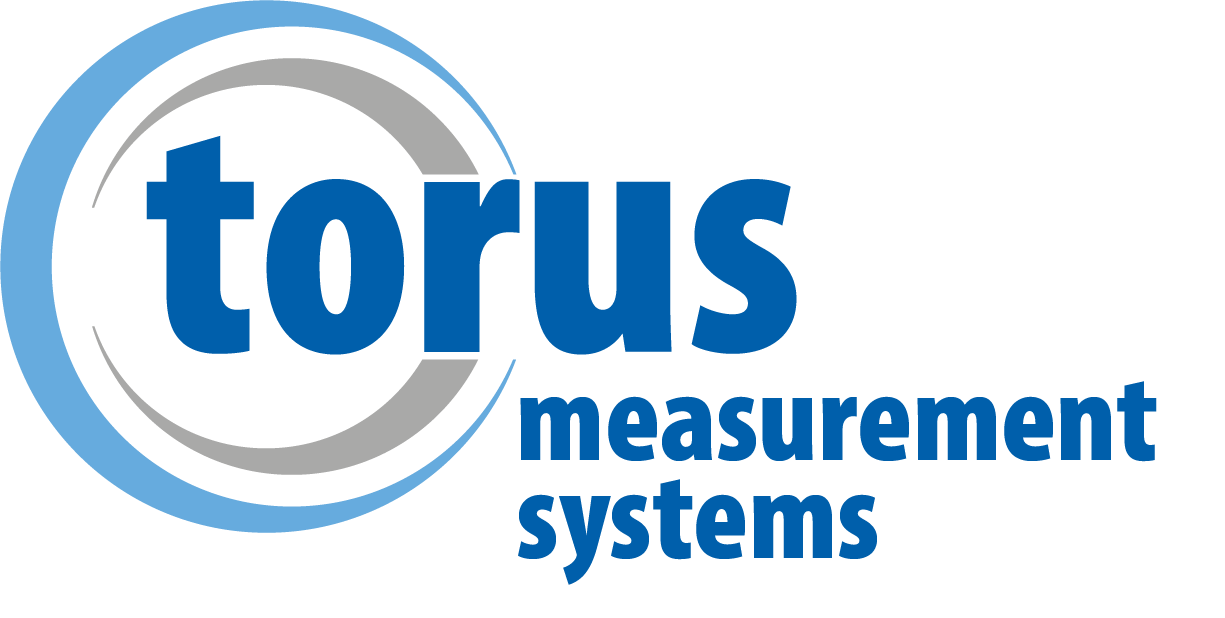

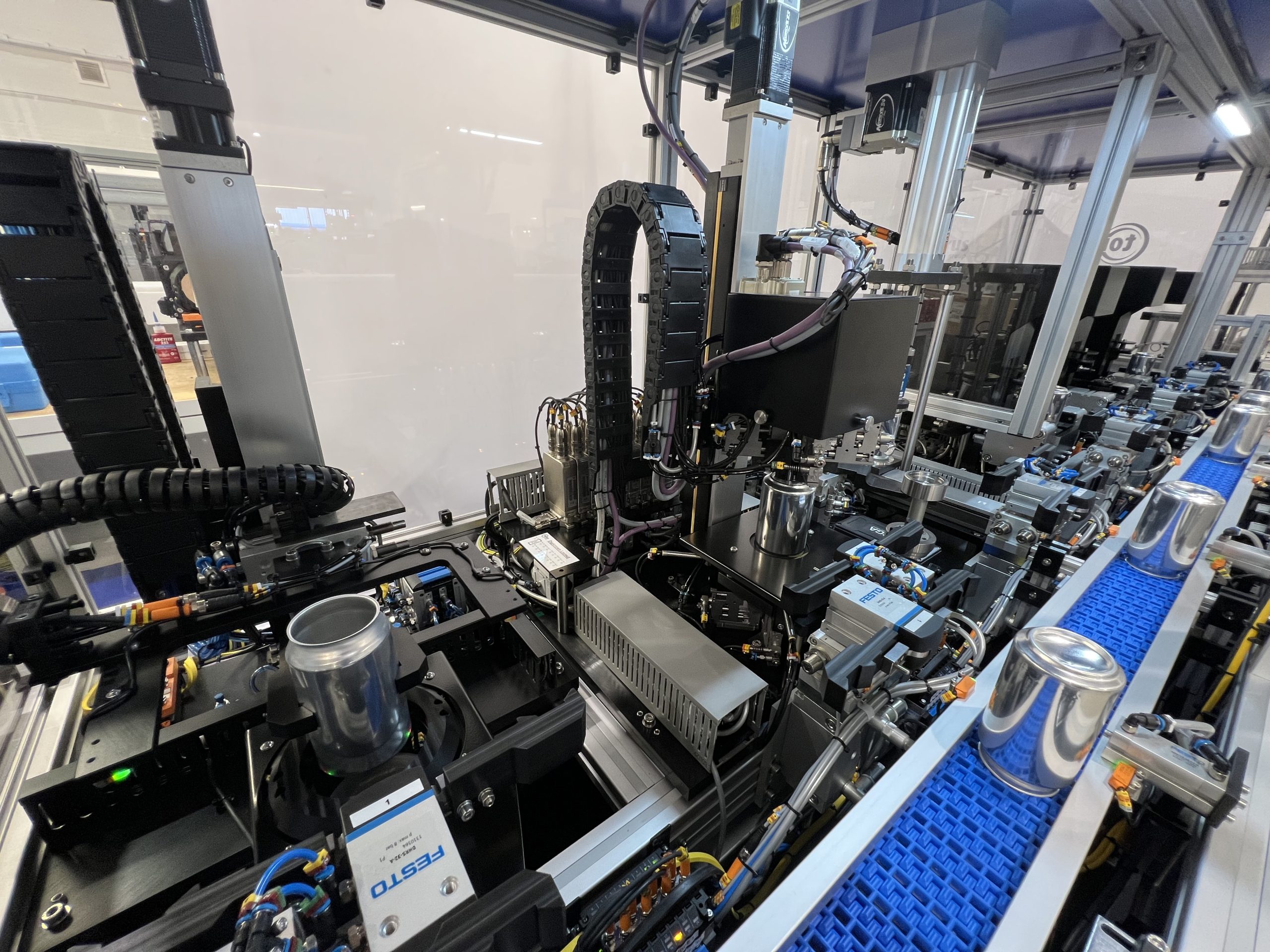

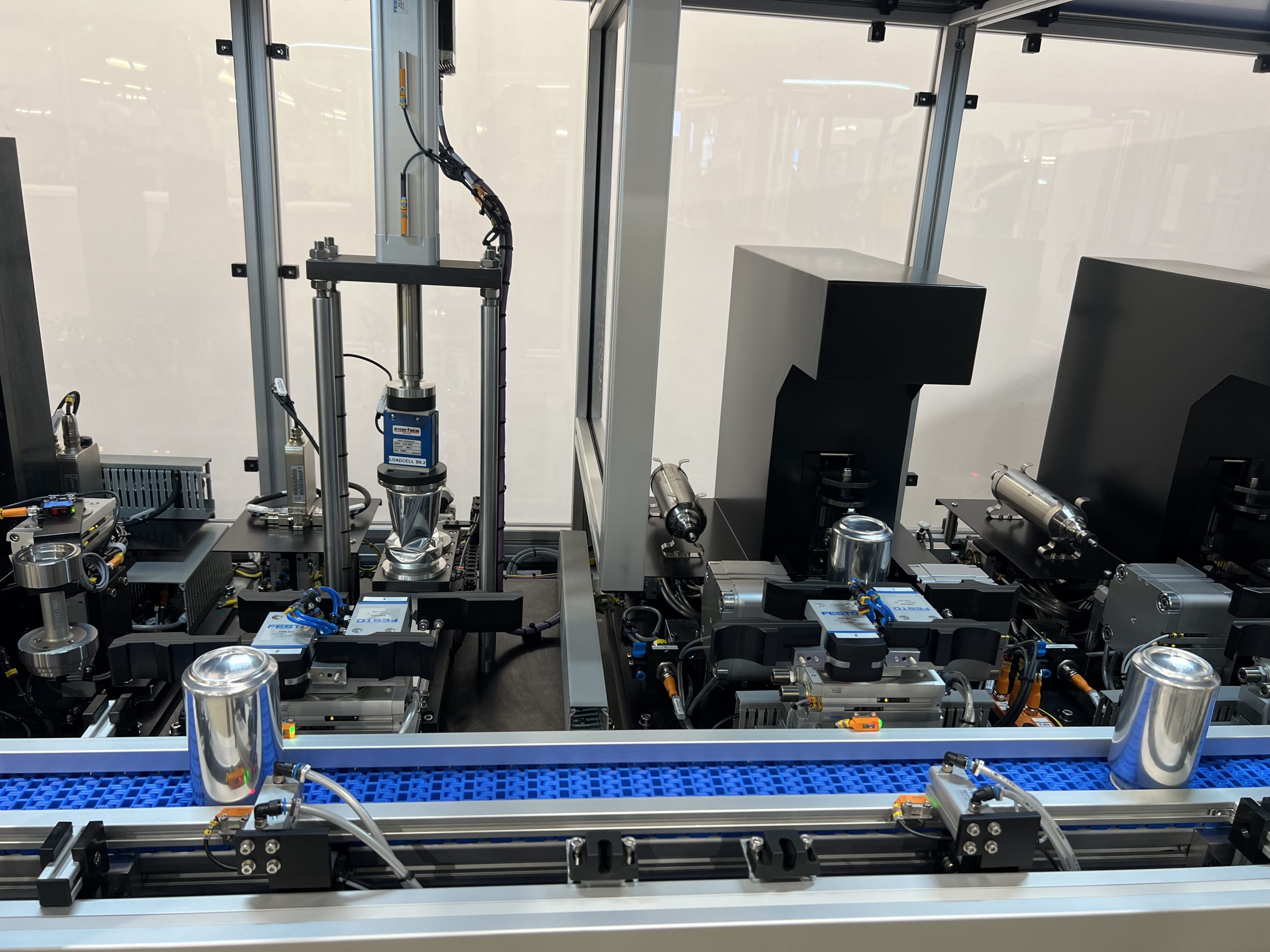

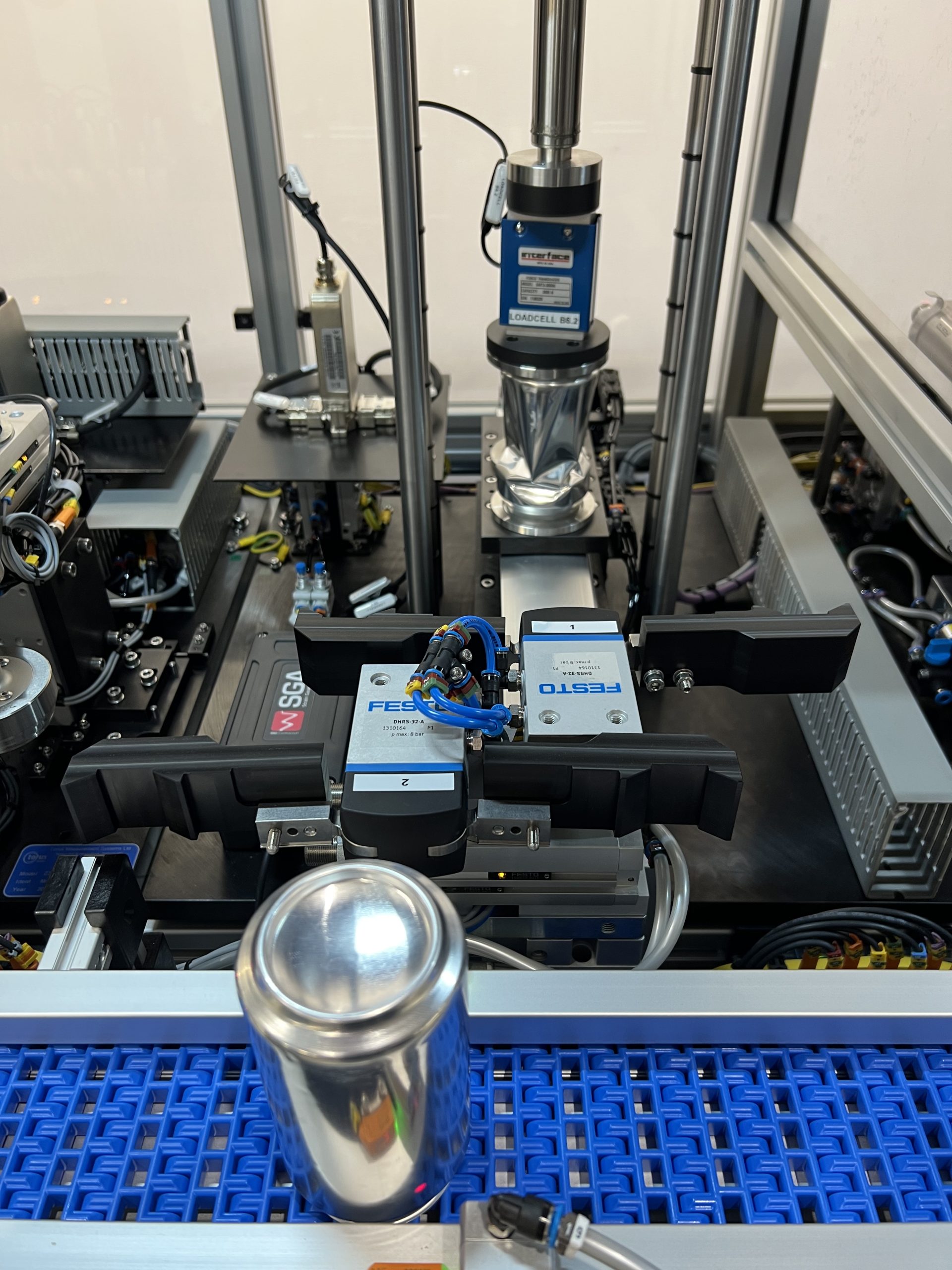

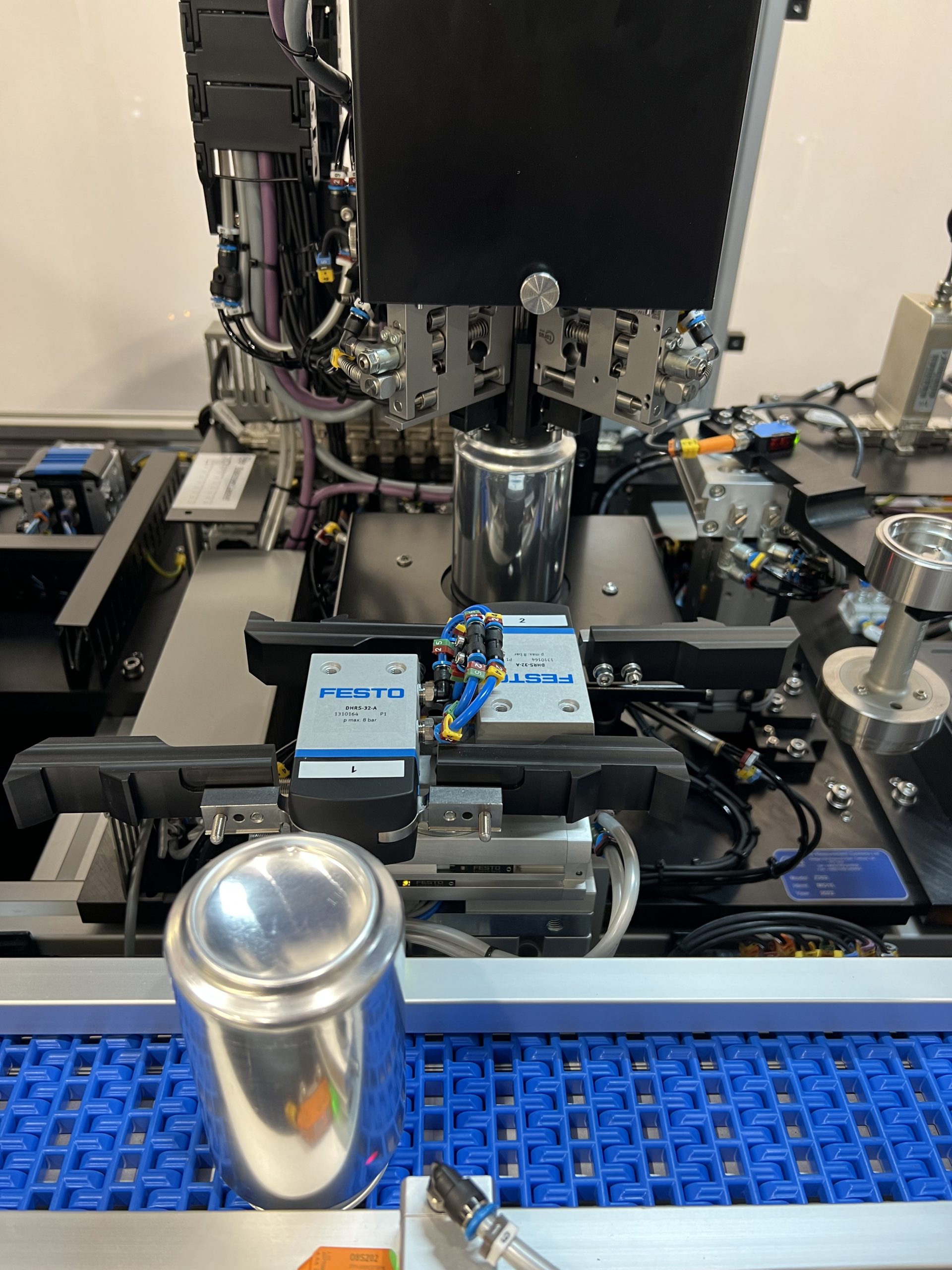

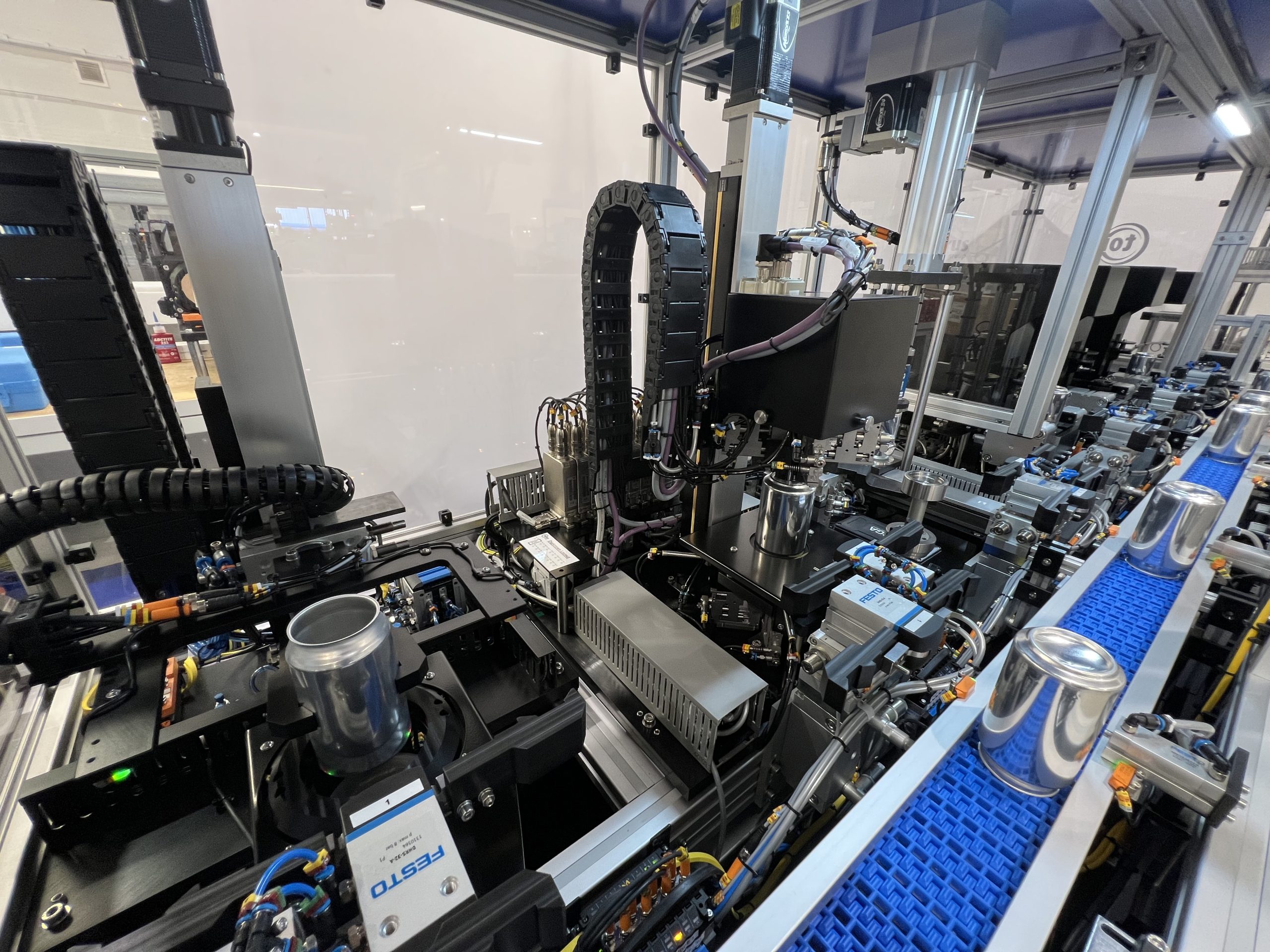

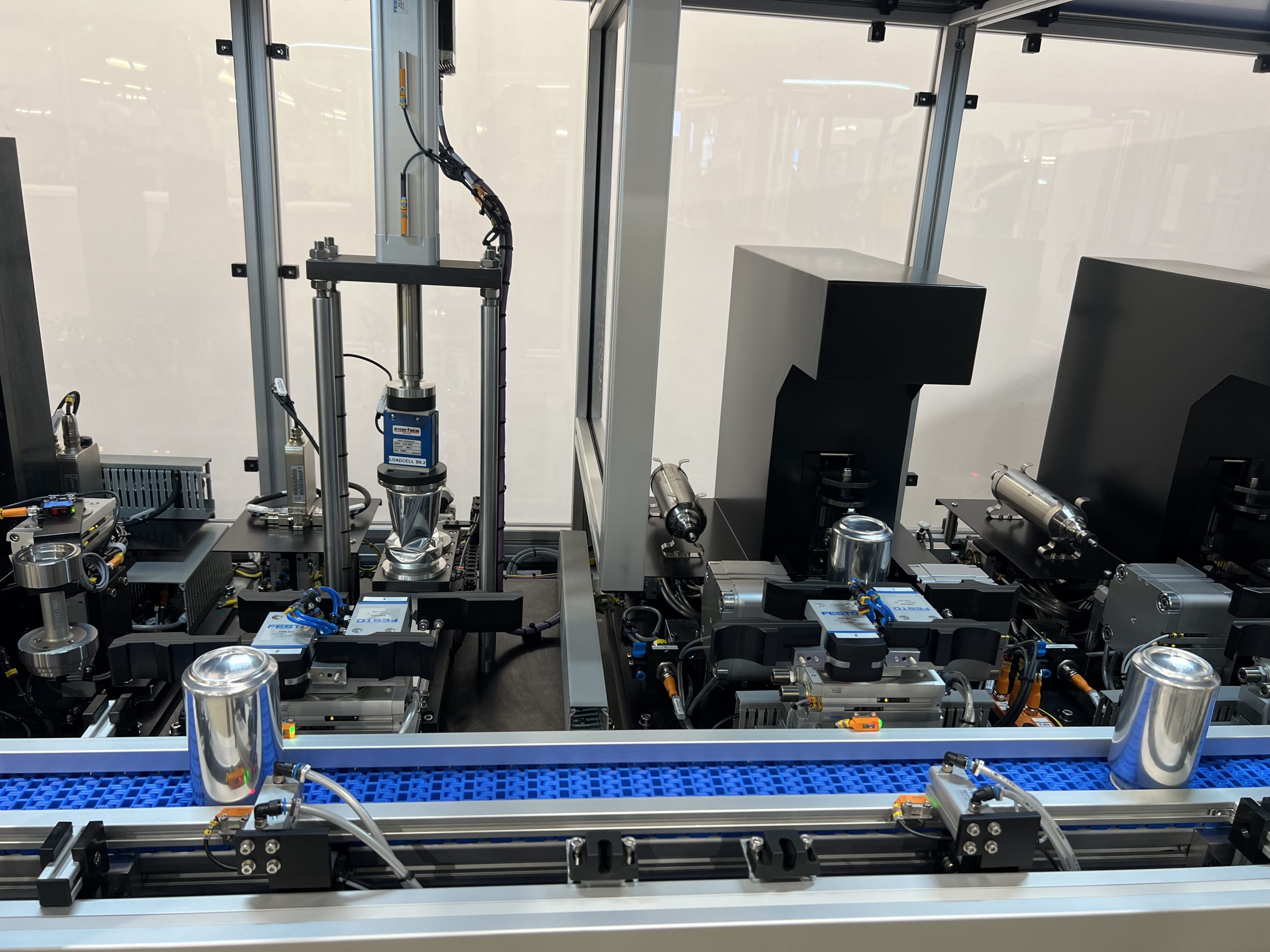

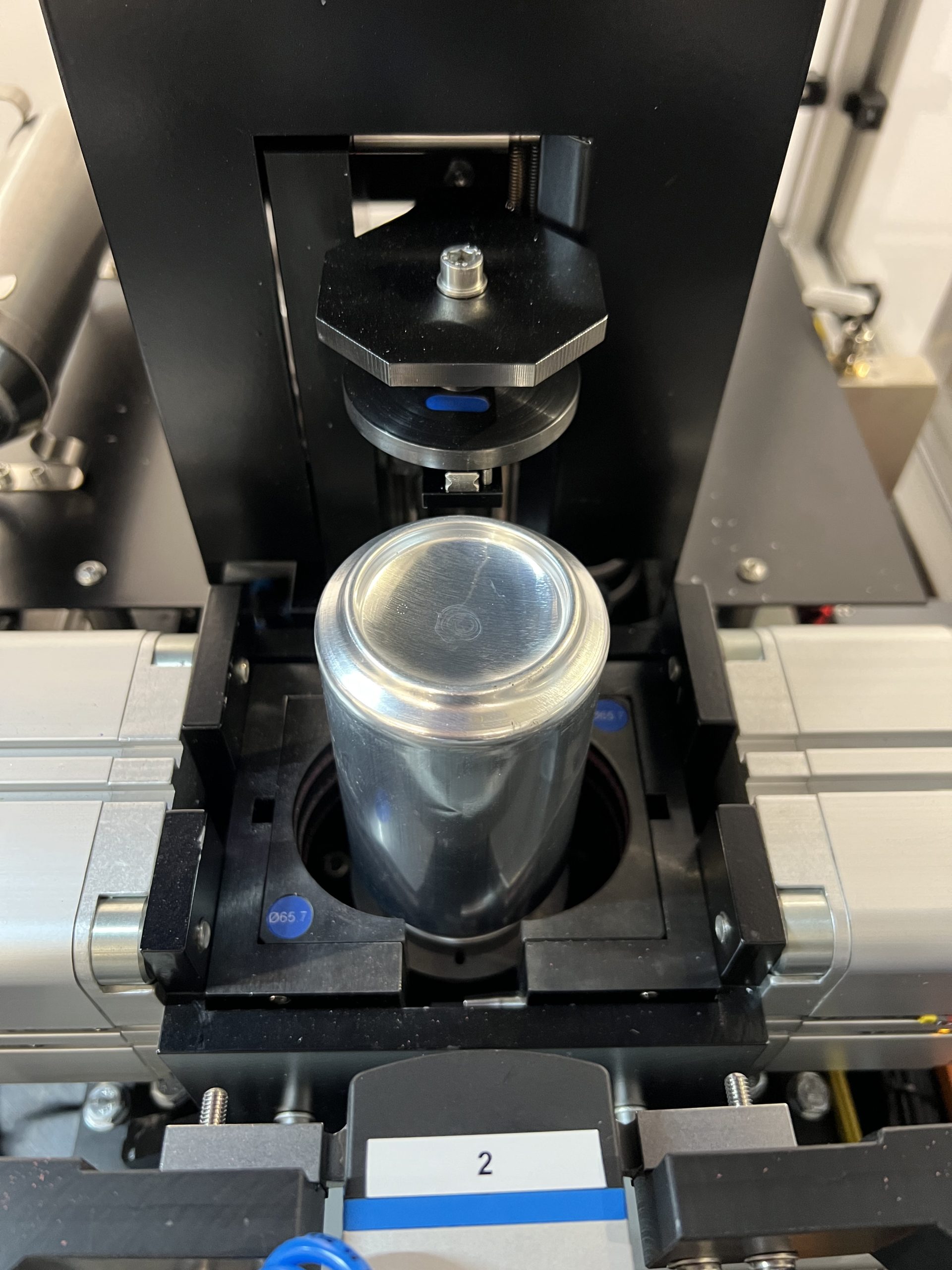

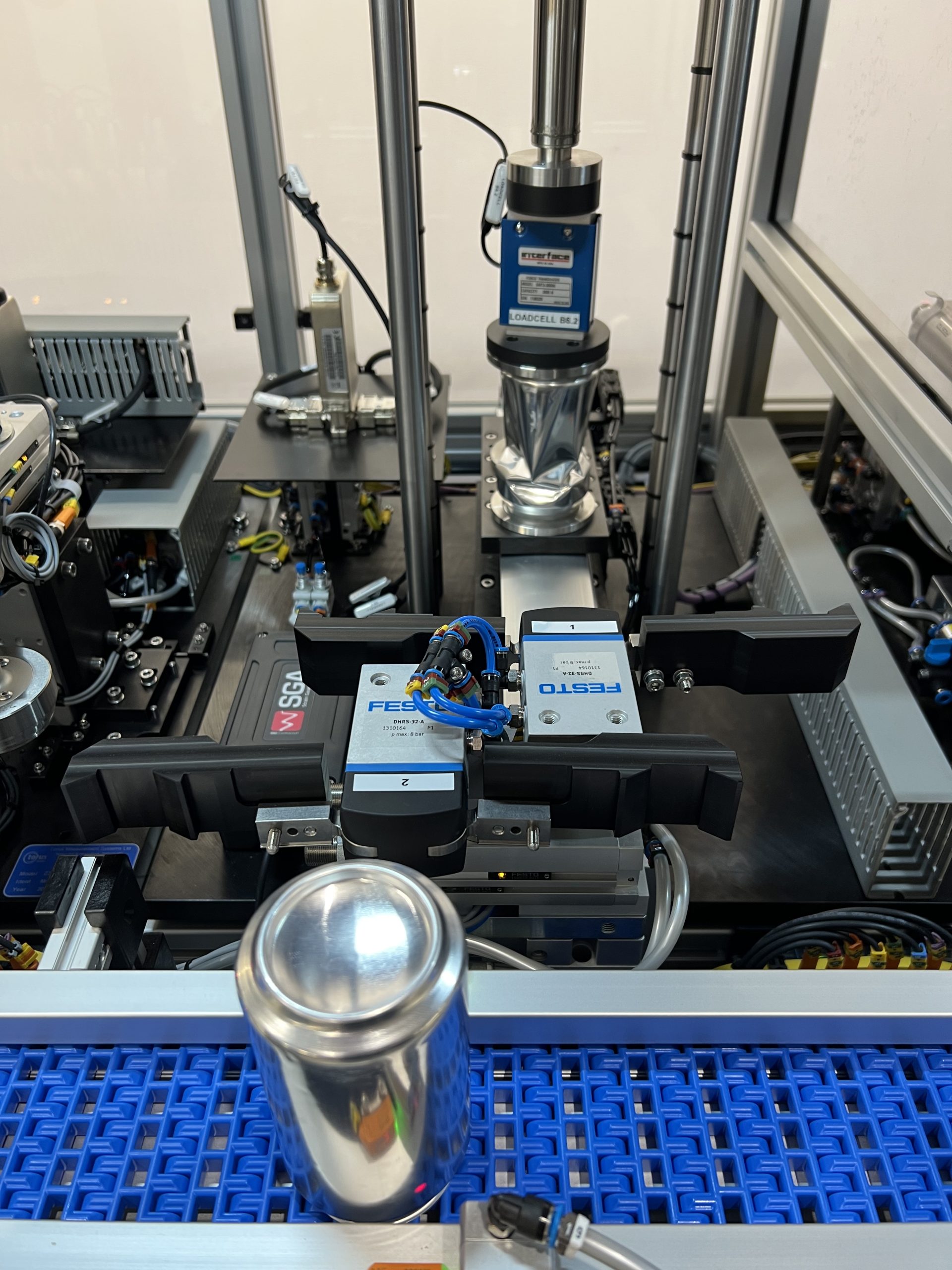

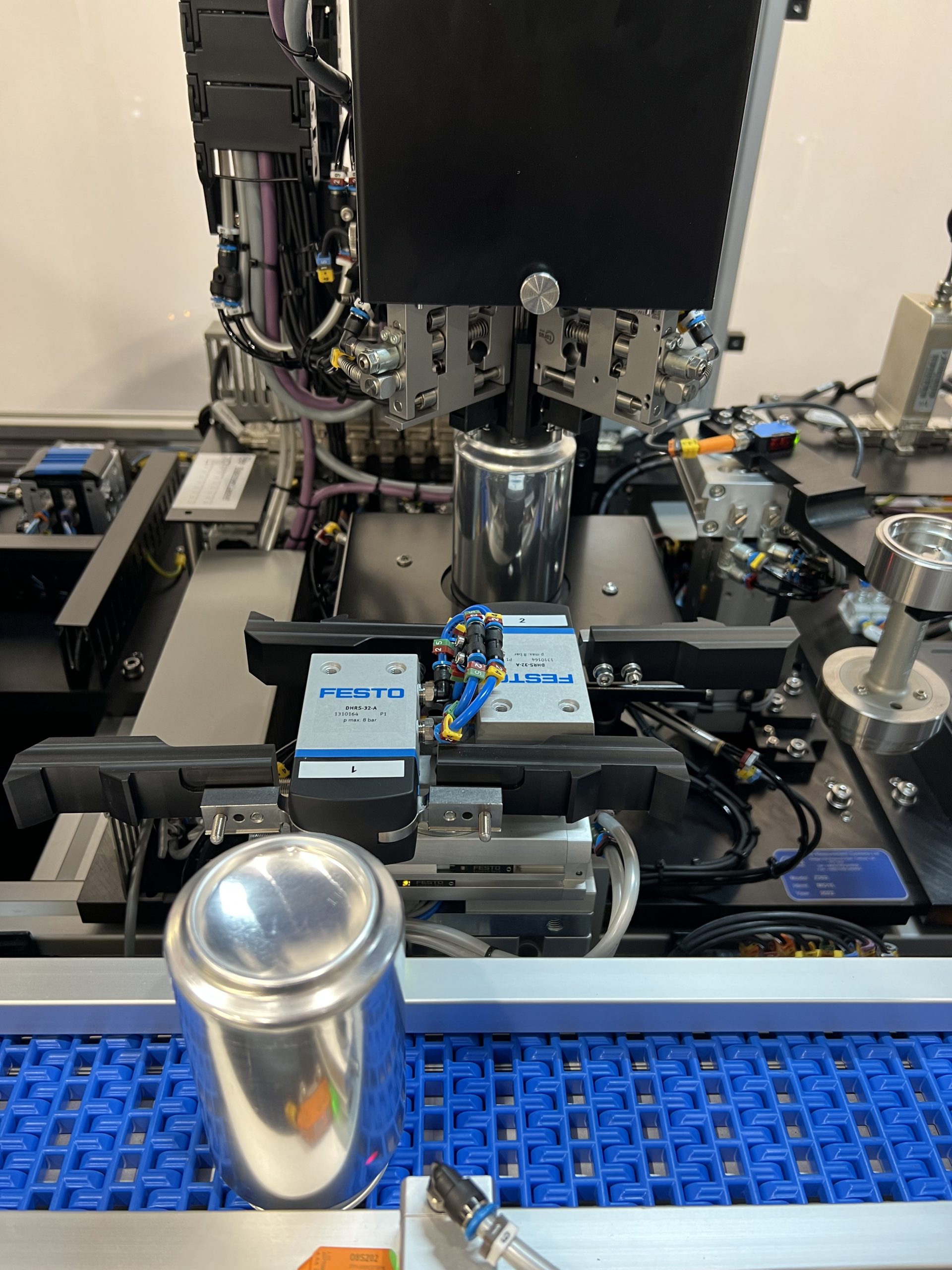

The Z302 Finished Can Back End Inspection Gauge features high-precision transducer technology, using dedicated probe contact for accurate, reliable and traceable measurement of your finished cans 24/7.

An additional option is available for component rotation to enable additional radial measurement positions, giving you significantly increased measurement data allowing increased data analysis for instant process control.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999