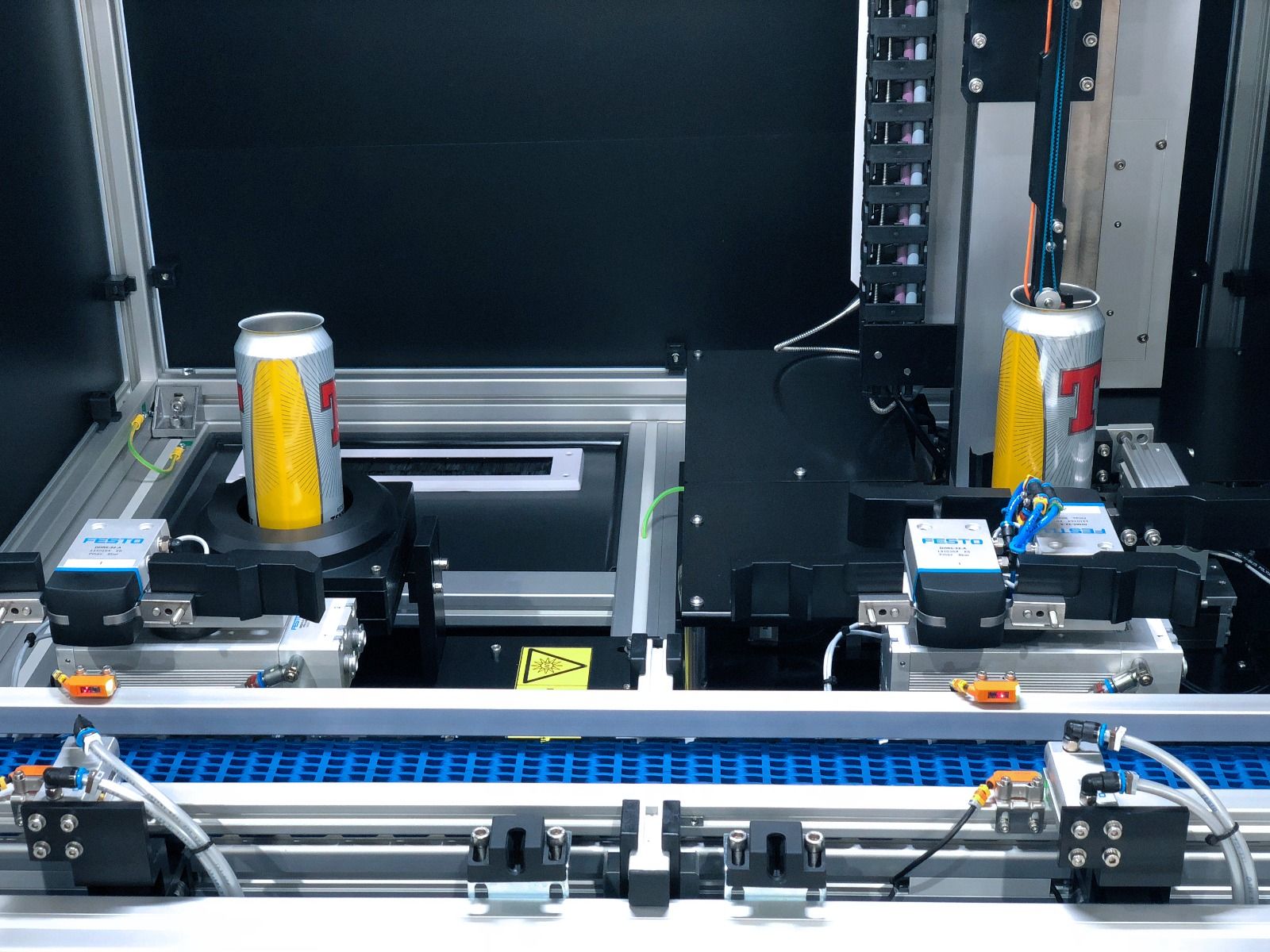

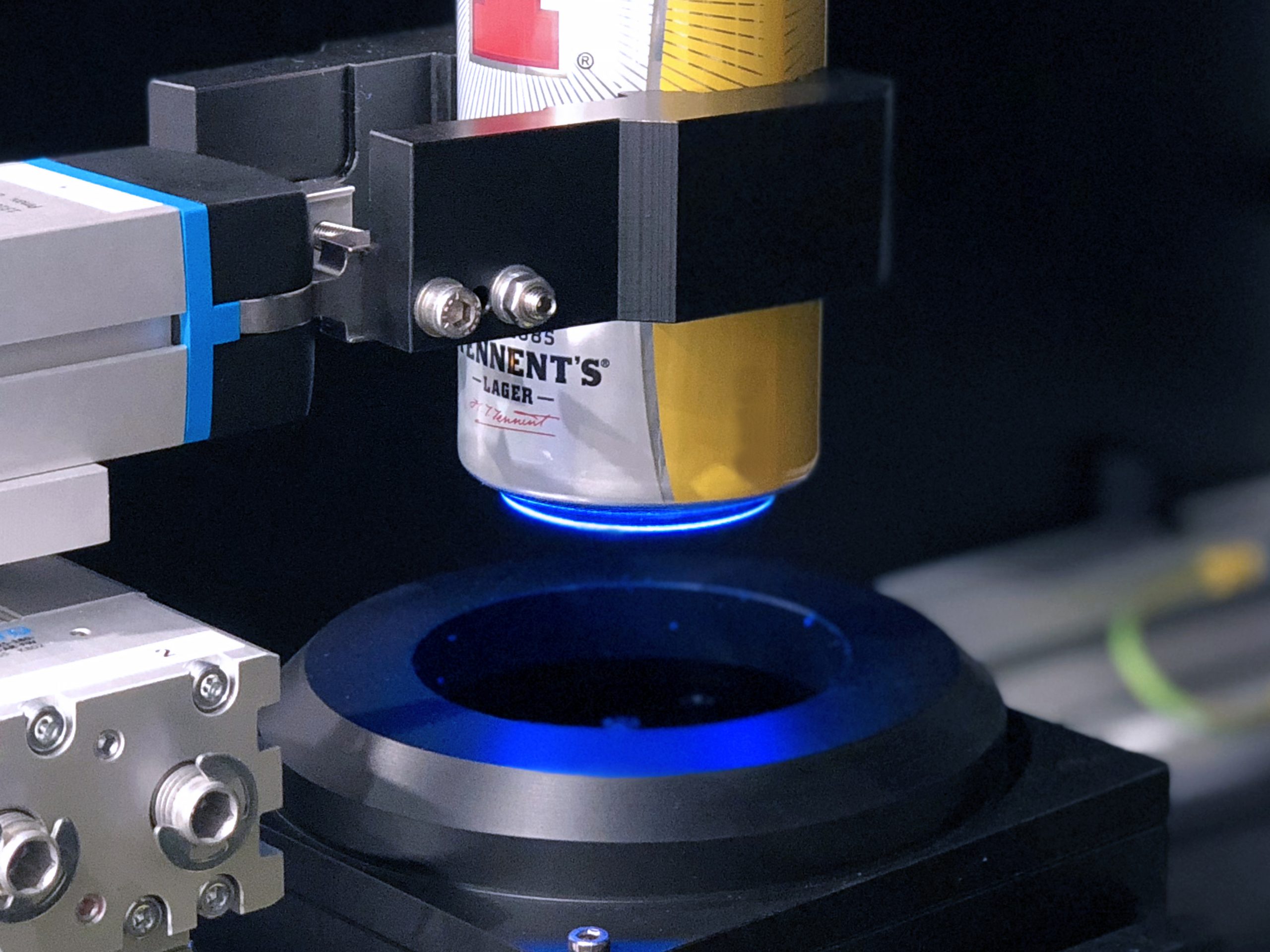

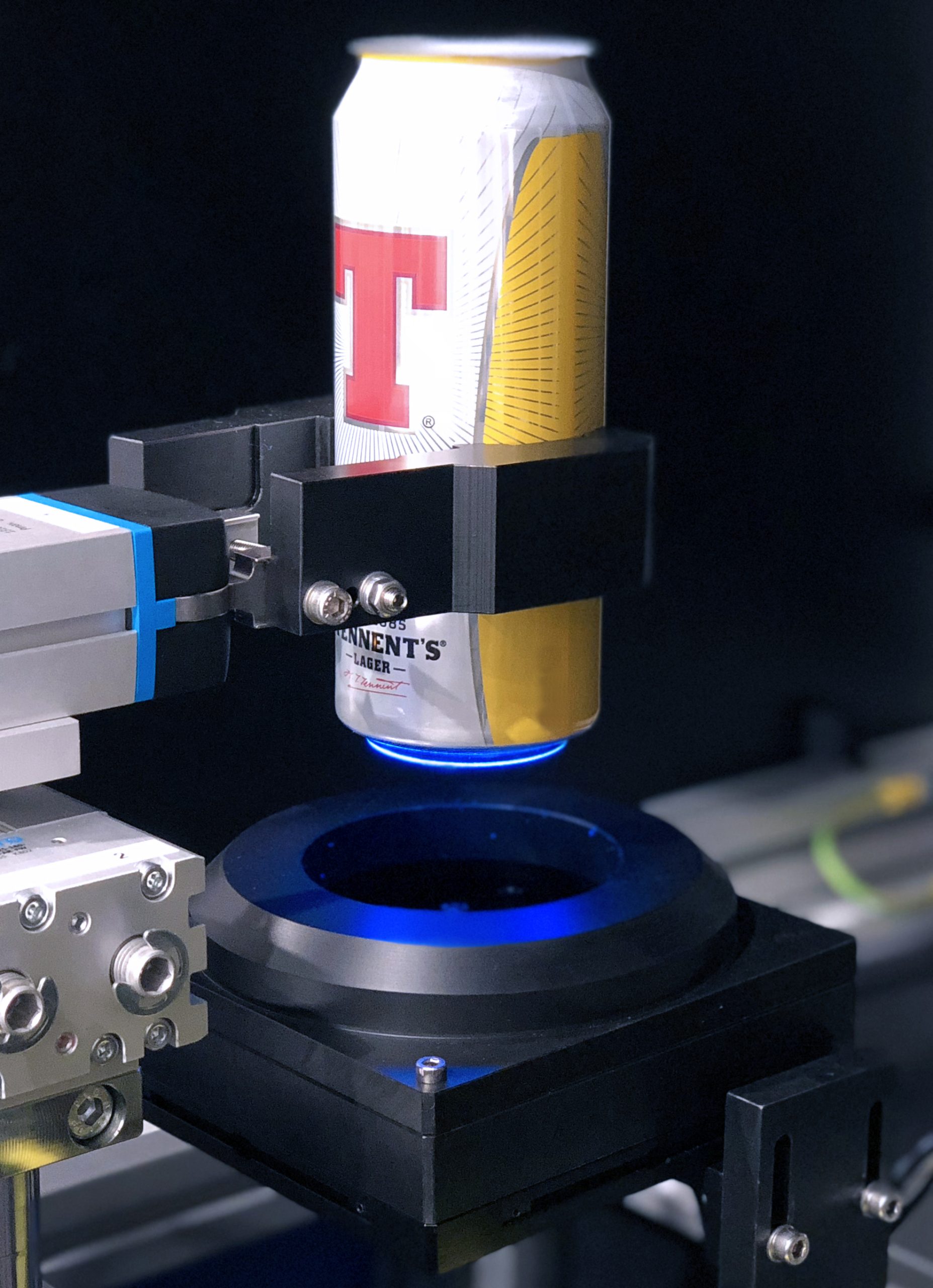

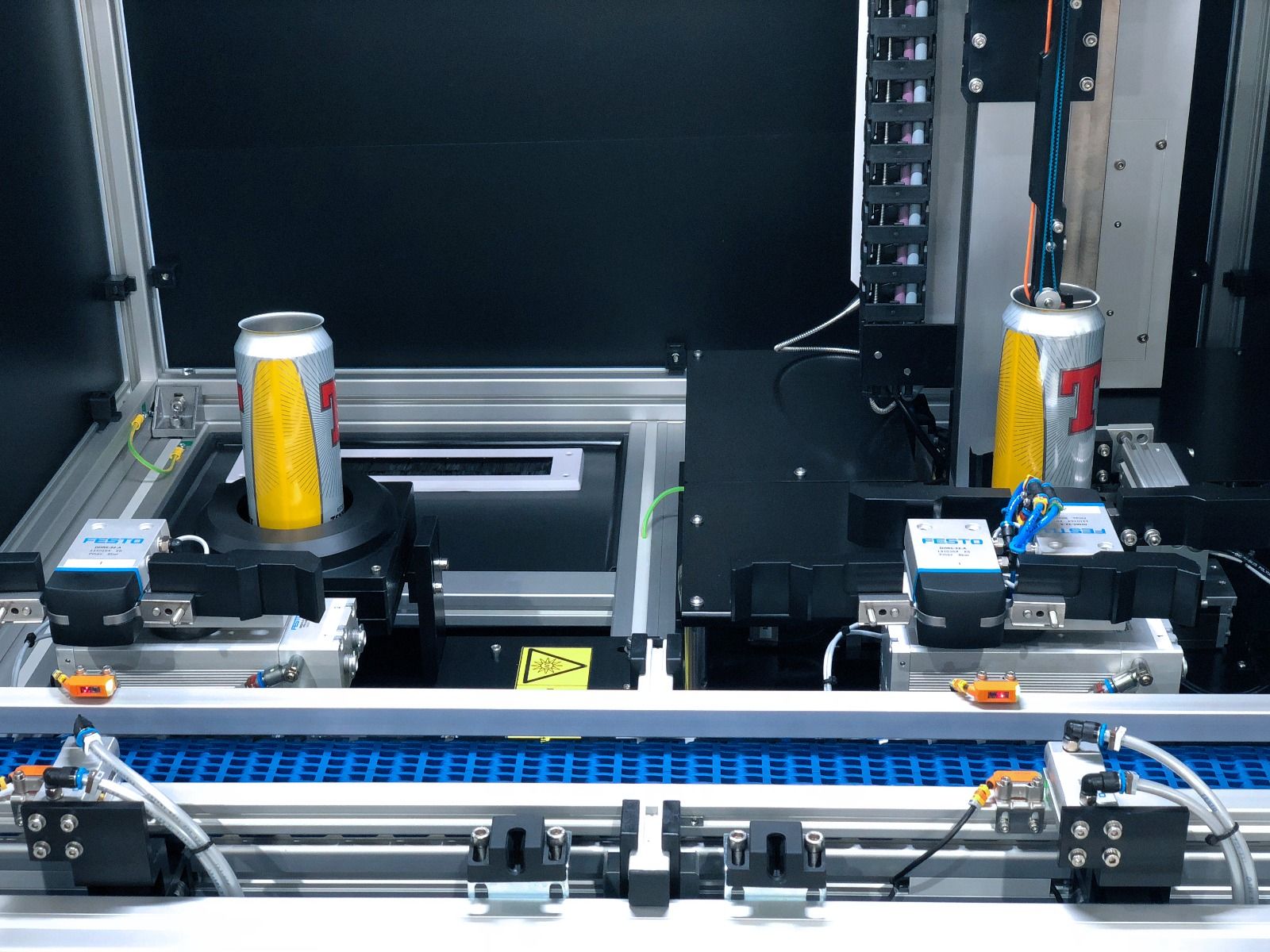

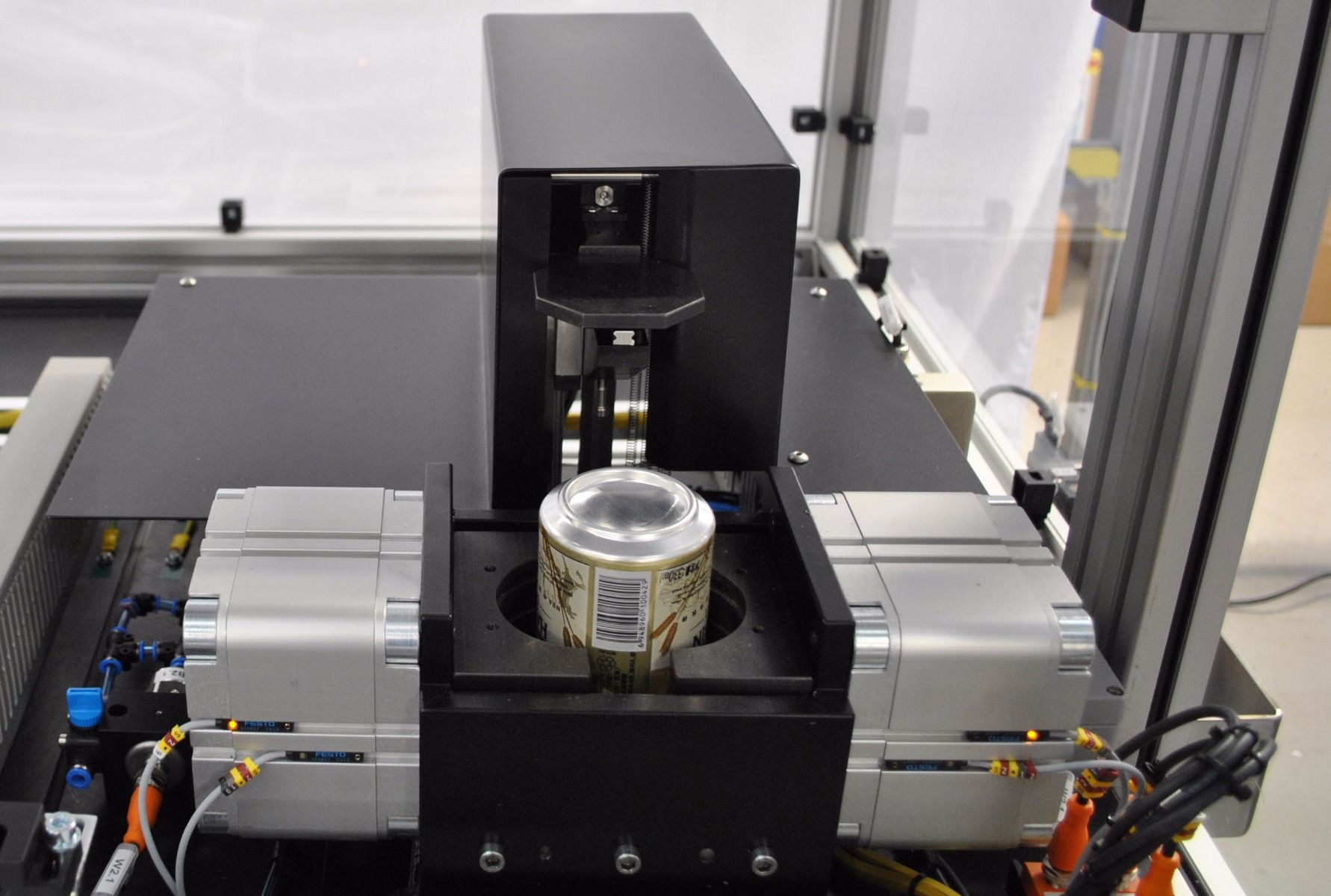

Torus’ Z345 is the world’s first Automatic Colour Inspection System powered by X-Rite®. Providing true quantitative colour measurement for aluminium and steel beverage cans in an automatic system.

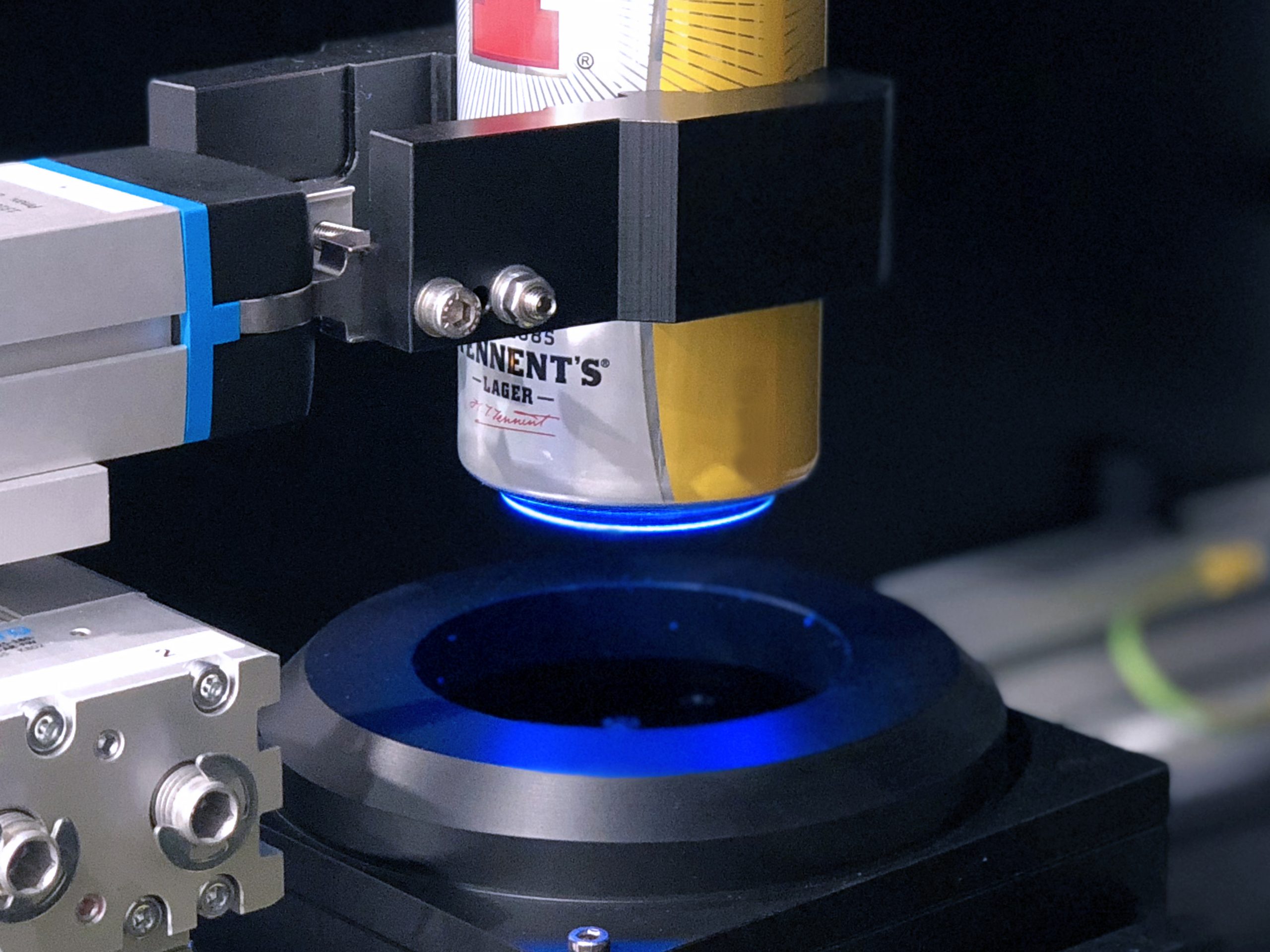

The Z345 is capable of inspecting 202-300 body diameter, straight walled and finished cans with minimal change parts. Cans may be loaded in any orientation, either on to an automatic in-feed conveyor or directly from the production line. A high-resolution colour scan camera reads and ‘unwraps’ the label and aligns it to a master image. The can is then accurately presented to the Ci64 for inspection at pre-defined, user selected locations with unmatched positional repeatability.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

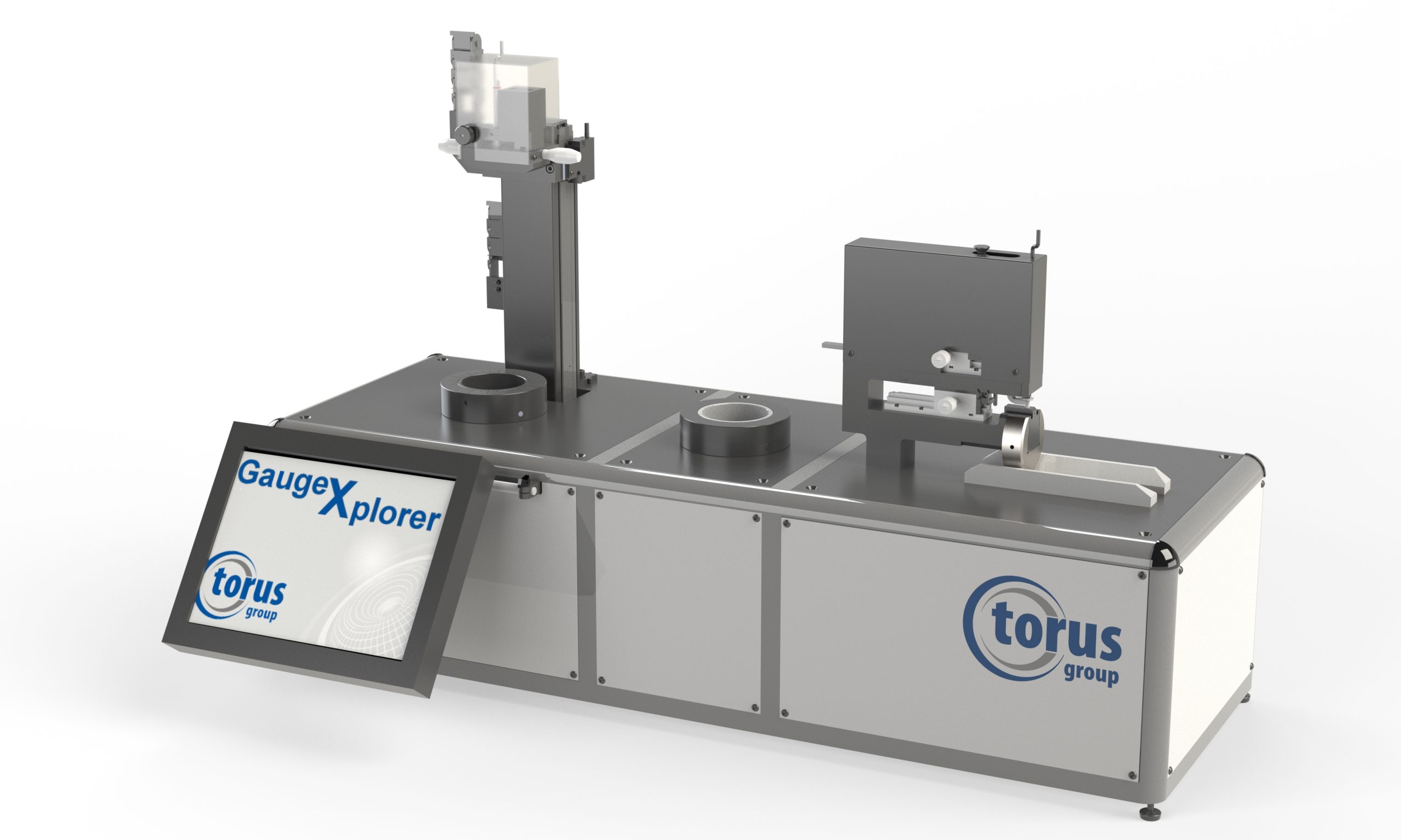

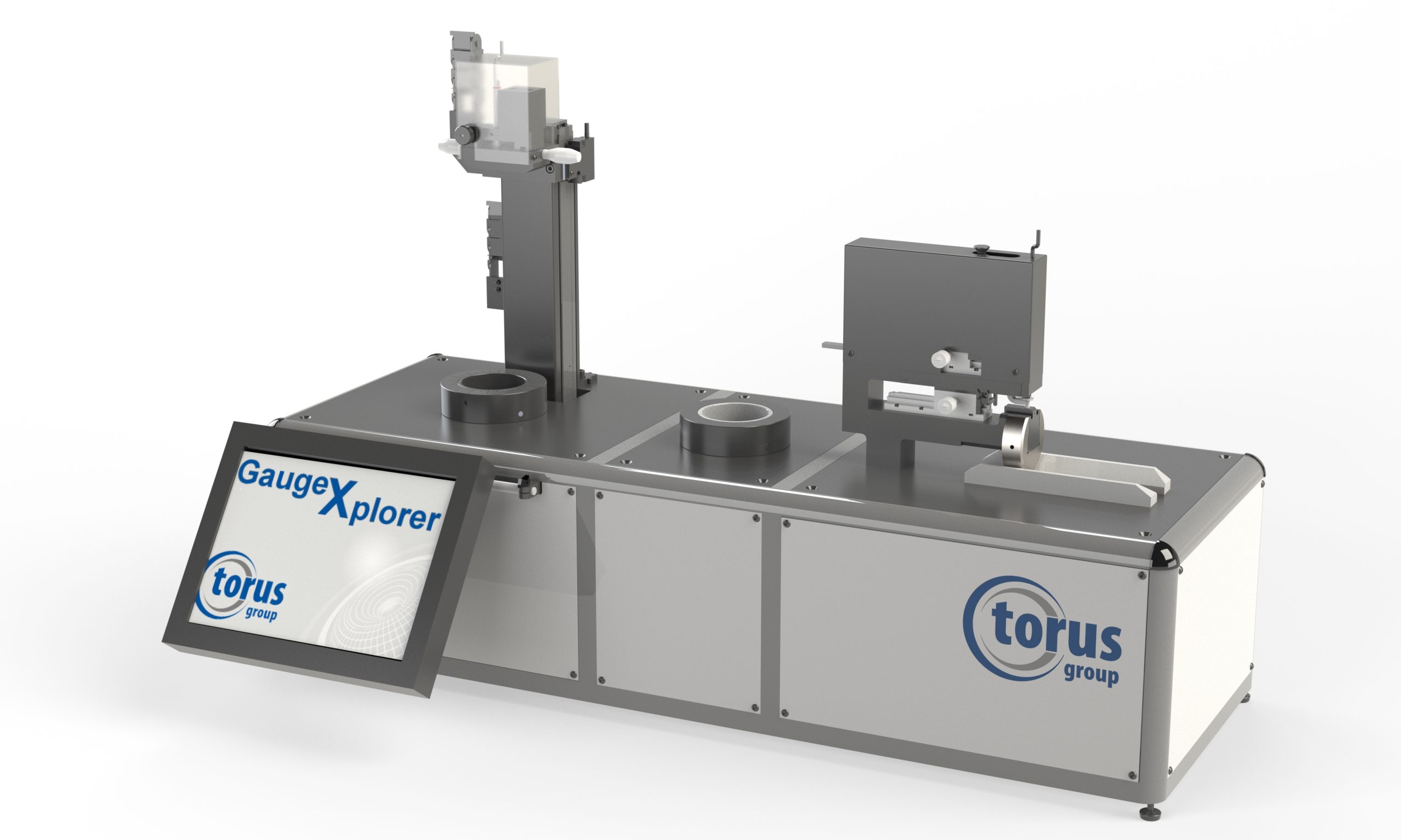

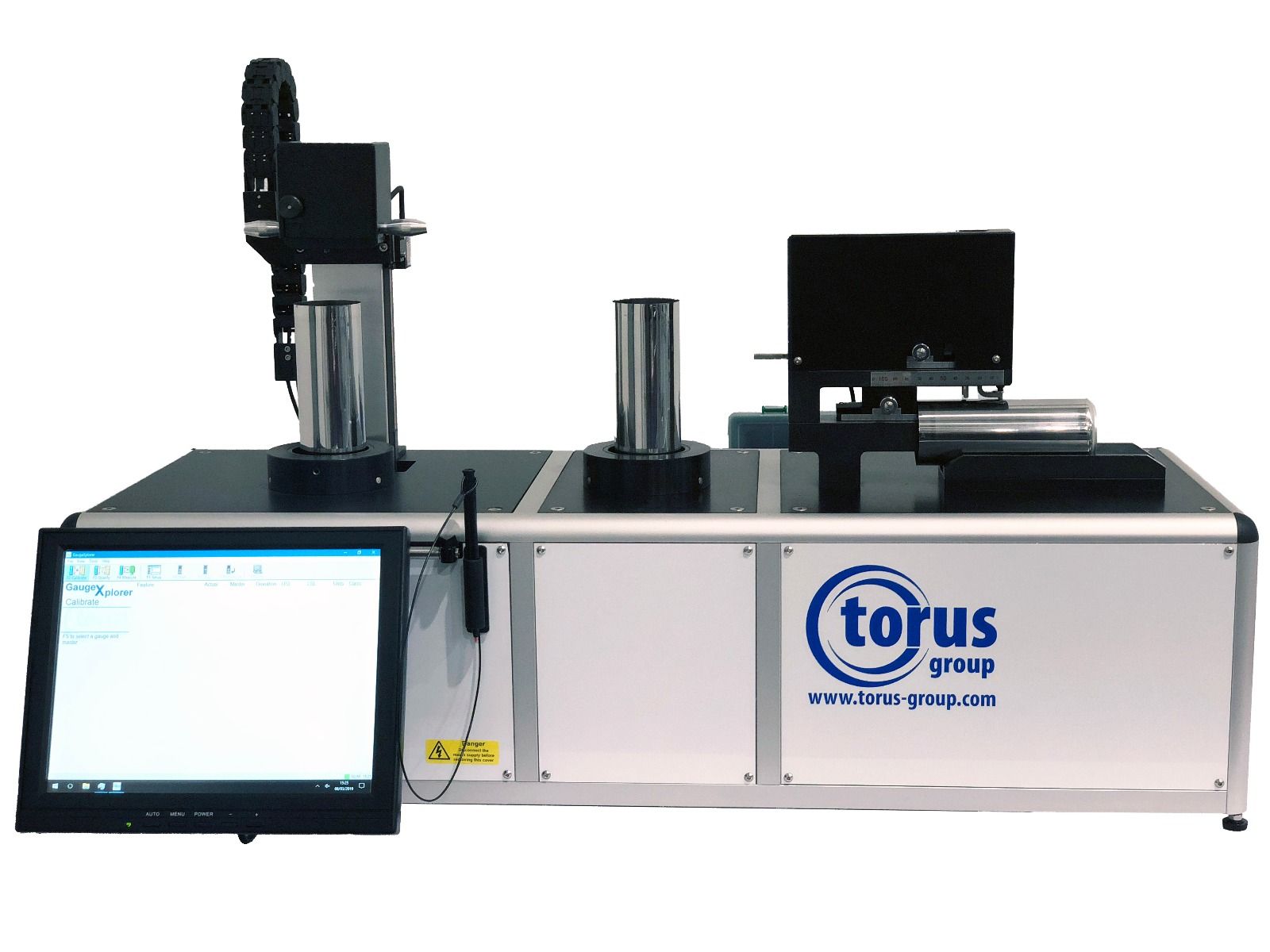

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

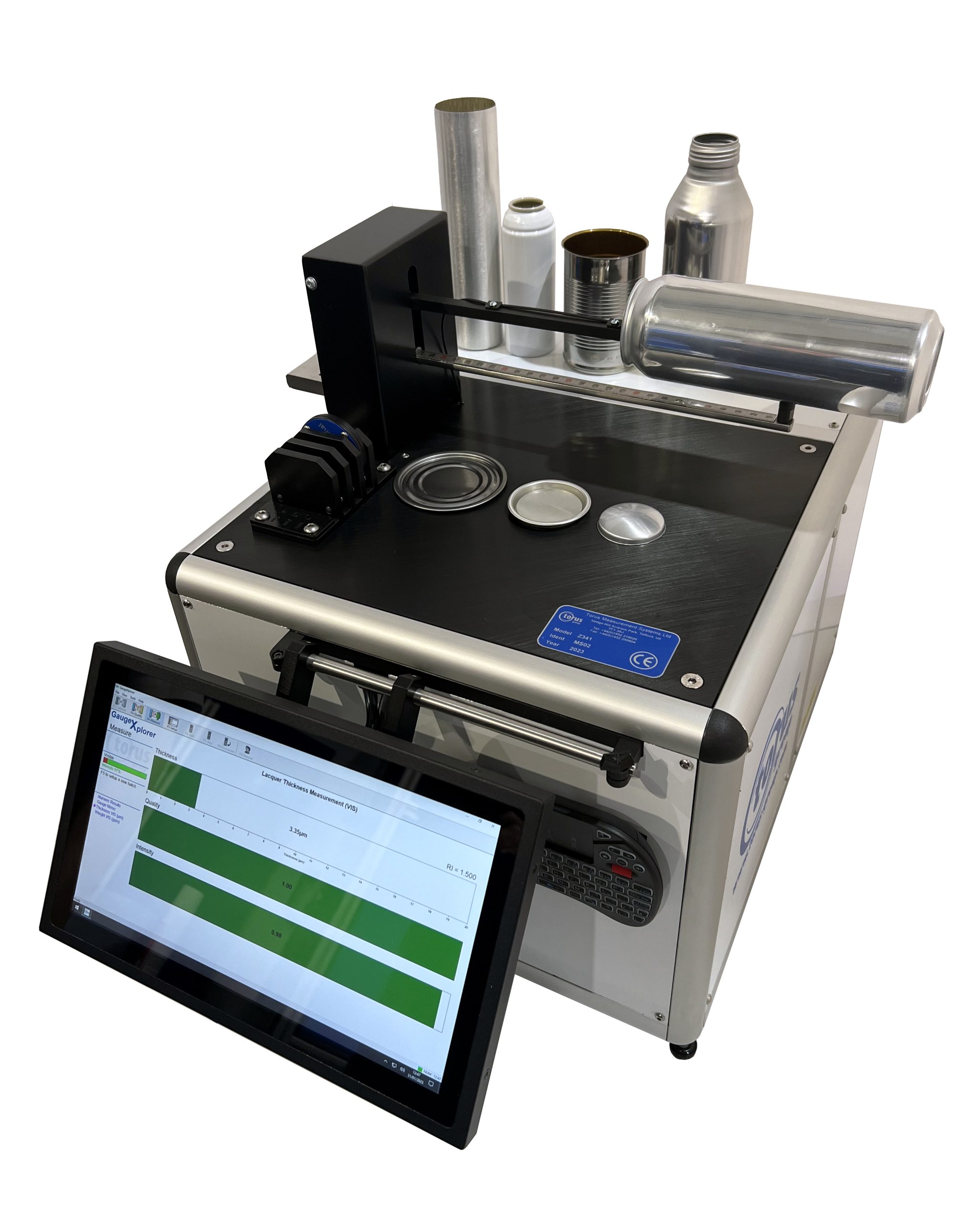

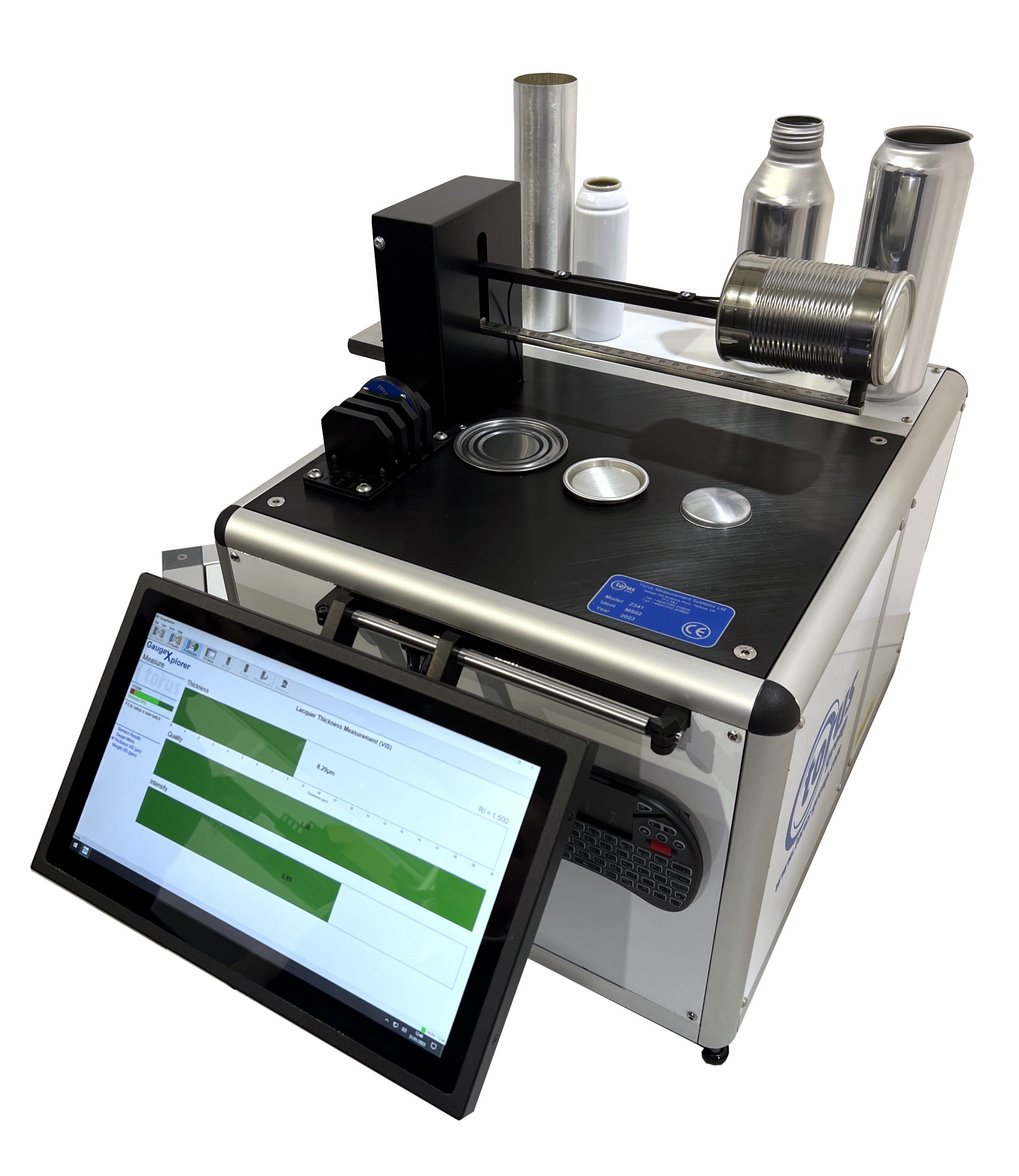

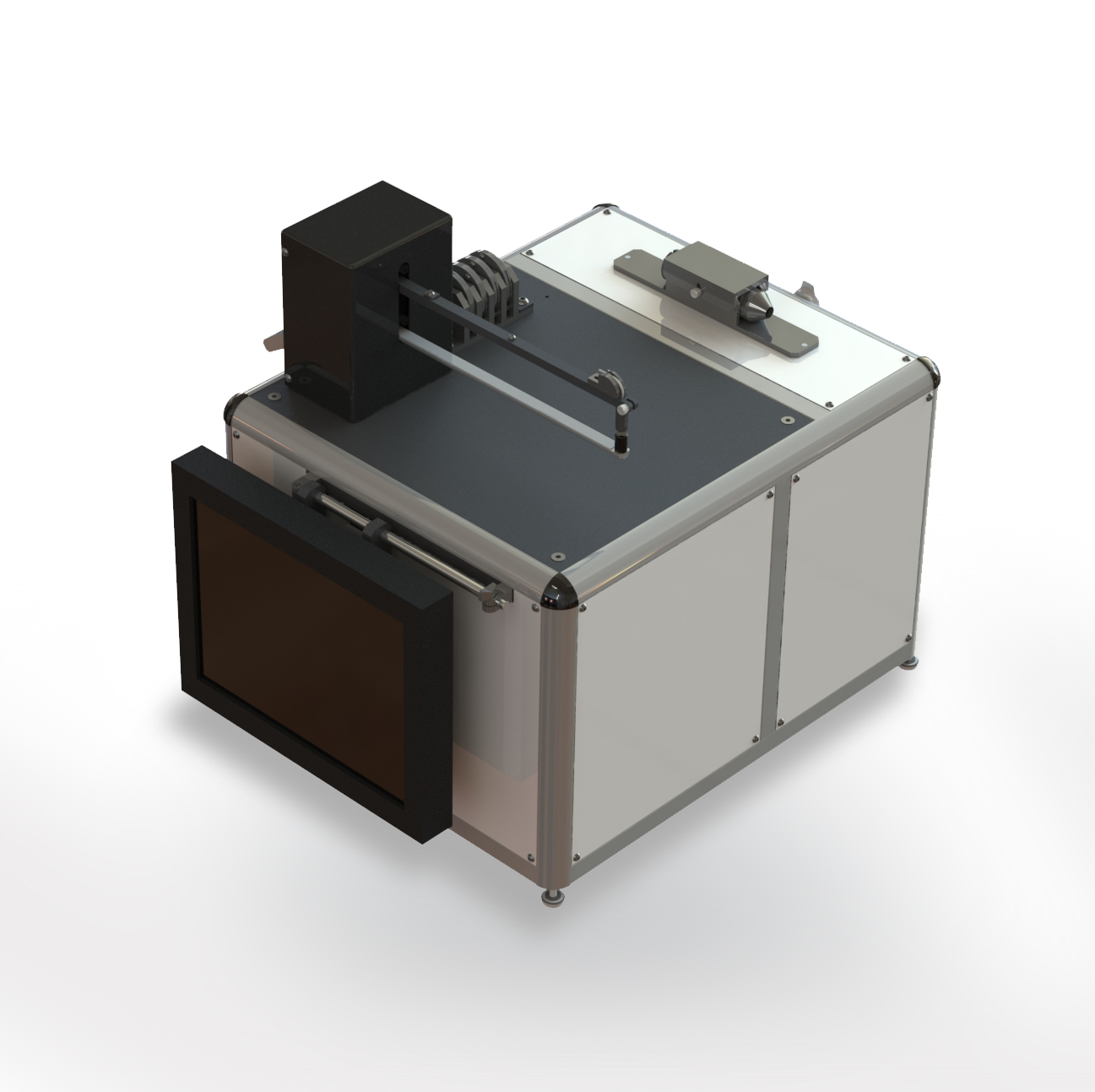

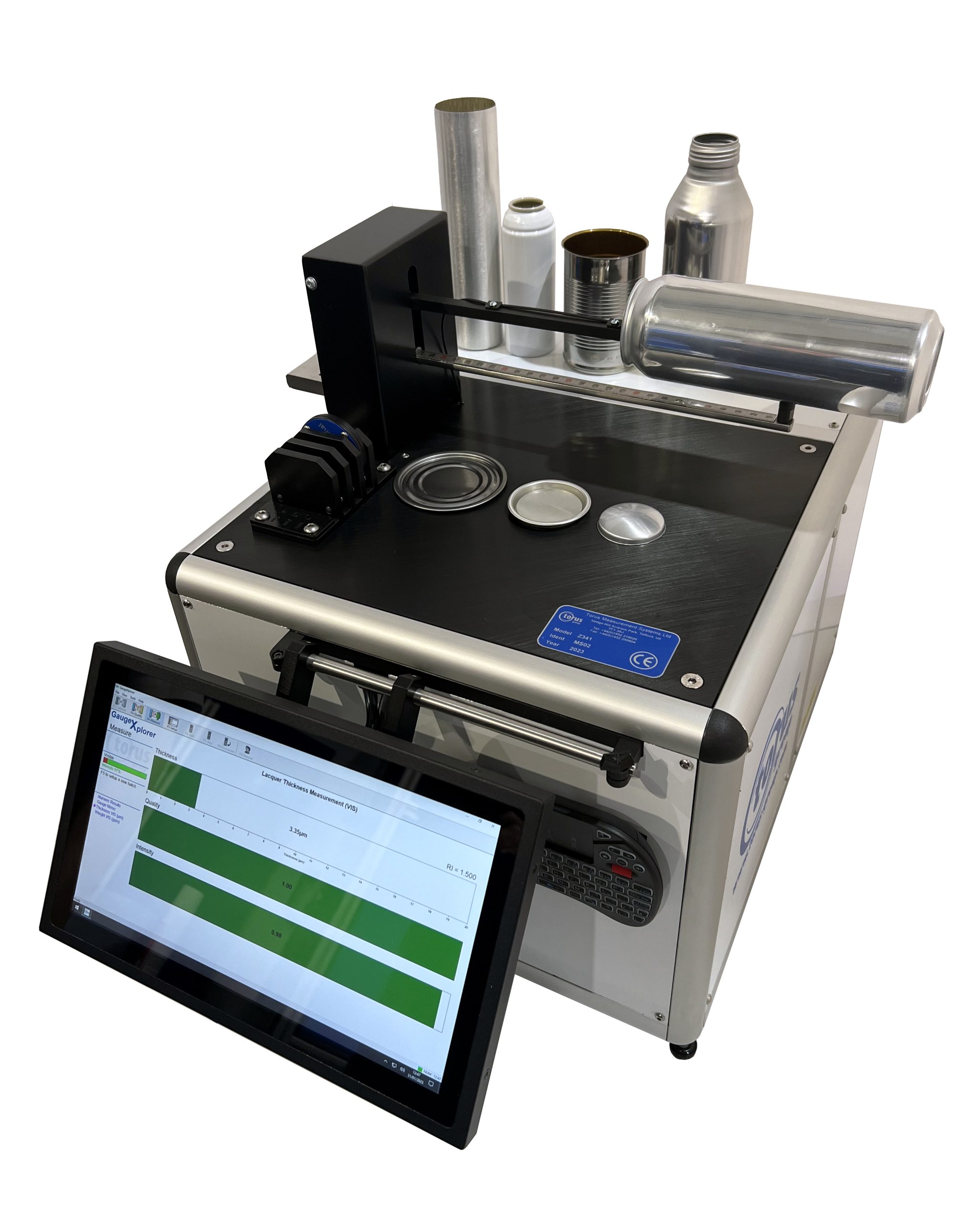

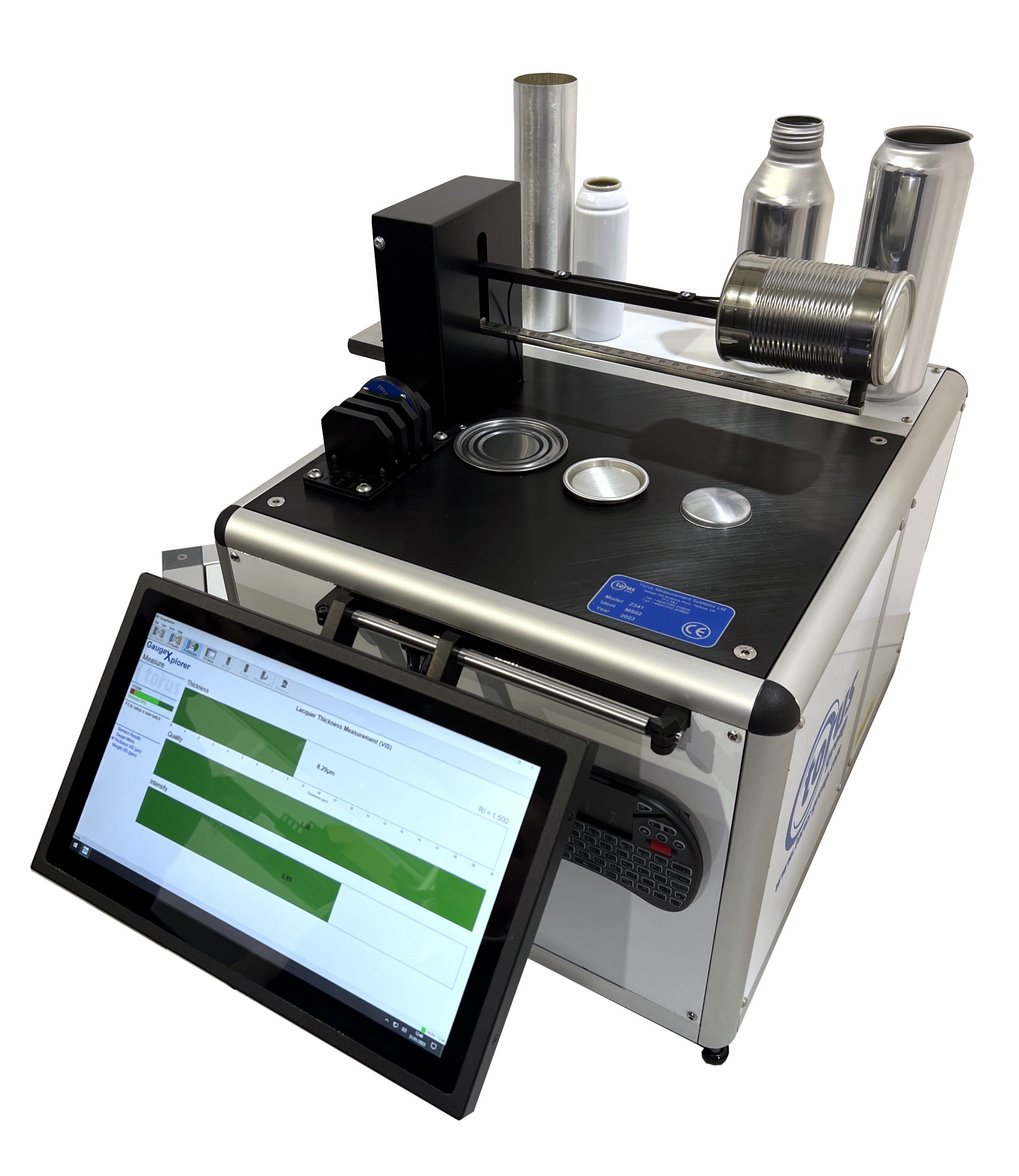

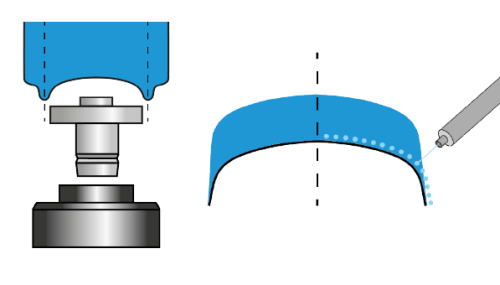

The Z341 Manual Coating Analyser has been developed to give fast and accurate measurement of the internal lacquer, sprayed during today’s 2 piece can manufacturing process

By cutting the can to give suitable access, the dome area of the can is able to be checked by the system.

No “lacquer panels” are required for calibration and measurement data can be exported via on board USB or LAN ports to your factory data acquisition systems where required.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

Gauge Features

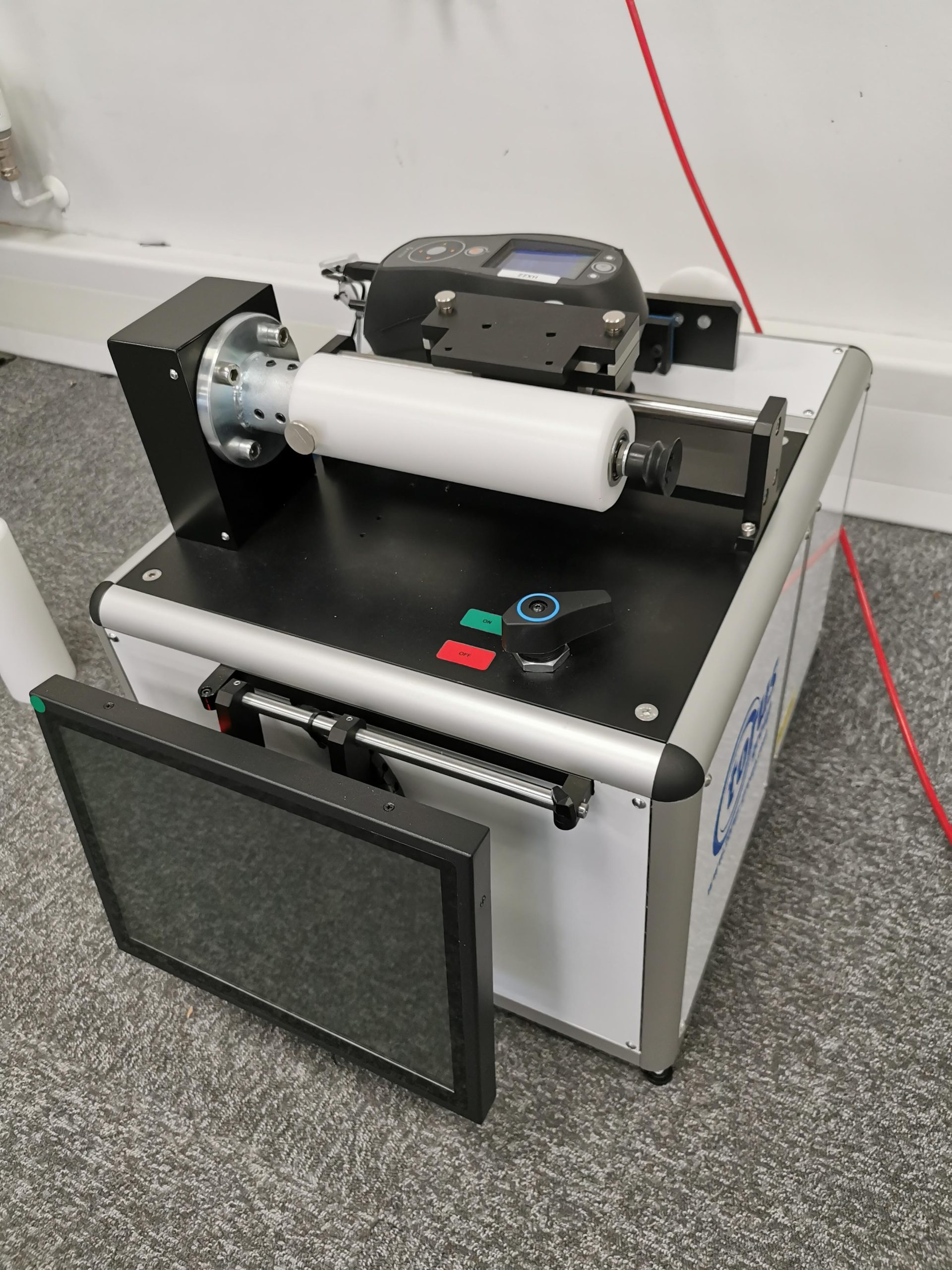

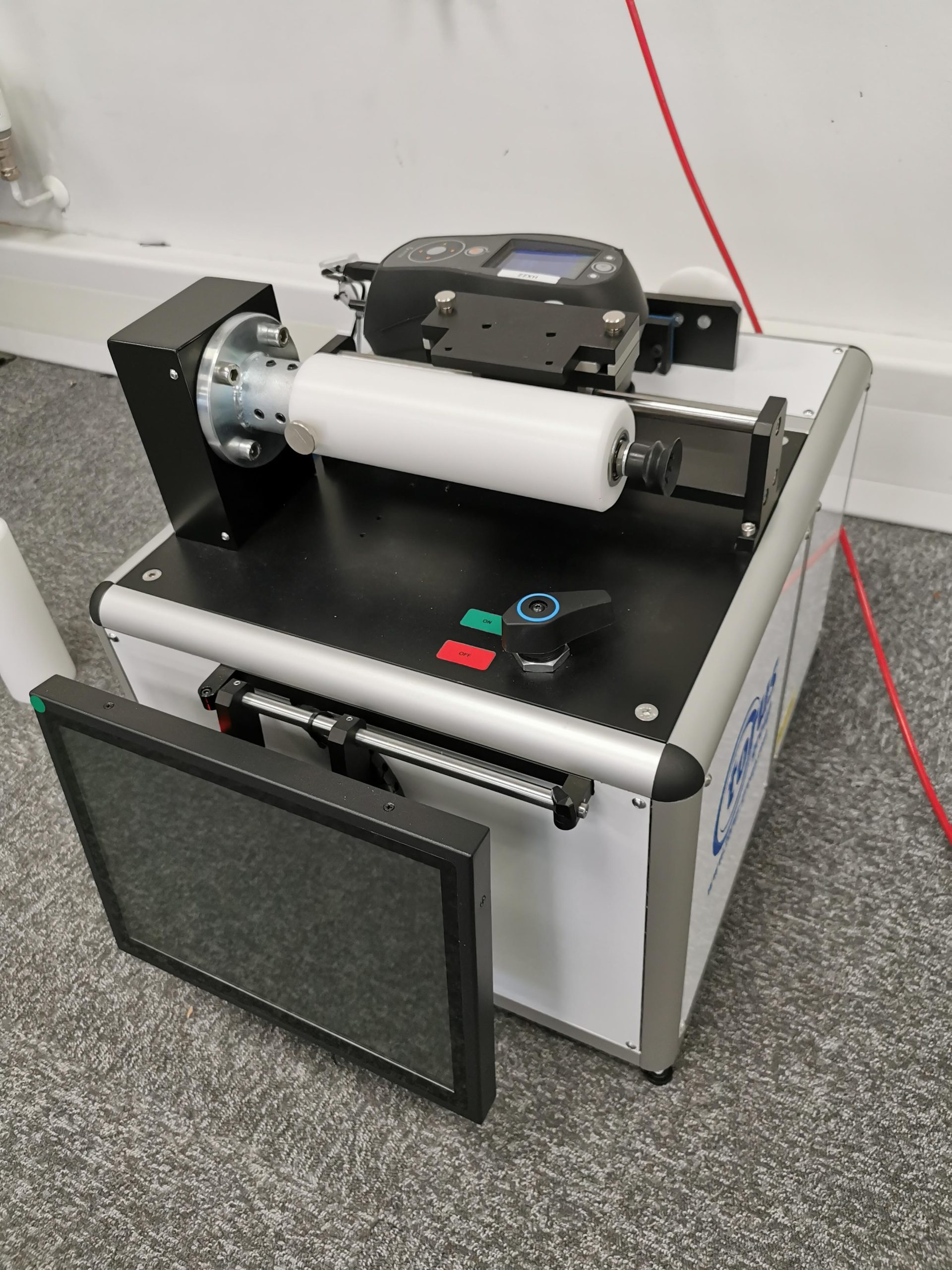

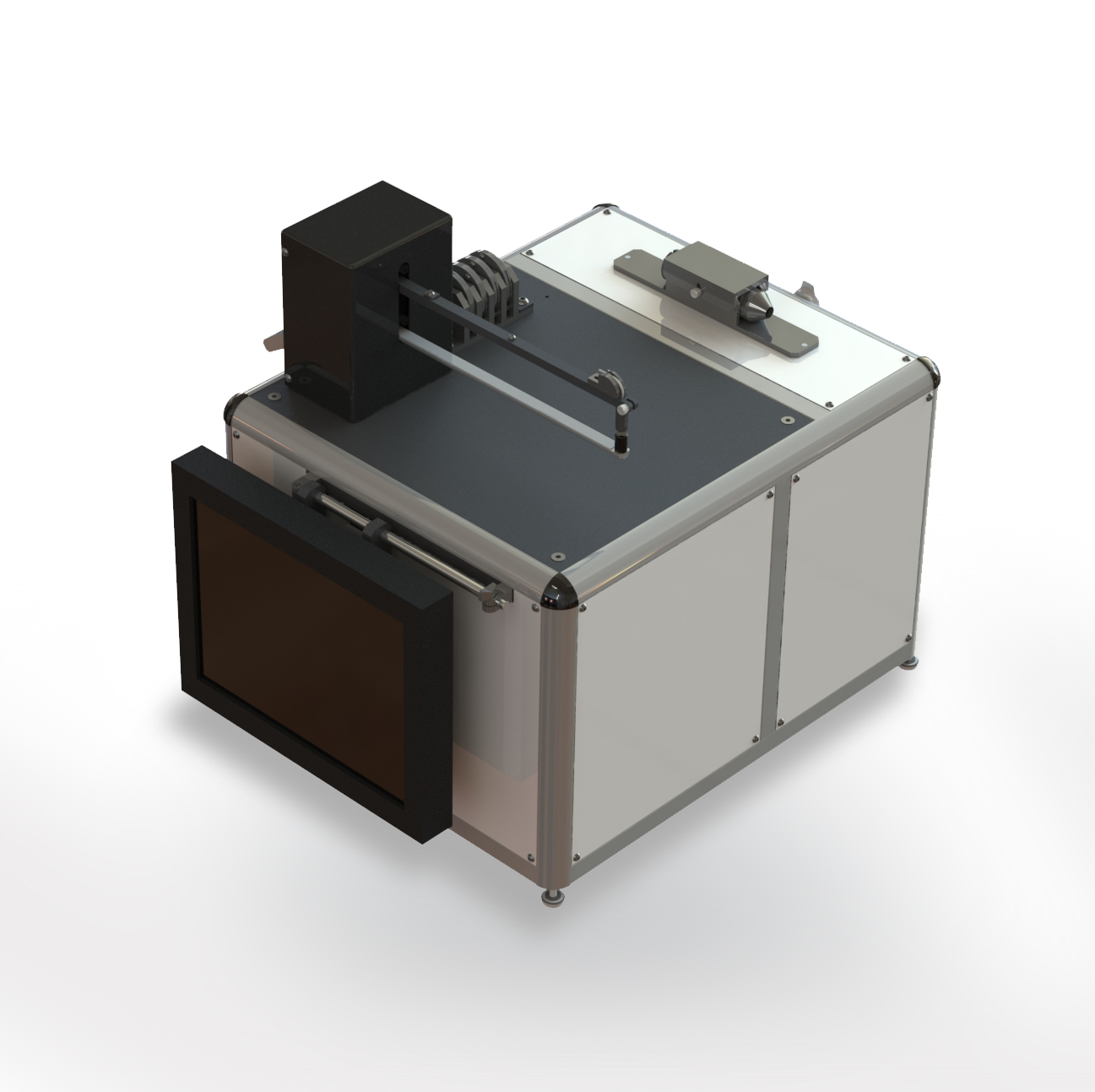

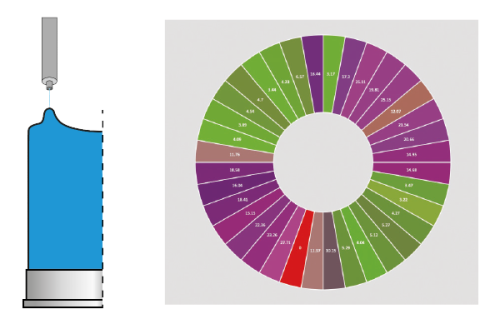

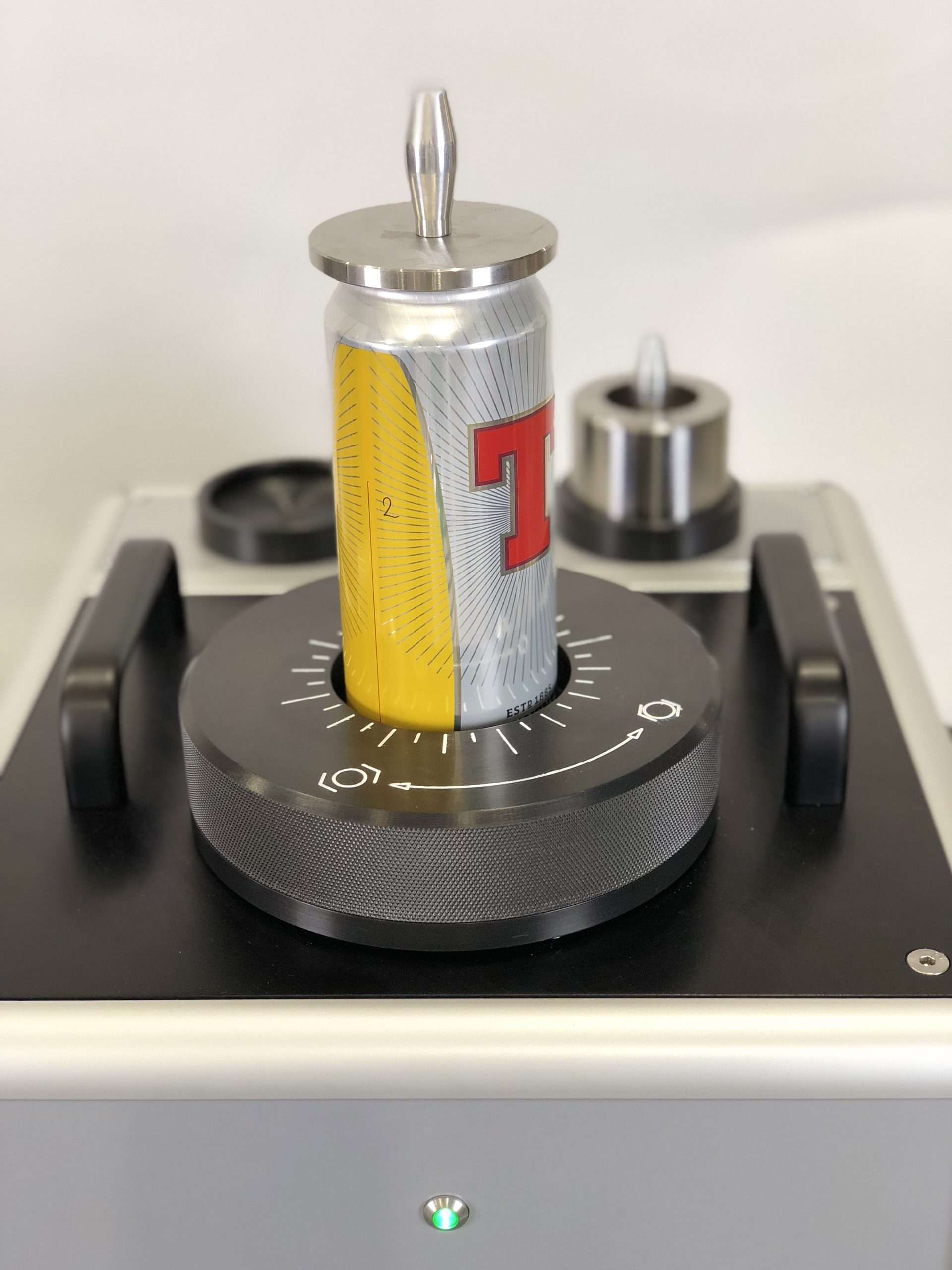

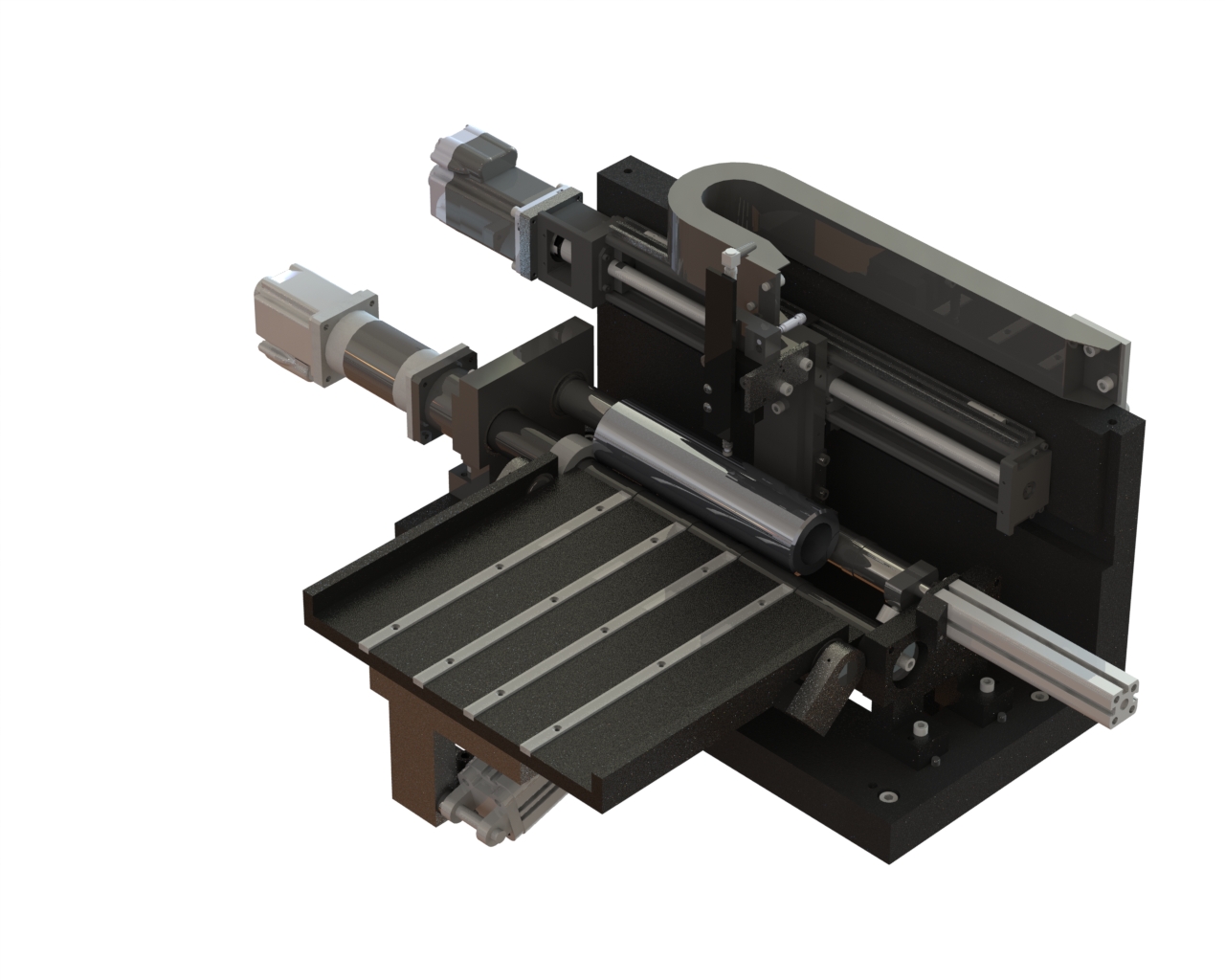

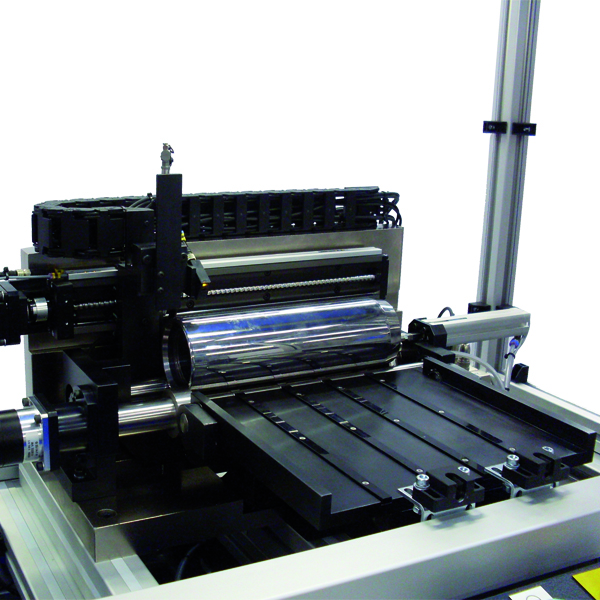

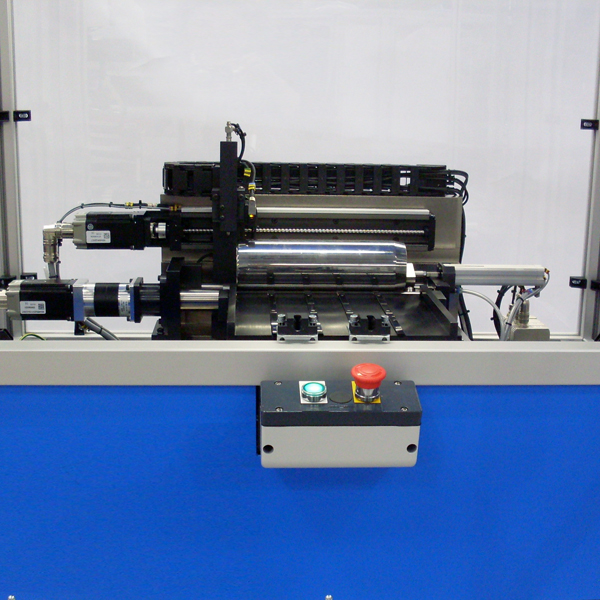

The Z340 Semi-Automatic Bench Top Coating Analyser has been developed to give detailed distribution analysis of the internal and external lacquer on a beverage can

The system utilises state-of-the-art non-contact spectroscopy techniques and is suitable for both aluminium and steel can inspection.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

Gauge Features

Start with the standard Z340 Semi-Automatic Bench Top Beverage Can Coating Analyser…

… add any of the below detailed optional modules at any time

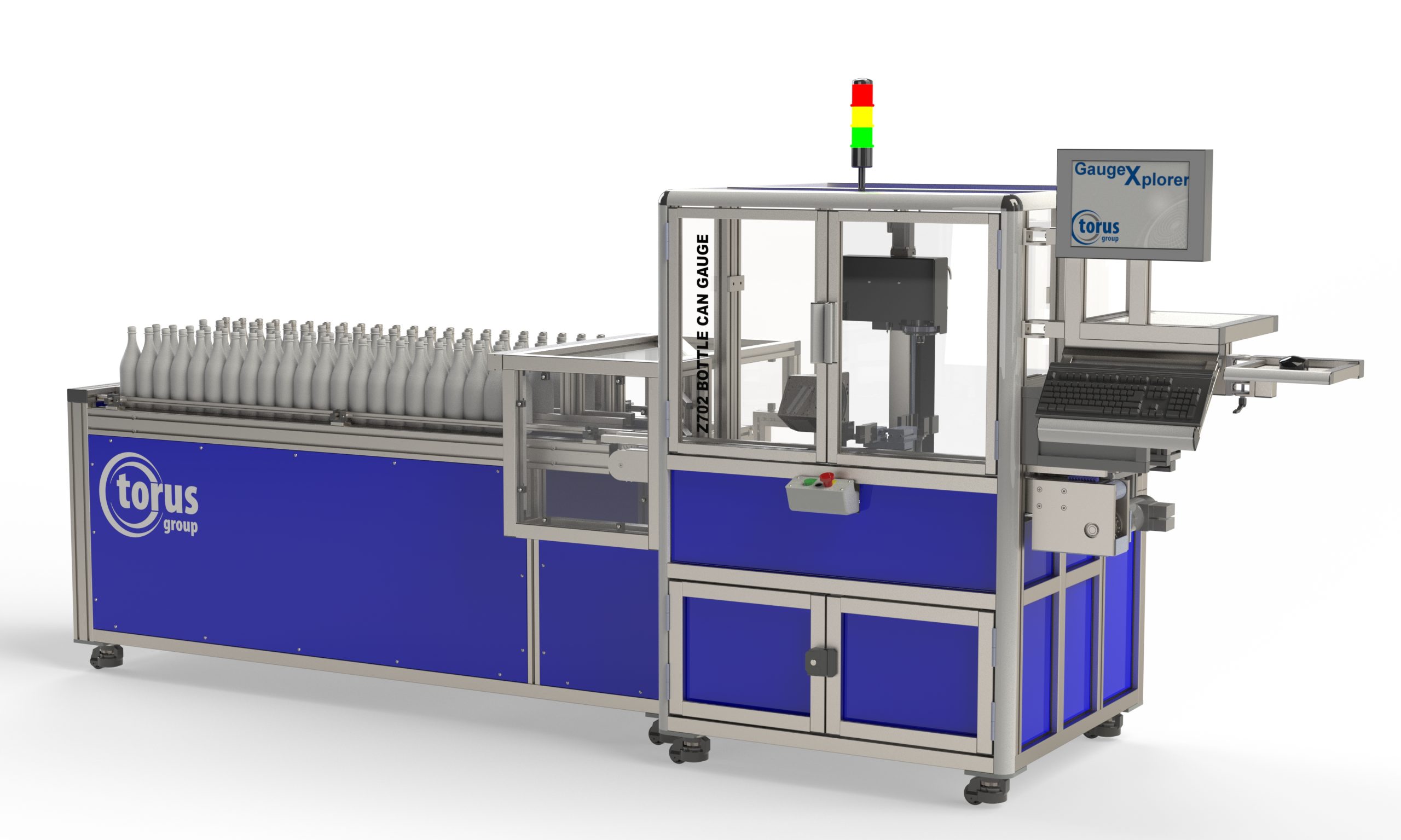

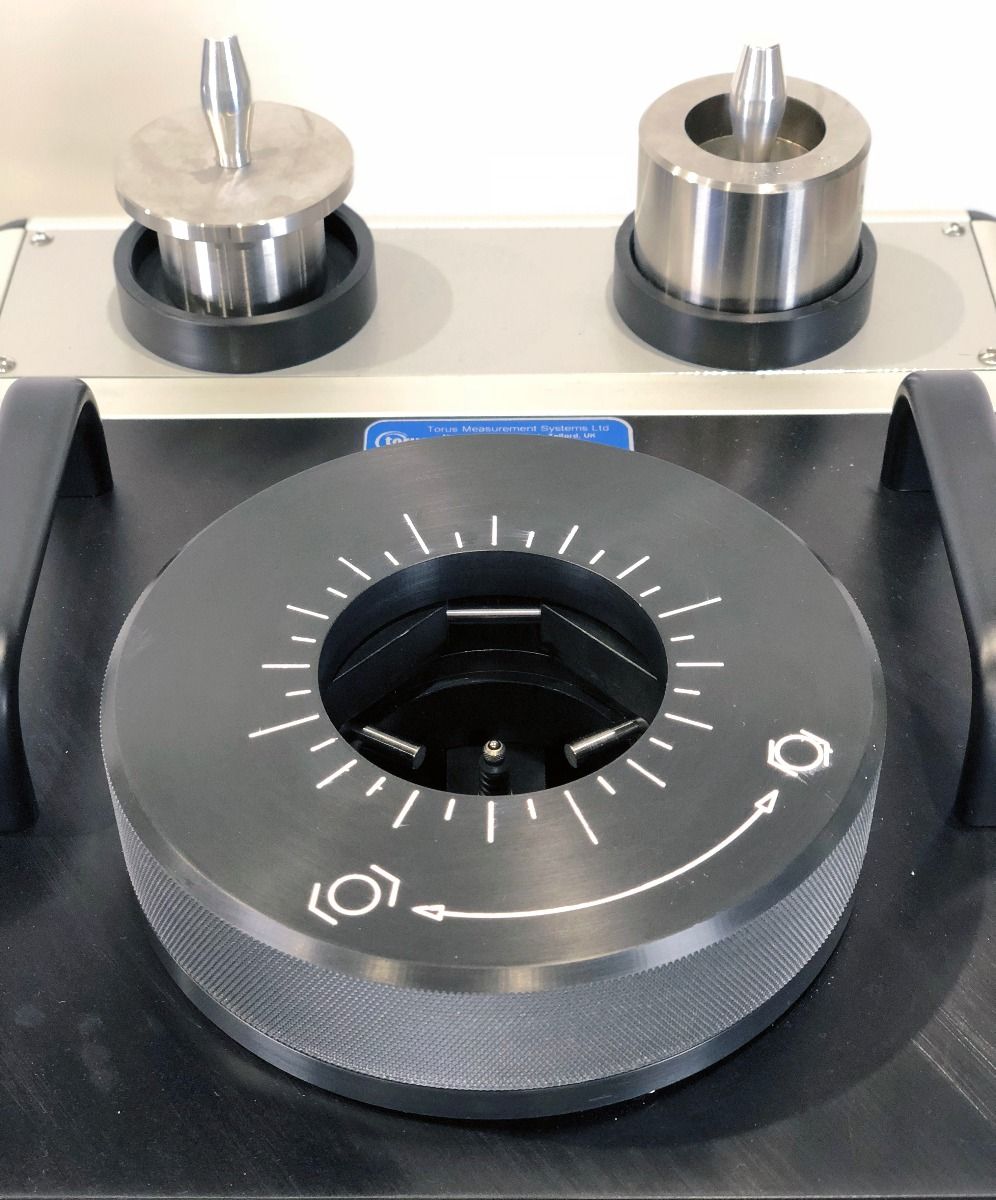

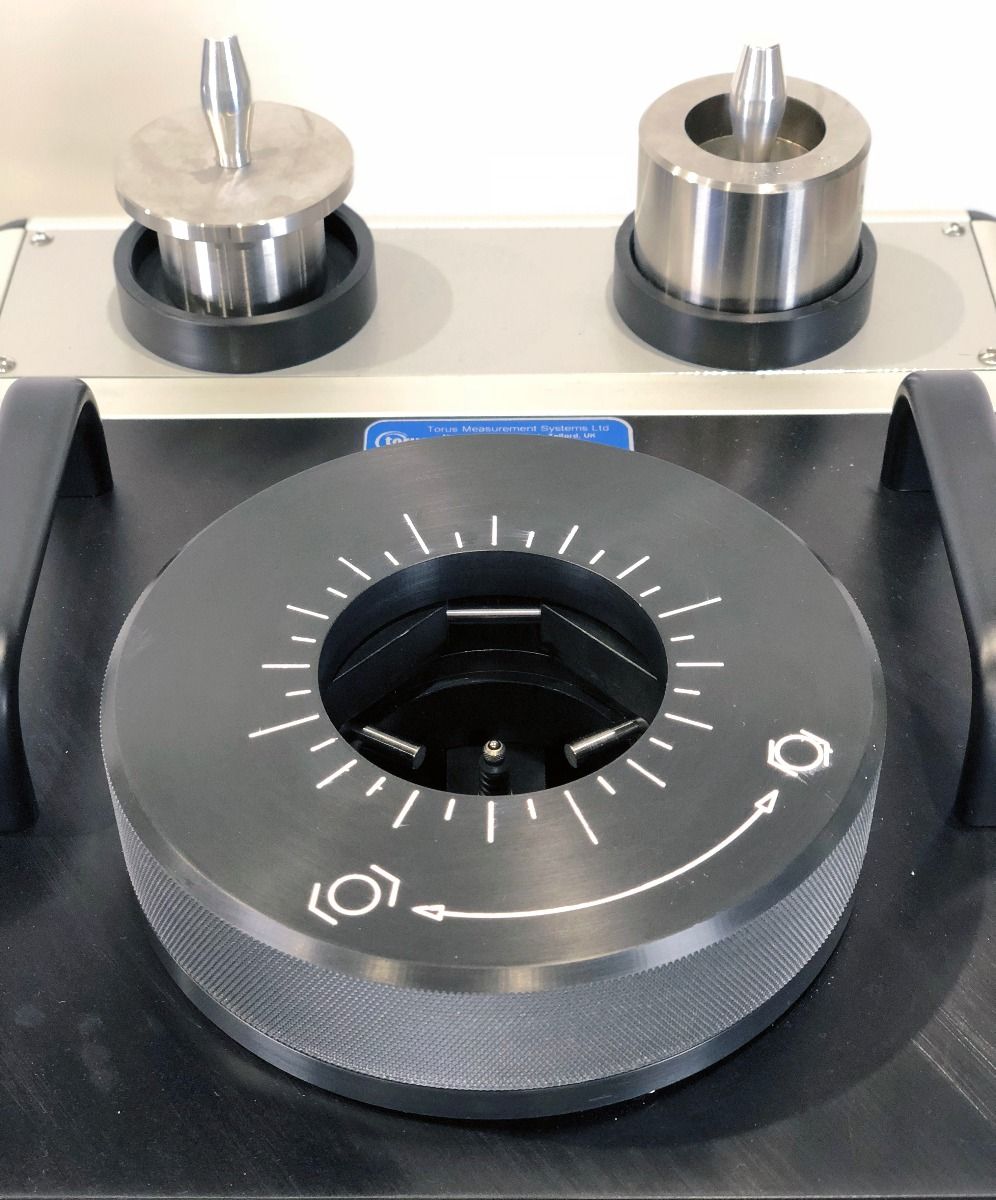

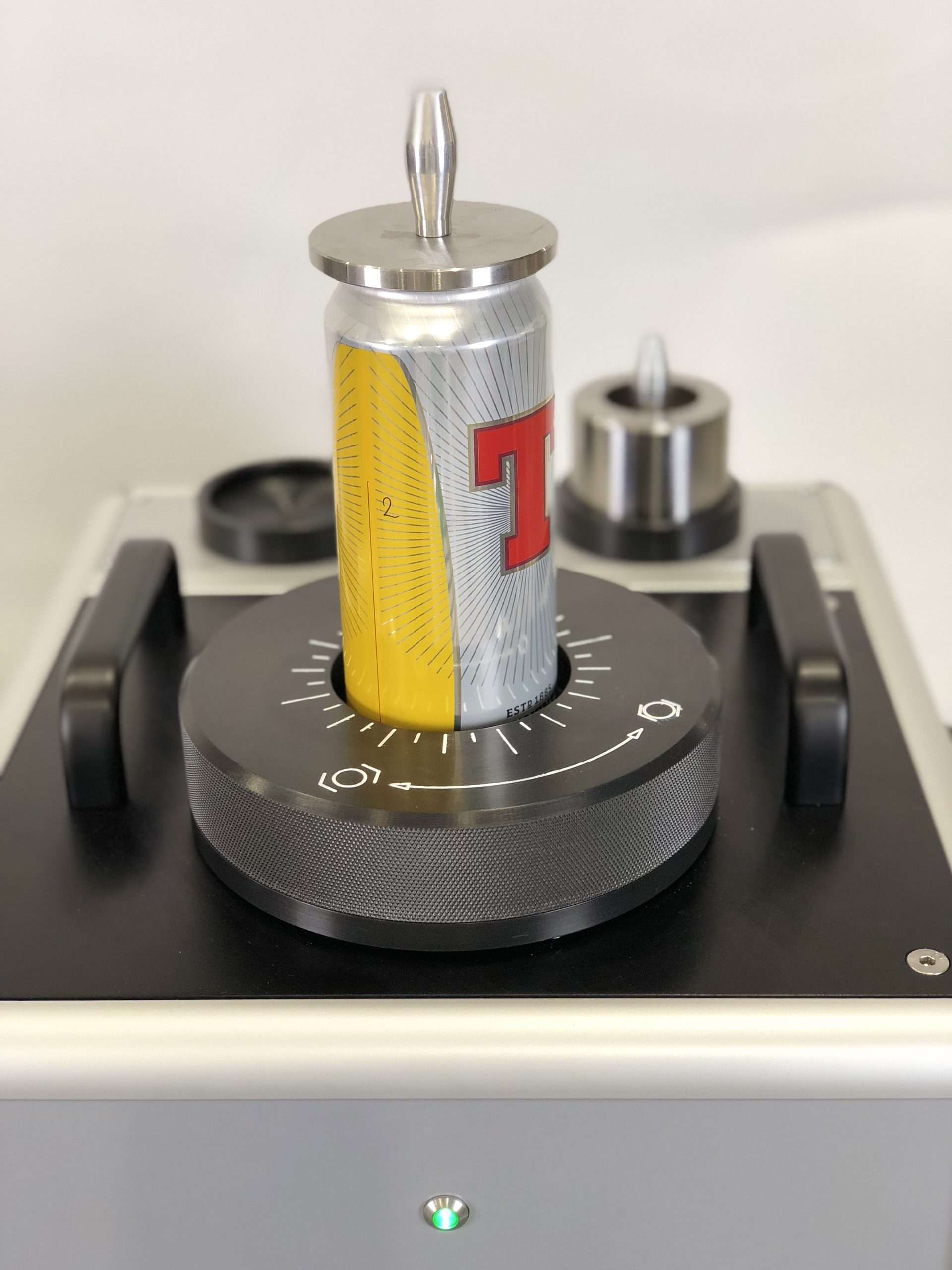

The Z302 Finished Can Back End Inspection Gauge features high-precision transducer technology, using dedicated probe contact for accurate, reliable and traceable measurement of your finished cans 24/7.

An additional option is available for component rotation to enable additional radial measurement positions, giving you significantly increased measurement data allowing increased data analysis for instant process control.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

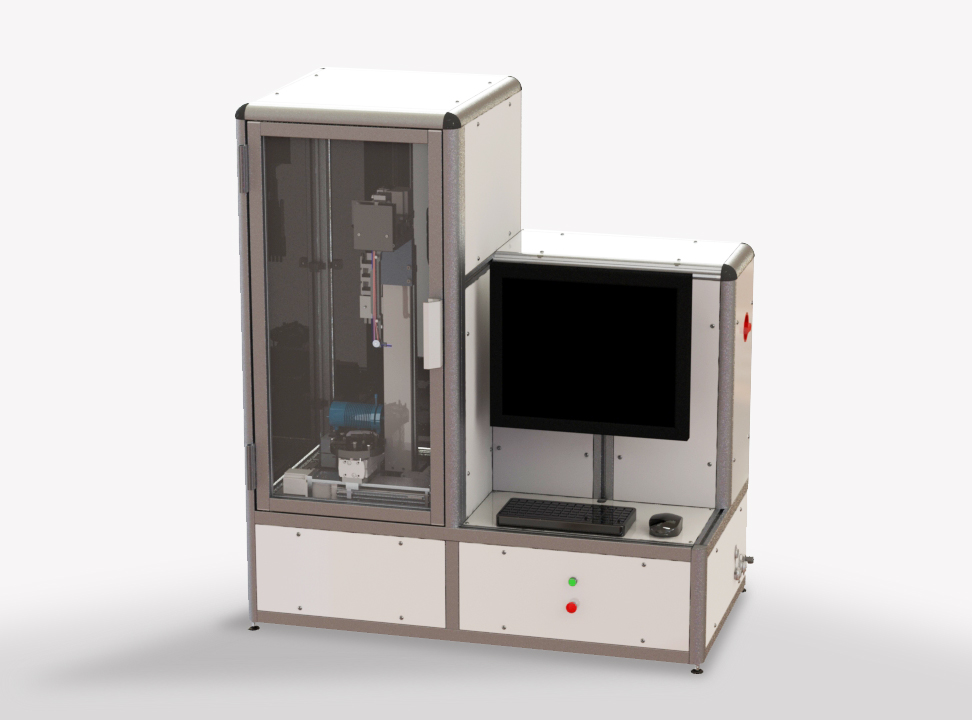

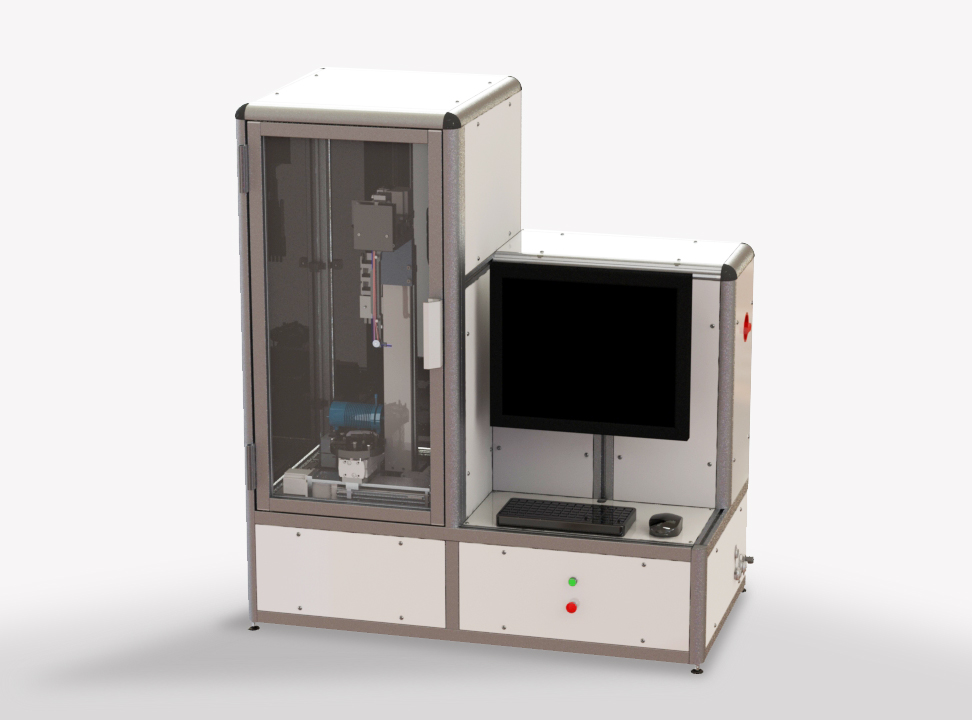

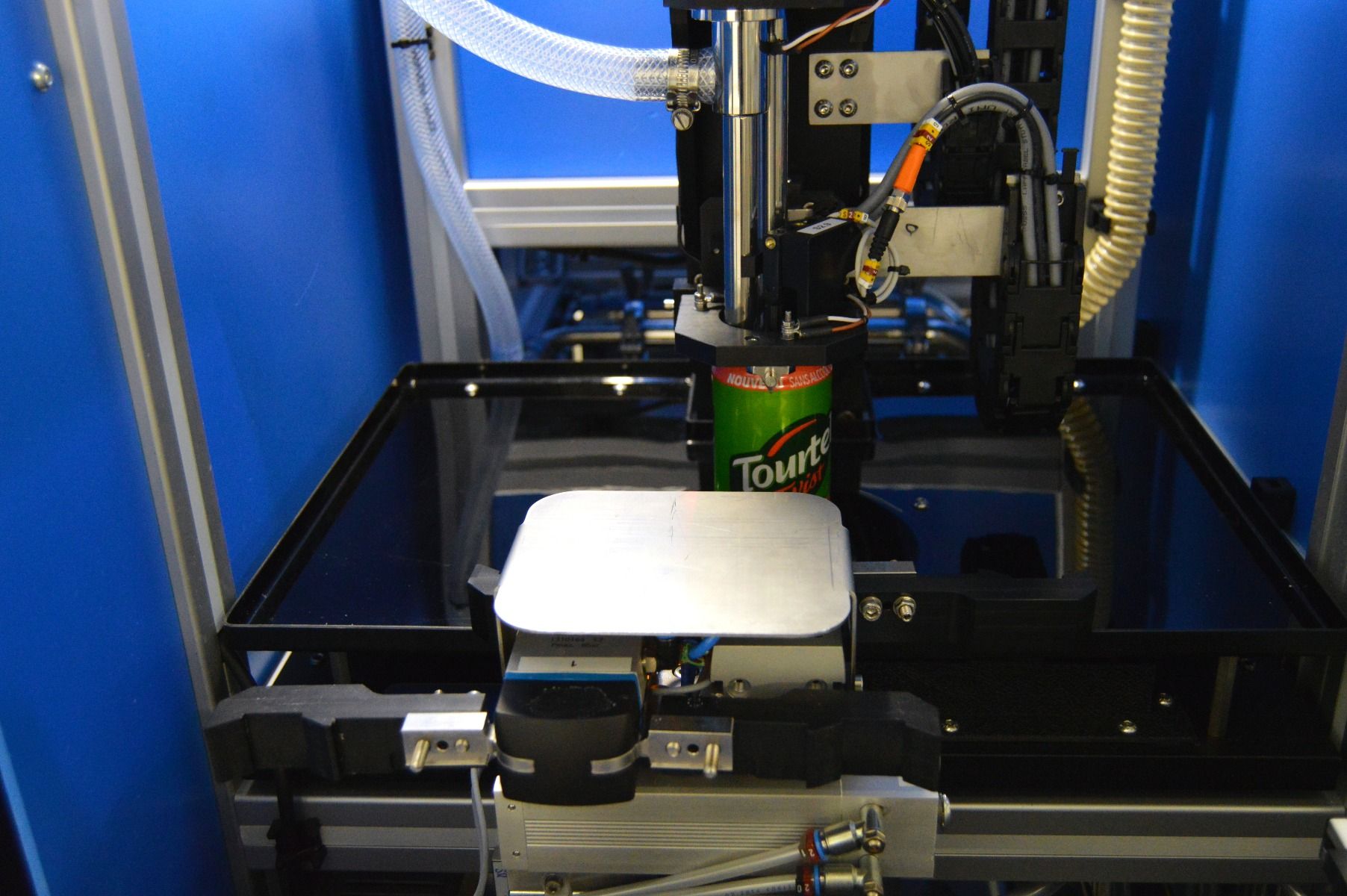

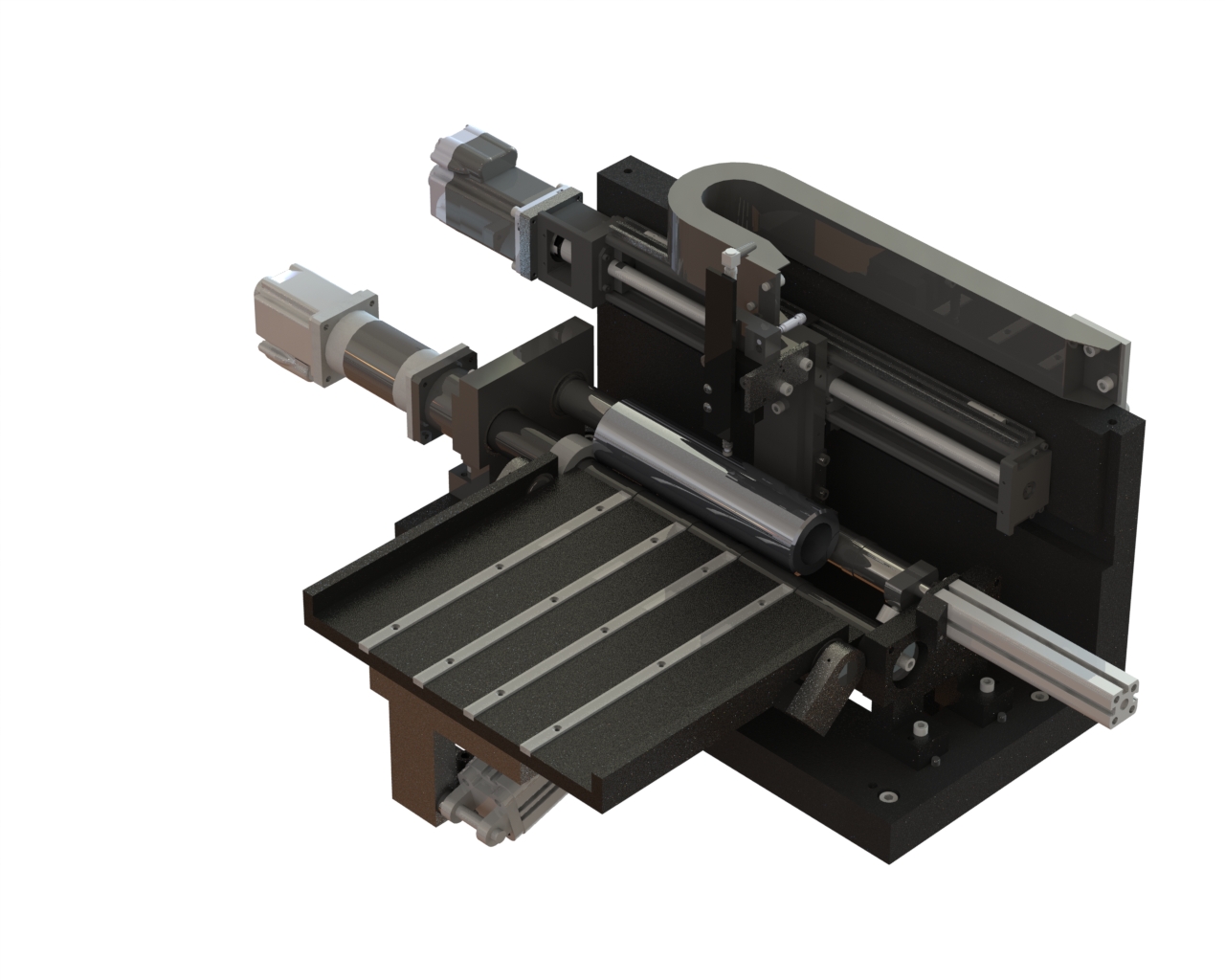

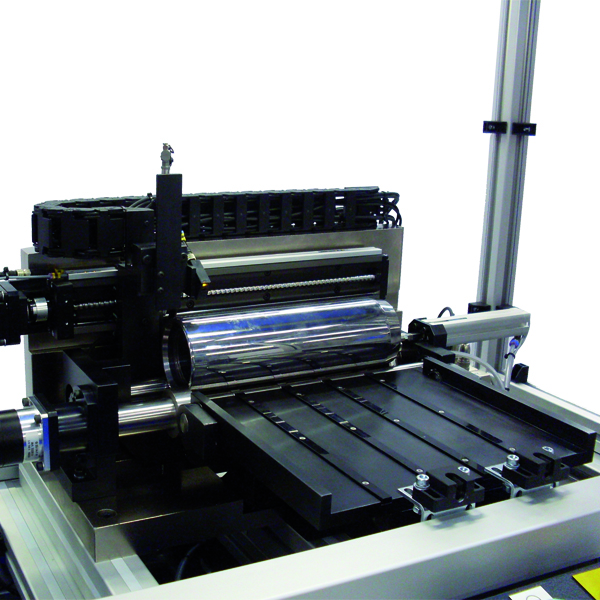

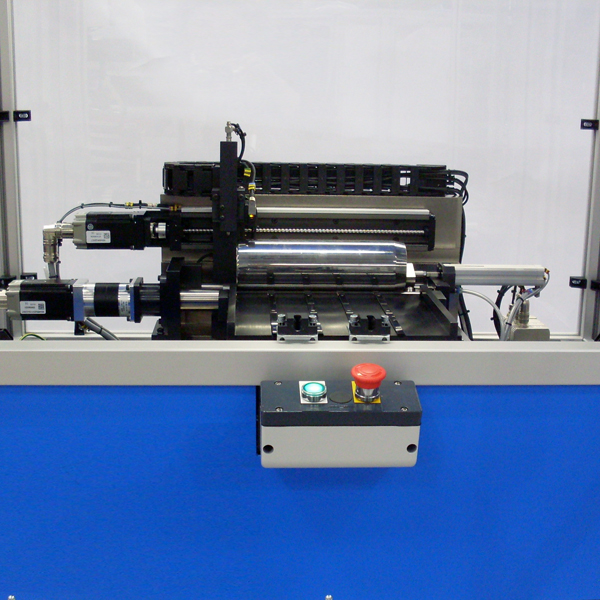

The Z340 Automatic Coating Analyser has been developed to give detailed distribution analysis of the internal lacquer on a beverage can

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

Gauge Features

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

The Z338 Manual Front End Gauge has been designed to measure typical features for Front End Inspection including; Trimmed Can Height, Mid and Top Wall Thickness and Dome Depth.

Whether being used at the front end for body maker setup checks, in the quality area for off-line inspection, or as a backup during routine maintenance for your automatic gauges, exact correlation gives you 100% confidence in your process.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

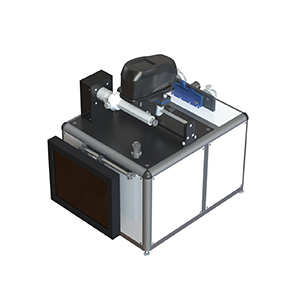

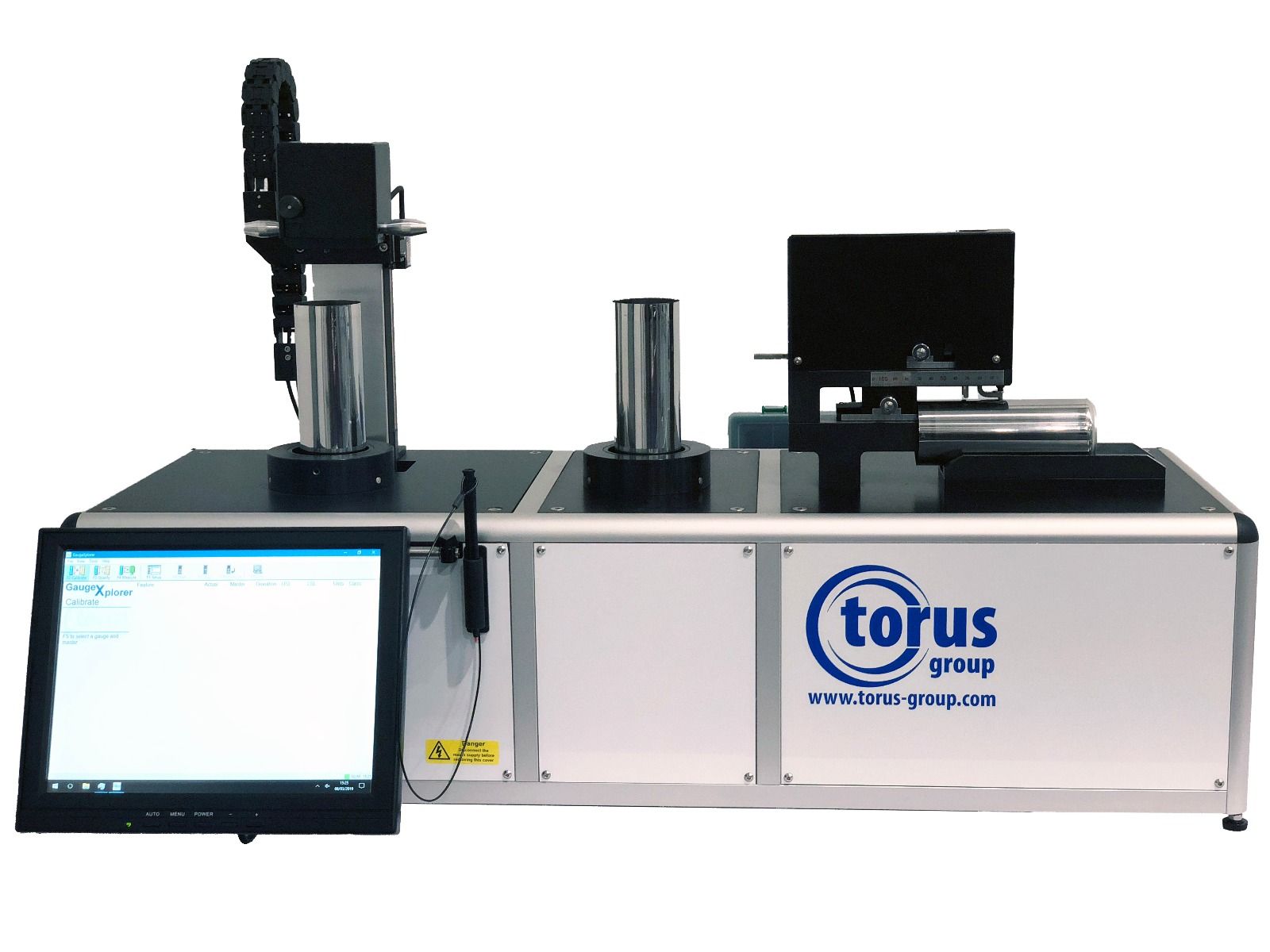

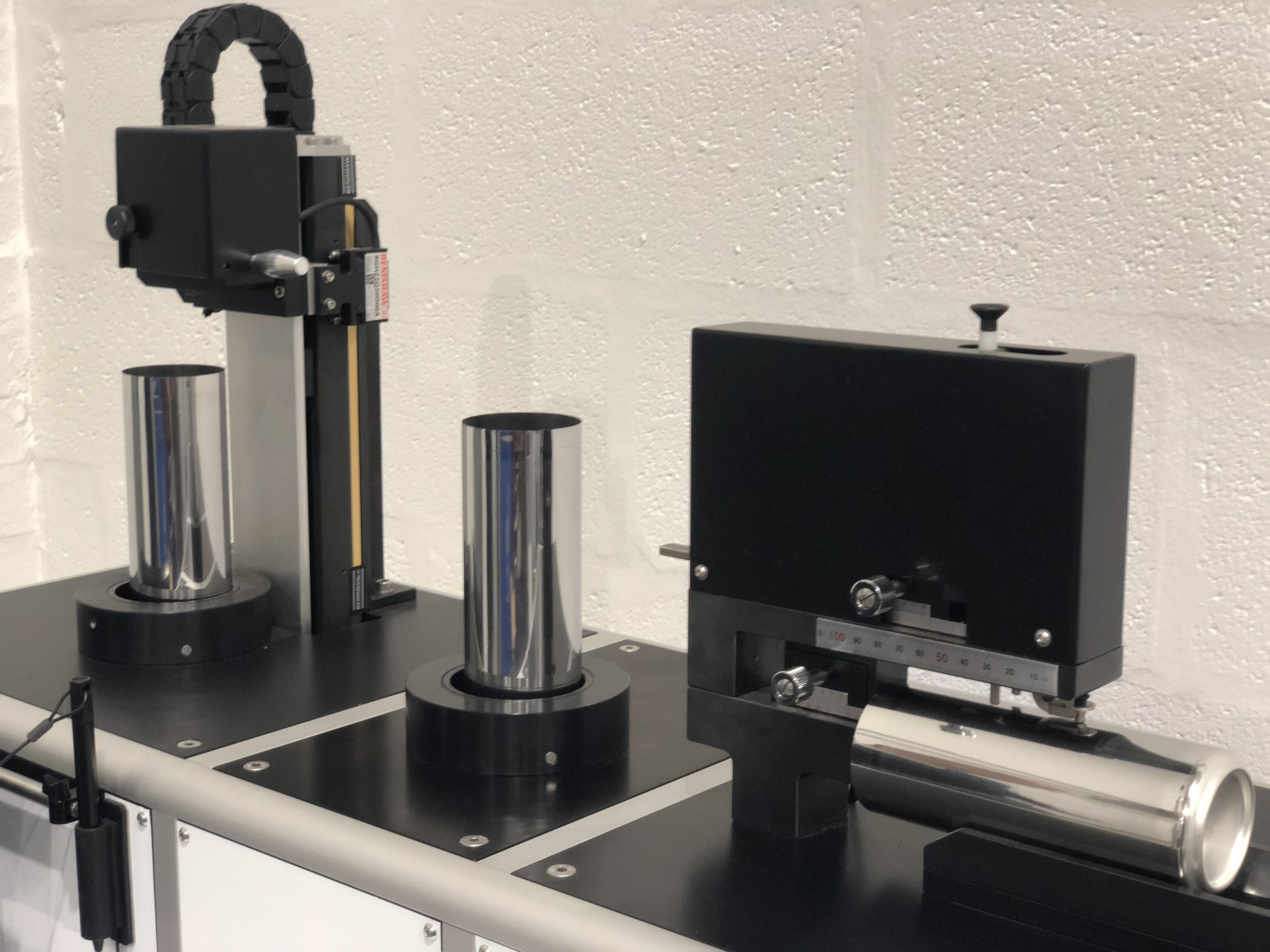

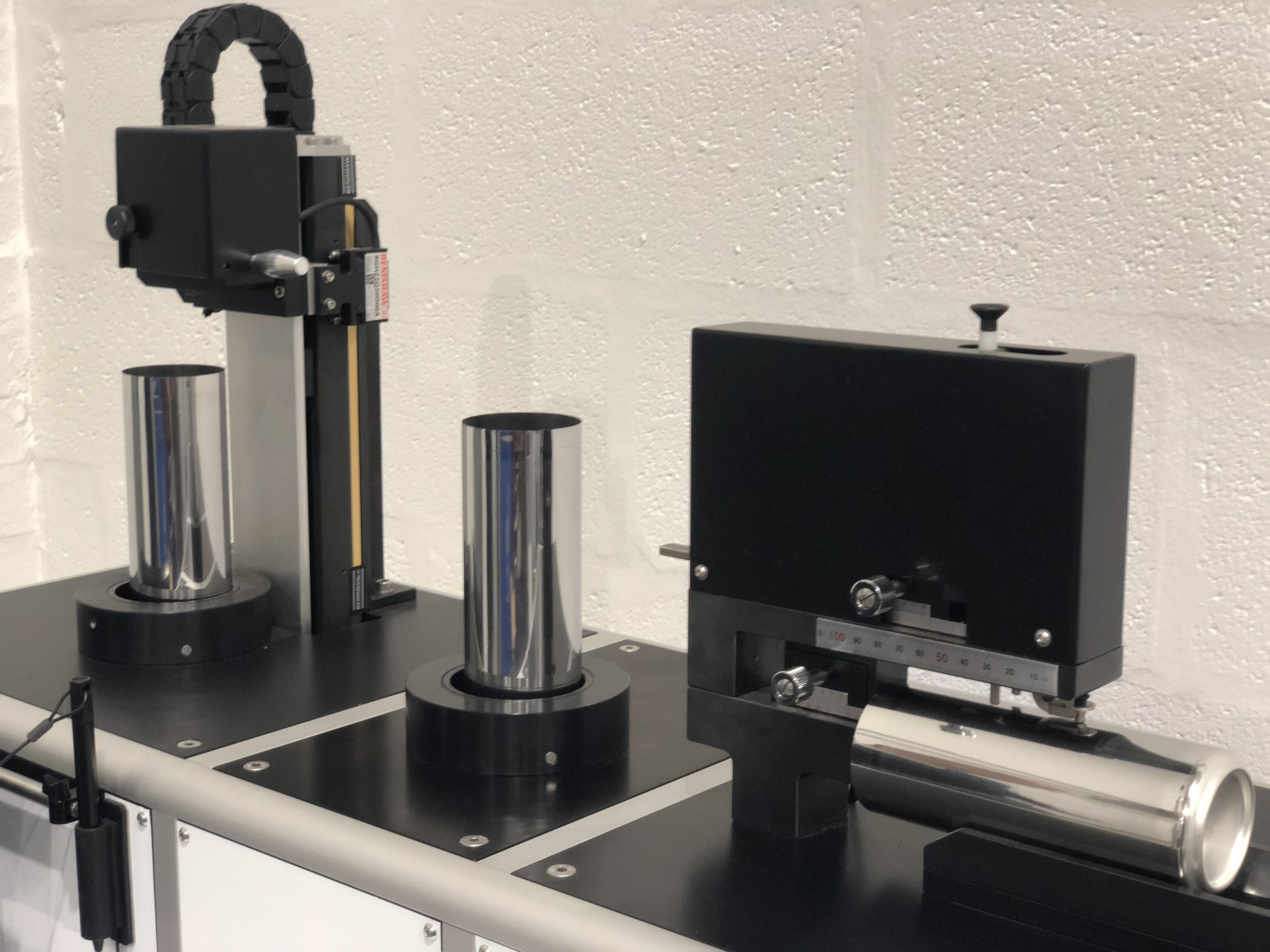

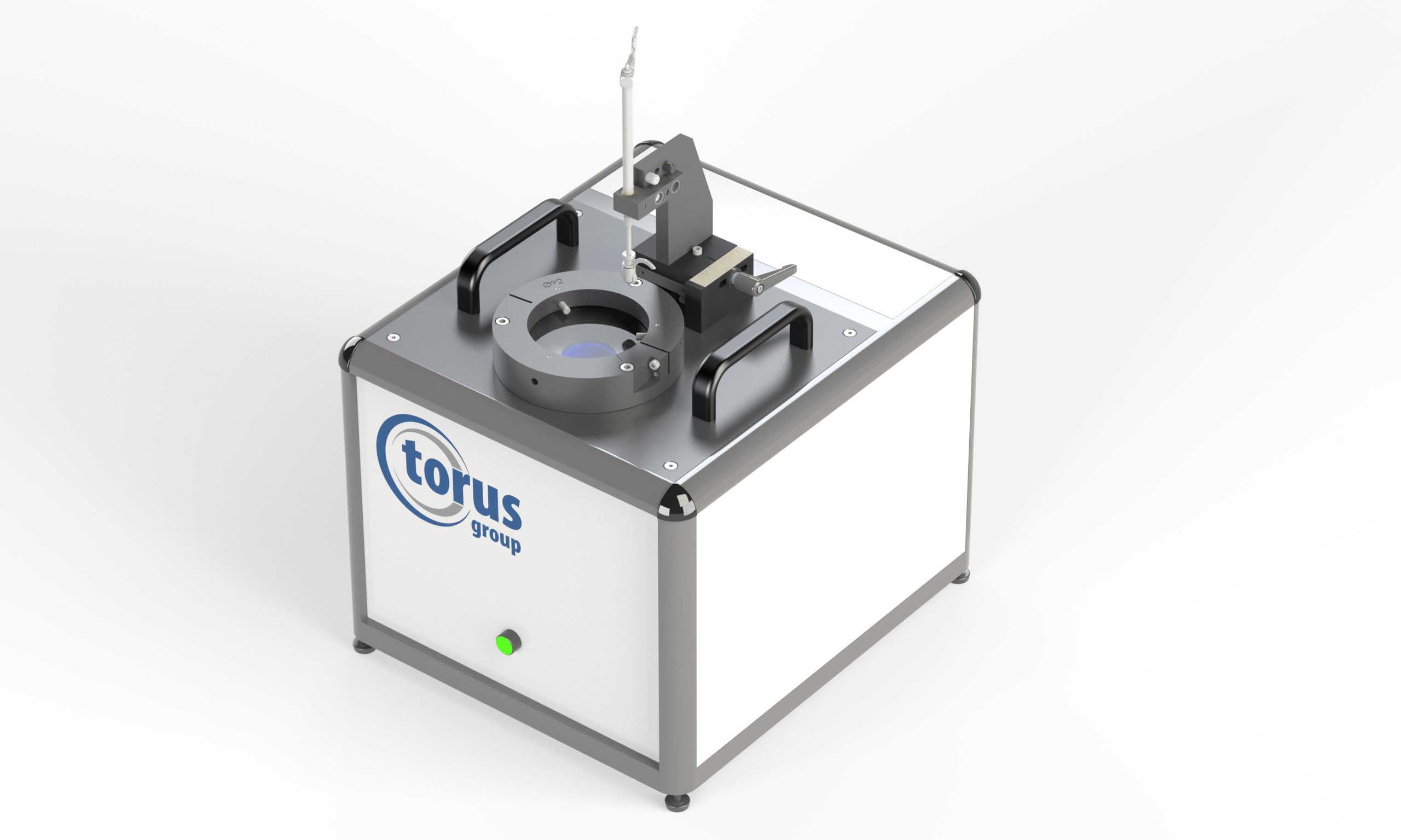

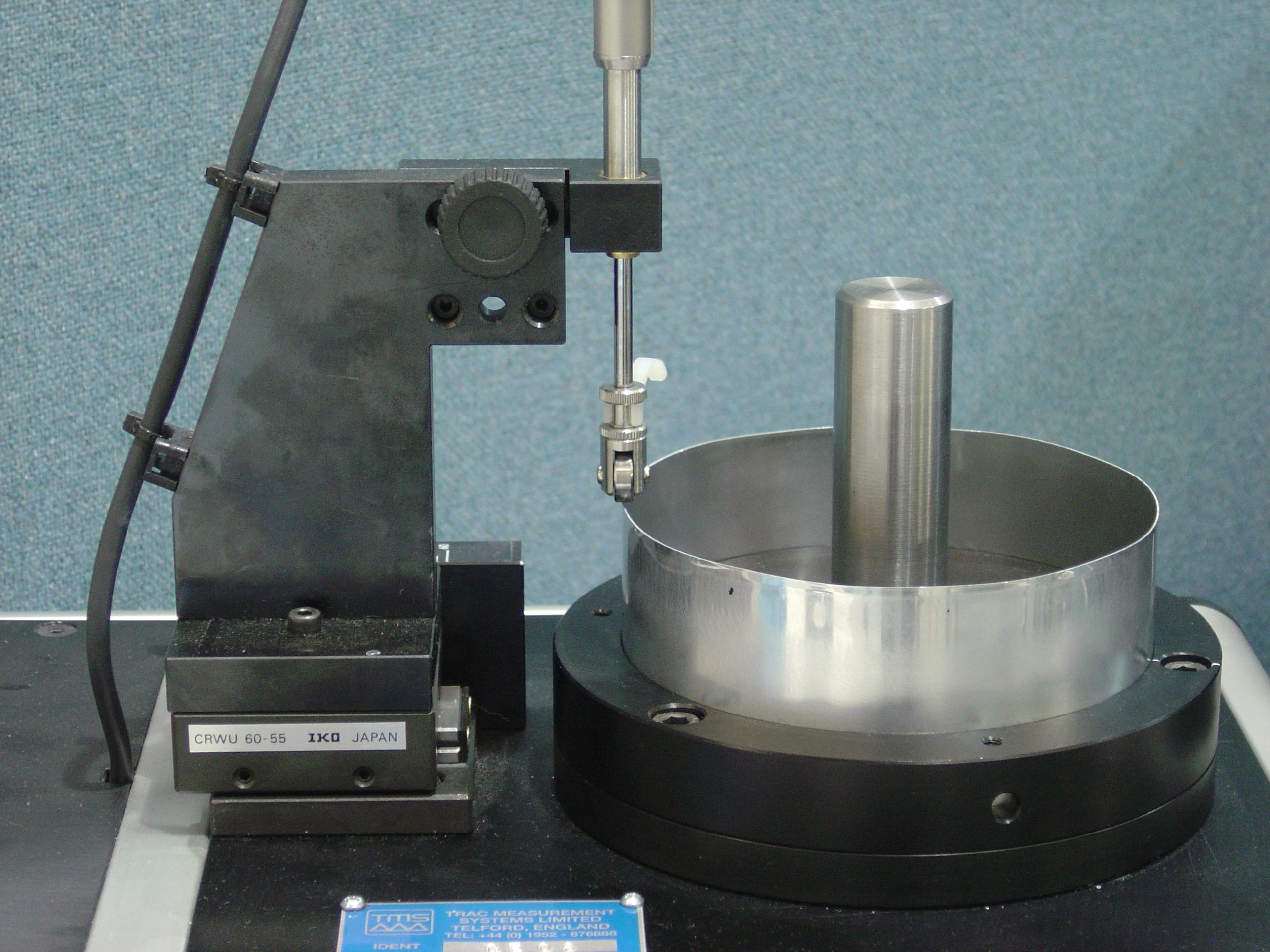

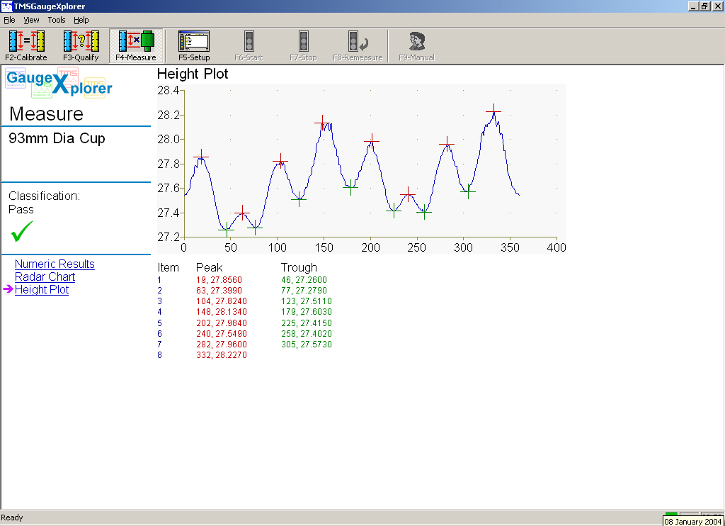

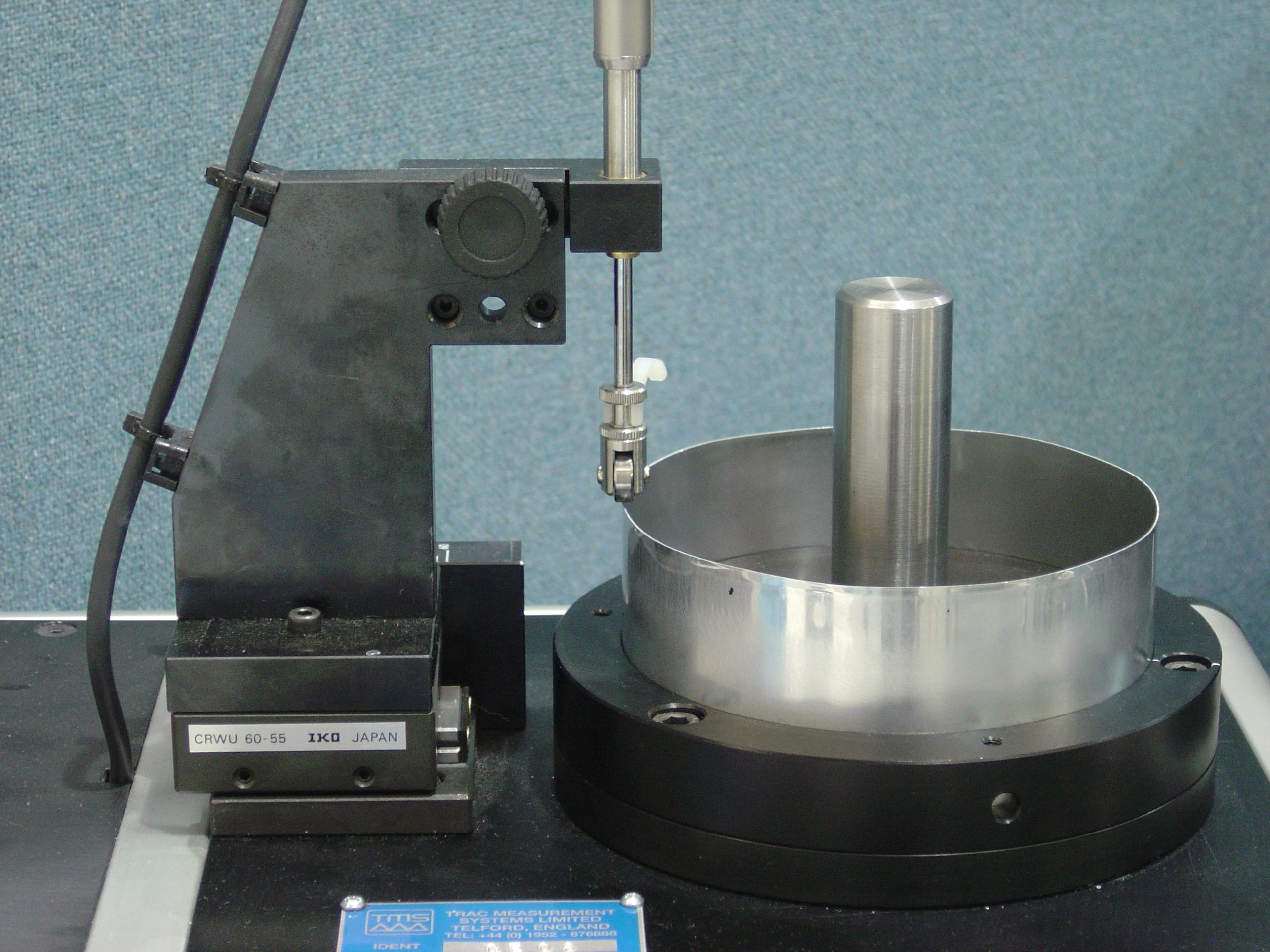

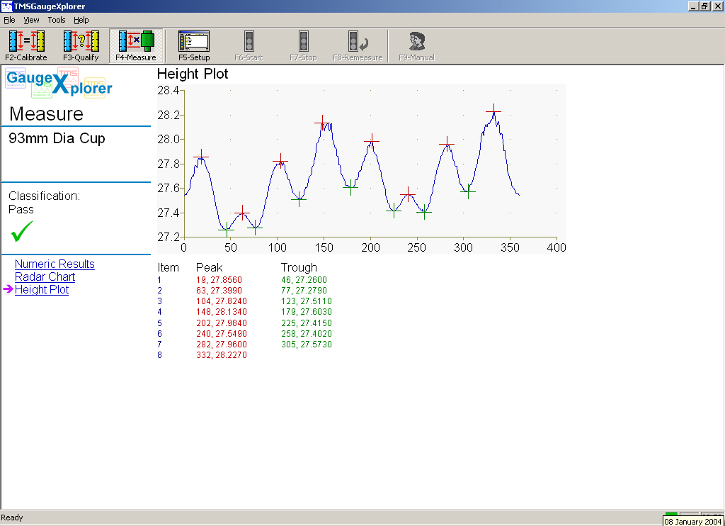

The Z334 is a bench-top system for cup height analysis.

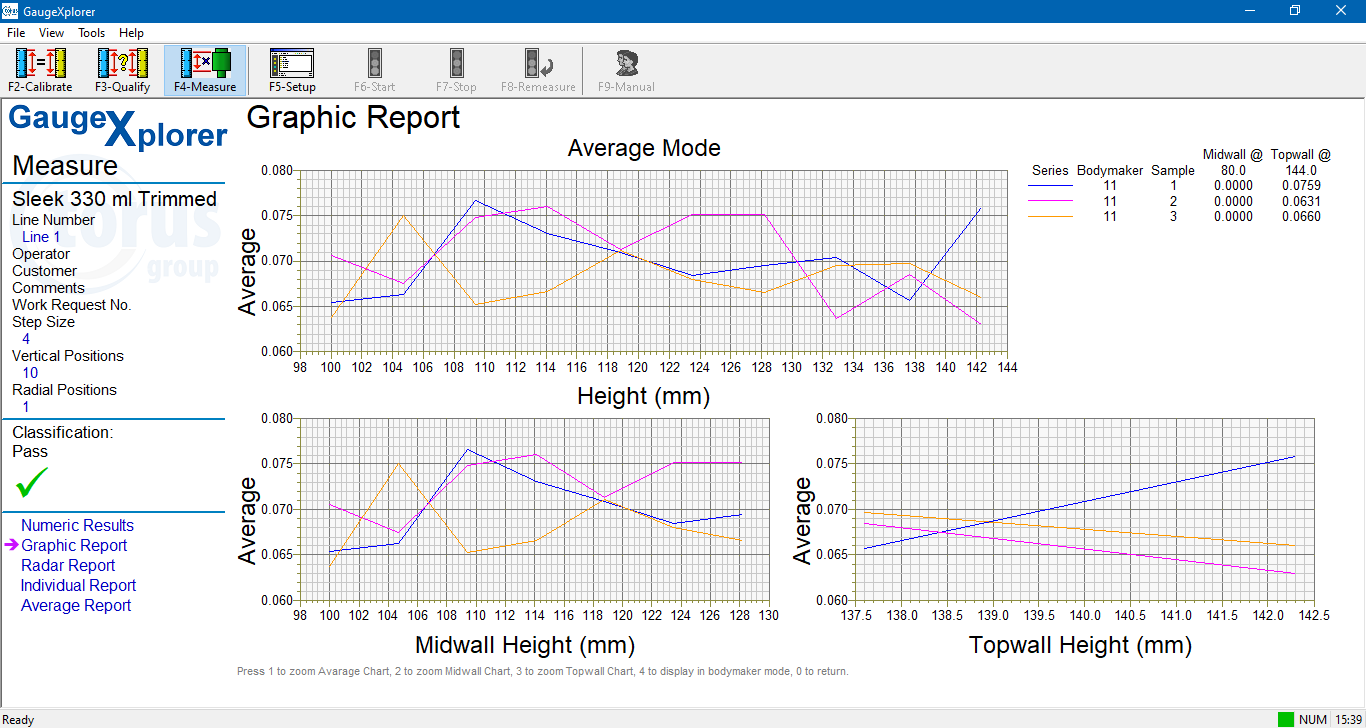

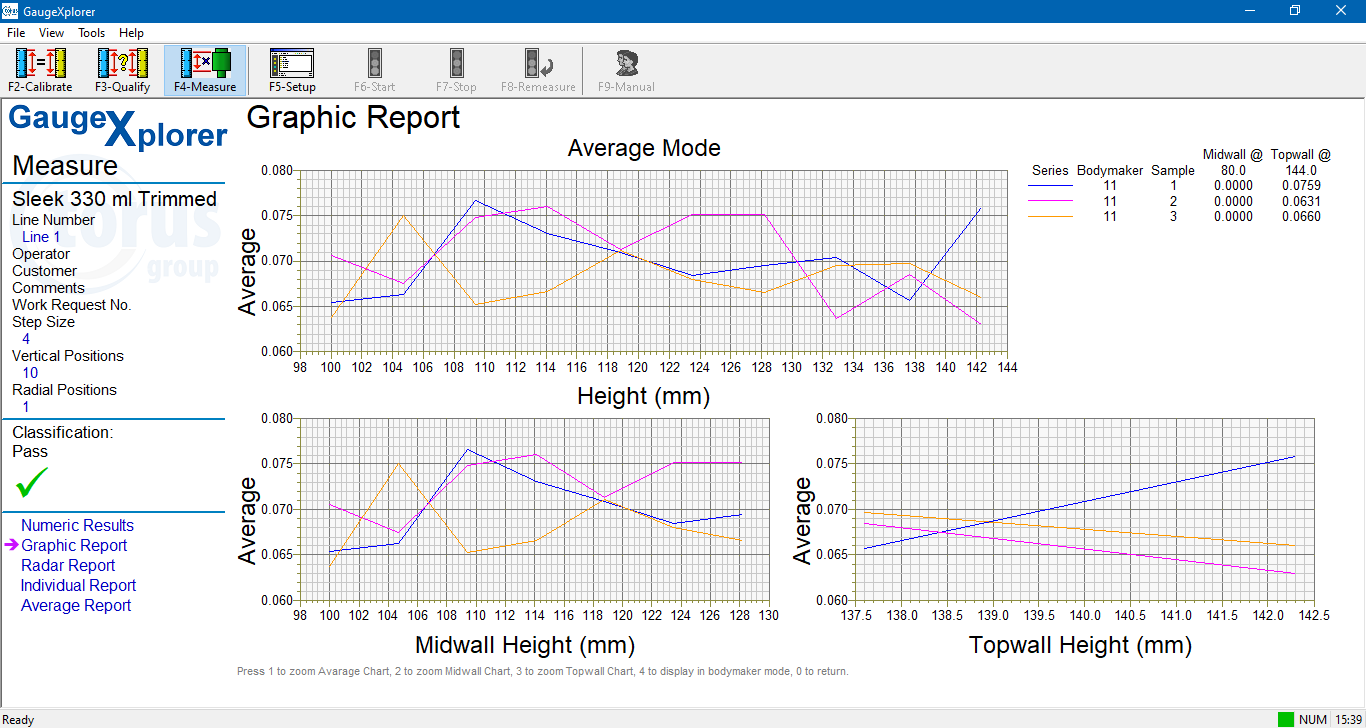

Each cup to be inspected is manually loaded into the gauge and the measurement cycle is initiated via the PC running the TMS GaugeXplorer measurement and machine control software. Setup screens allow the operator to enter traceability information and select the number of samples and heads from which data is to be collected.

Once the component has been measured, the operator may visually accept or reject the software’s calculated ‘peaks’ and ‘troughs’, which will be used in the Earring calculations.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

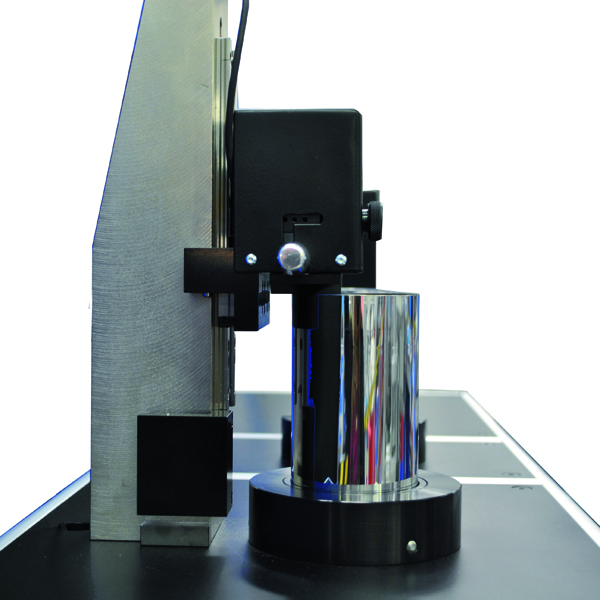

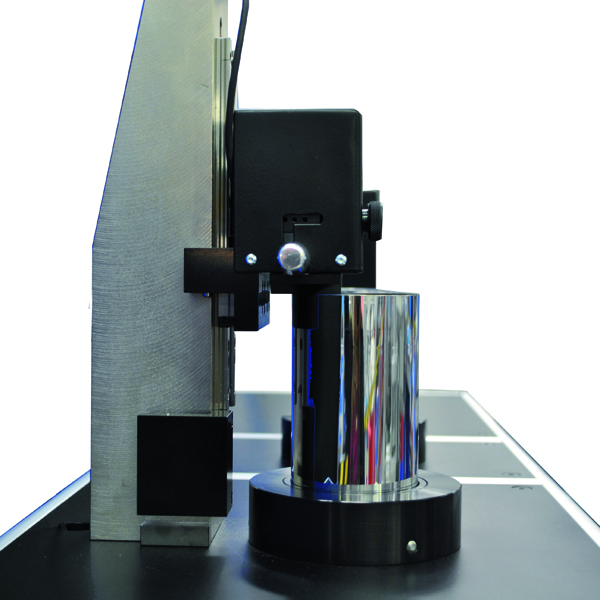

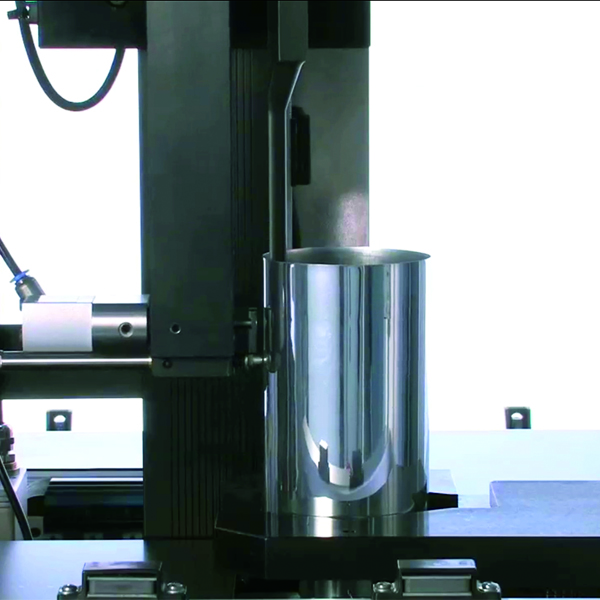

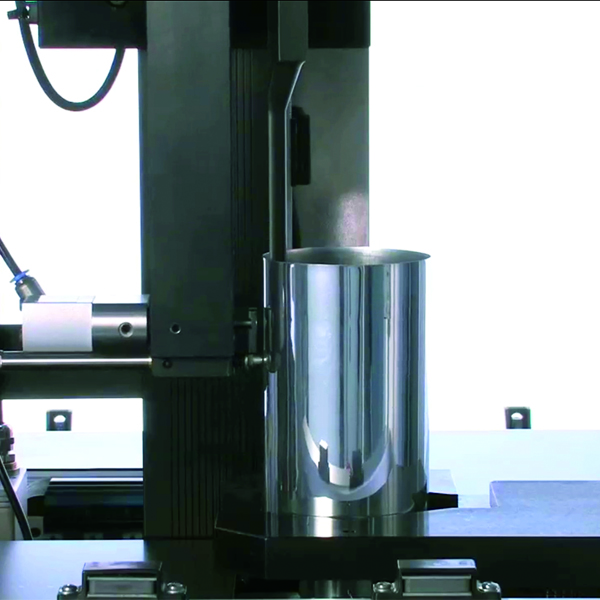

The Z314 Semi-Automatic Wall Thickness Analyser defines the standard for dimensional inspection

The Z314 measures cups and straight walled cans’ wall thickness. Utilising a single point wall thickness transducer based on industry standard Torus Z301 Front End Gauge.

The Z314 Wall Thickness Analyser ensures accurate wall thickness inspection of cups, straight walled cans or 2pc bottle cans with no need for tooling changeover.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

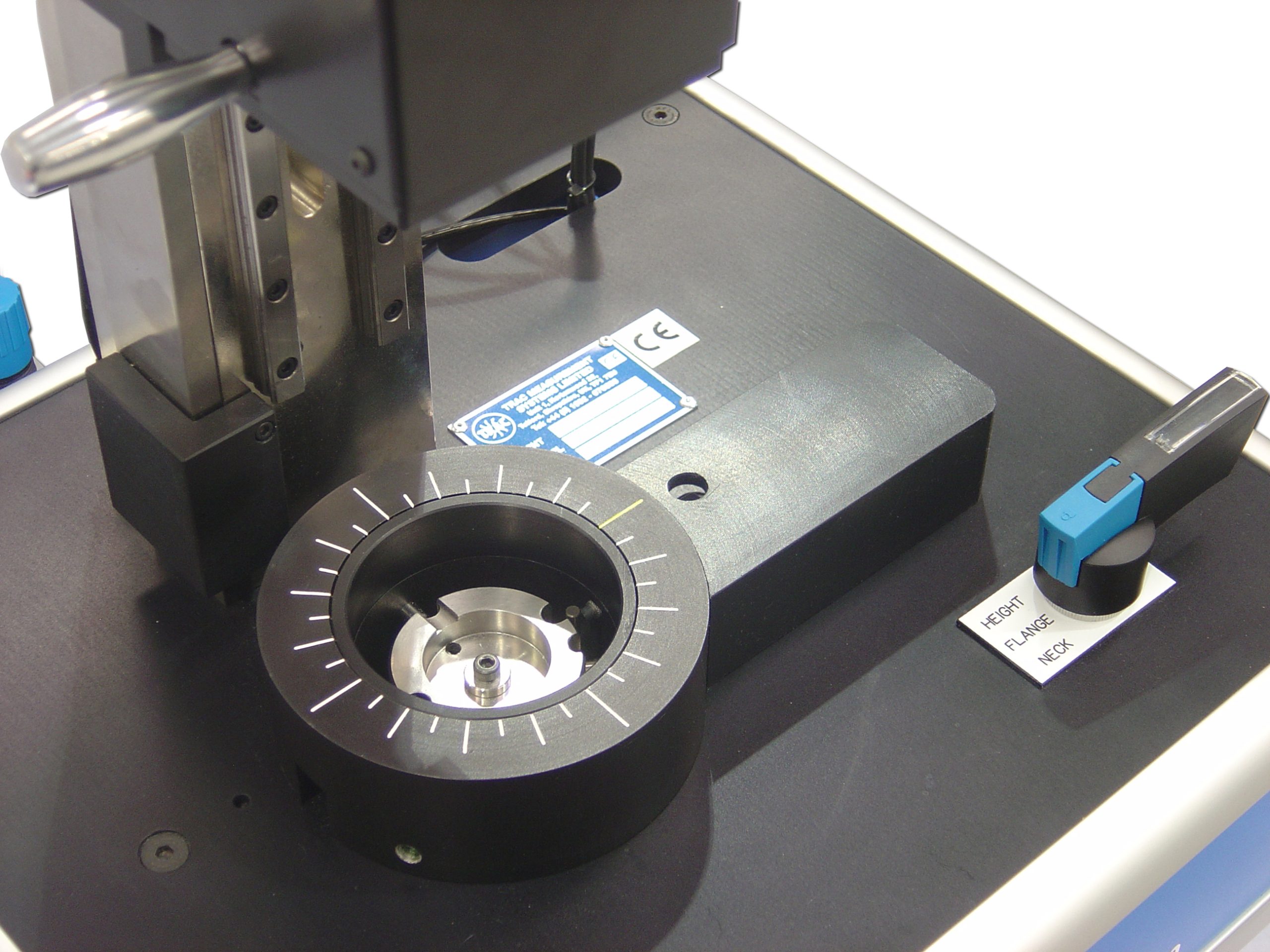

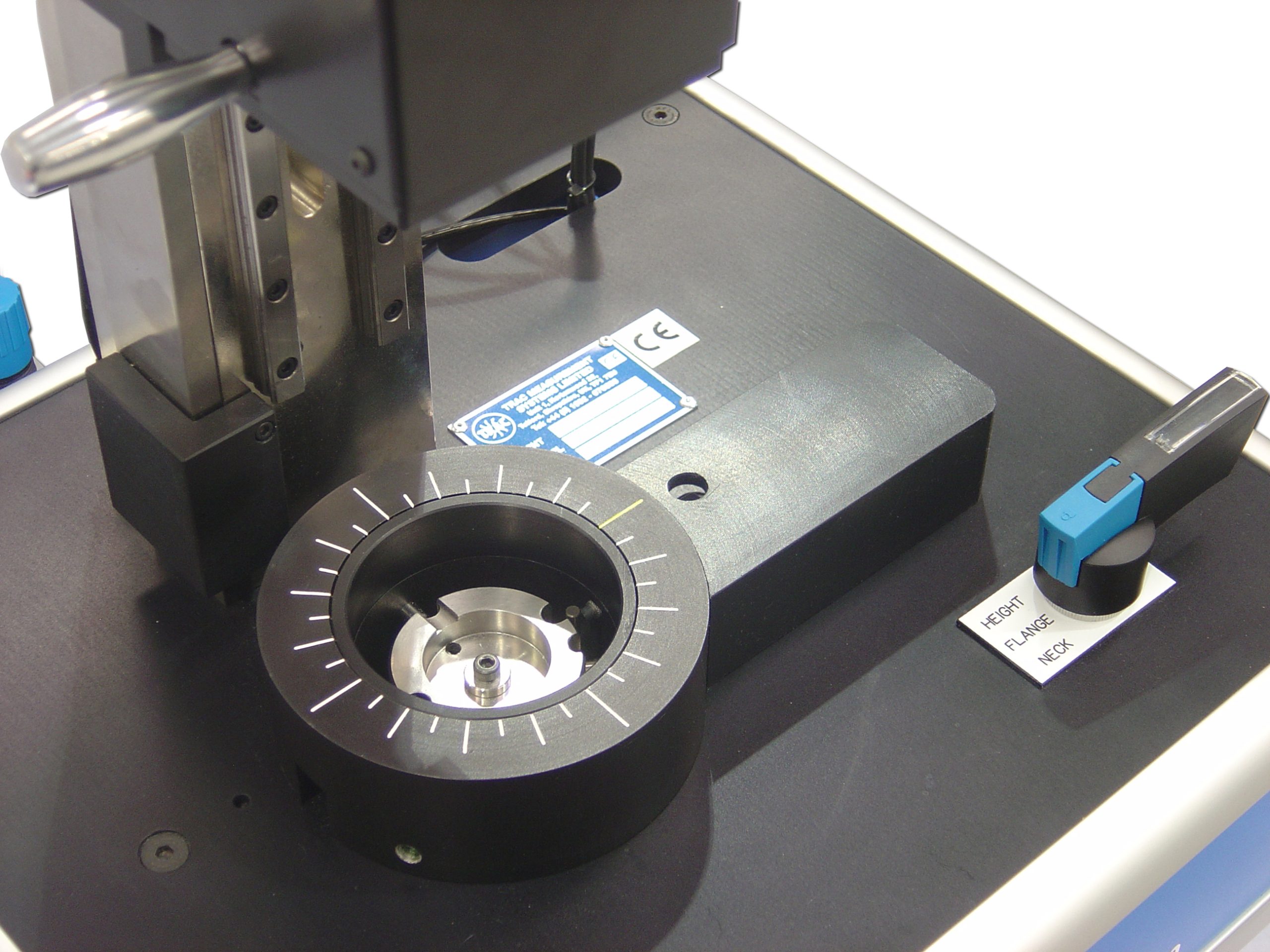

The gauge is designed to ensure correlation with the Z302 series inspection system by utilising common measurement principles and instrumentation

Each component is manually loaded by the operator and orientated to the required position for measurement. All features are simultaneously checked at each position, allowing a typical can inspection in under 30 seconds.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

Designed specifically for 2 piece can manufacturers who “reform” their cans, this small inspection gauge gives critical measurement information on the setup of each head of your reformer

The scanner utilises proven contact measurement technology to scan the form of the reformed profile and incorporates a entering check to accurately locate Ø 202 – Ø 300 body cans.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

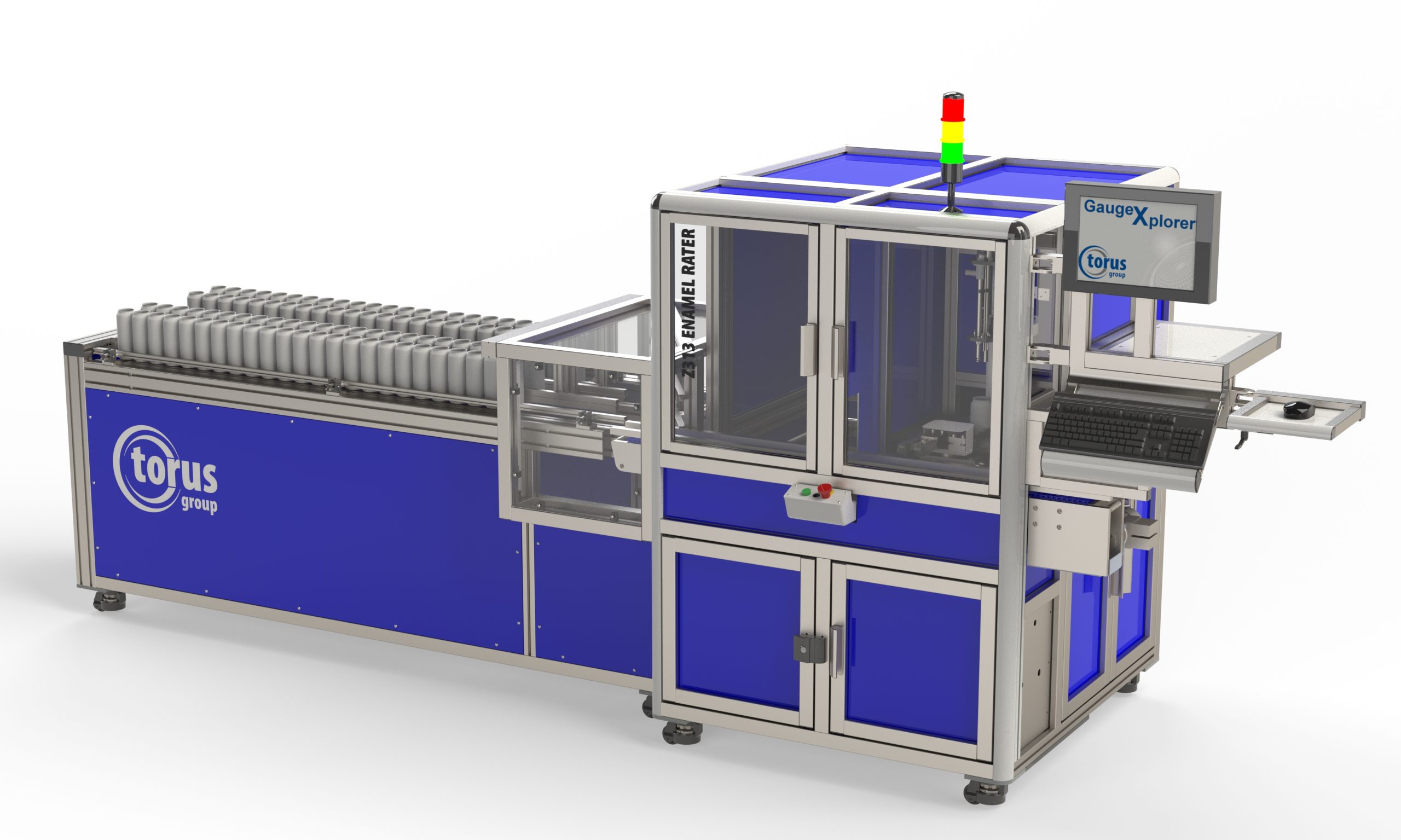

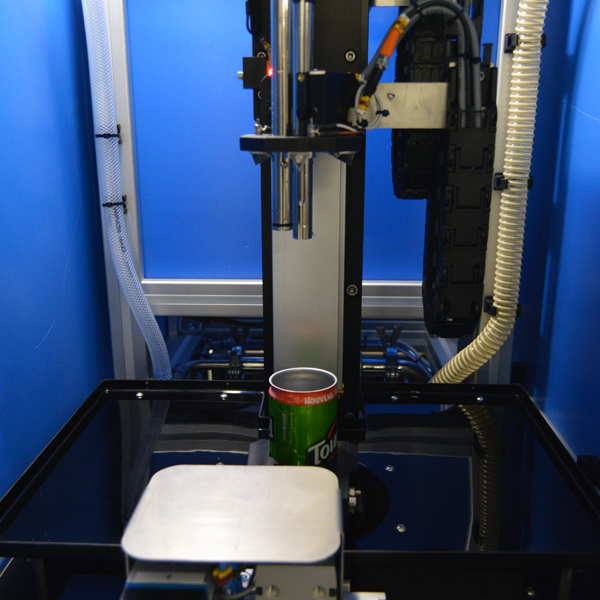

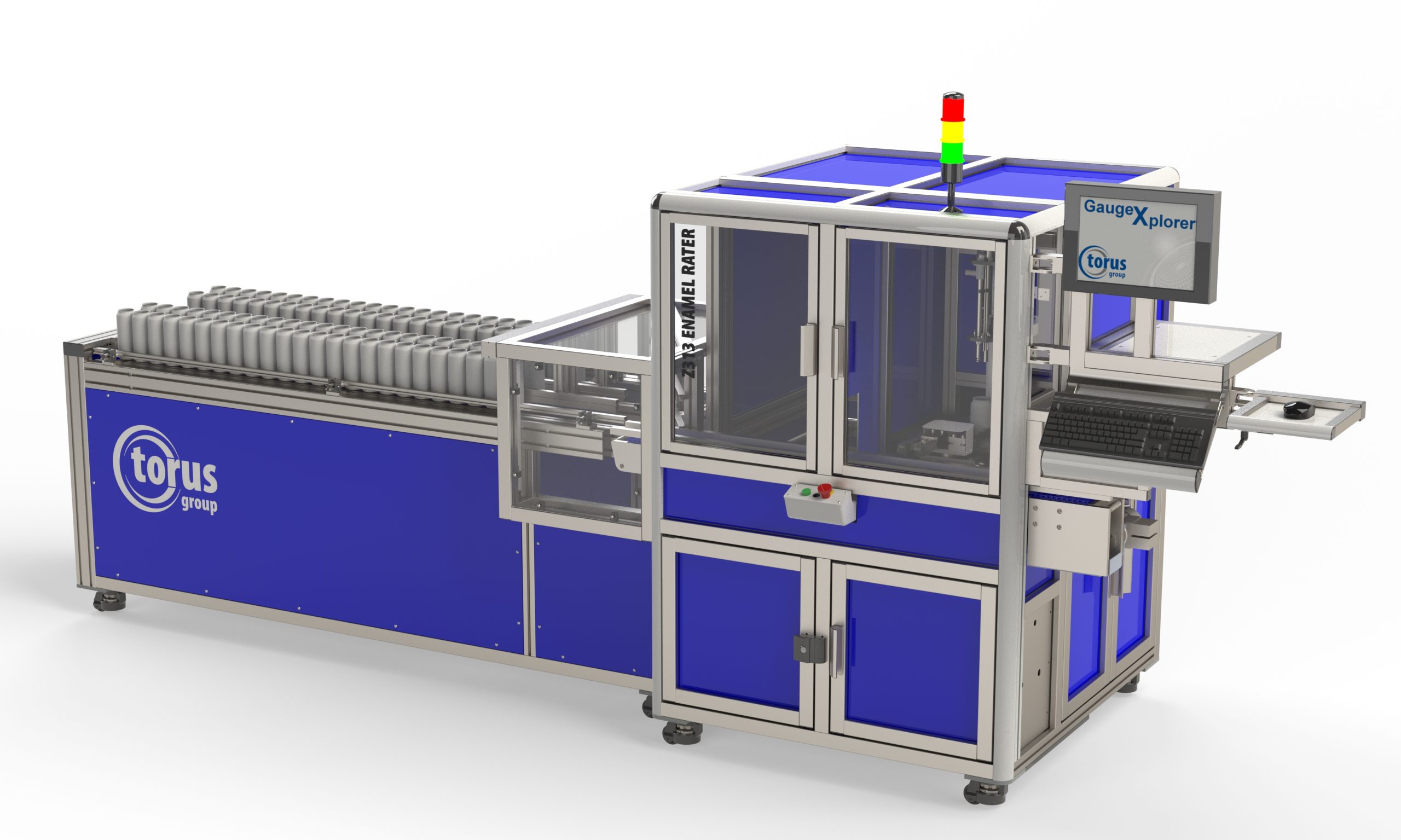

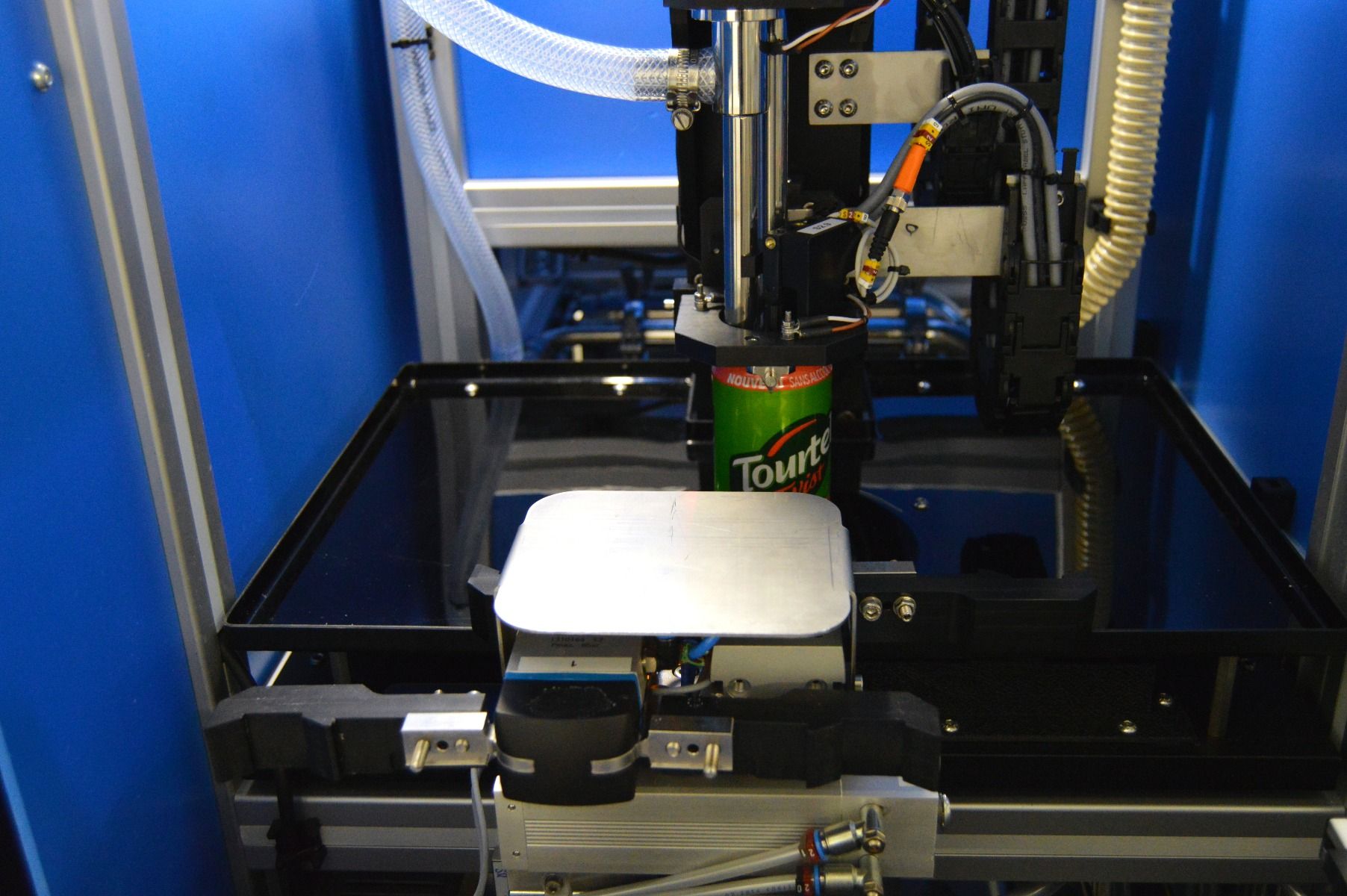

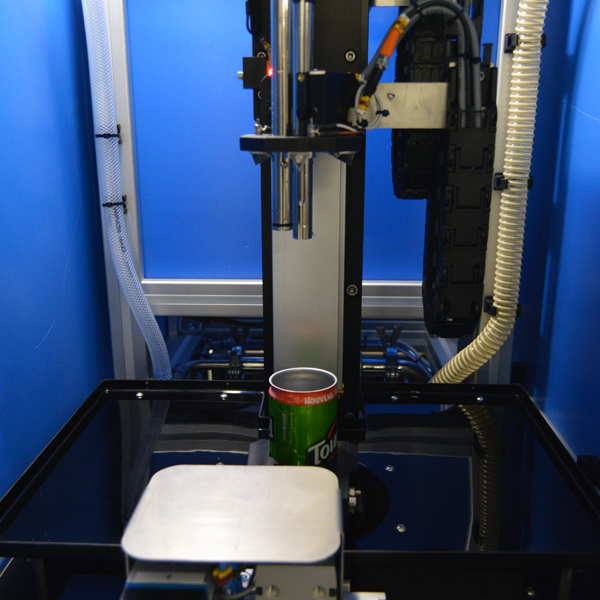

The Z313 Series Enamel Rater can be specified for conveyor loaded (automatic) or fully line fed (in-line) operation

The Z313 Enamel Rater measures the lacquer integrity of metal cans, with a typical throughput speed of 3 cans per minute.

The system can be specified with Torus’ optional LSM/ISG Recognition Camera Module, ensuring SPC data output is “tagged” with the relevant traceability for effective remedial actions.

Torus Beverage Can Gauging

Measurement Features

Standard

Measurement Features

Hi-Res (typically for plants running steel cans)

Technical Specification

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

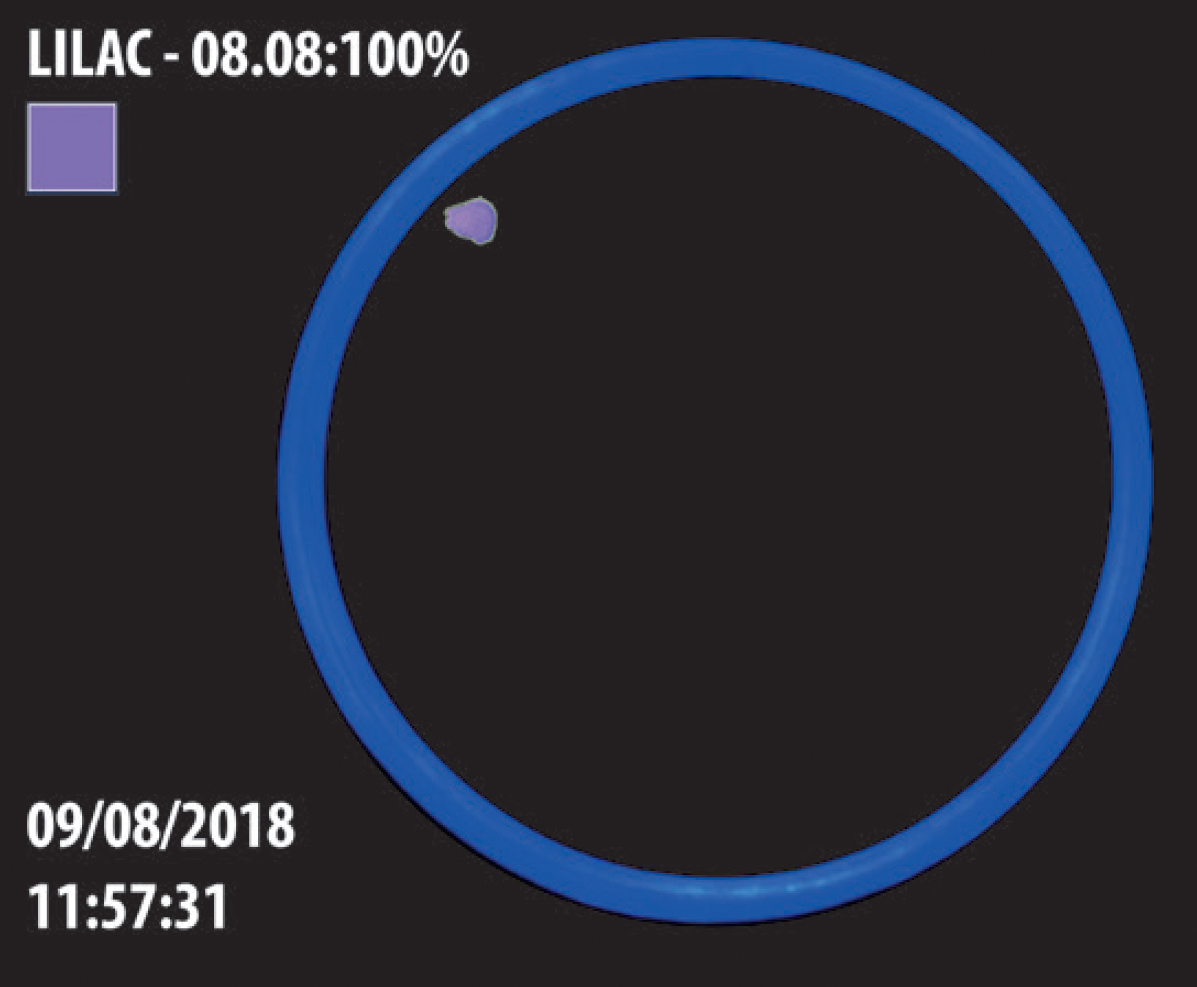

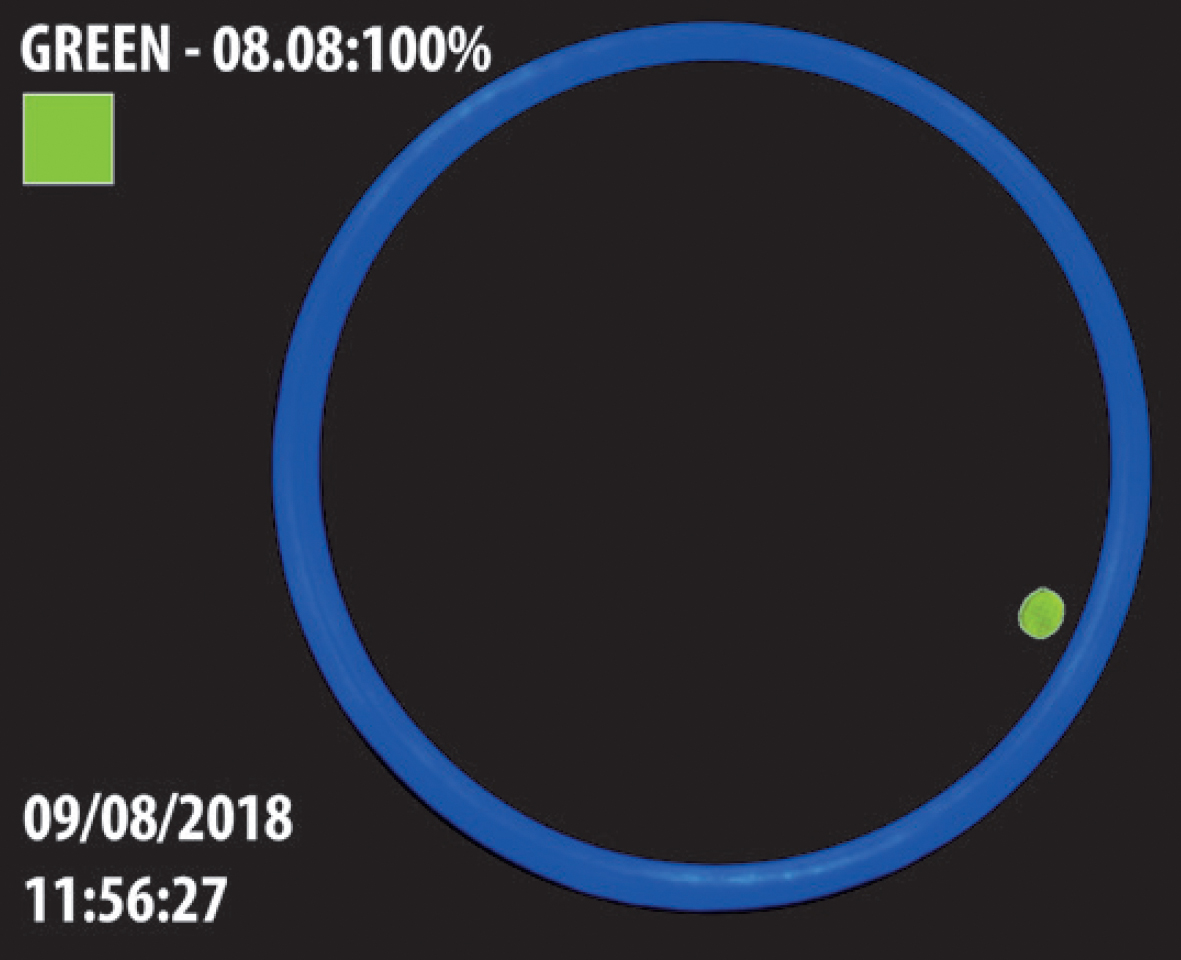

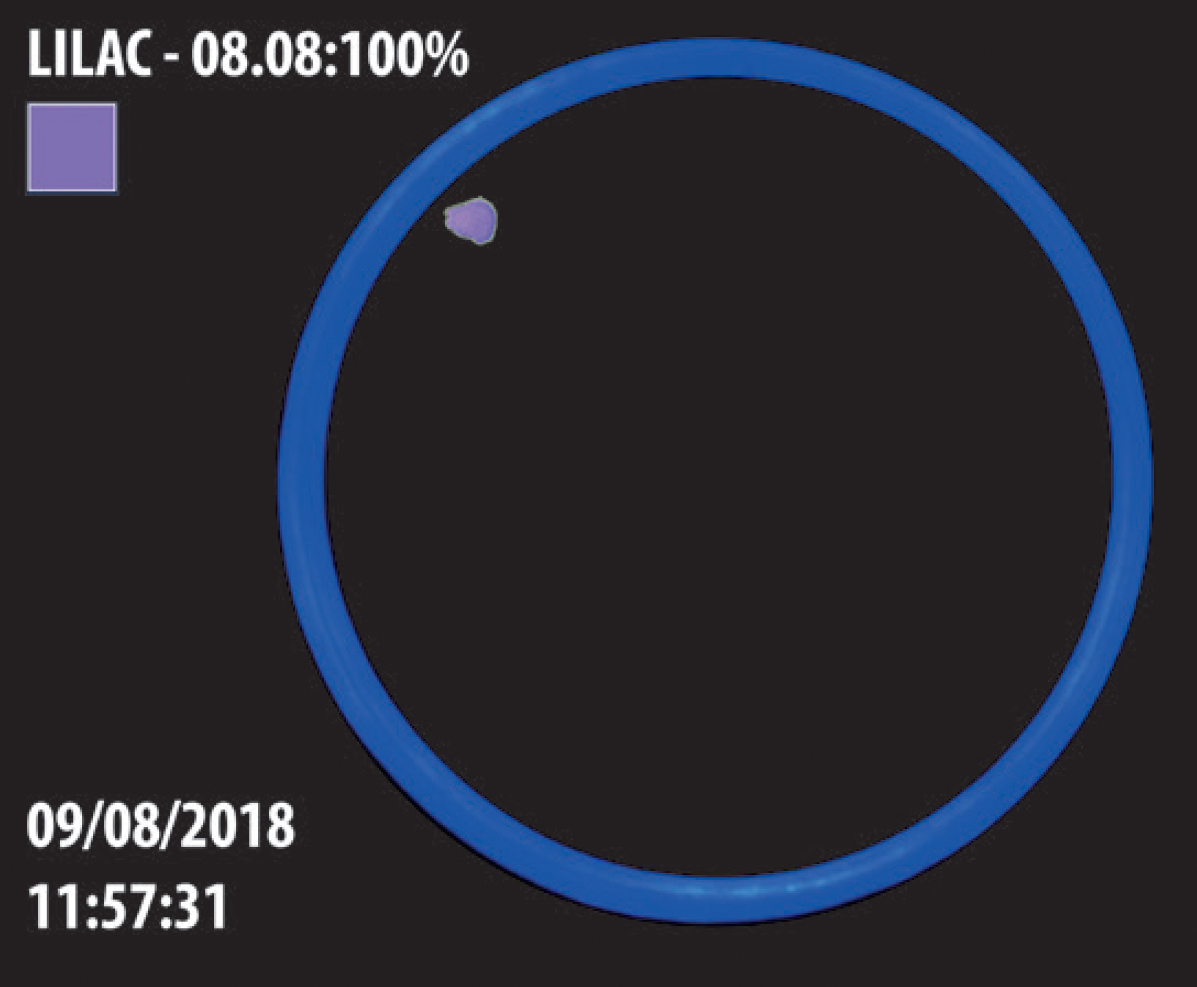

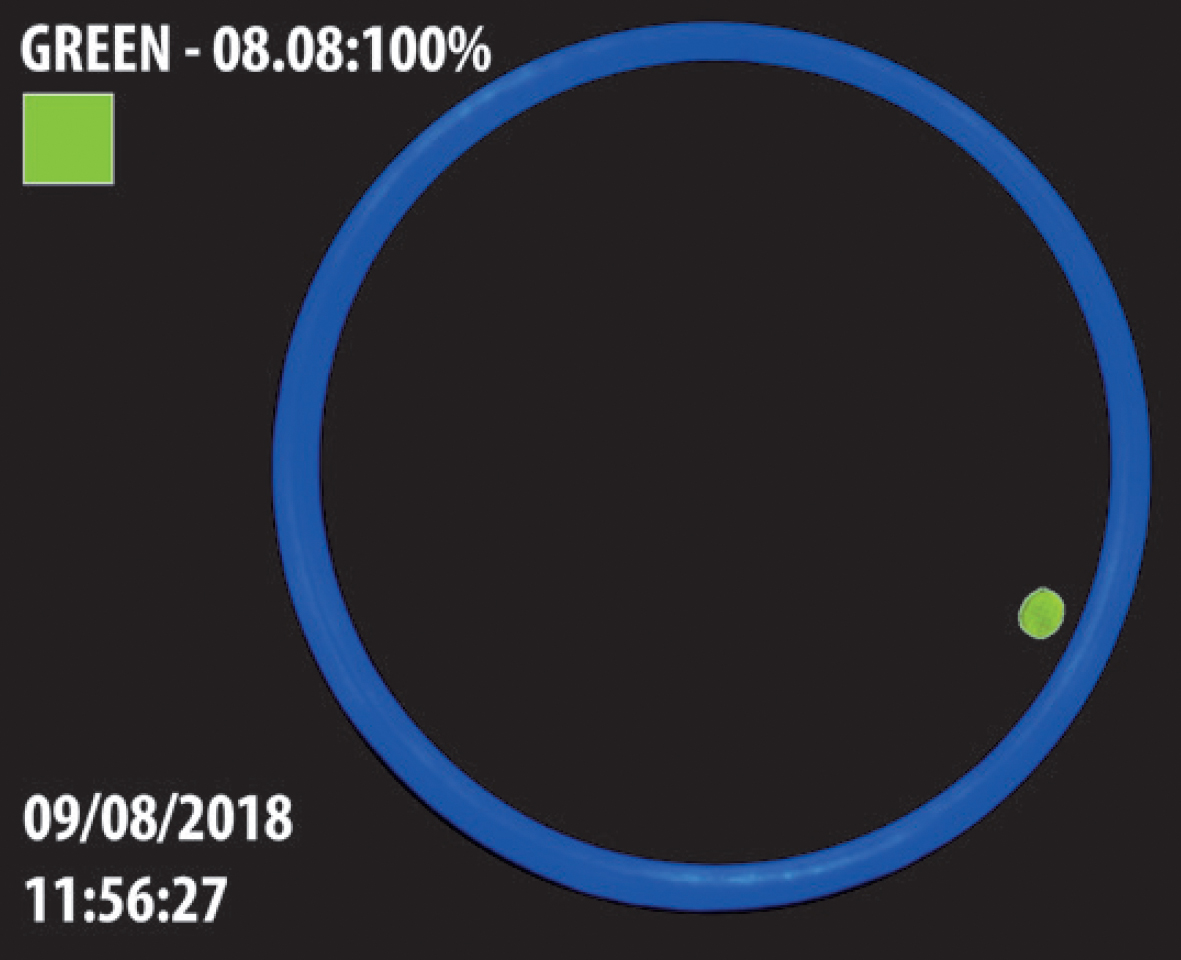

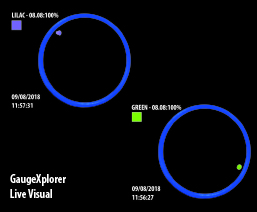

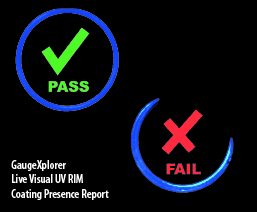

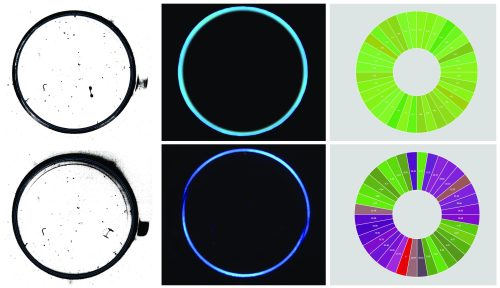

The Z312 Vision Module tests for all industry standard ISG recognition, including UV/BRC presence in one system.

The Z312 Vision Module quickly identifies the application of UV base rim coat presence, indicating in split seconds a percentage coverage based on parameters set within Torus’ GaugeXplorer software. The live report instantly denotes if the rim coat has either been under applied or damaged.

Designed with flexibility in mind the Z312 module can be integrated into any new or existing Torus gauge, or alternatively supplied as a standalone system. The flexible module boasts multi size capability with no change parts allowing the system to be located anywhere on the shop floor.

Torus Beverage Can Gauging

Gauge Features

UV Base Rim Coat Presence (BRC)

• Visible Spray Dot

• UV Spray Dot

• 2 & 5 Digit Dot Matrix Character Code (Visible/UV)

The Z312 works together with and complements Torus’ Z340 Coating Analyser to provide Base Rim Coat Distribution Analysis, aimed to show operators how the BRC is distributed and thus showing up any potential areas to save resource.

The Z311 Punch Inspection Gauge defines the standard for dimensional inspection of 2 piece beverage/beer can punch tooling

The Z311 Punch Gauge has been designed to measure a wide range of Punch sizes typically found in the metal container industry. Available as a semi-automatic (manually loaded) system, designed to measure a wide range of punch sizes typically found in the metal container industry.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

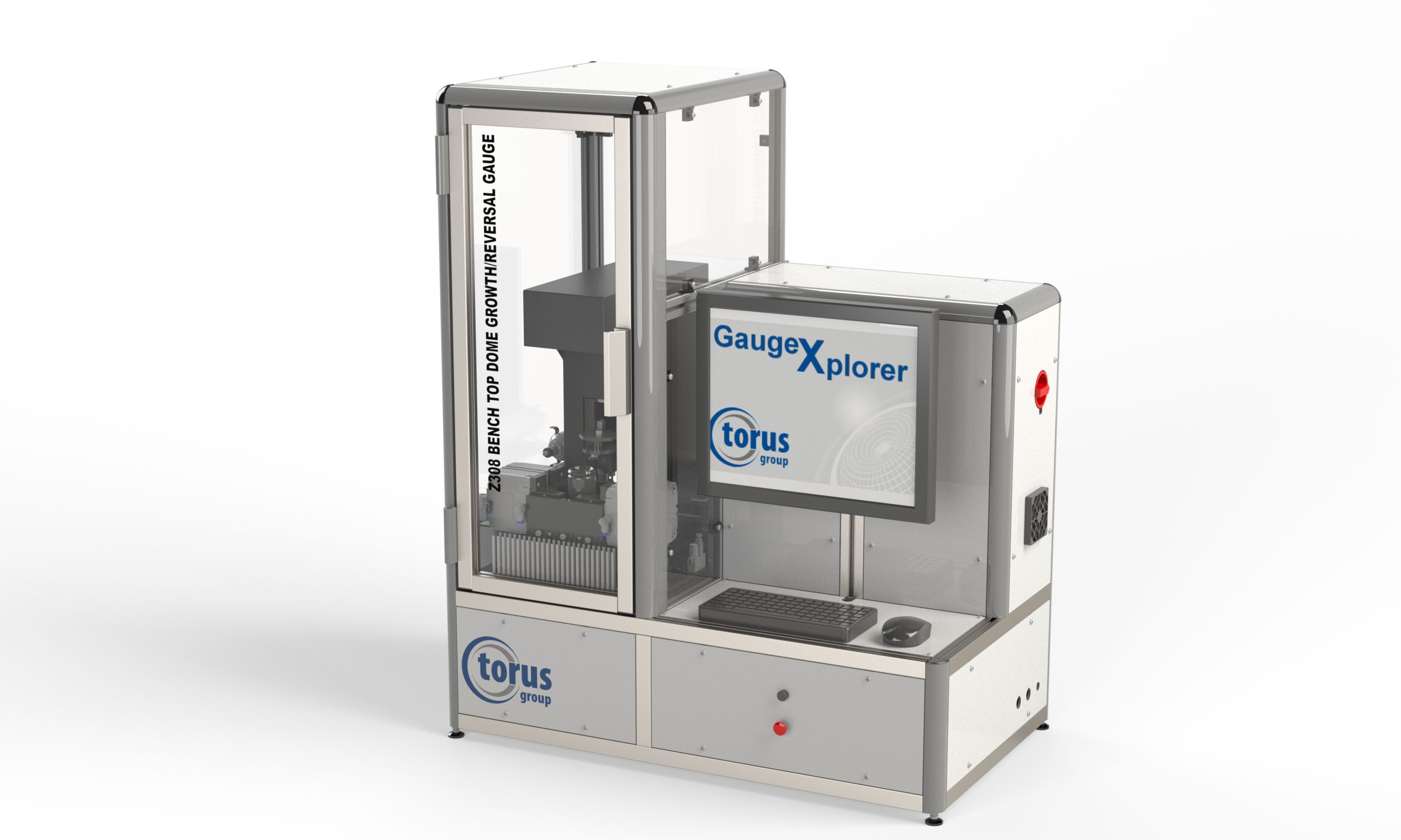

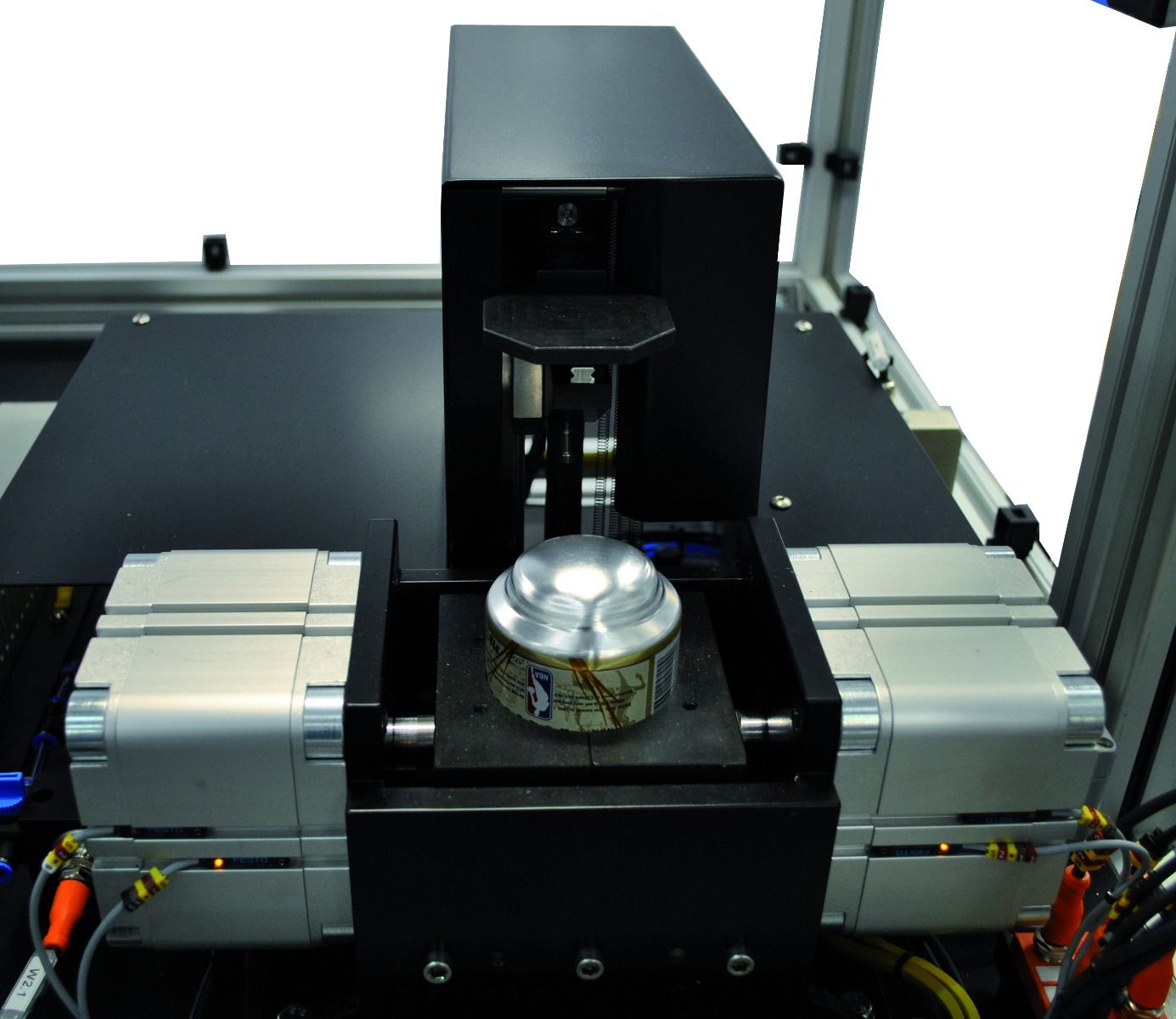

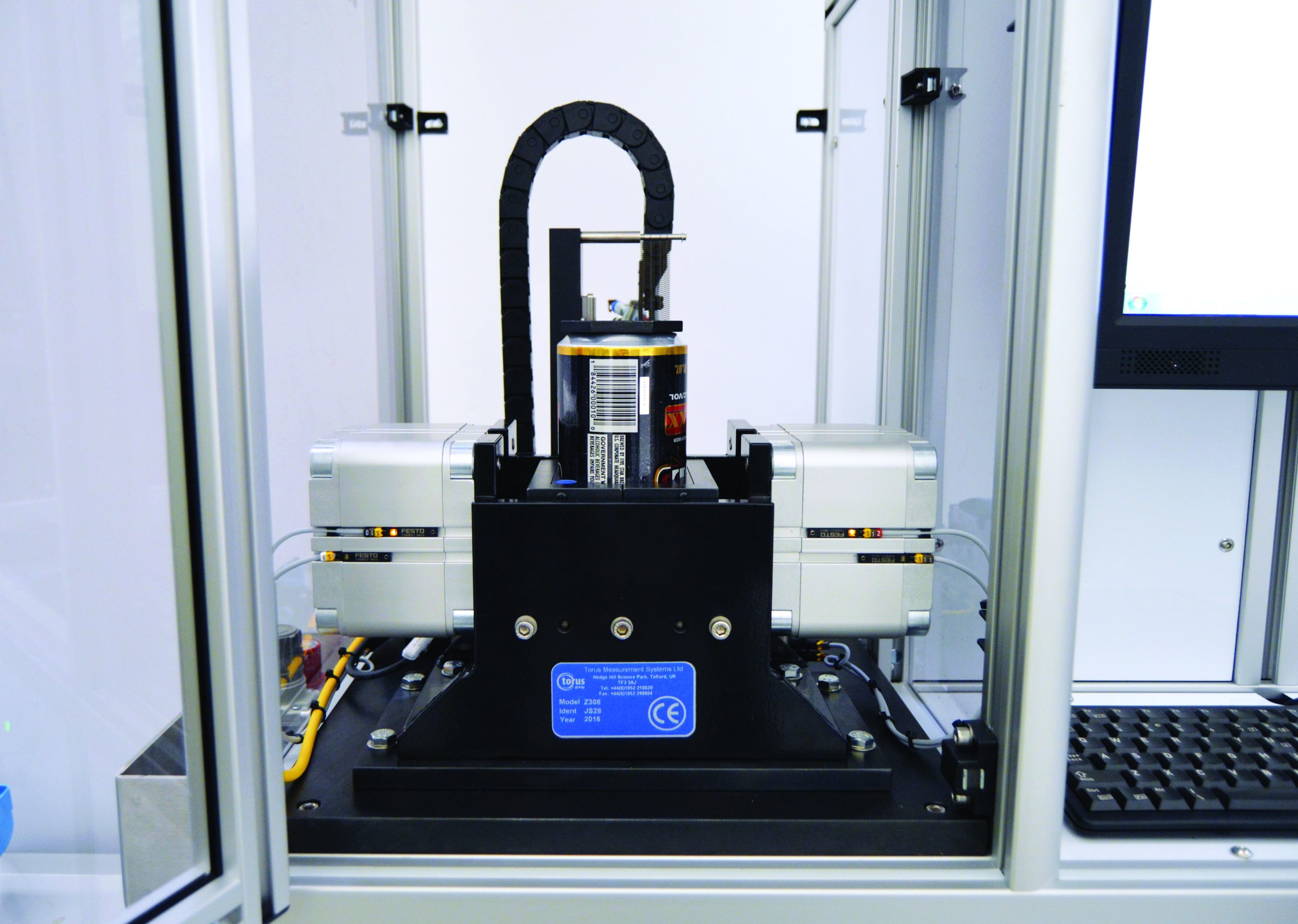

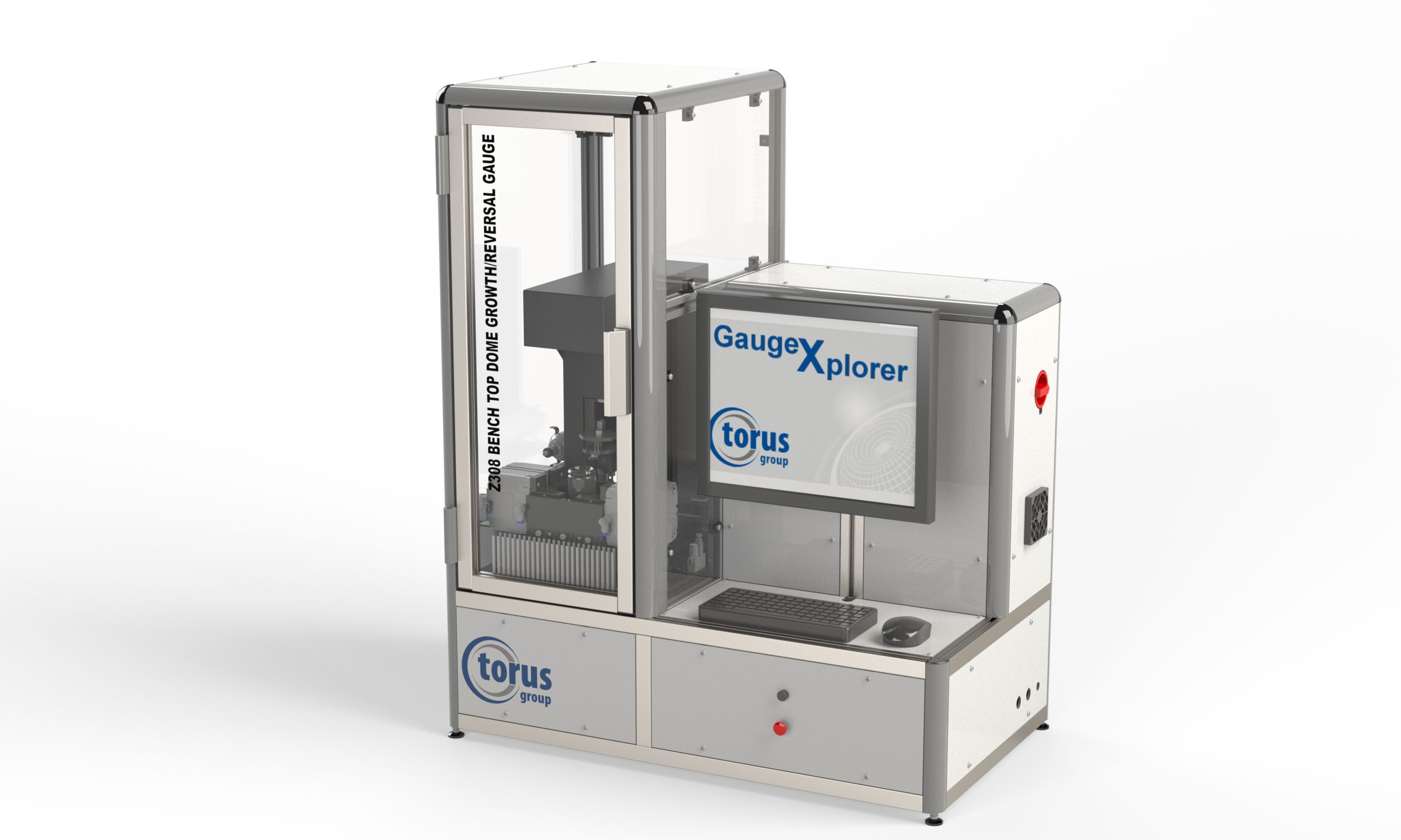

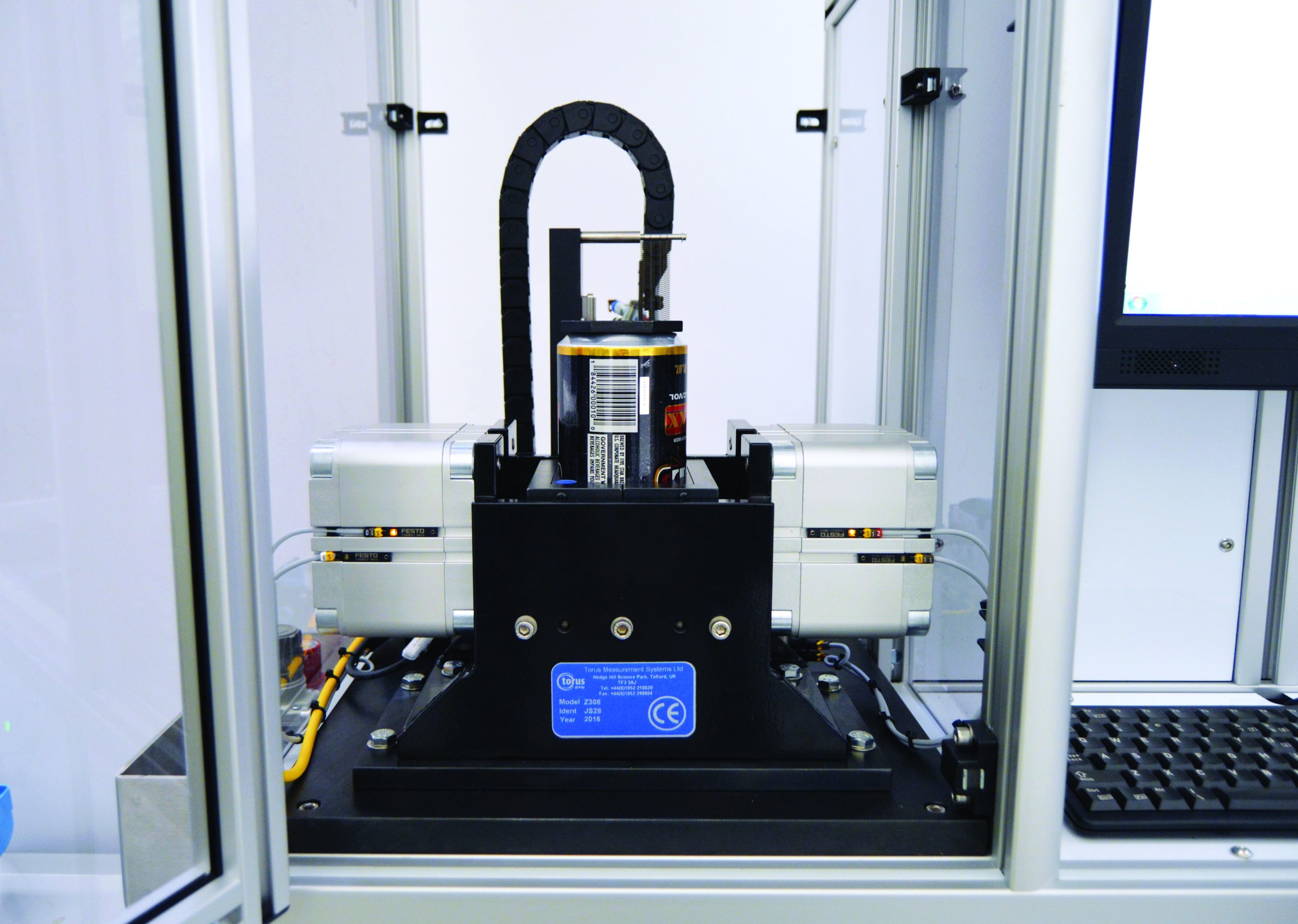

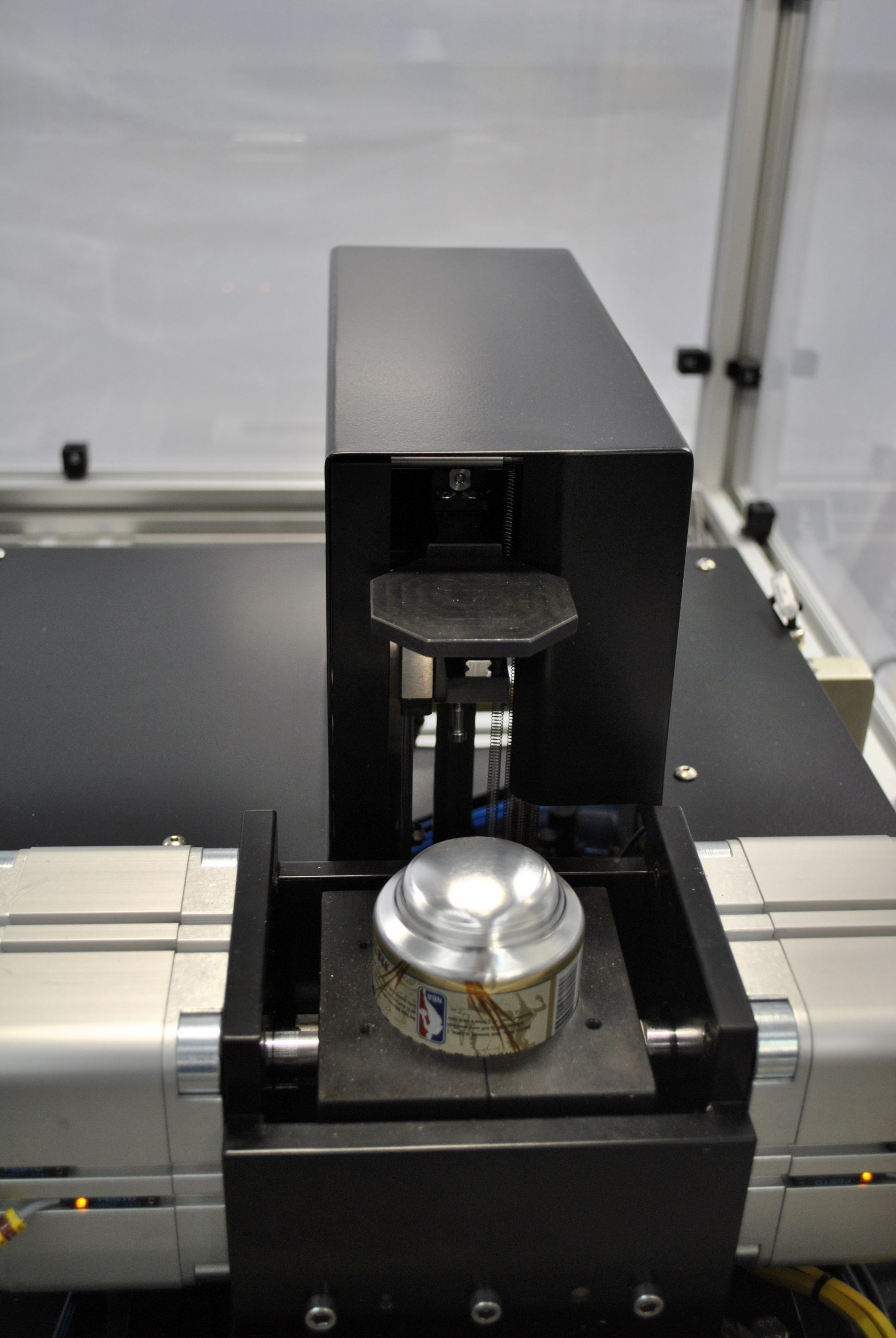

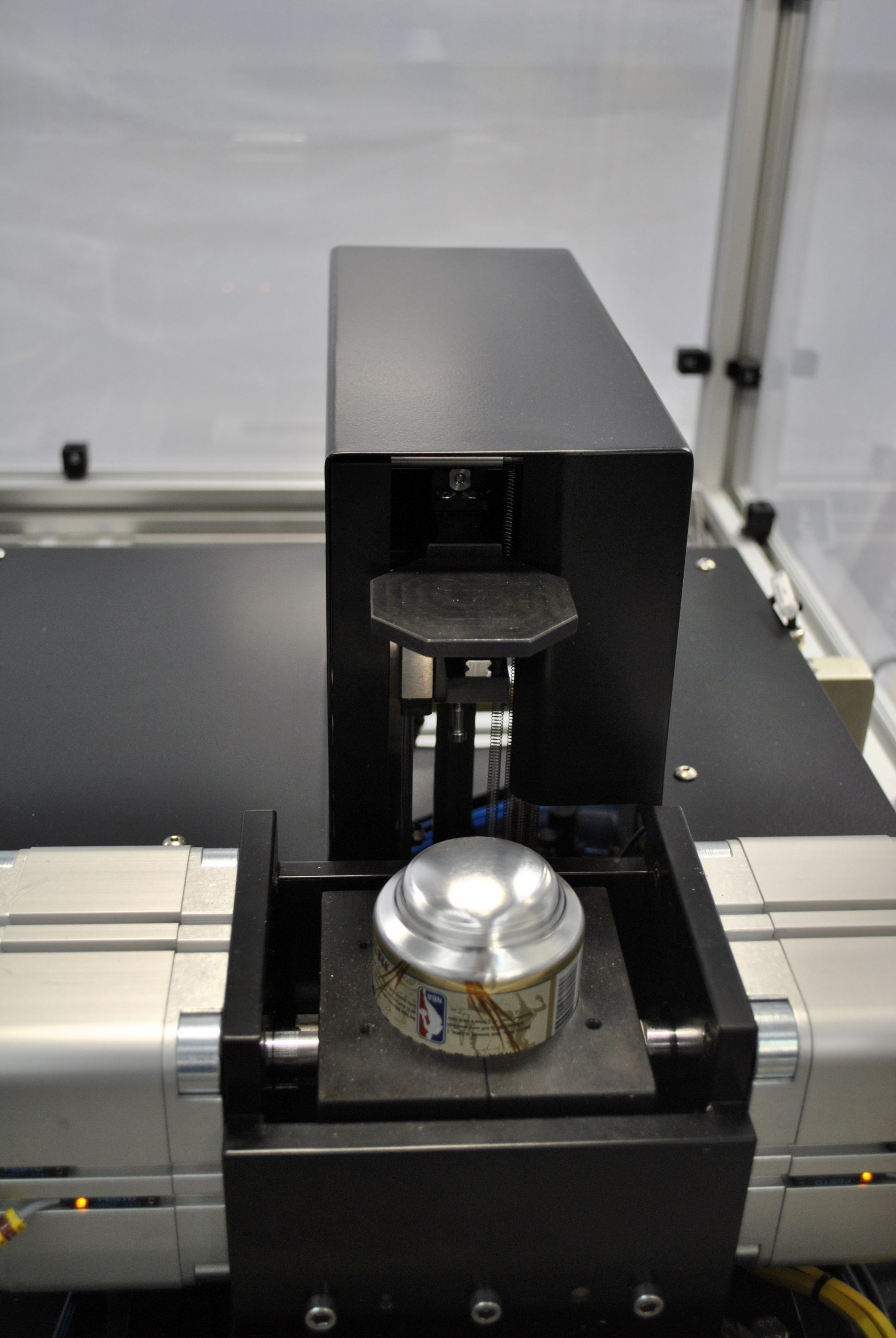

The Z308 Dome Reversal Gauge provides detailed information about the overall change in length of the can when pressure is applied and subsequently removed.

Measurement Features

Technical Specification

Gauge Features

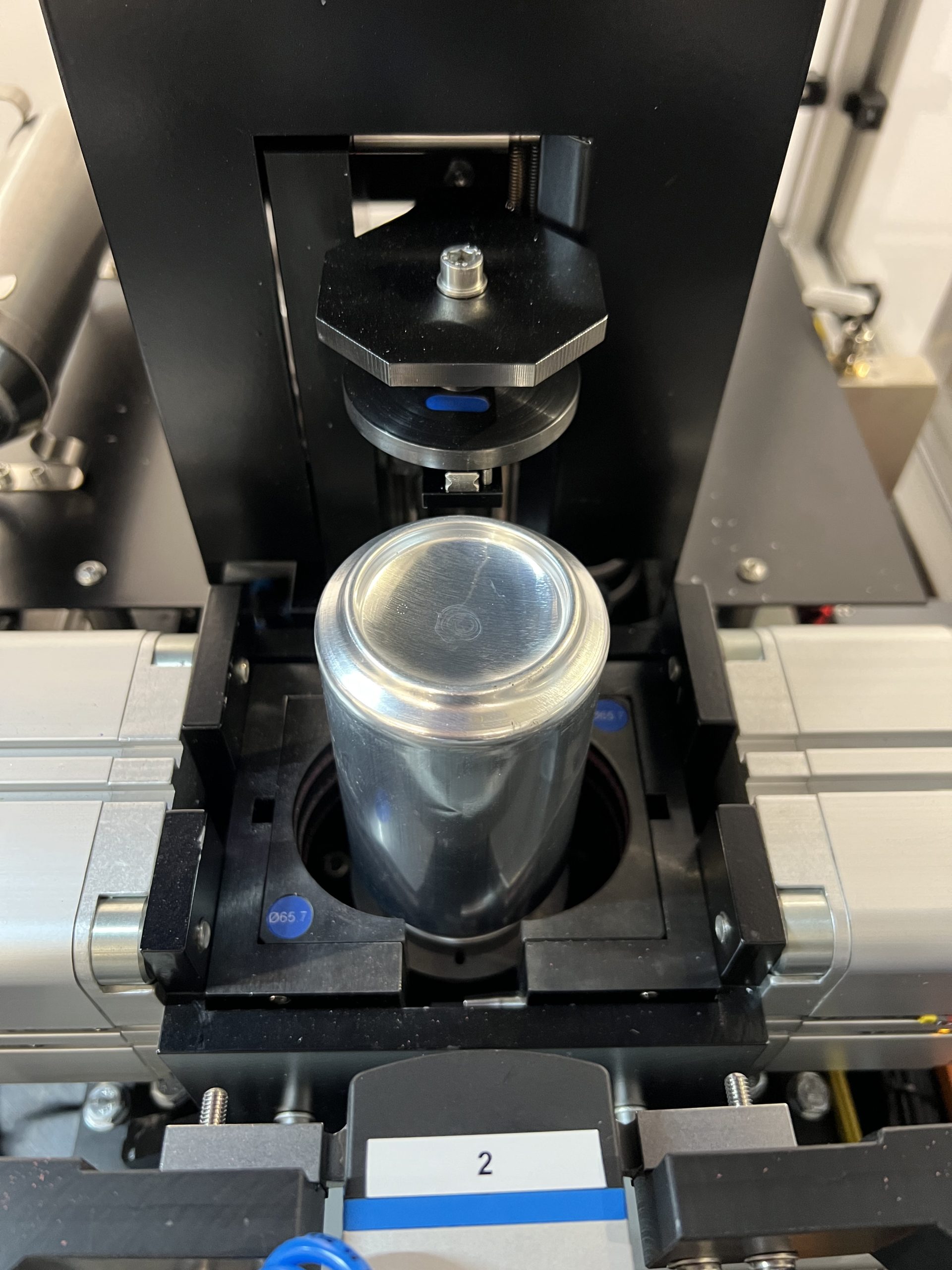

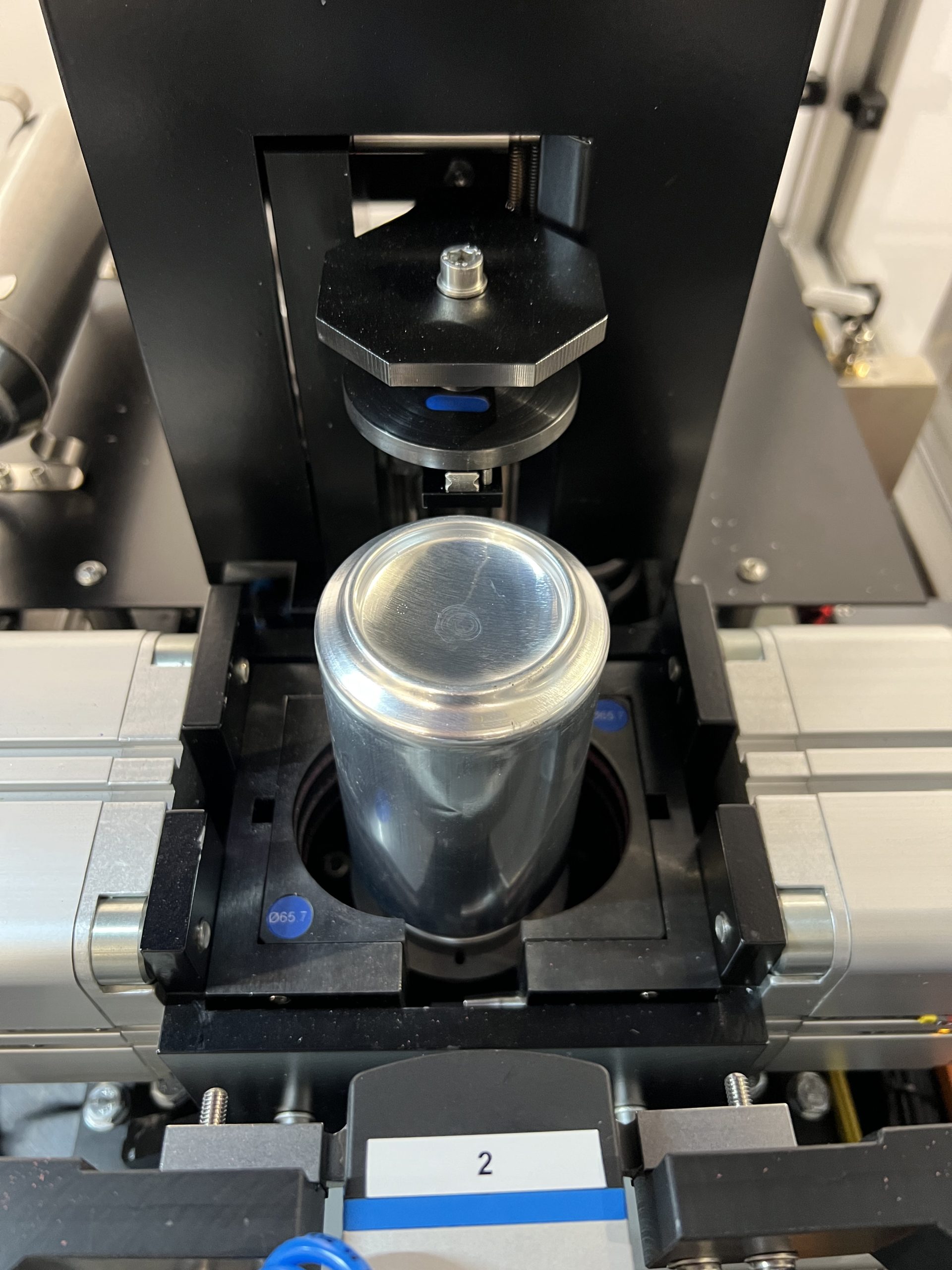

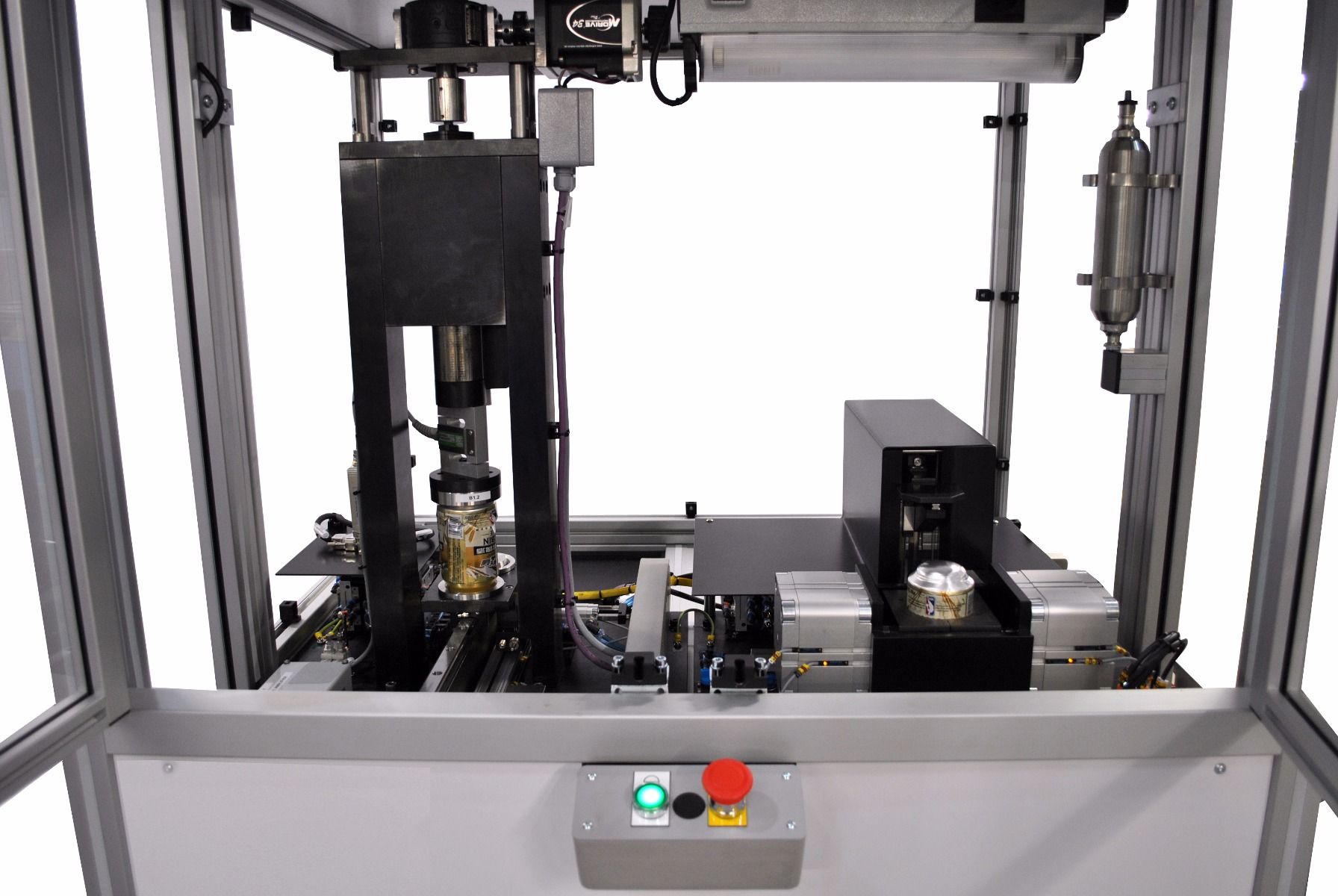

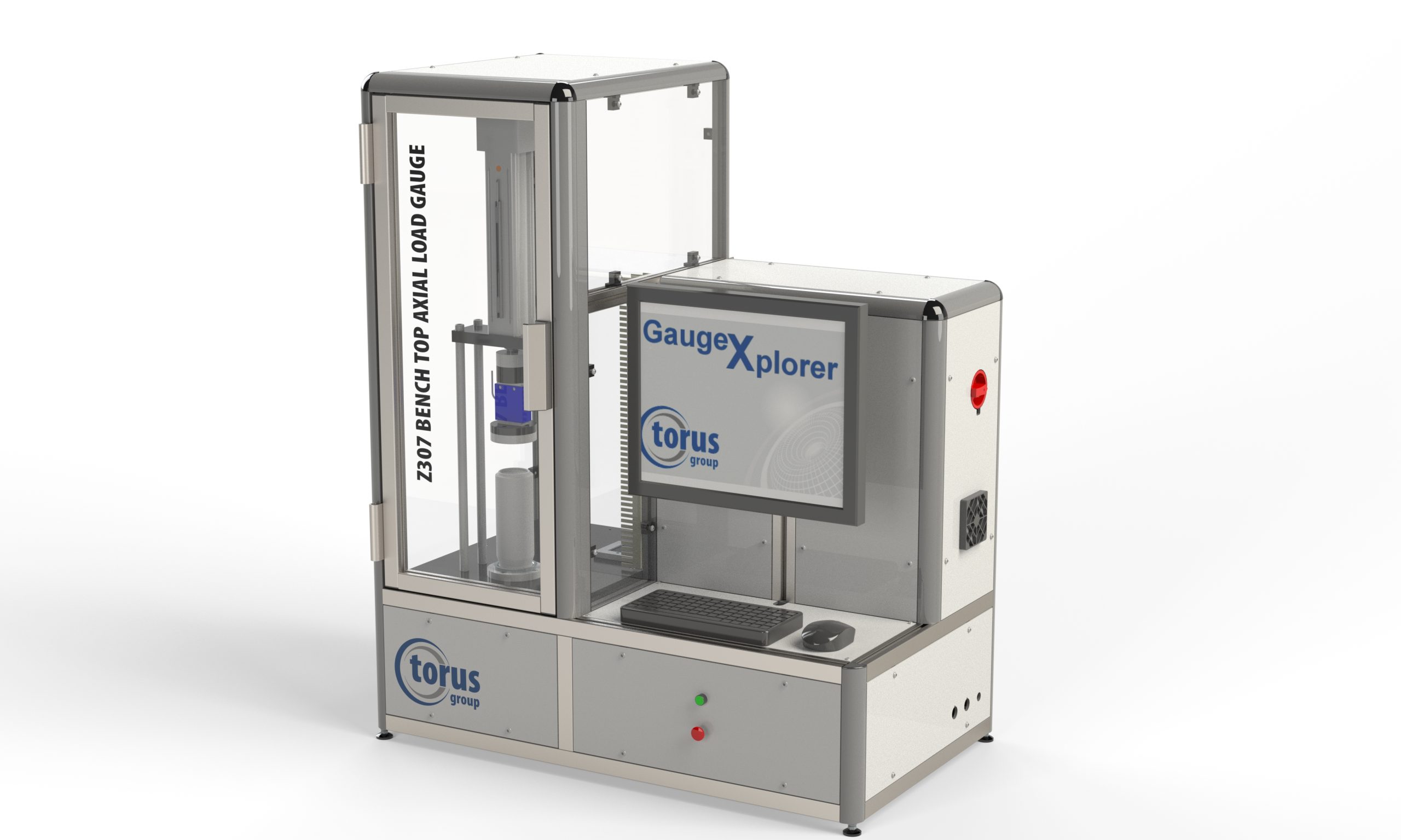

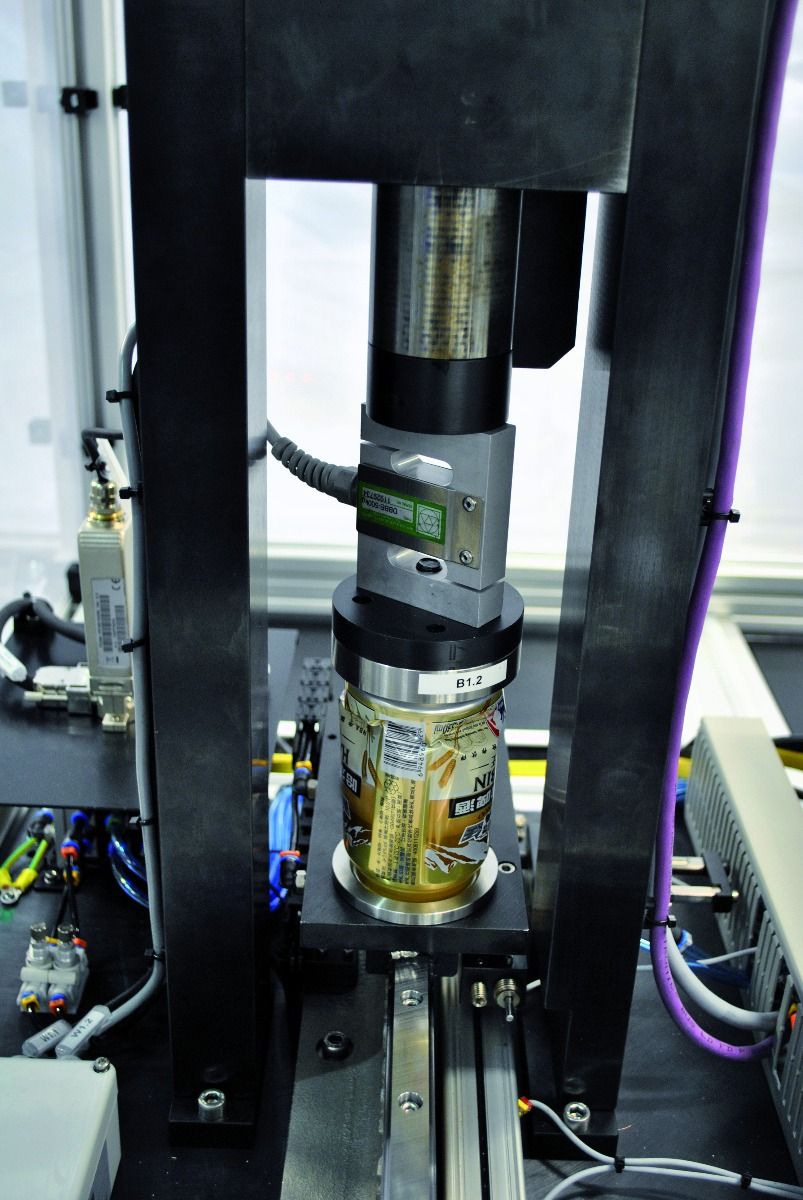

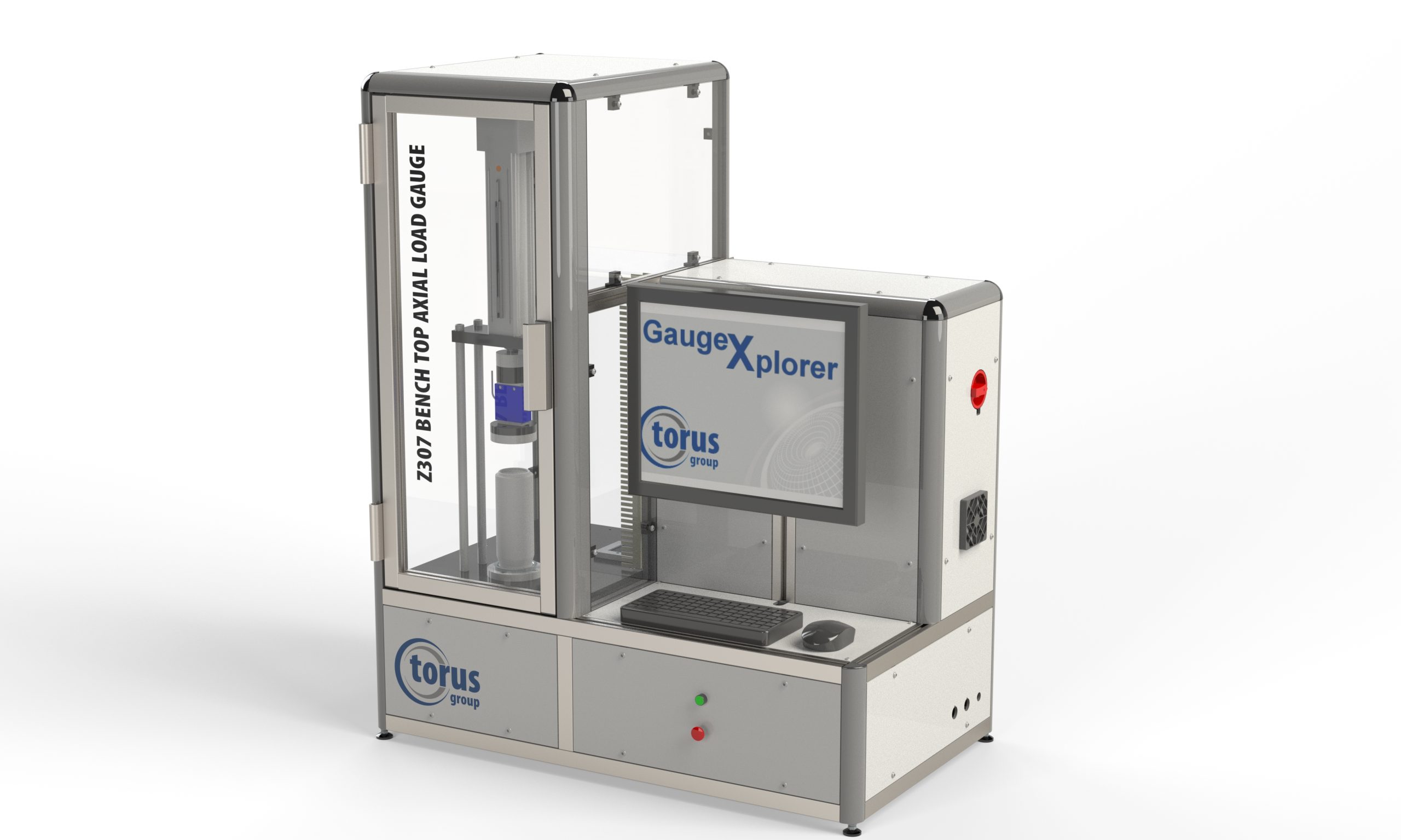

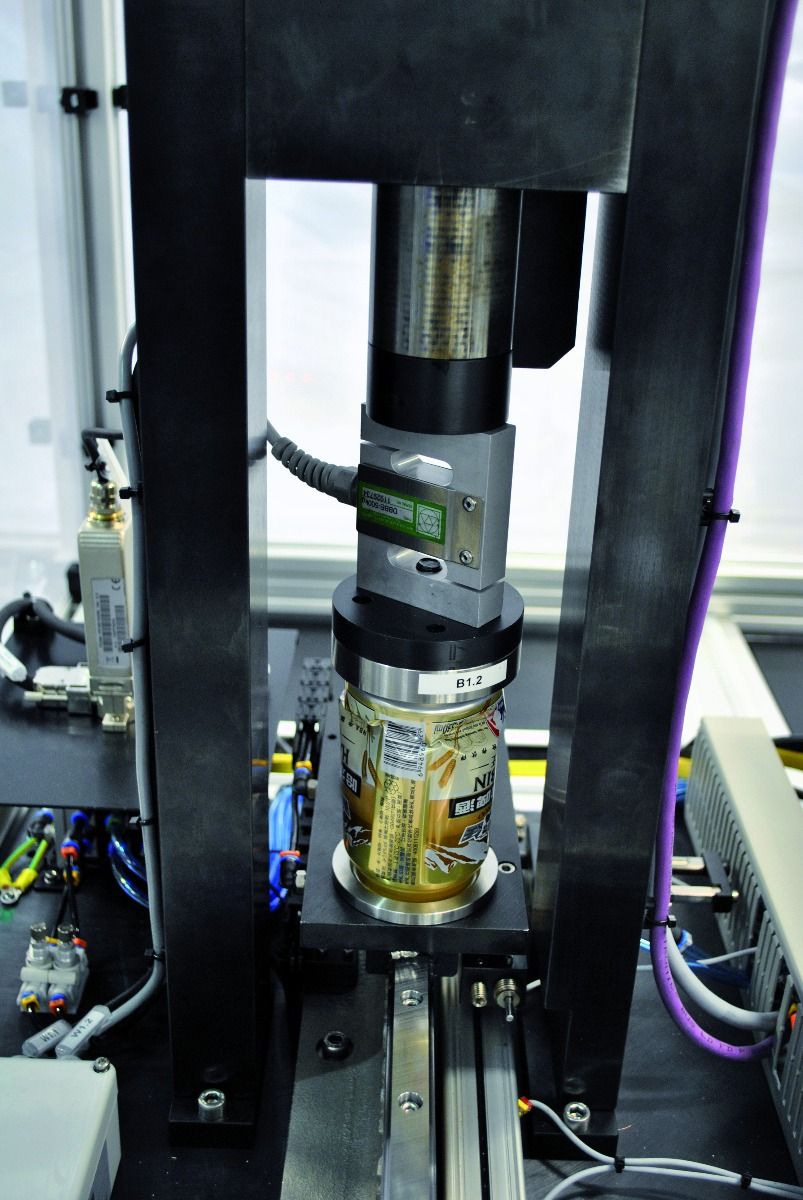

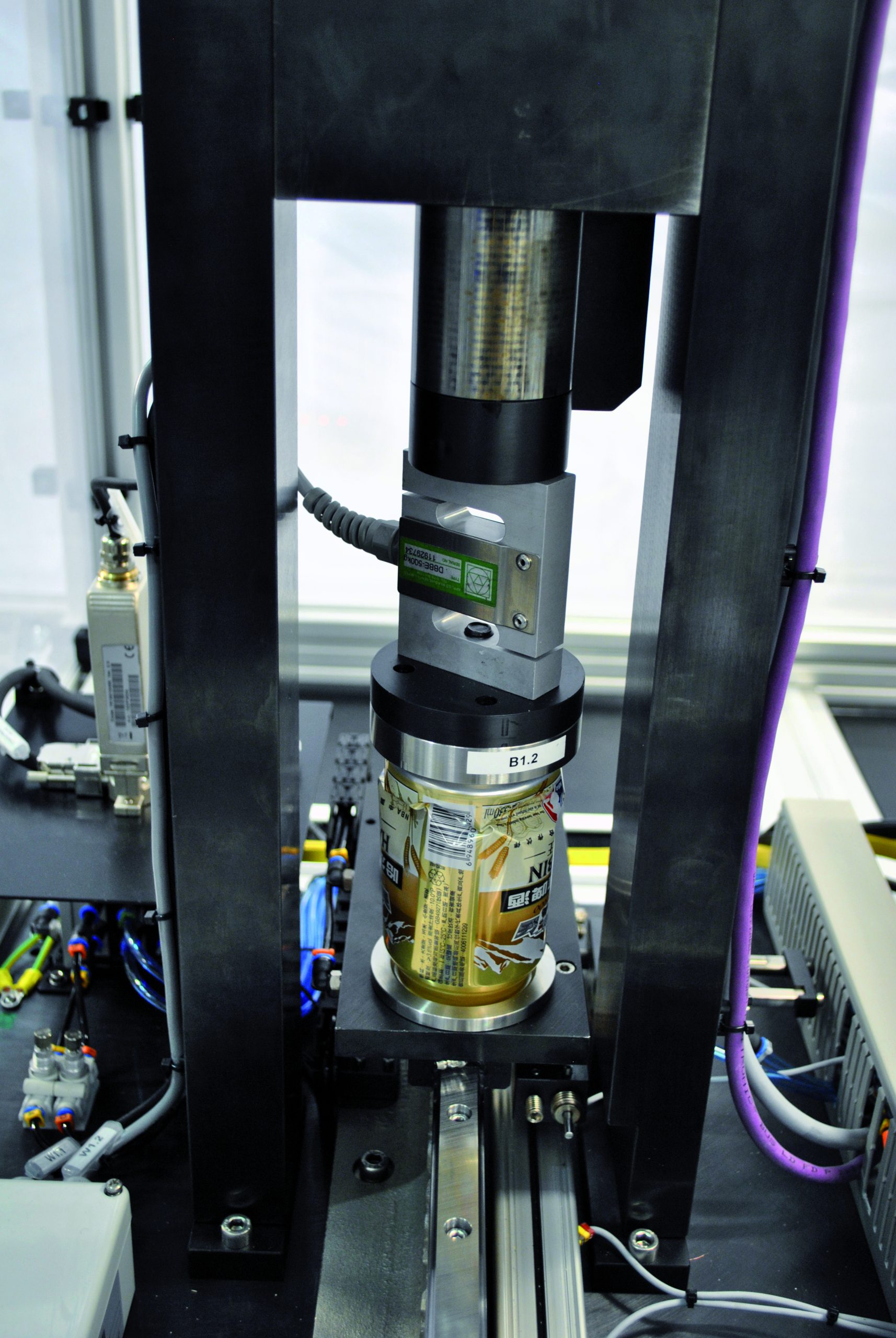

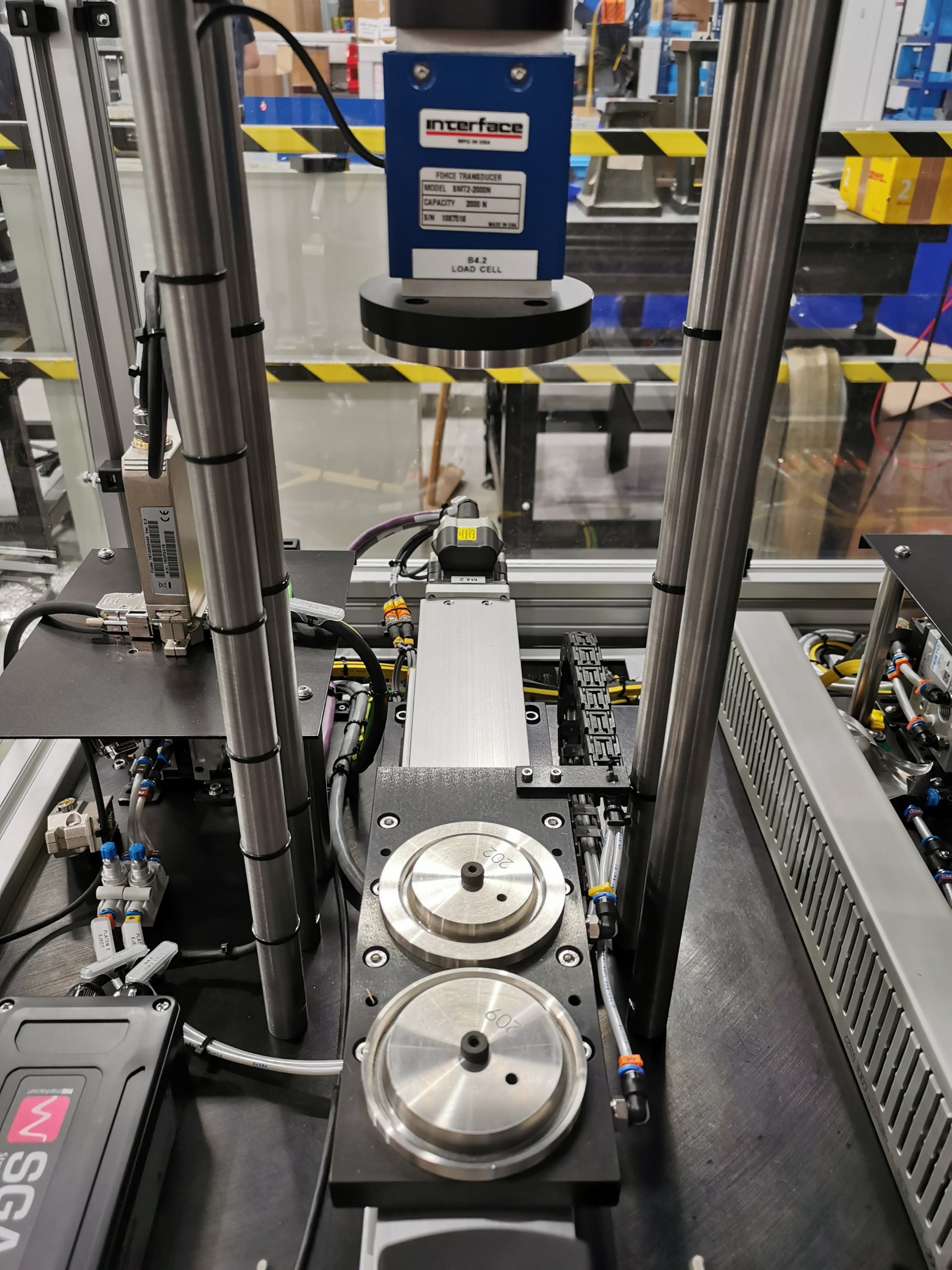

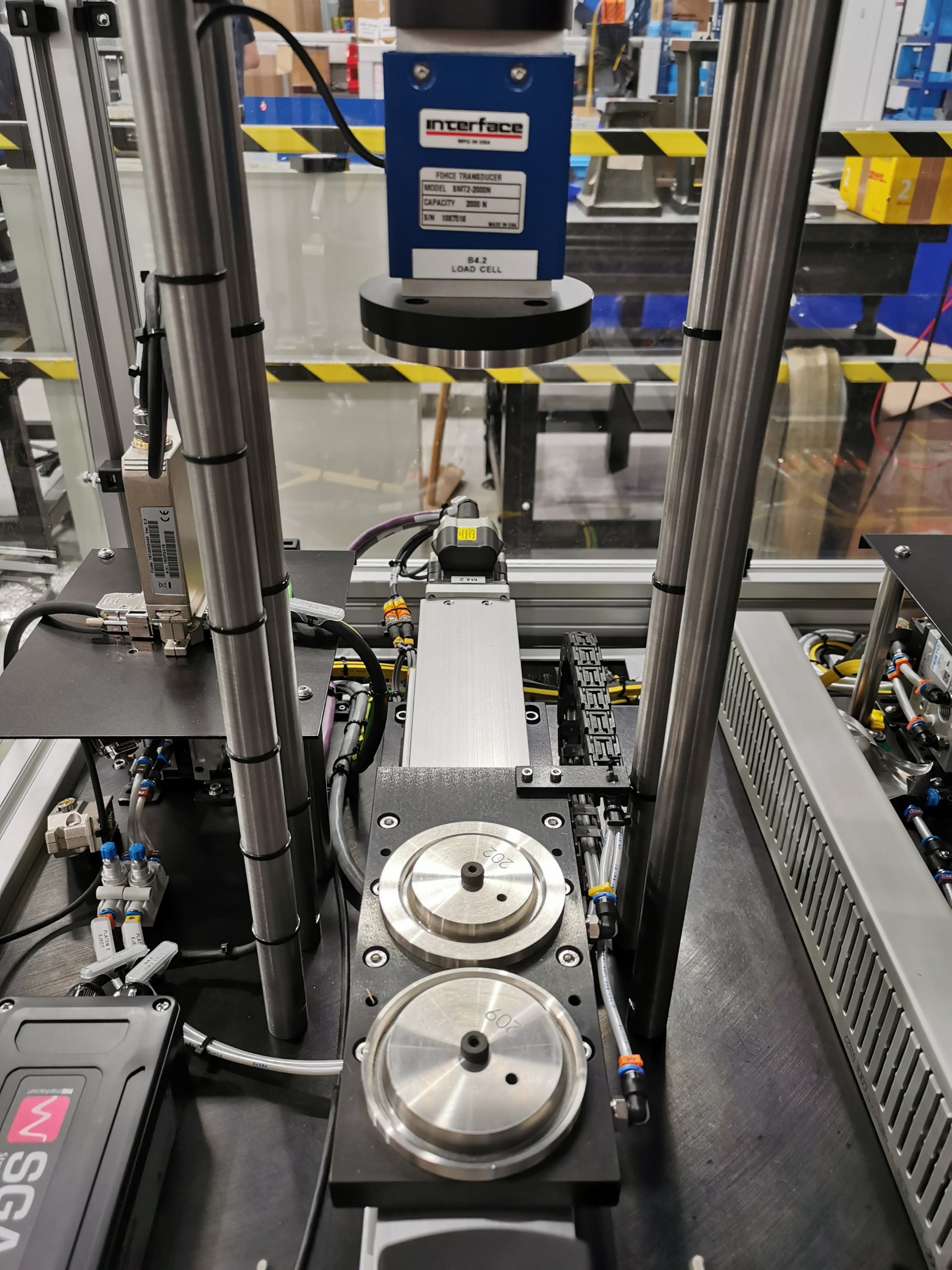

The Z307 Axial Load Gauge determines the maximum axial load force which can be applied prior to container failure, within a short cycle time.

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

Torus Beverage Can Gauging

Measurement Features

Axial Load – The maximum force at which the container fails/collapses | Accuracy: +/- 10 N

Technical Specification

Gauge Features

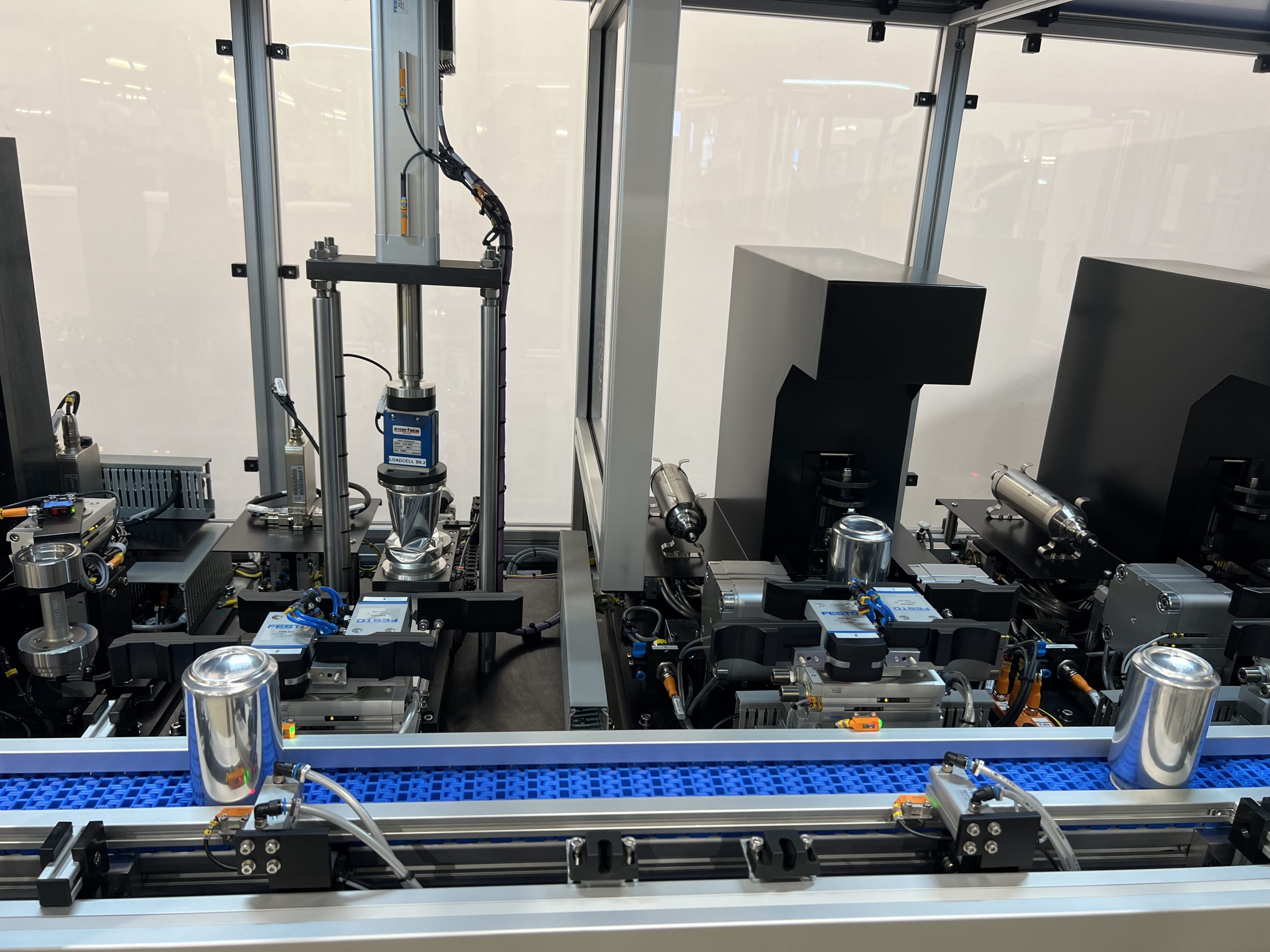

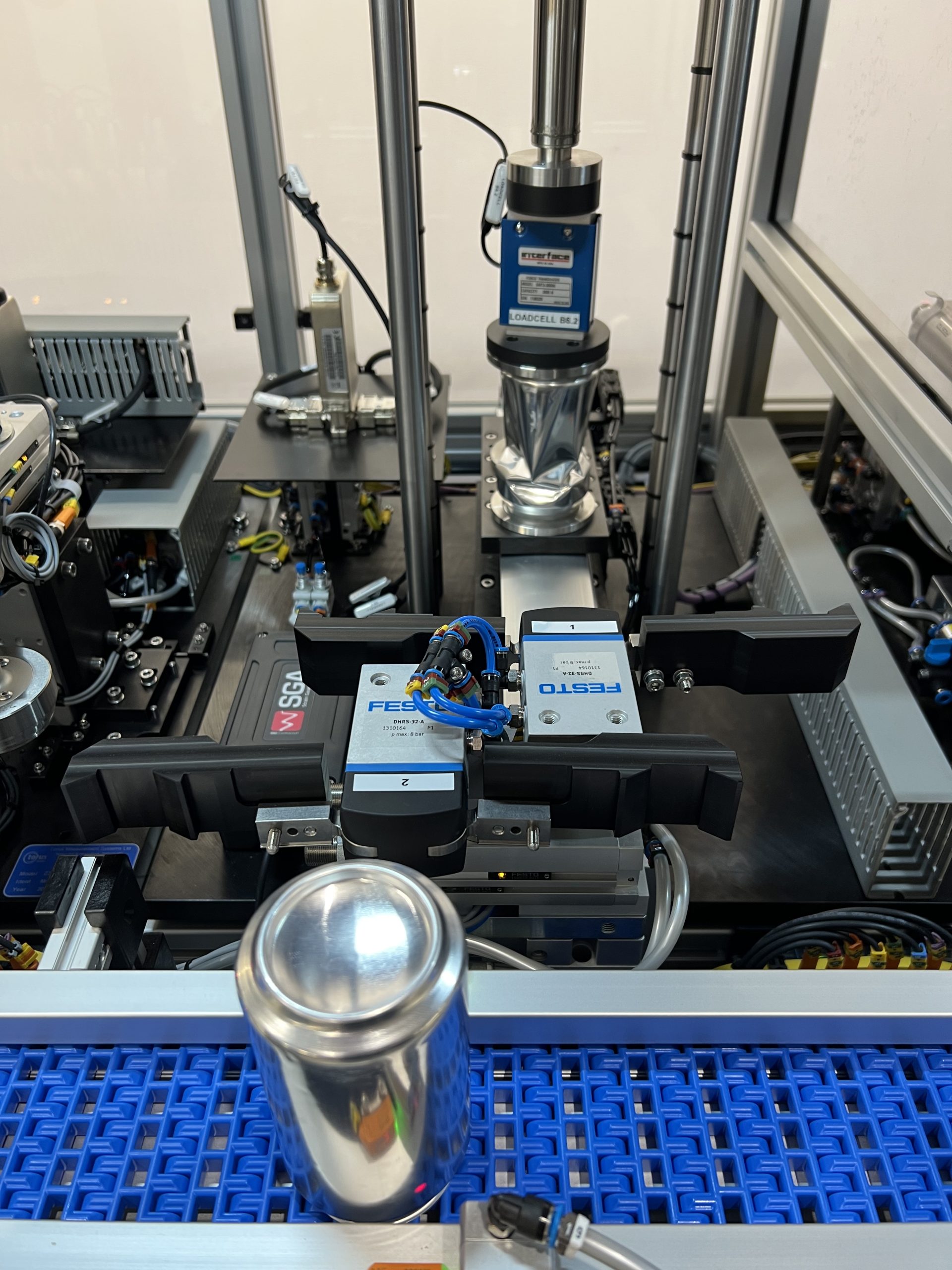

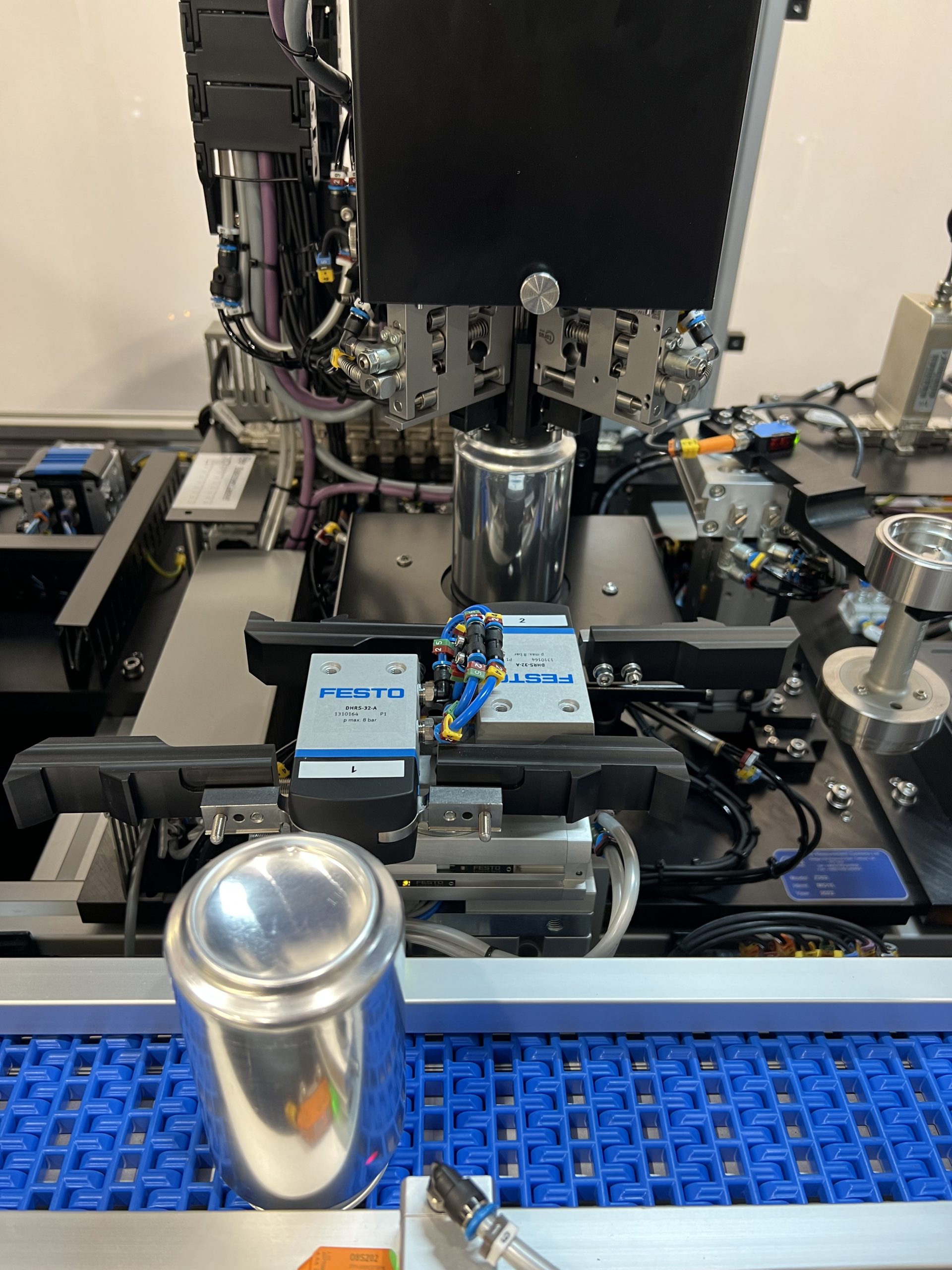

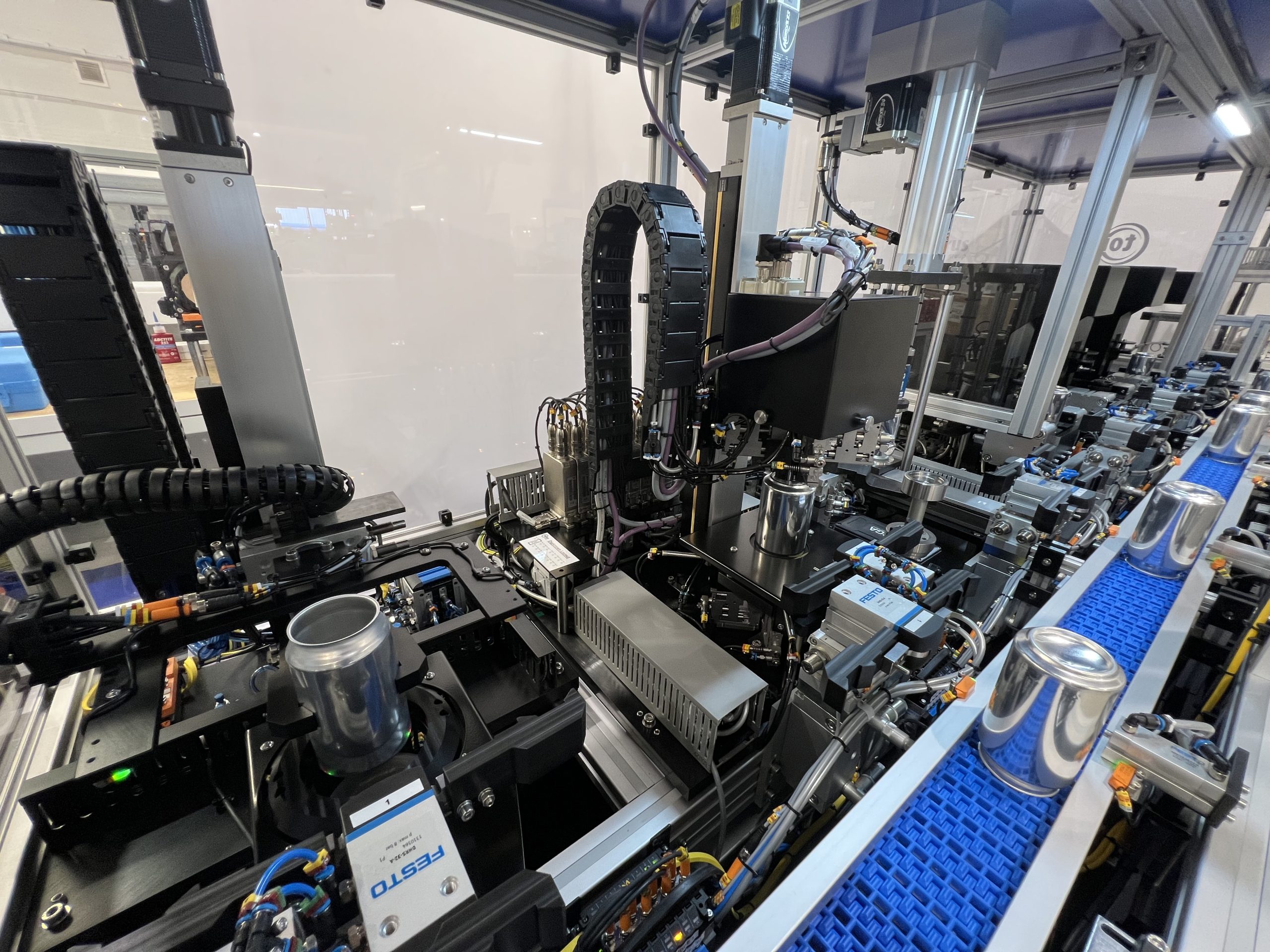

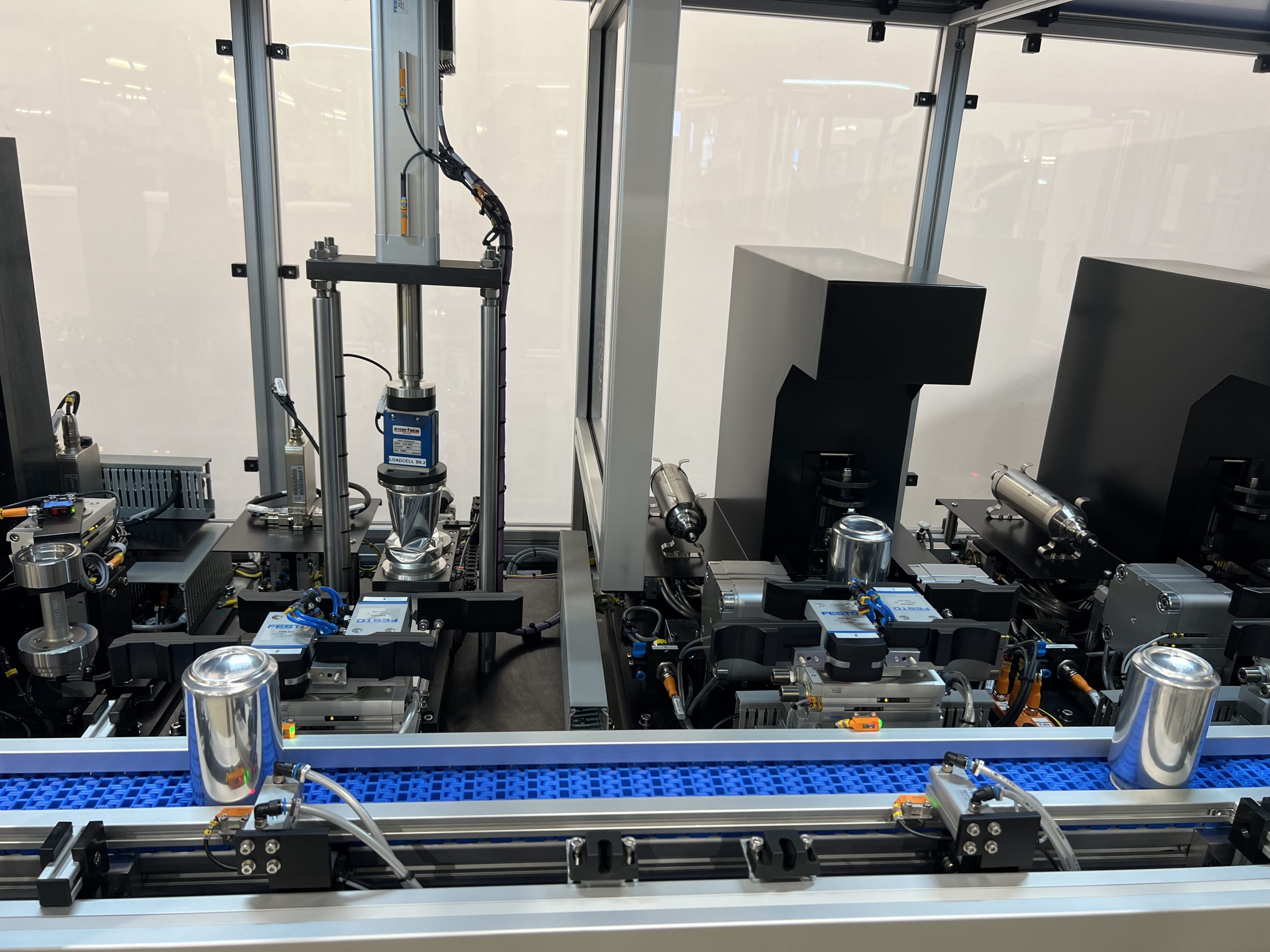

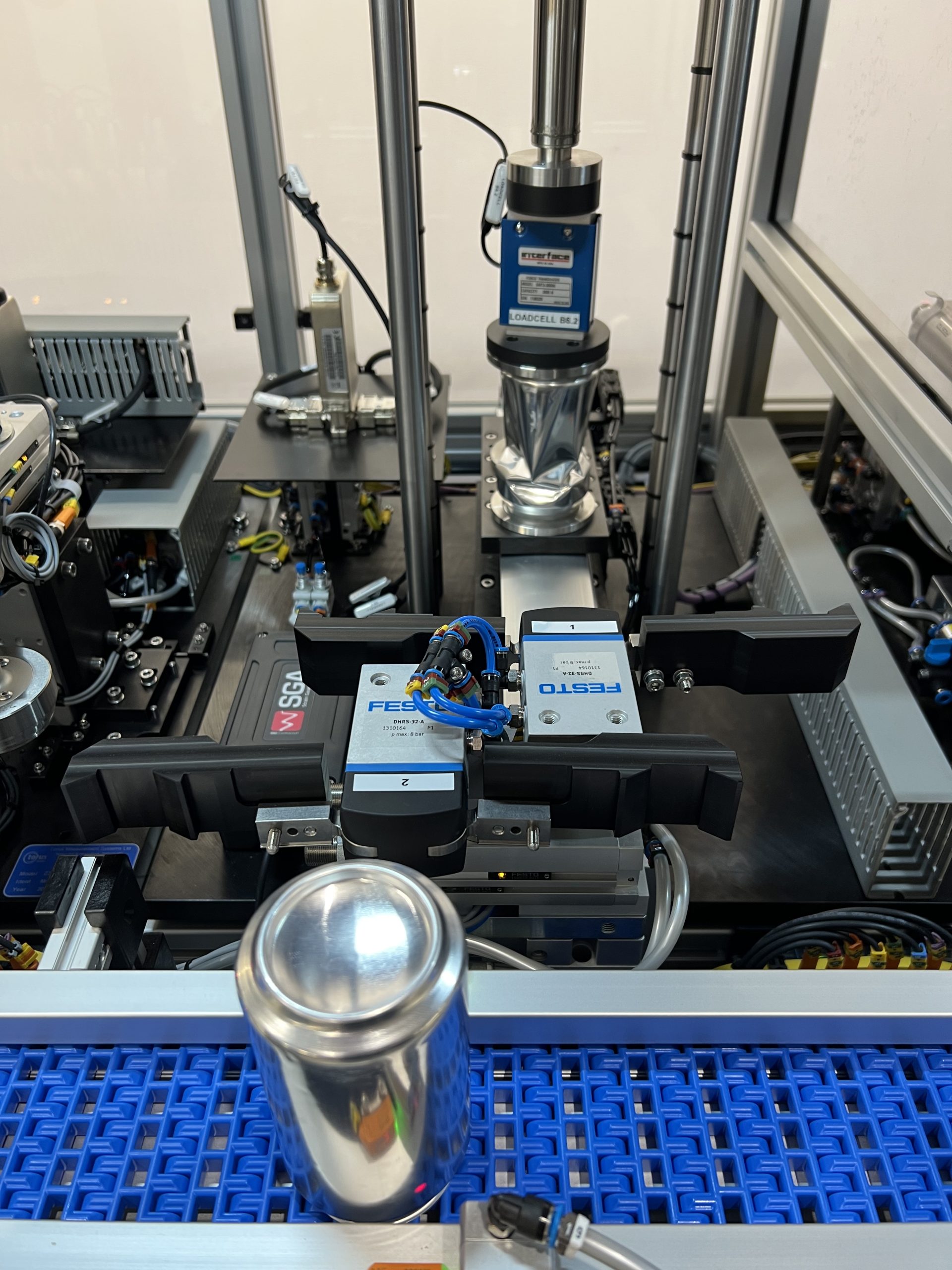

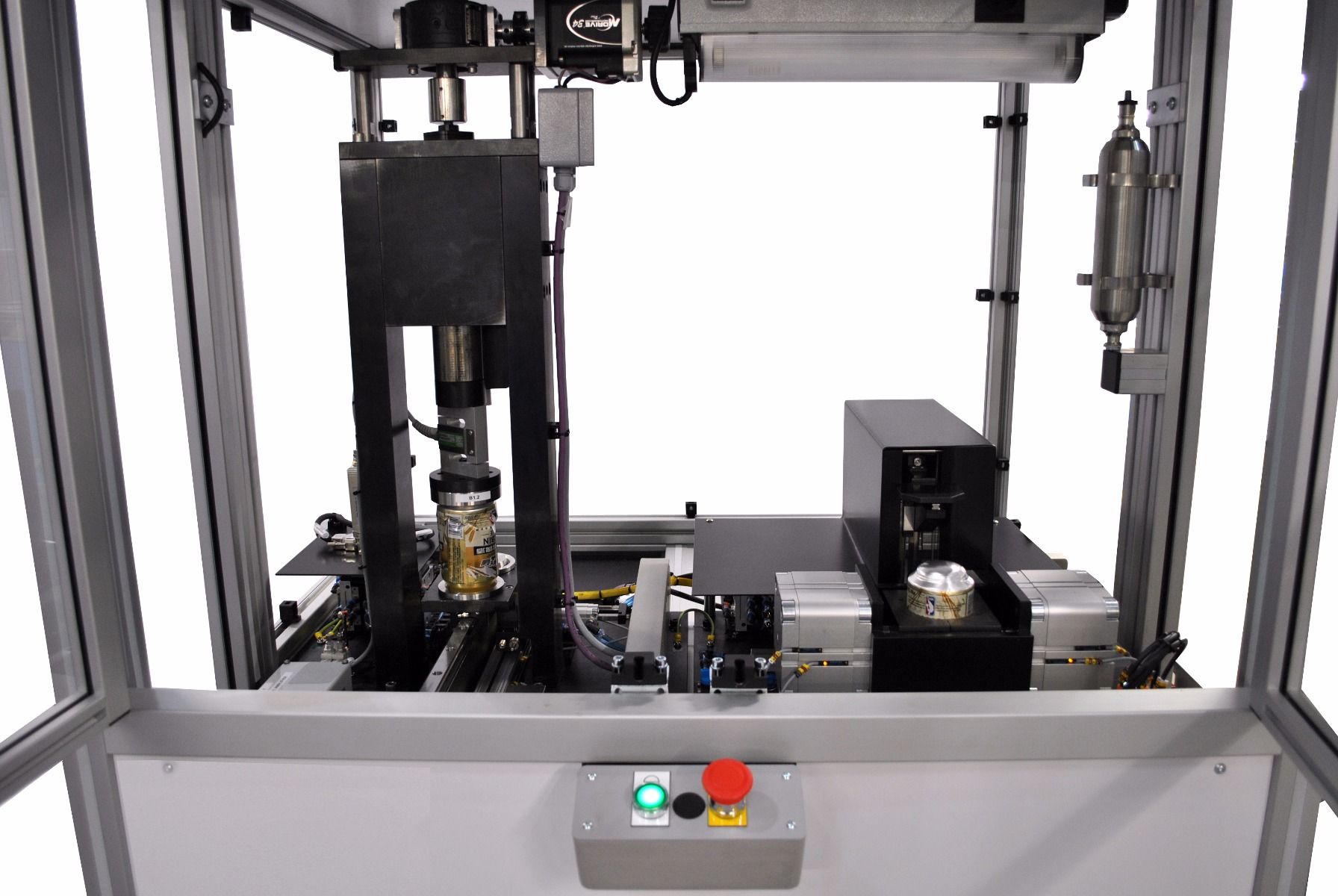

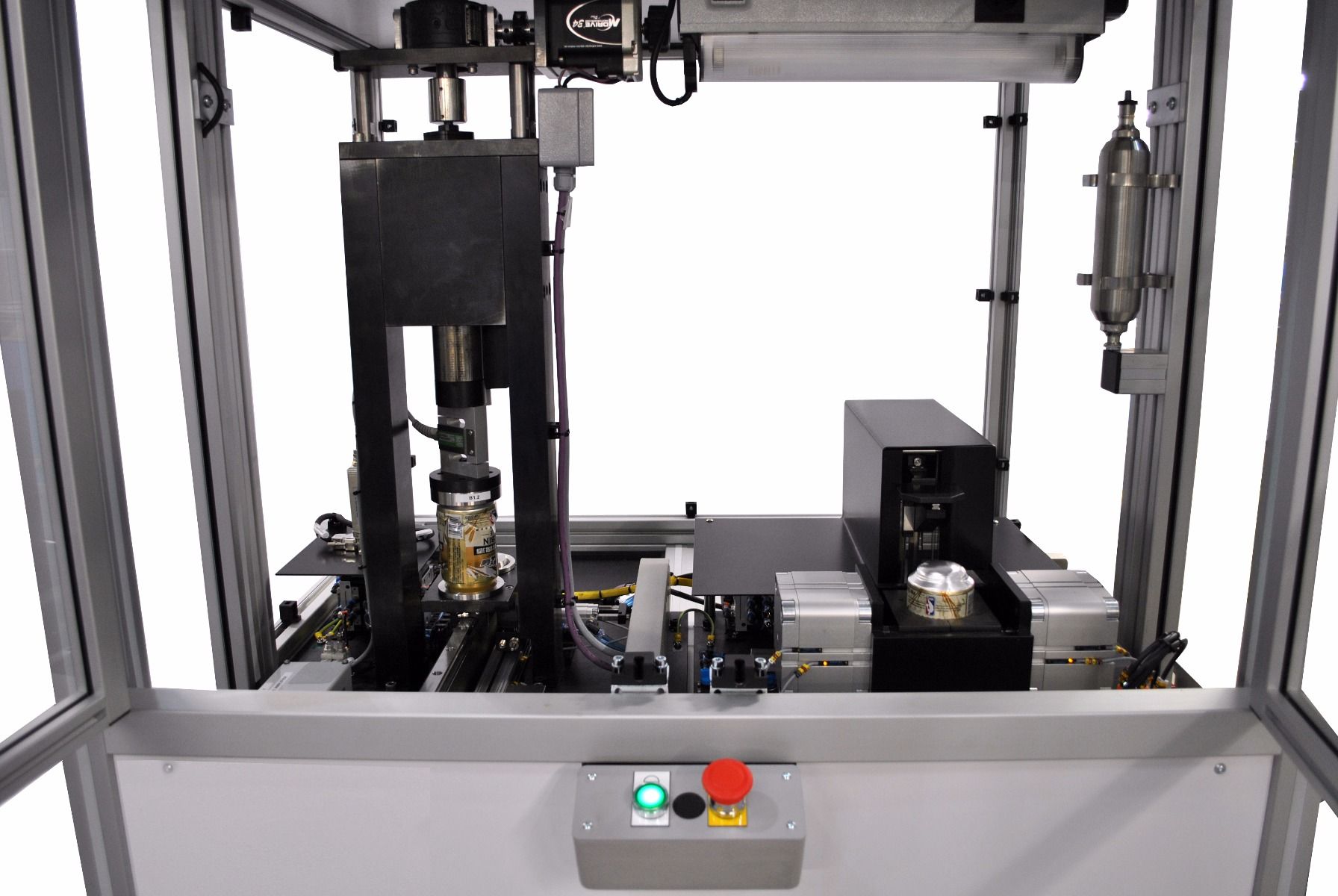

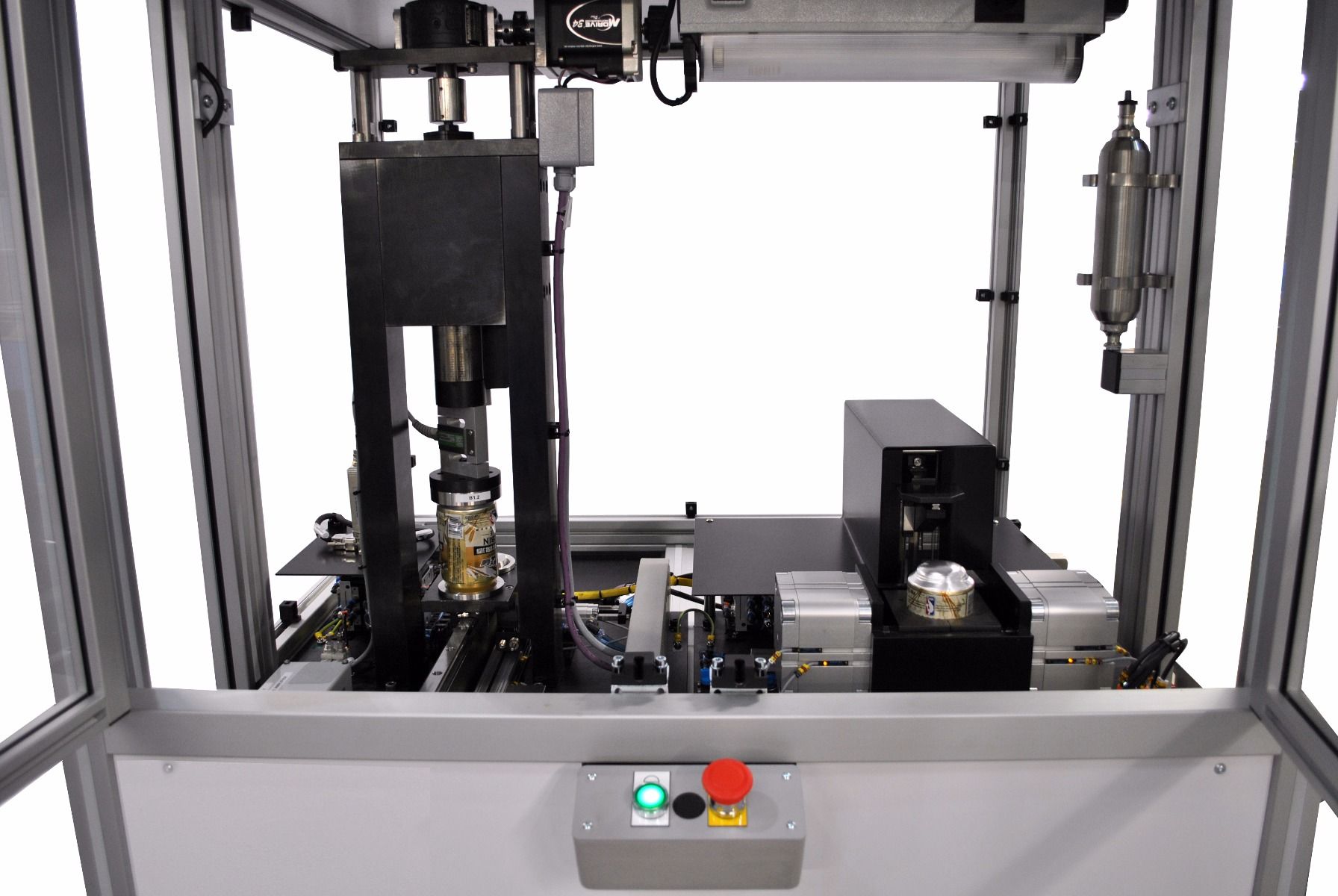

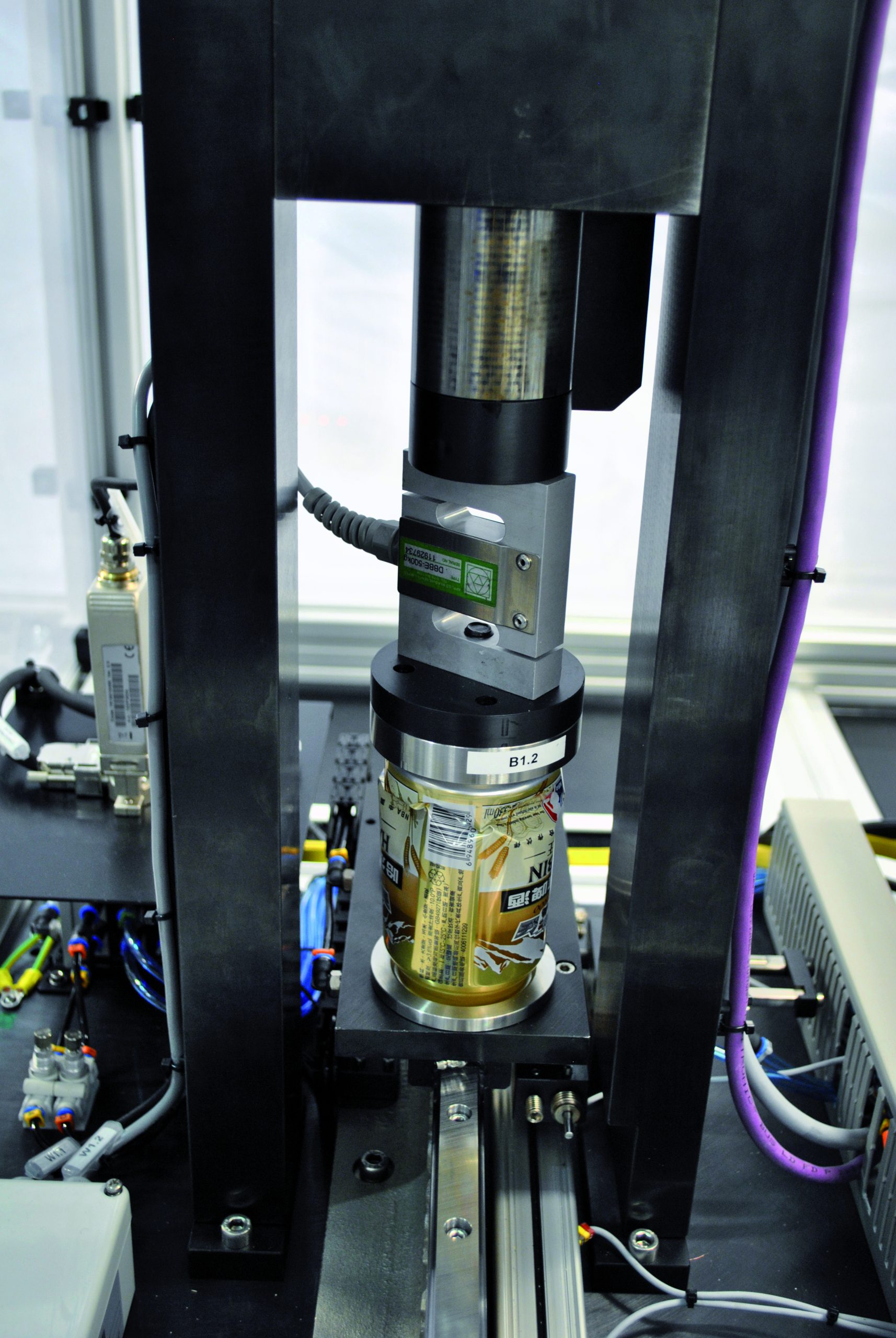

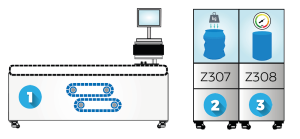

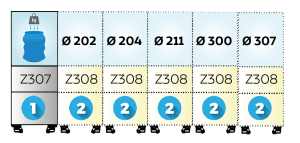

Torus’ Z307 series defines the standard for destructive testing and inspection

The Z307 Automatic Axial Load module determines the maximum axial load force that can be applied prior to container failure, within a short cycle time.

The Z308 Dome Growth/Dome Reversal module provides detailed information about the overall change in length of the can when pressure is applied and subsequently removed. The system has programmable internal pressure capability to meet each customer’s exact needs for dome growth. After dome growth, the can sample can be reversed to find the maximum pressure the sample is able to withstand before failure (dome reversal)

Torus Beverage Can Gauging

Measurement Features

Technical Specification

Gauge Features

Option 1: Standard Setup

Z308 Option:

Interchangeable Jaws

Option 2: Dedicated Body Diameters

For dedicated body diameter product lines, the Torus modular concept is able to cover Ø 202 – Ø 307 body diameters (up to but not limited to) with a dedicated module for each with no change parts.

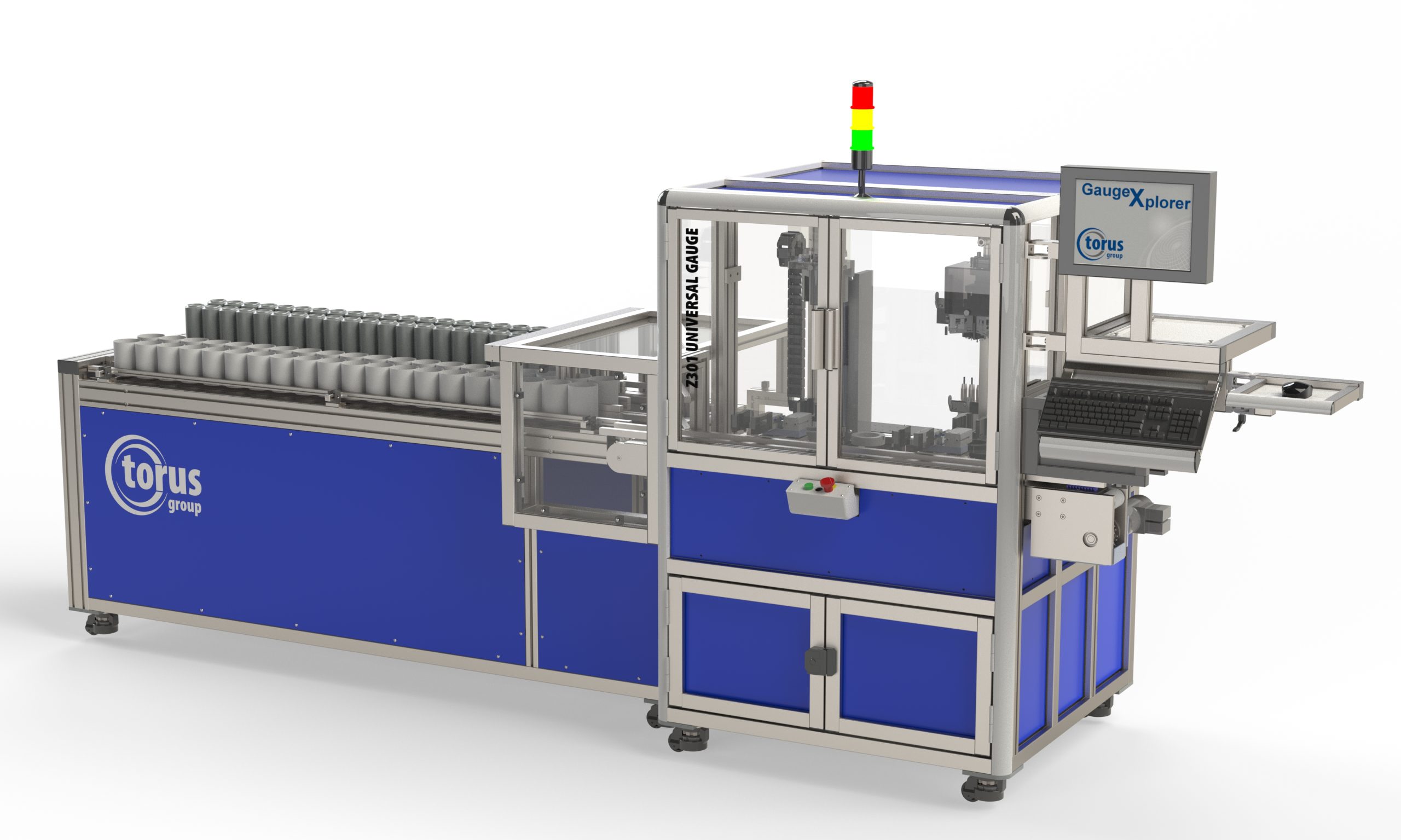

The Z301 Universal Gauge incorporates trimmed and finished can measurement into the same system, for full component measurement.

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

Torus Beverage Can Gauging

Measurement Features

Trimmed Can Features

Finished Can Features

Technical Specification

Trimmed Can Capabilities

Finished Can Capabilities

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999