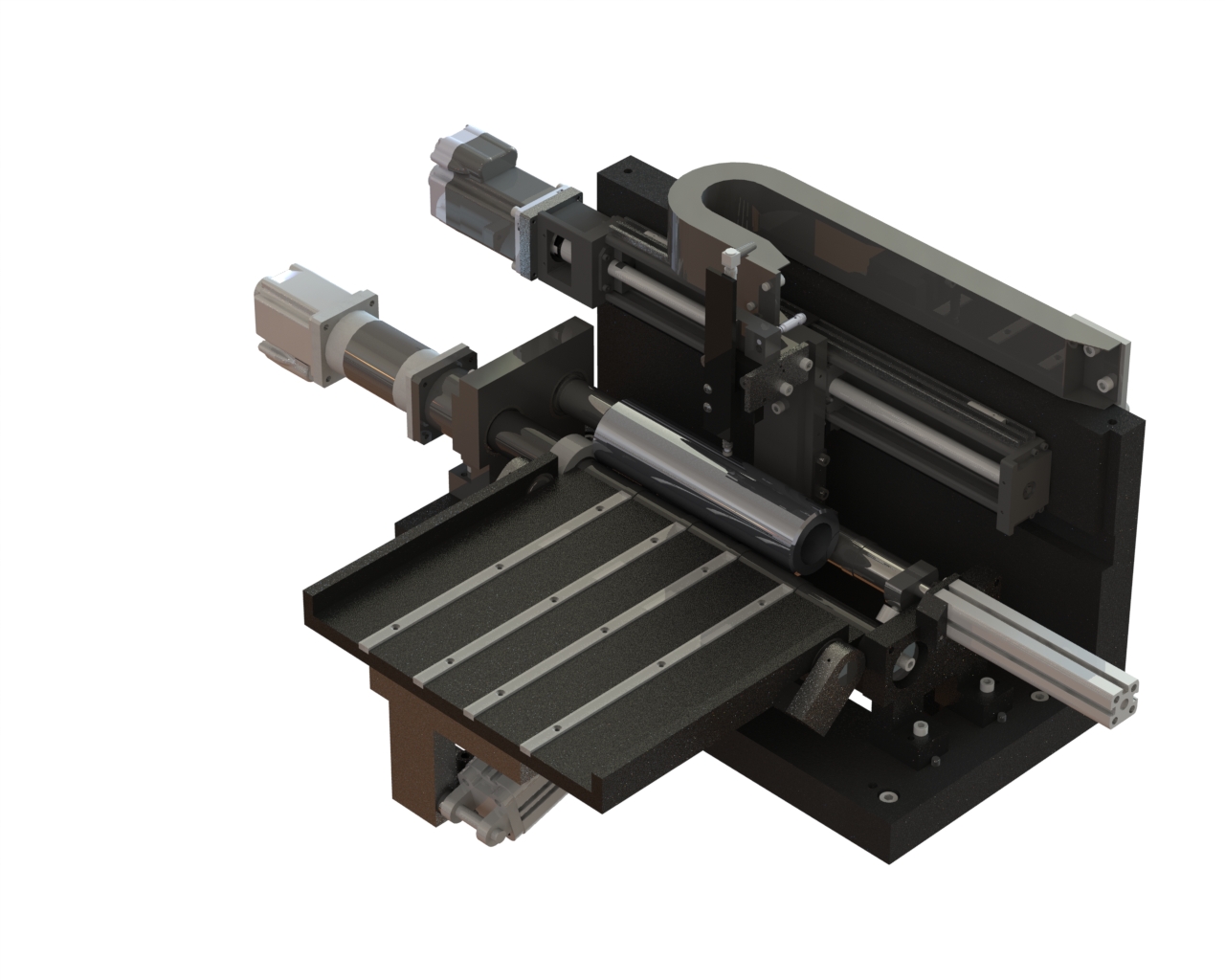

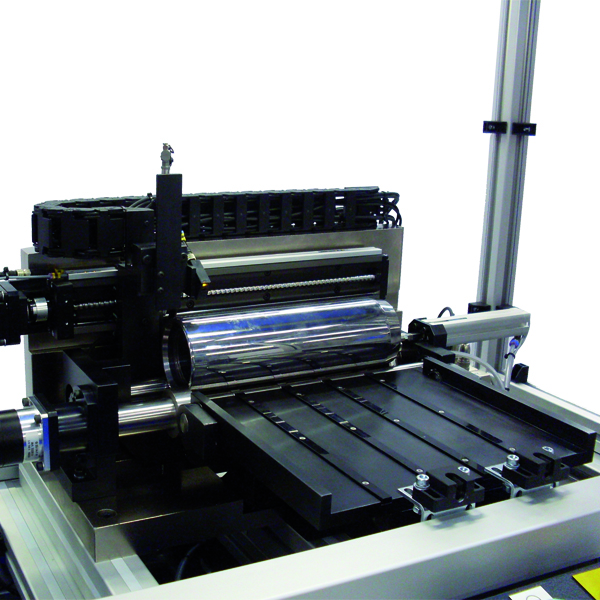

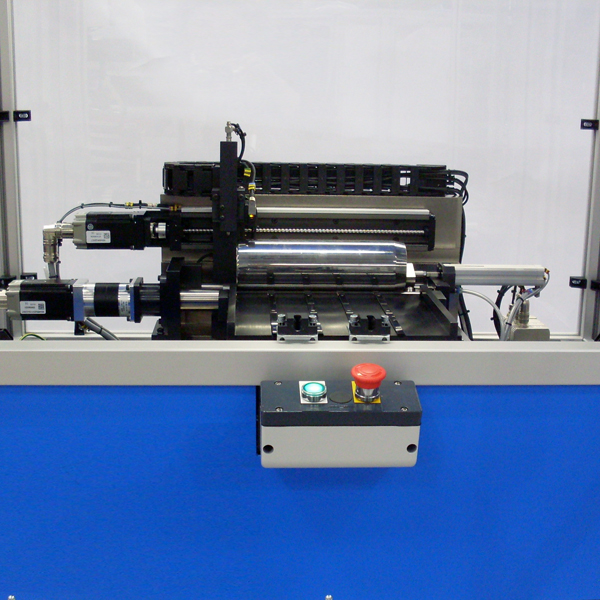

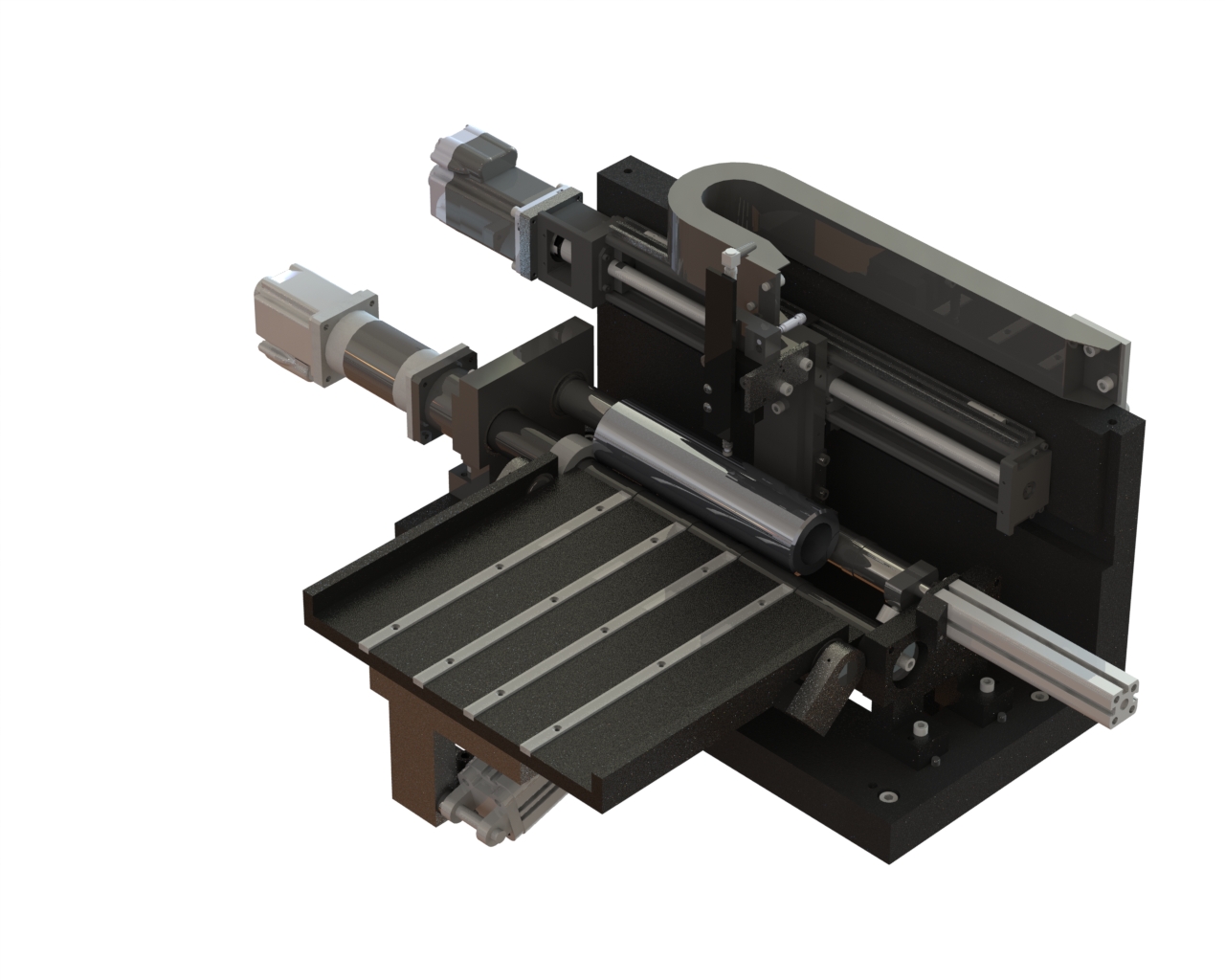

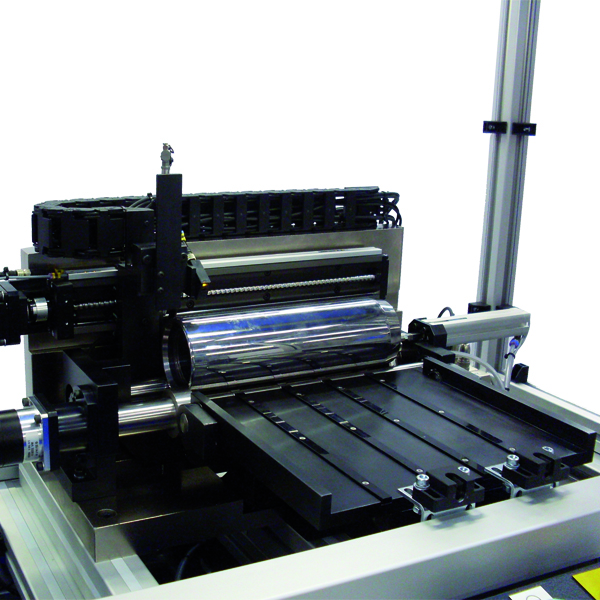

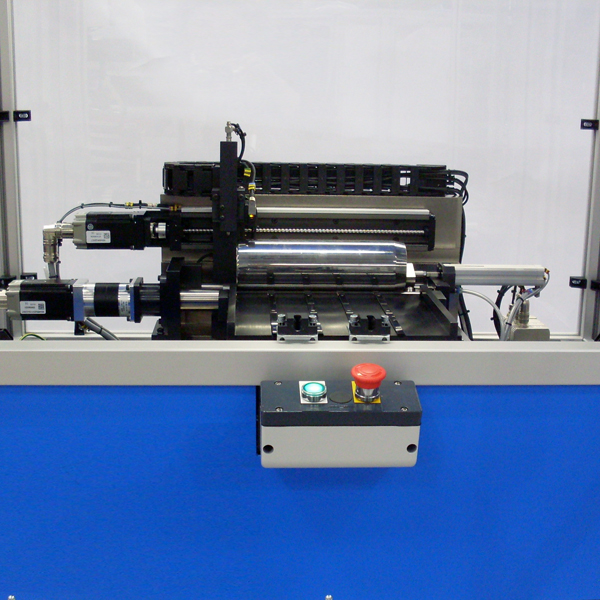

The Z311 Punch Gauge has been designed to measure a wide range of Punch sizes typically found in the metal container industry. Available as a semi-automatic (manually loaded) system, designed to measure a wide range of punch sizes typically found in the metal container industry.

Torus Beverage Can Gauging

Measurement Features

- Ovality

- Major Diameter(s): Max/Min/Average/Range

- Major Diameter Ovality: Max/Min/Average/Range

- Minor Diameter(s): Max/Min/Average/Range

- Minor Diameter Ovality: Max/Min/Average/Range

- Upper Transition

- Step ‘T’

- Verification Diameters

- Verification Taper

- Verification Dimension for Max Design

- Lower Transition Angle

- Step Intersection(s)

Technical Specification

- Punch Diameters | Typical Range: Ø 202 – Ø 307 (52 – 94 mm)

- Maximum Scanning Length | Typical Range: 235 mm (Maximum Loading Length: 260 mm)

- Flexible part programs allow the operator to define specific measurement positions on the punch and store them for future use

- Accurate, repeatable and traceable measurement of your punch tooling

- The ability to match punches to ironing dies to maintain can wall thickness

- Allows punch wear to be monitored in order to perform preventive maintenance

- Improves process control