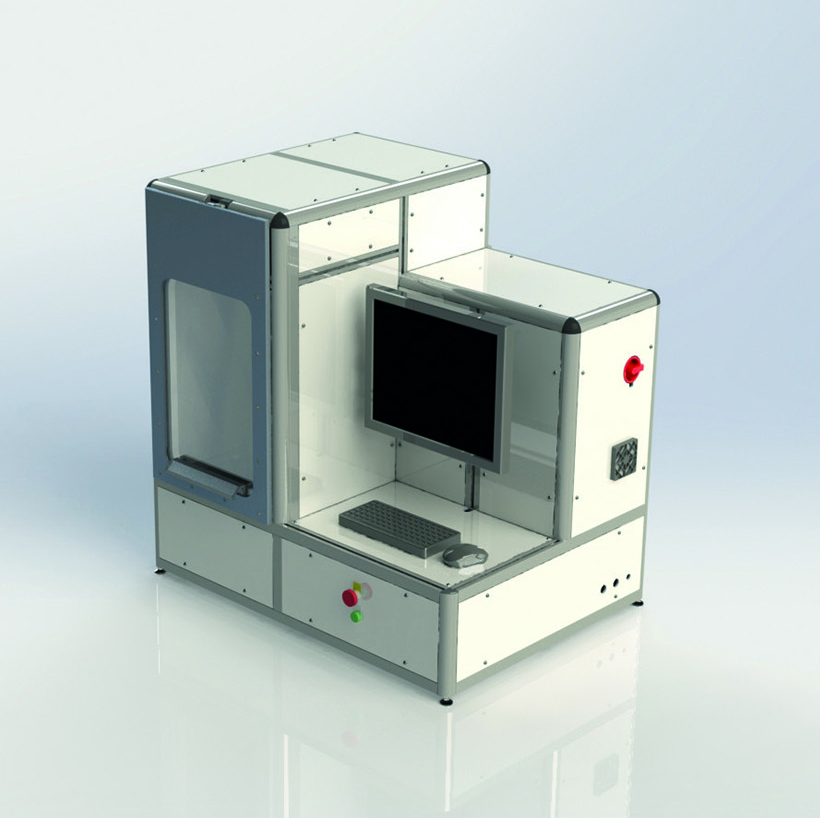

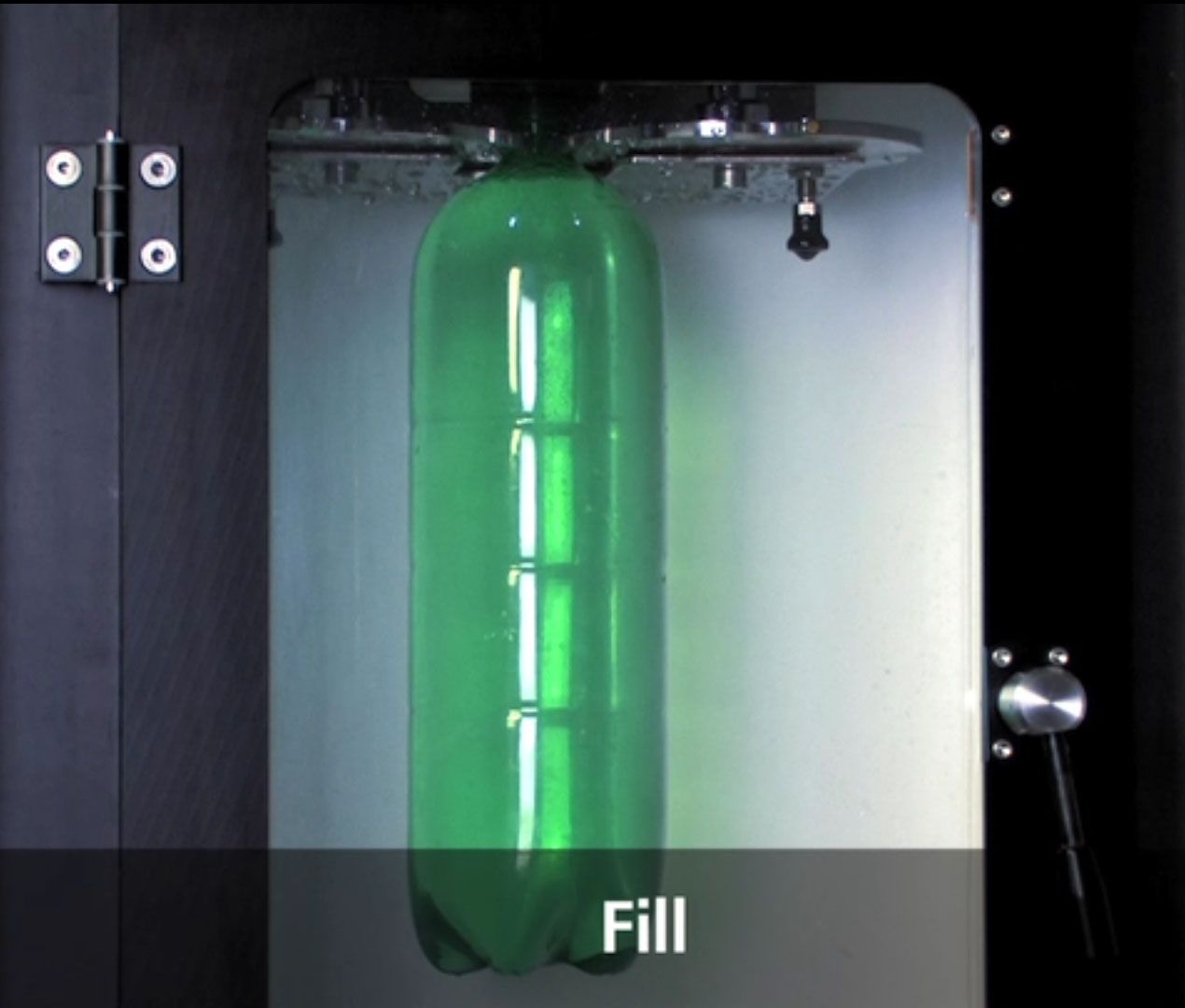

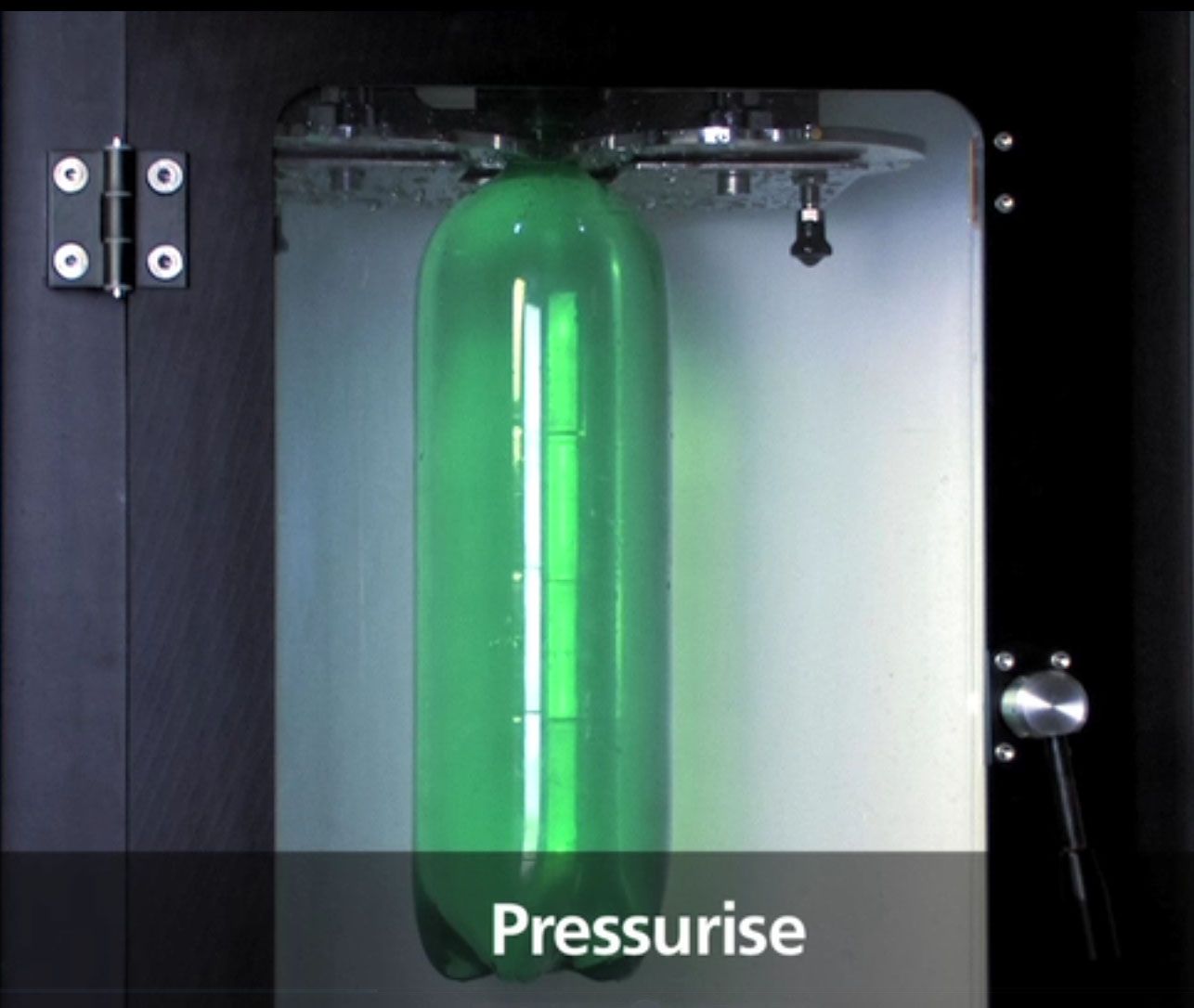

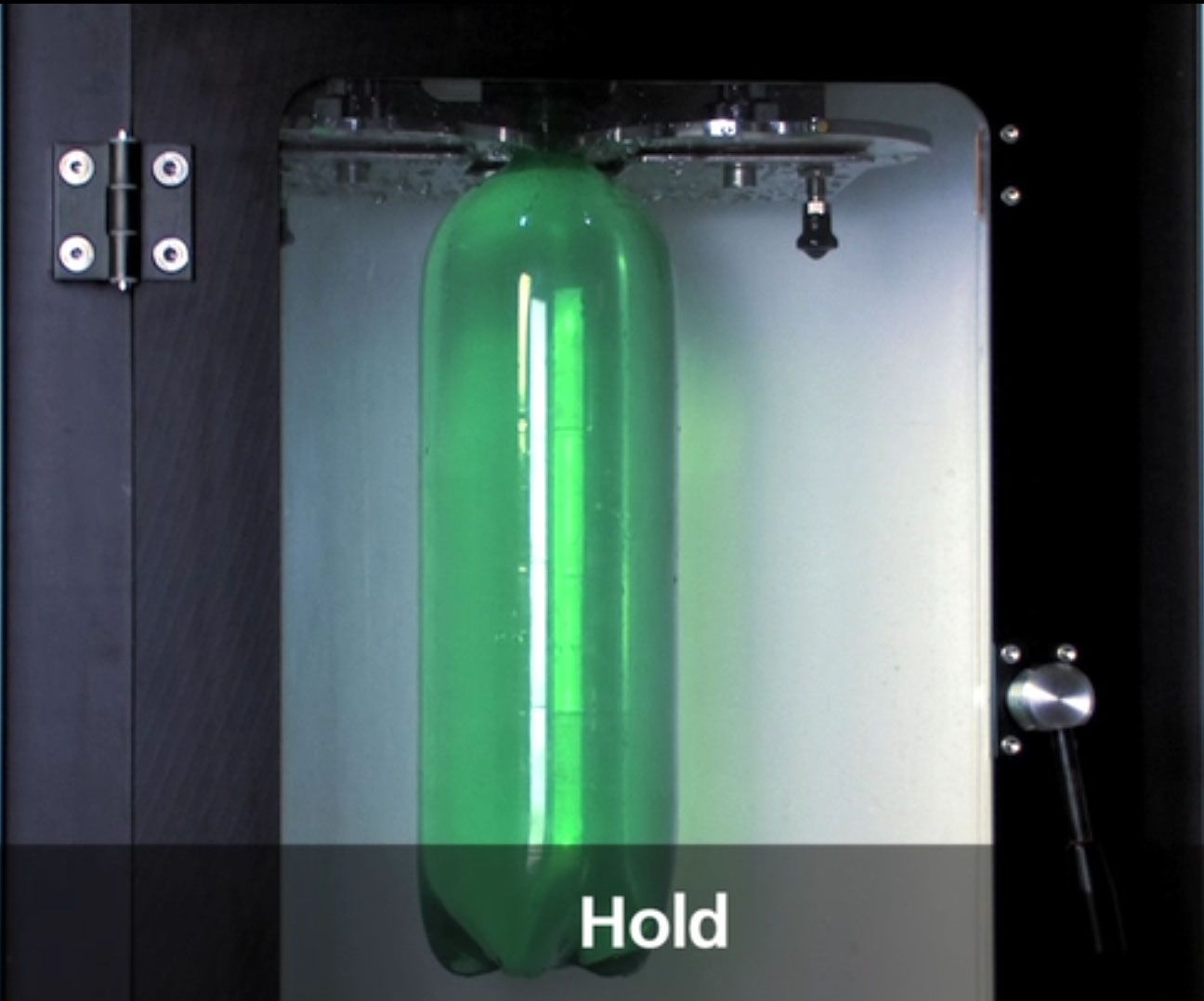

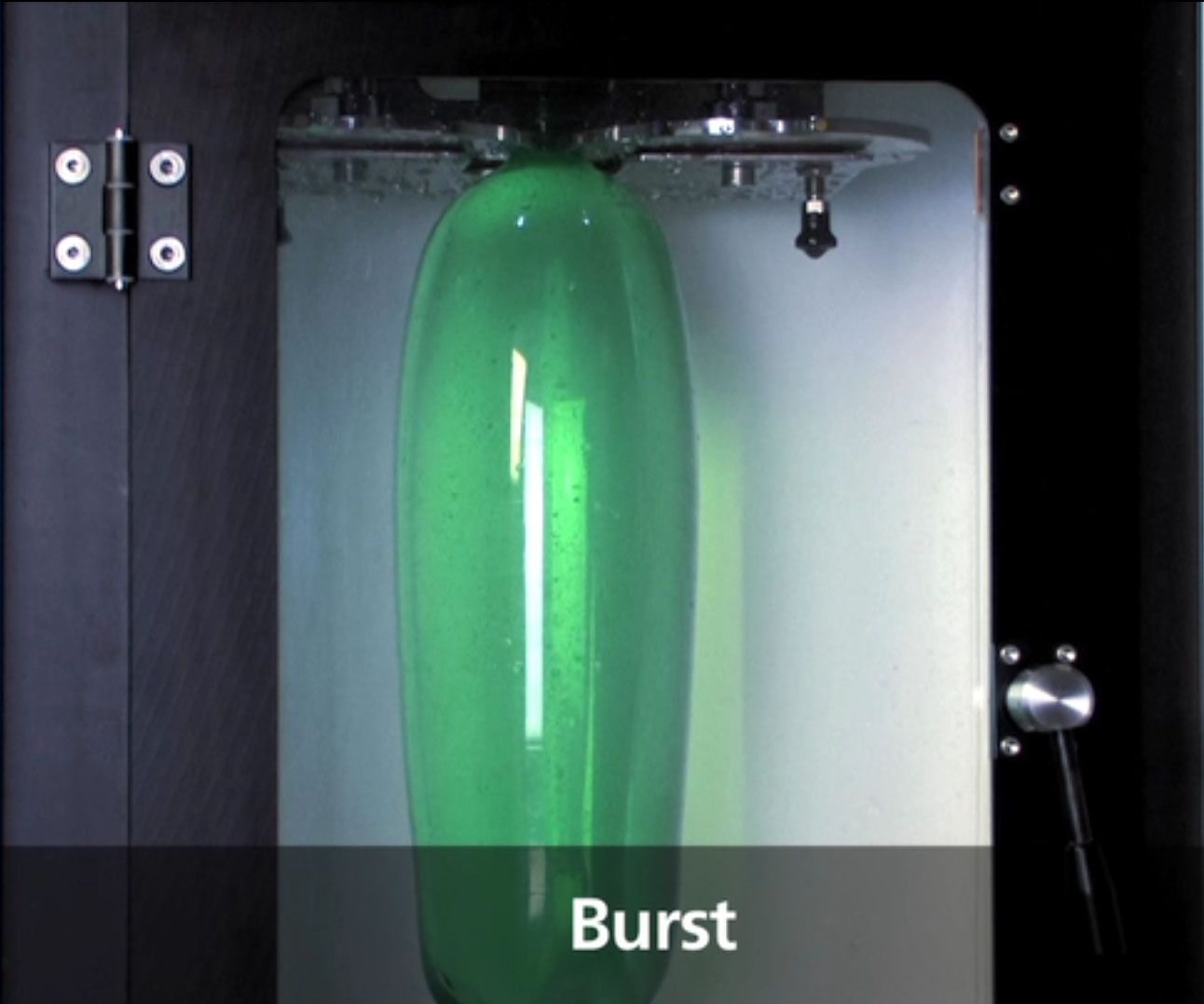

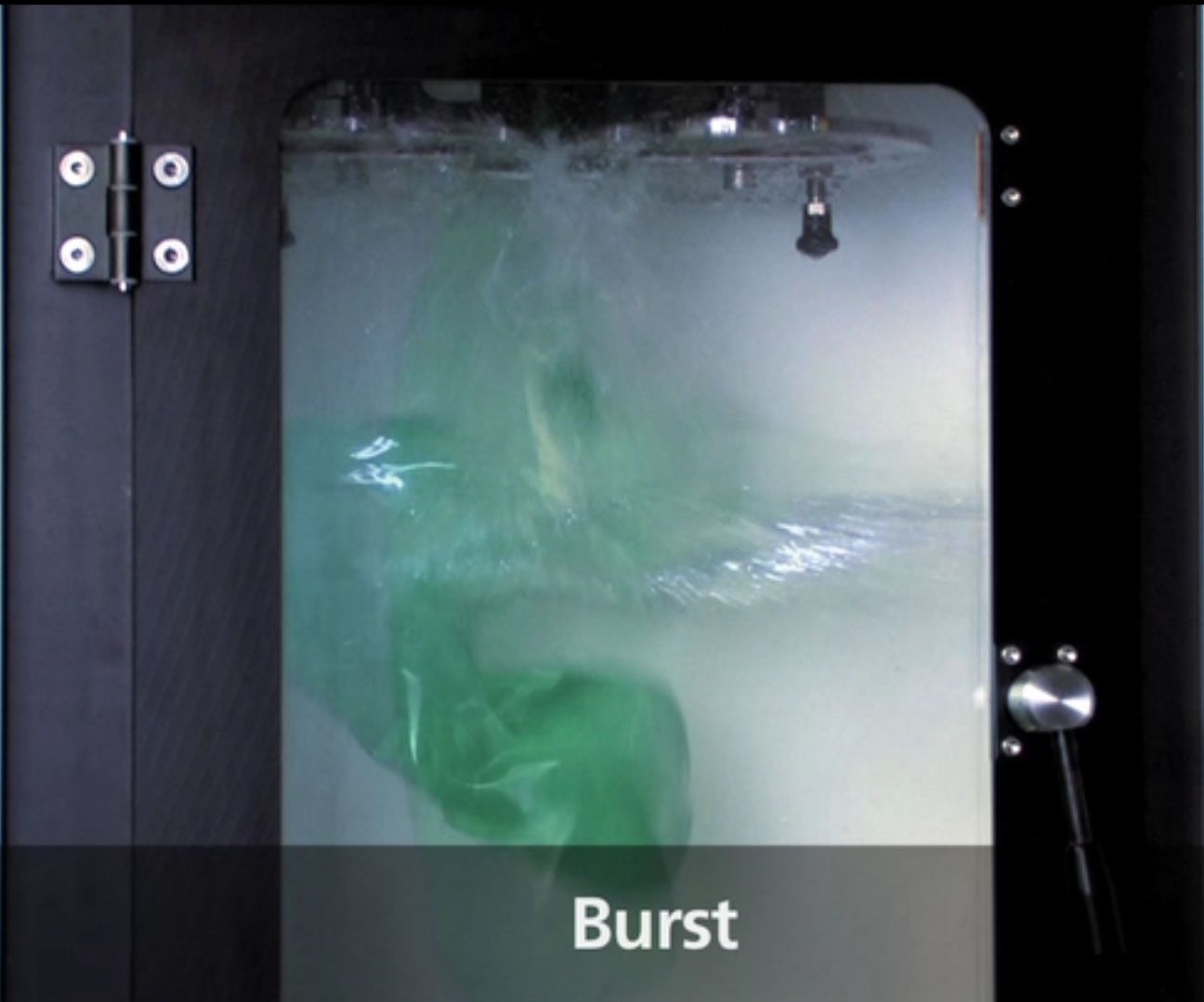

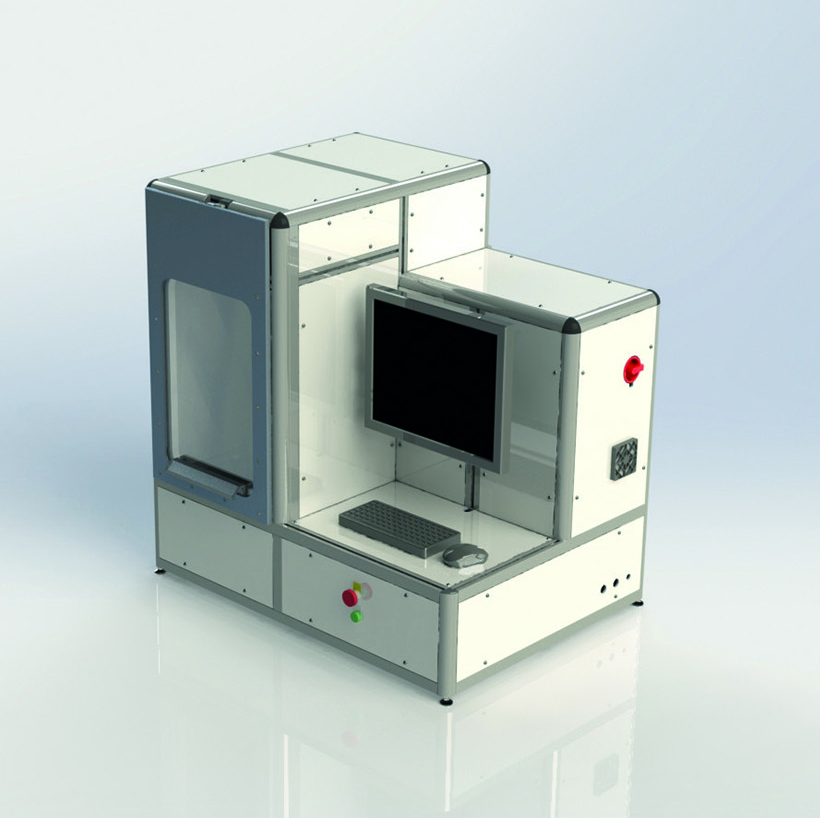

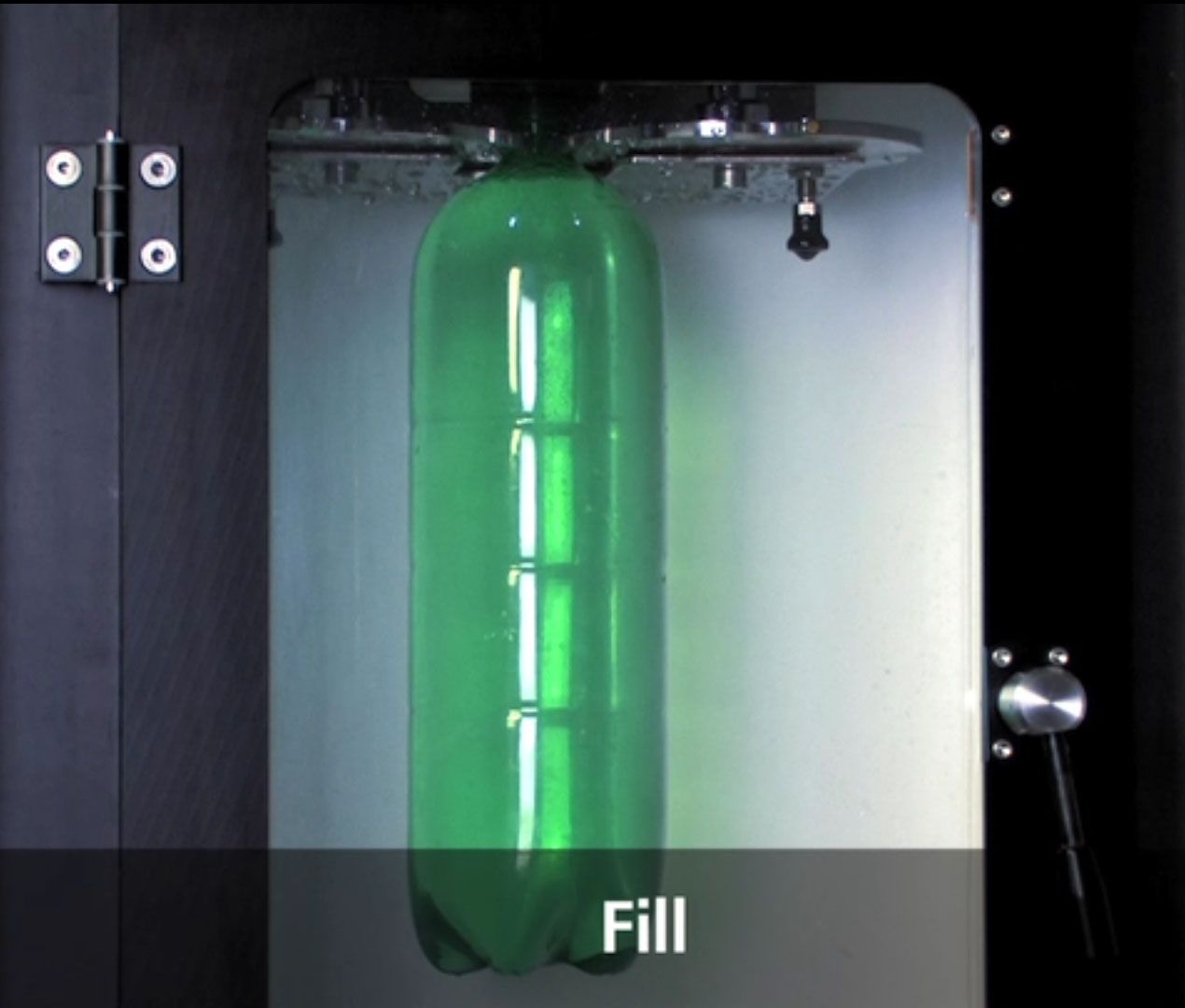

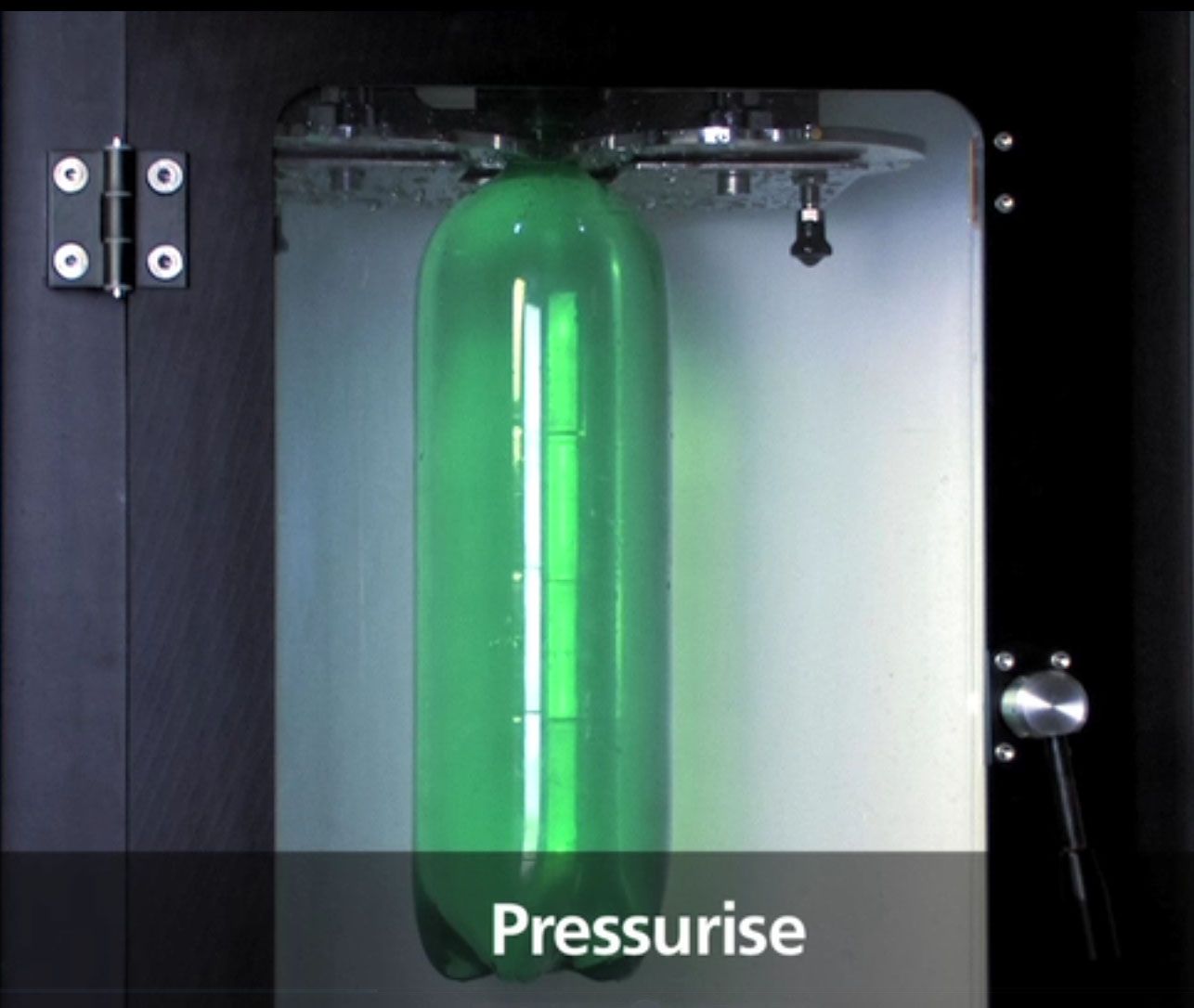

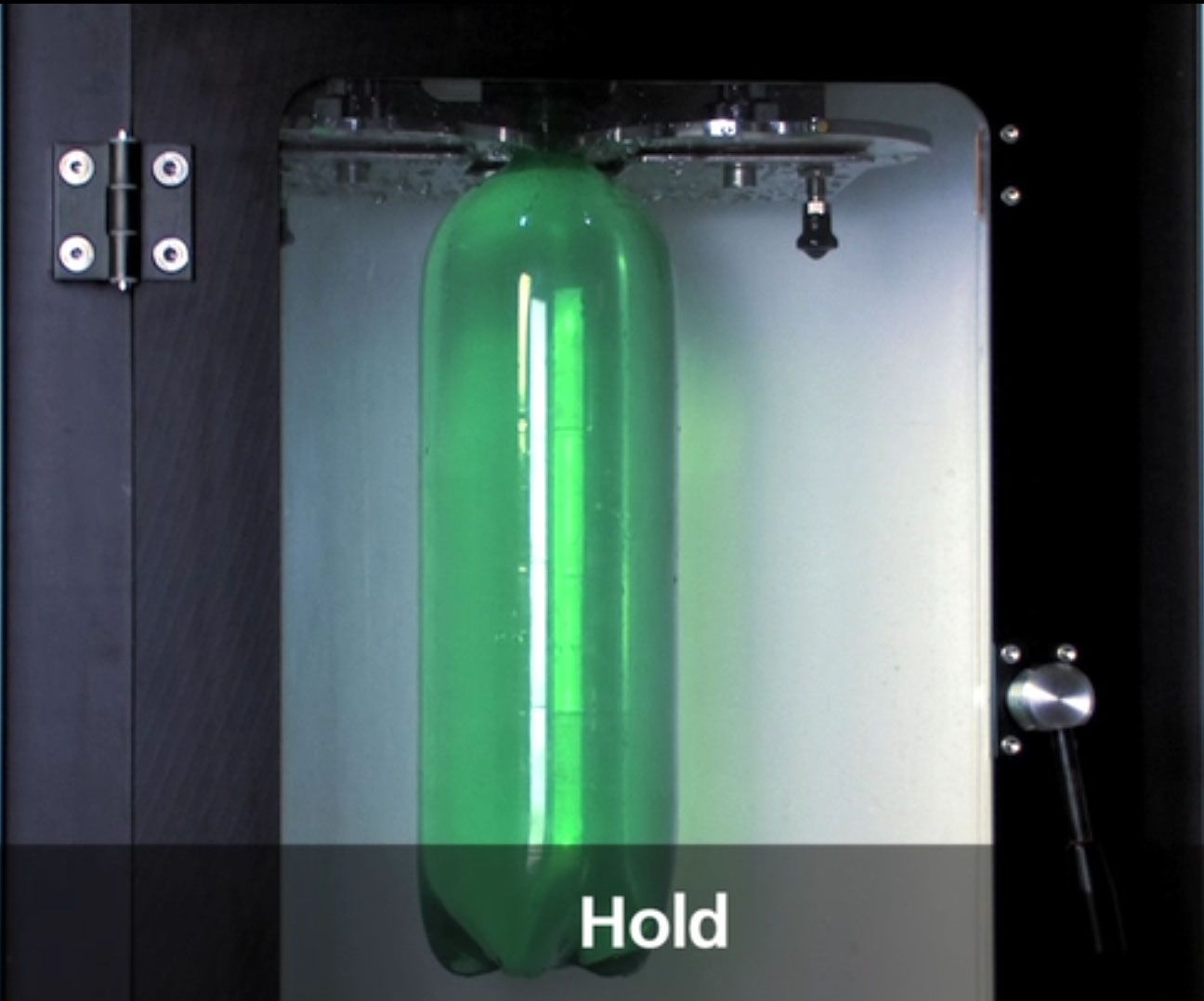

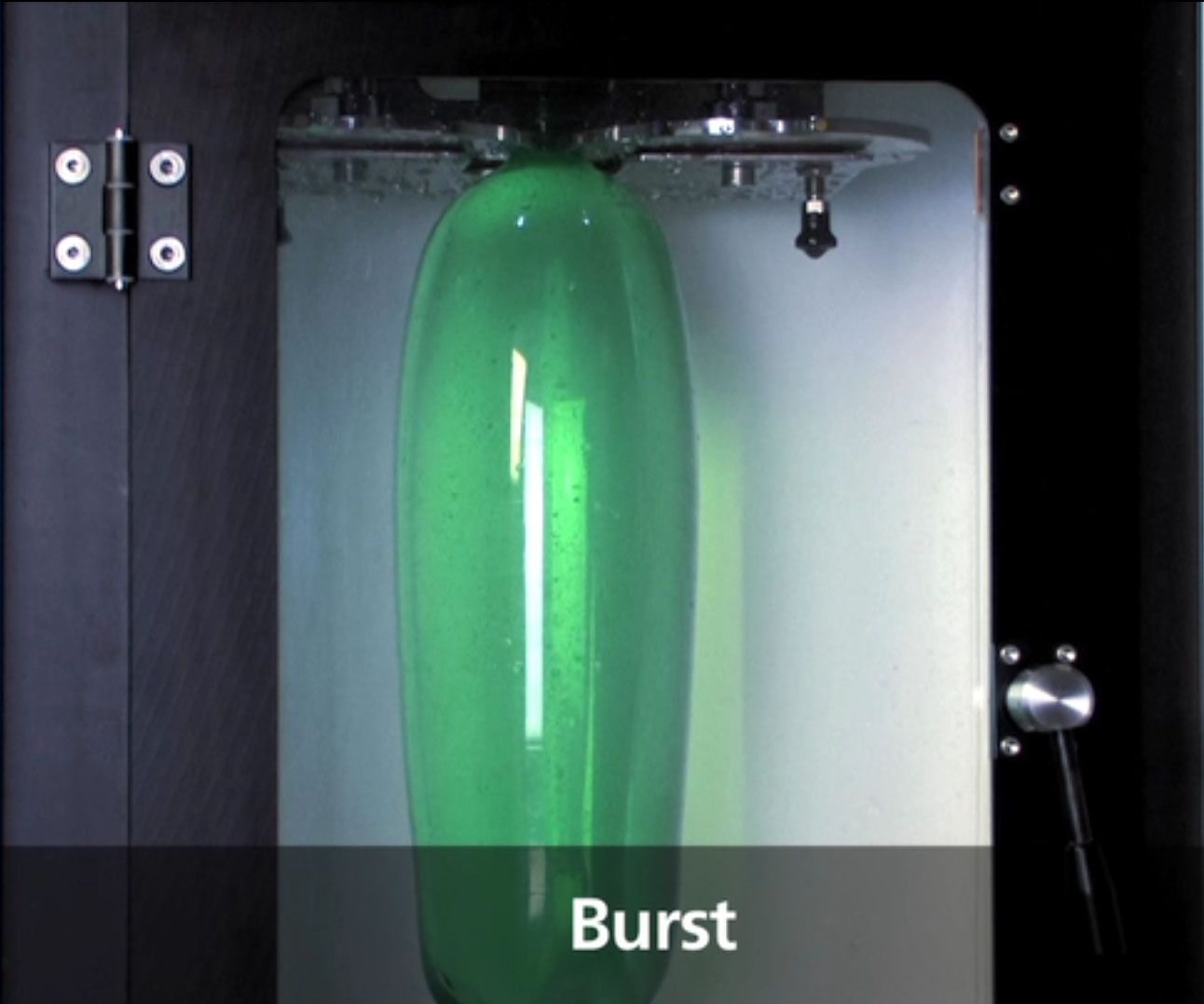

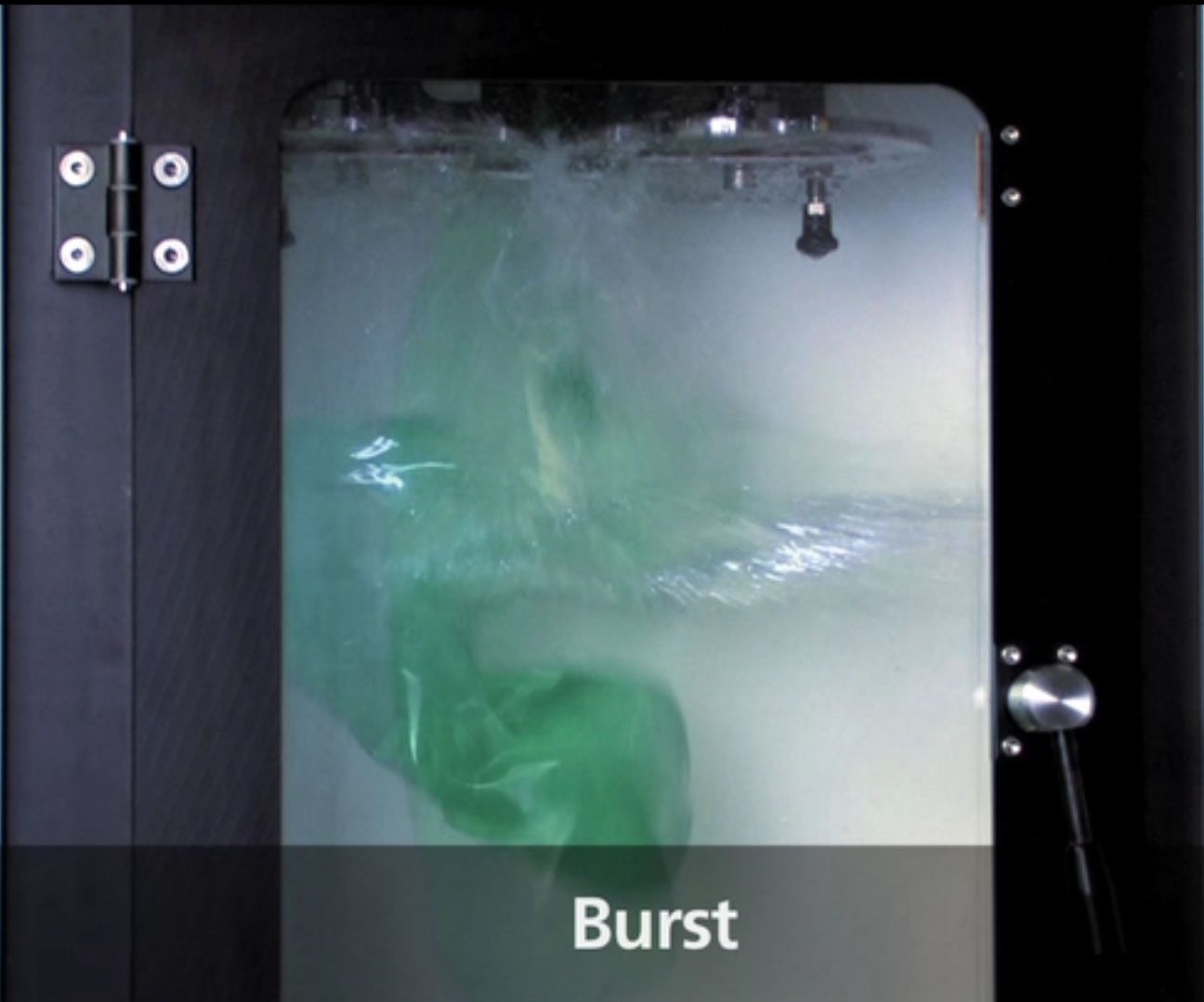

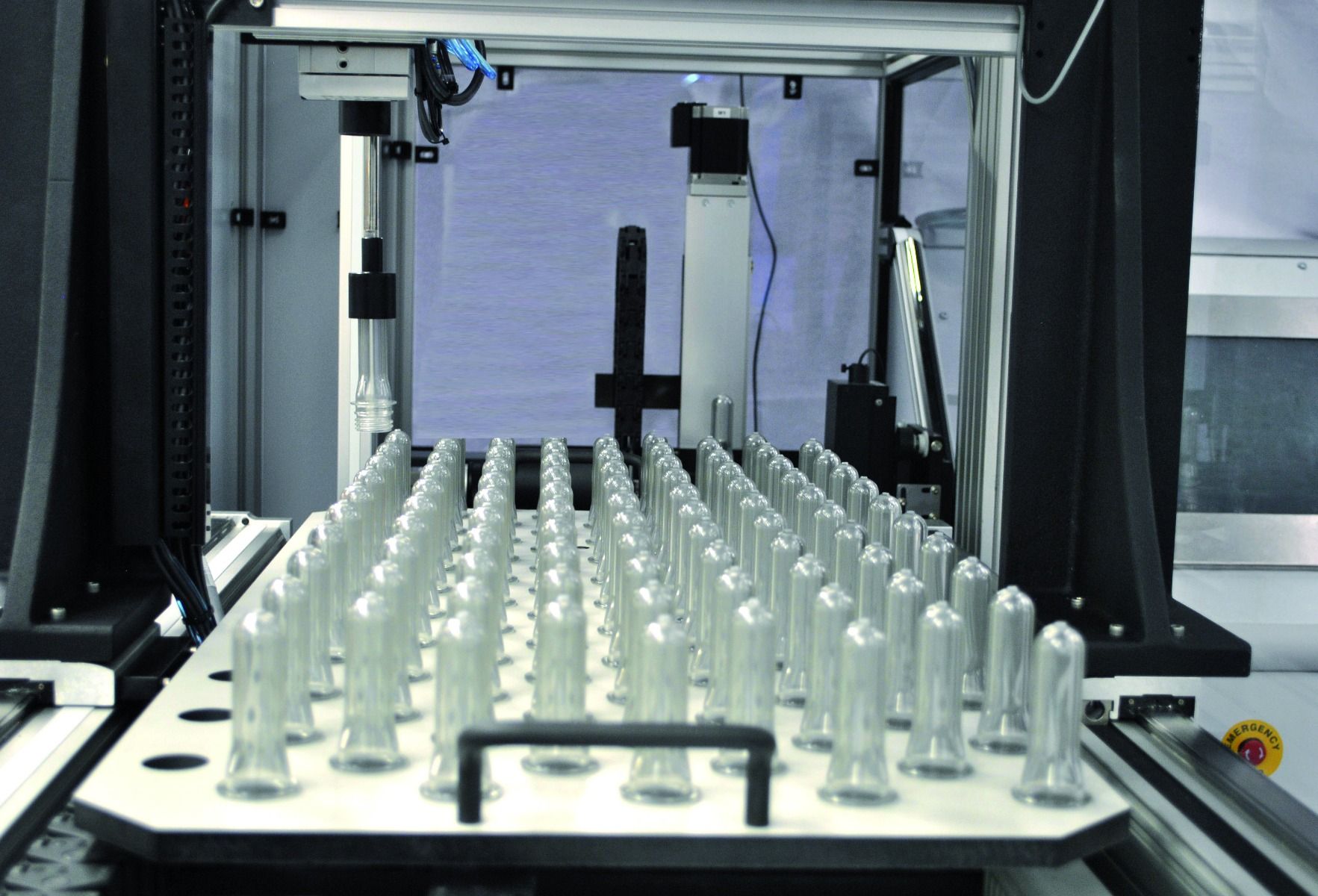

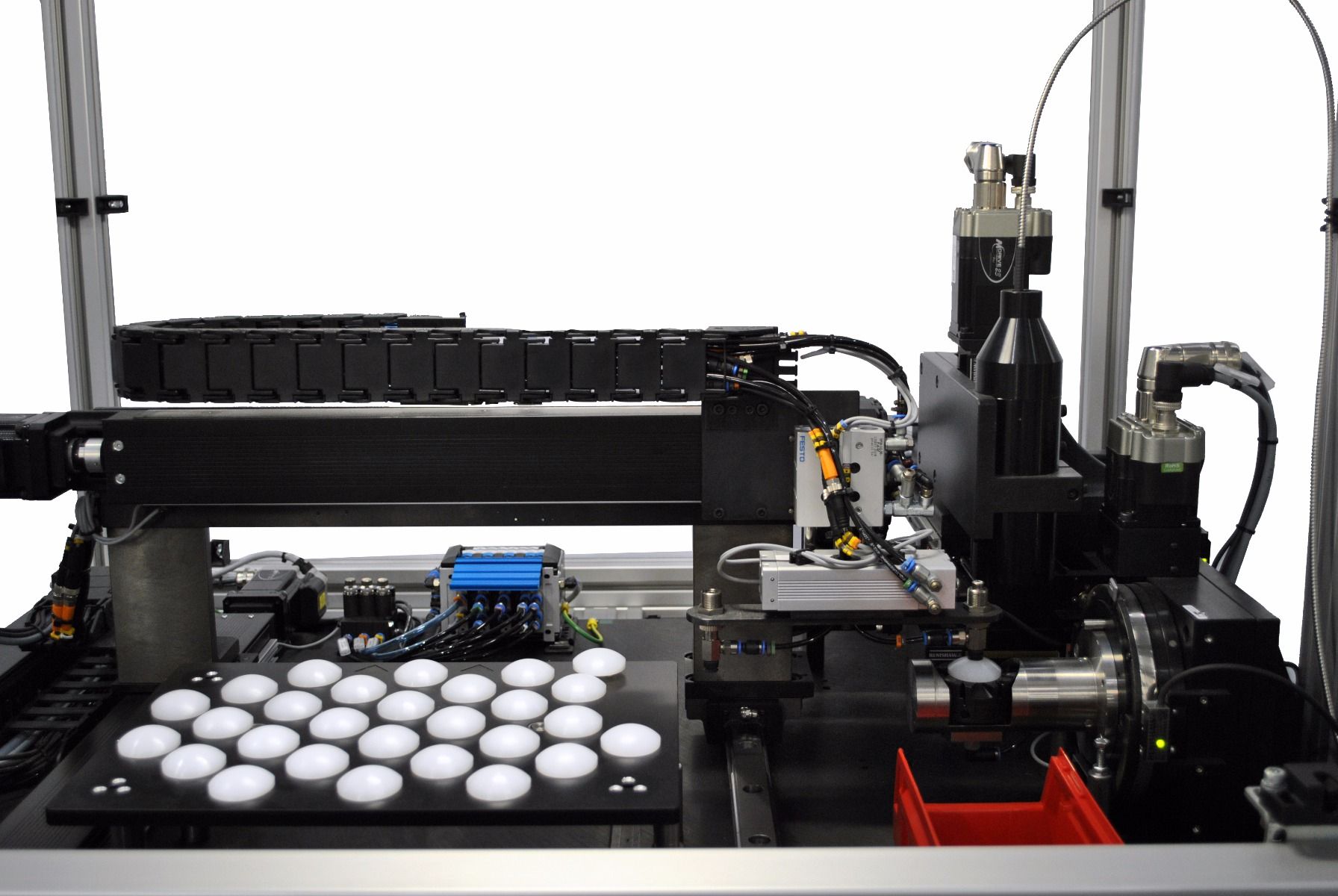

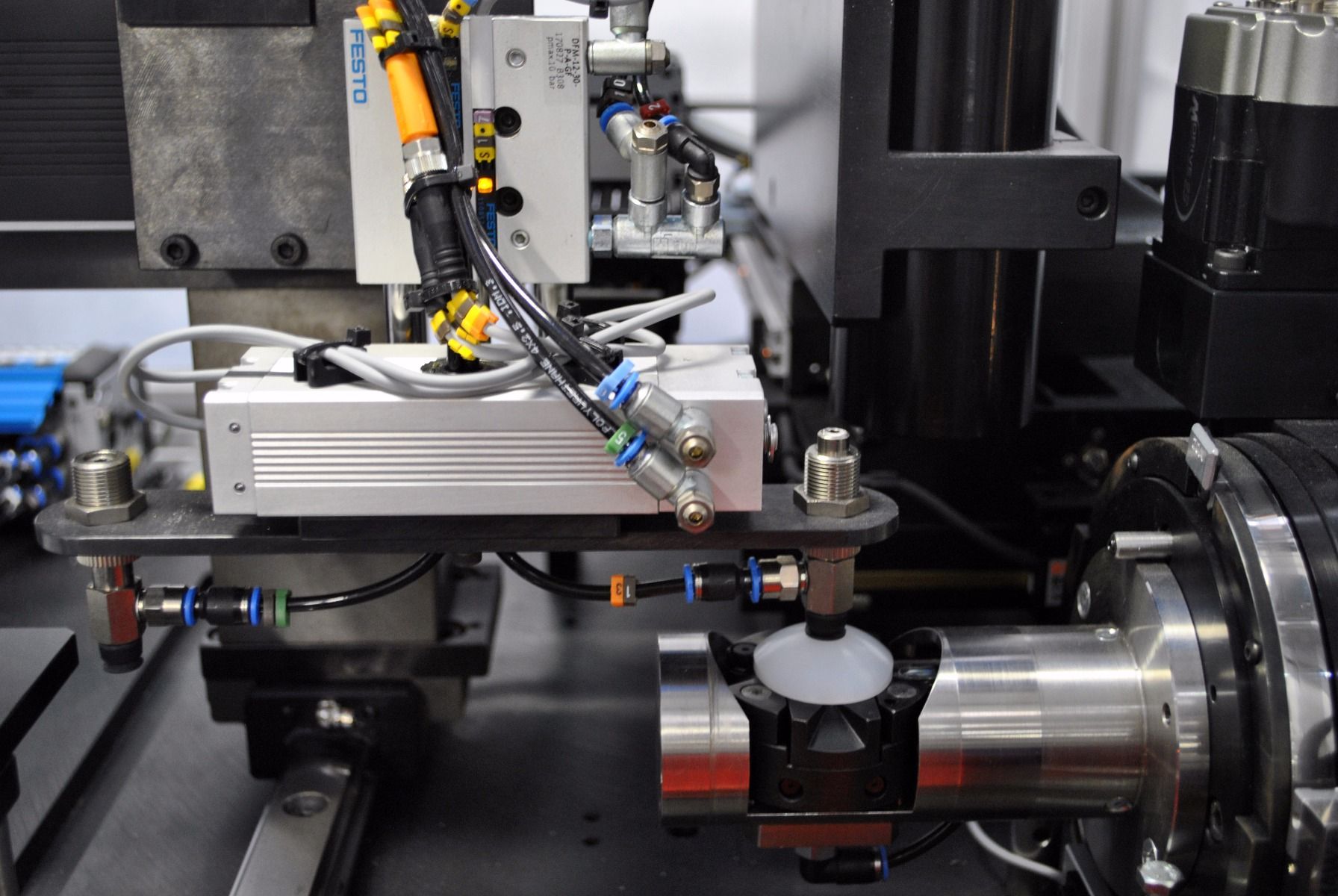

The B303 Semi-Automatic Bottle Burst Gauge has been developed to verify production containers meet the minimum pressure requirements.

The systems monitors expansion volumes and yield points to provide important information regarding the stability of the bottle.

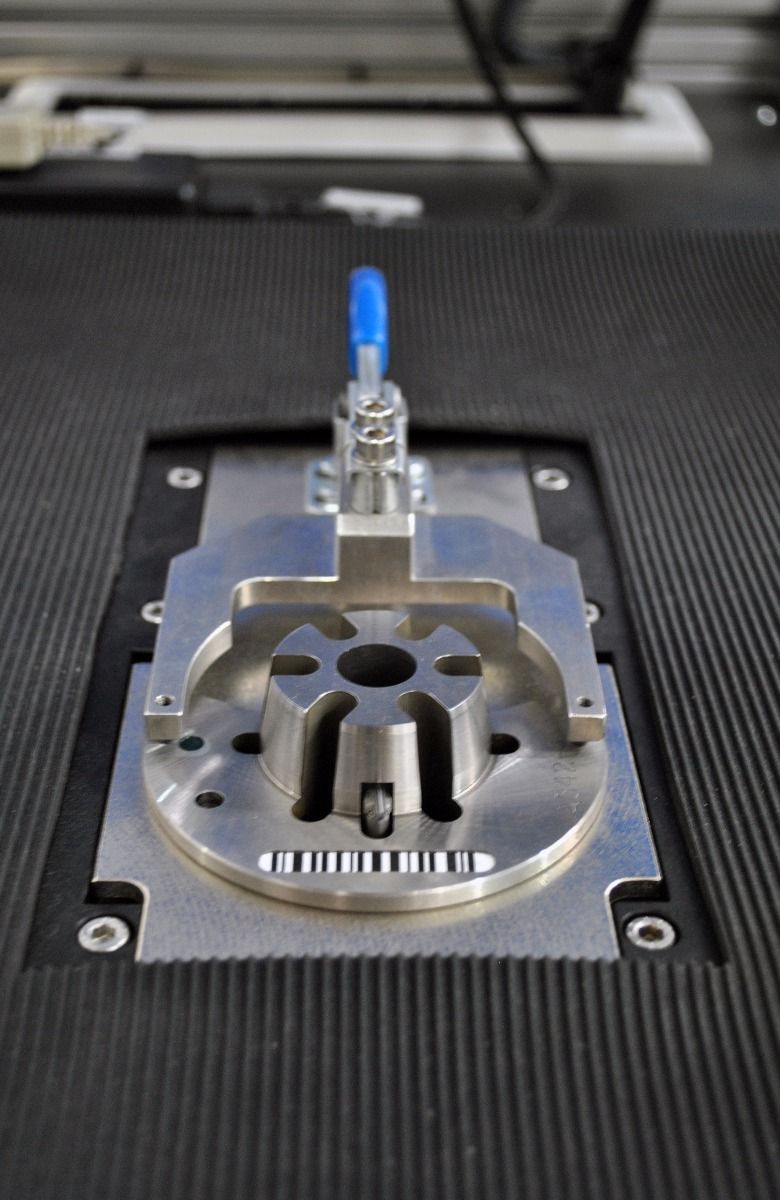

Quick-change tooling provides the capability to cover a wide range of industry neck finishes, future production proofing the machine as customer requirements and portfolios develop. With an expansion volume of up to 2400ml, the system covers small vials to large water keg containers.

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

The system has the option of being mains water supplied or recirculating from a local water tank, reducing running costs and therefore cost of ownership.

Reporting options such as standard CSV or Statistical Process Control (SPC).

Traceable to UKAS standards.

Measurement Features

Technical Specification

Pressure and Expansion Options

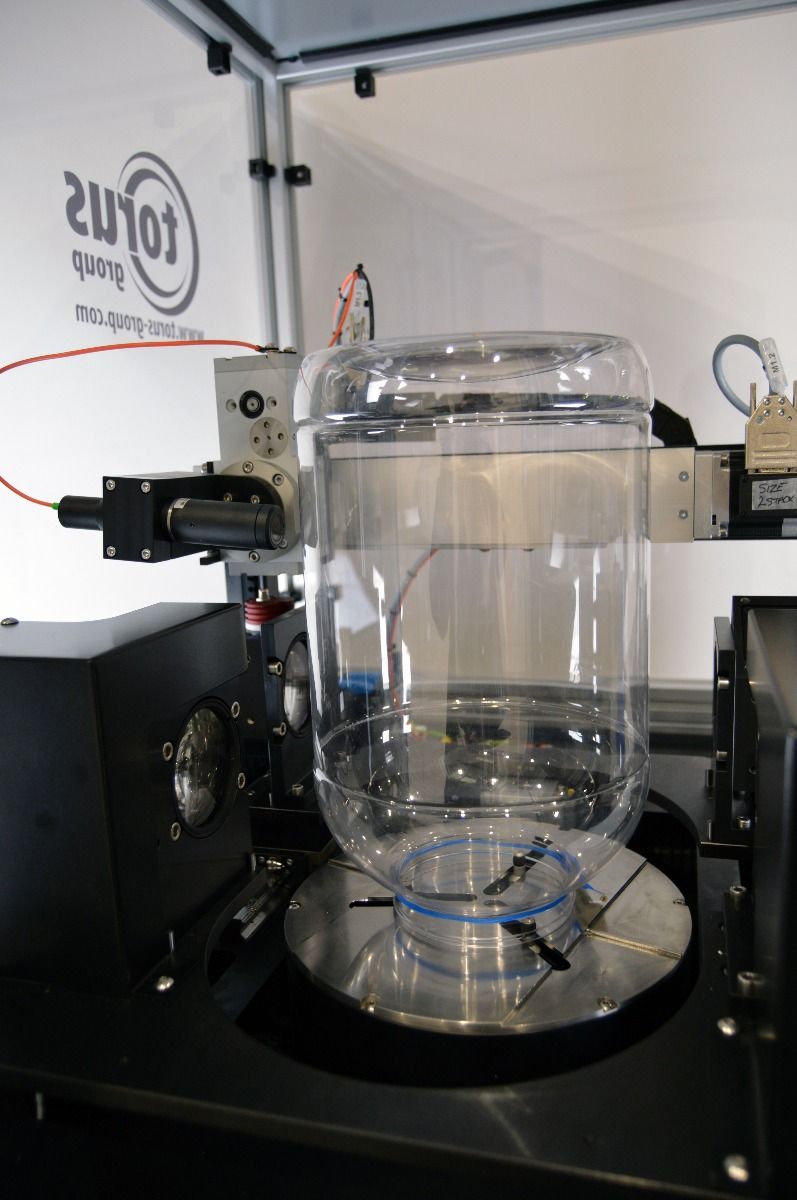

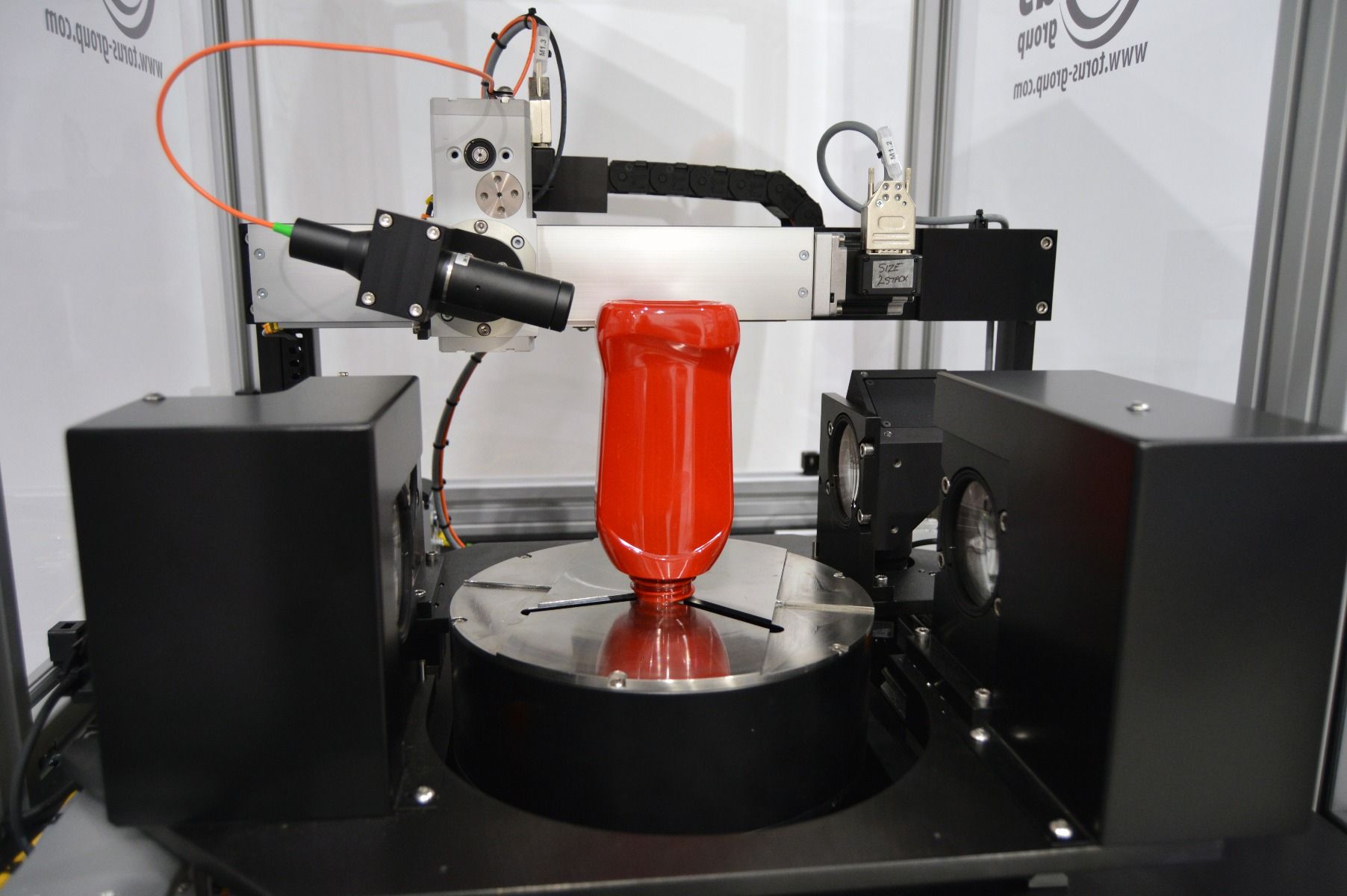

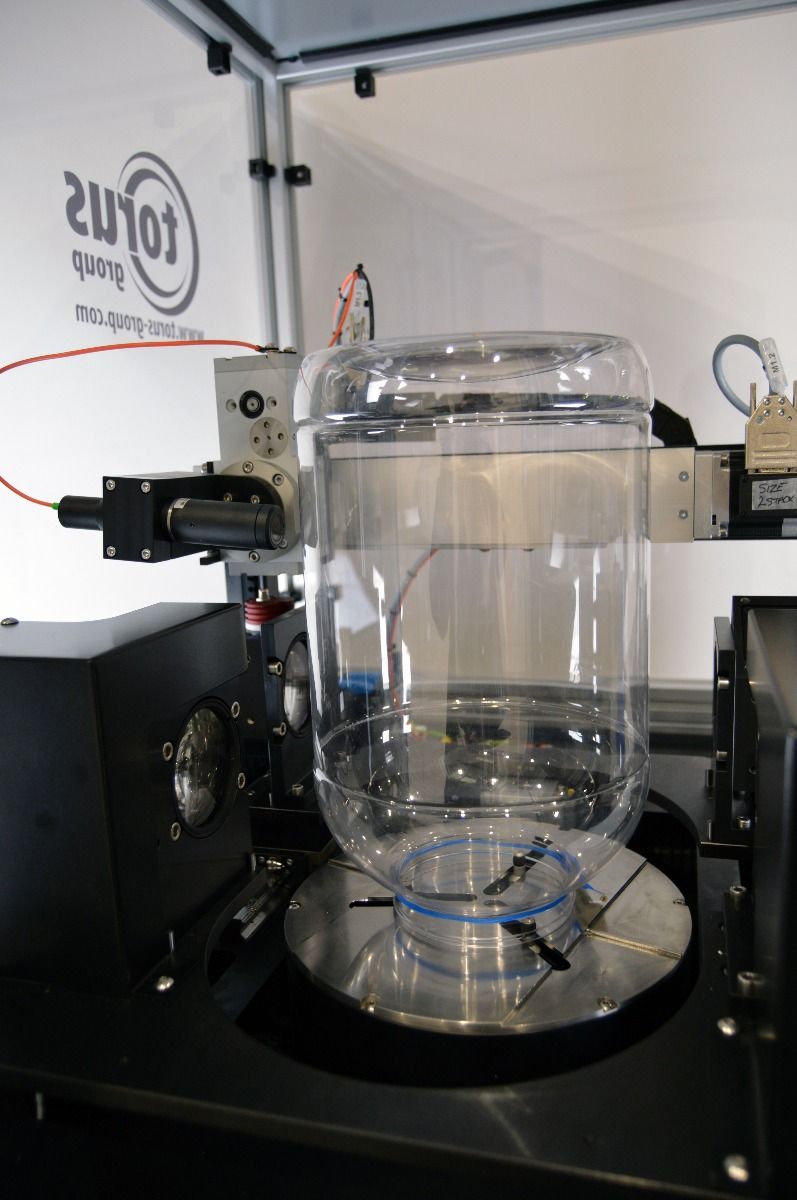

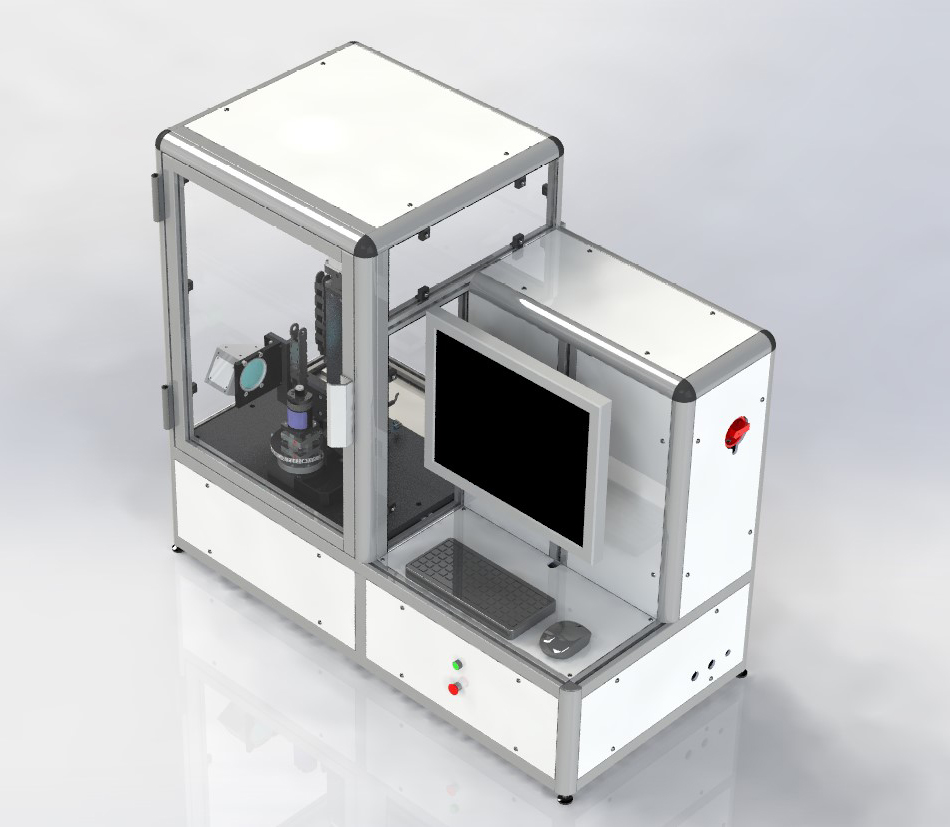

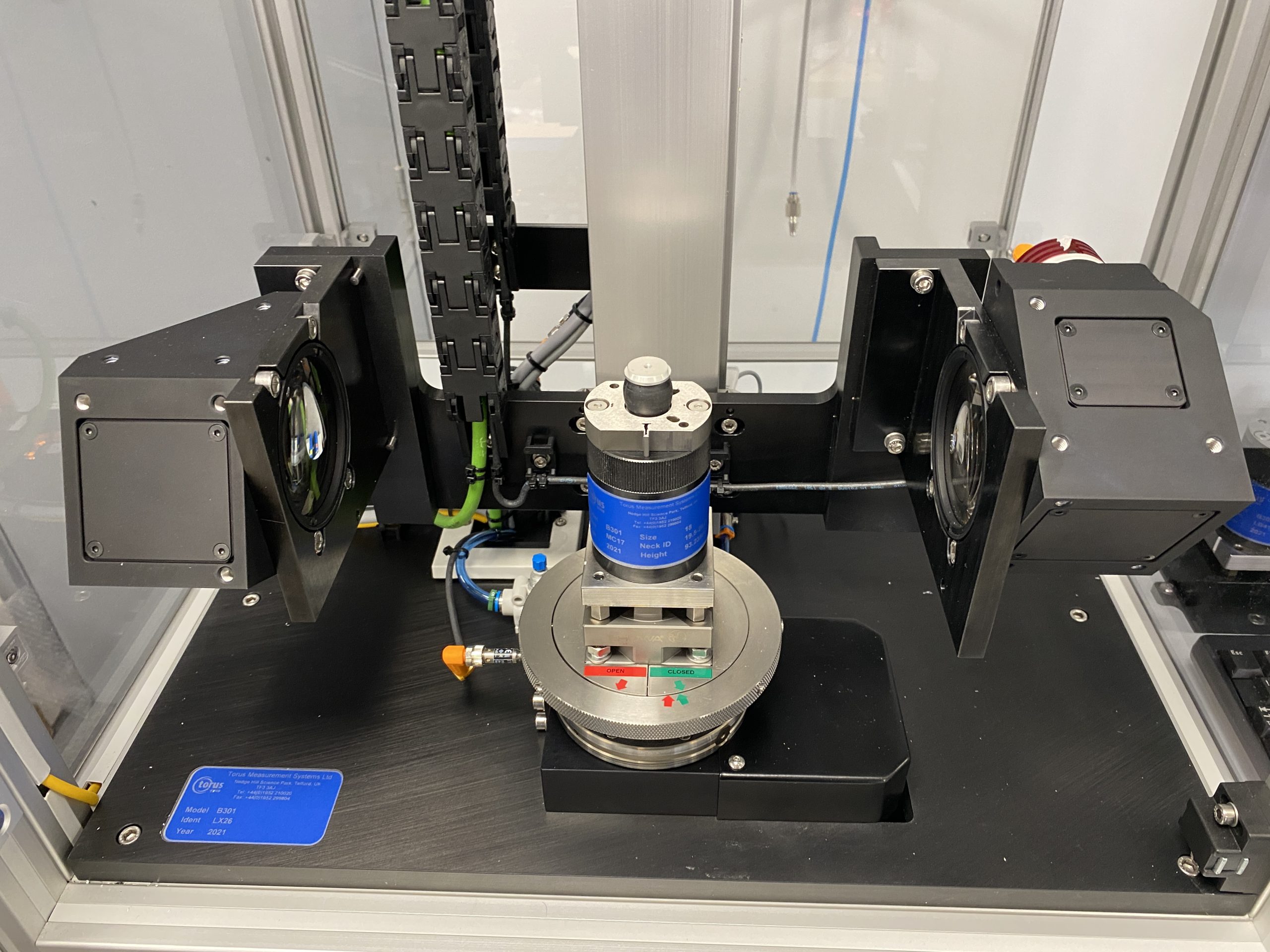

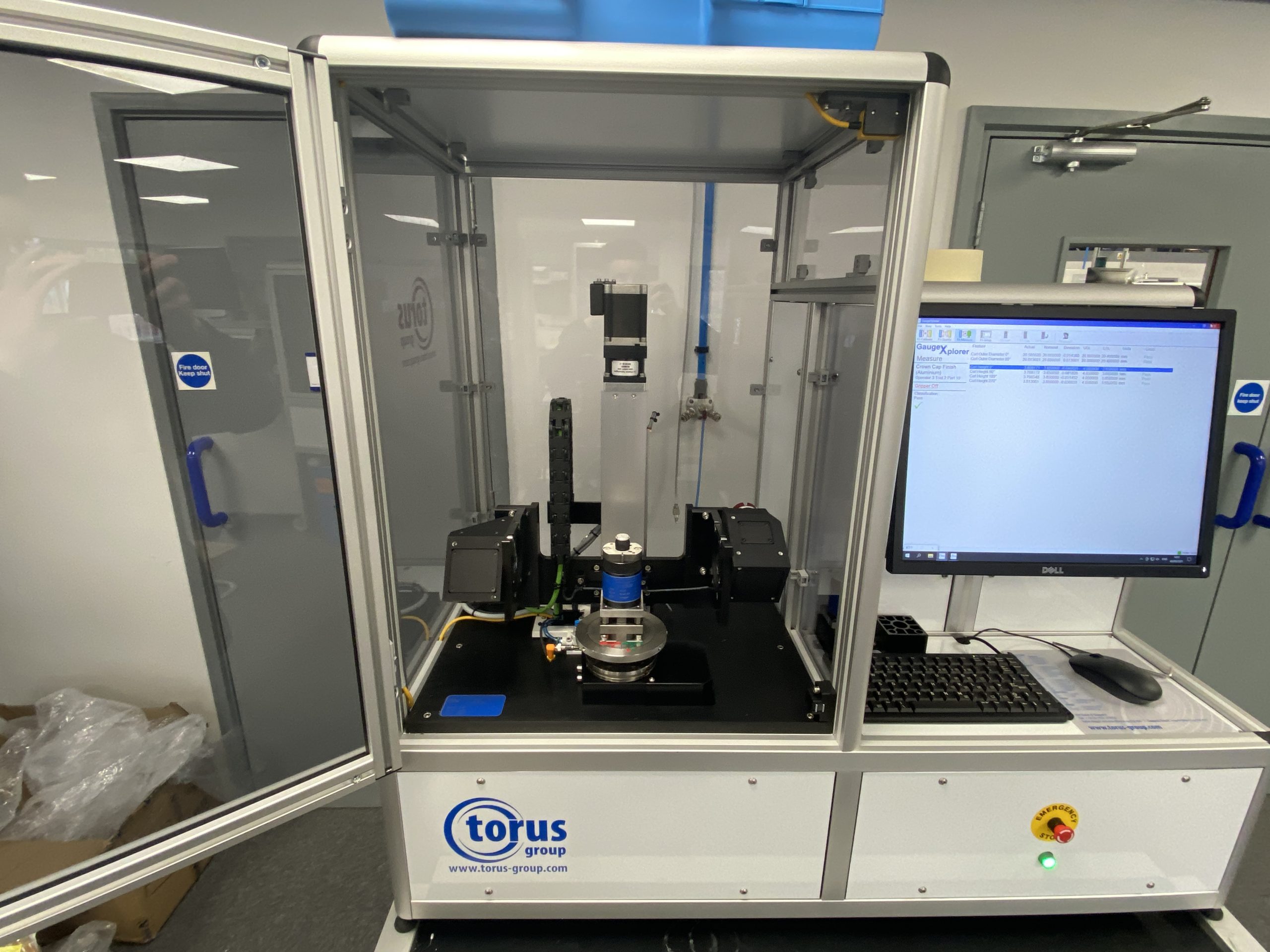

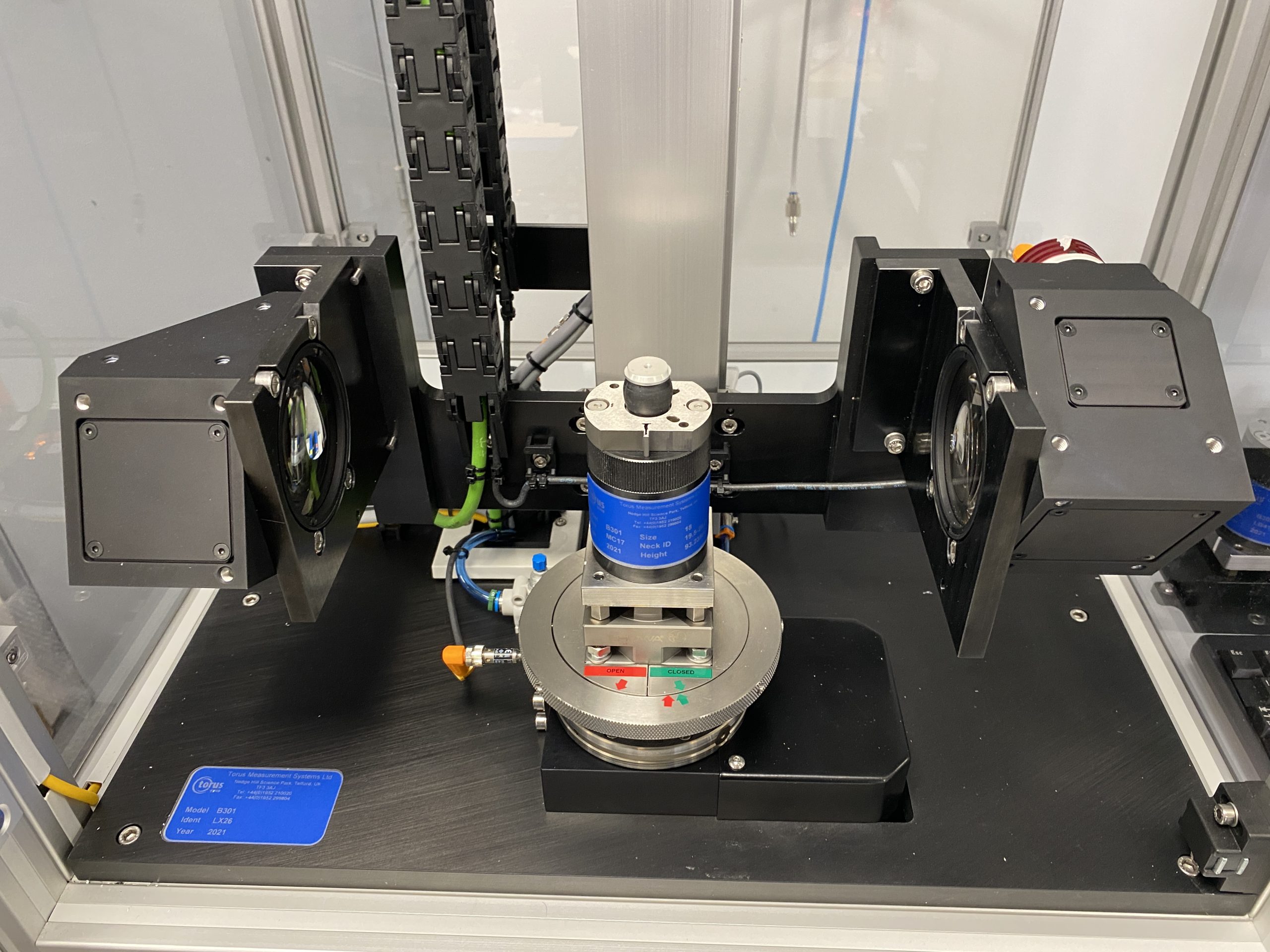

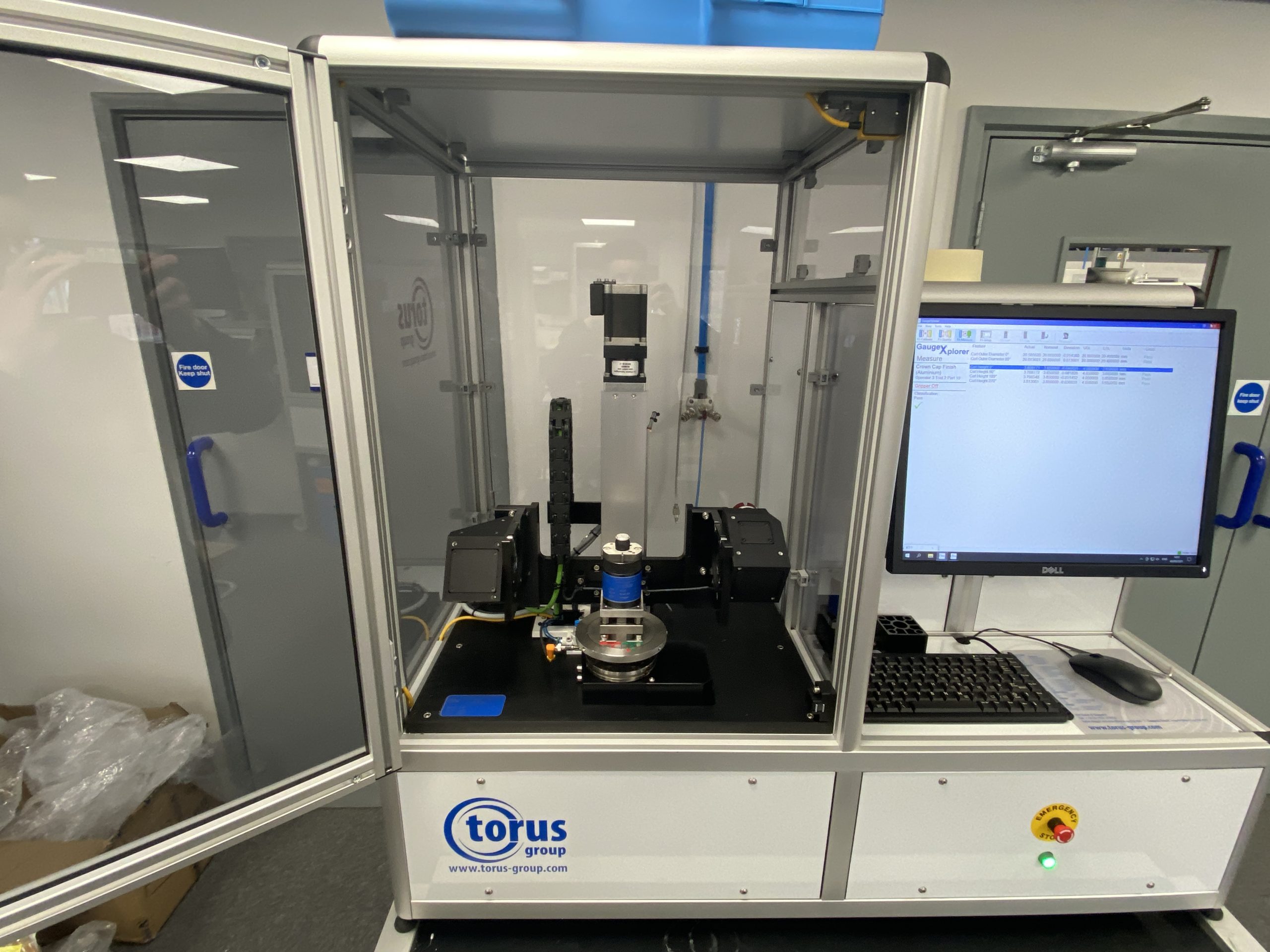

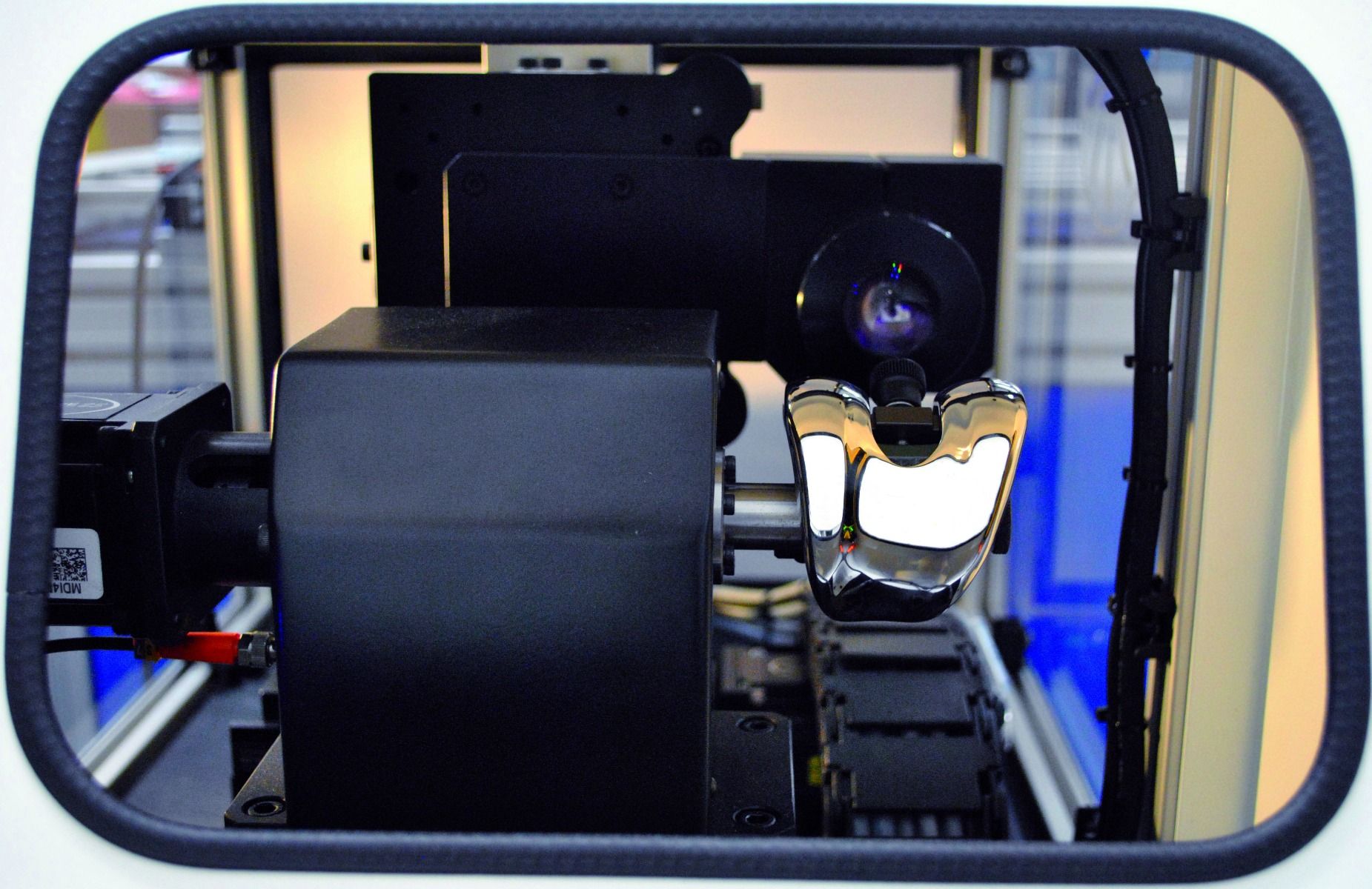

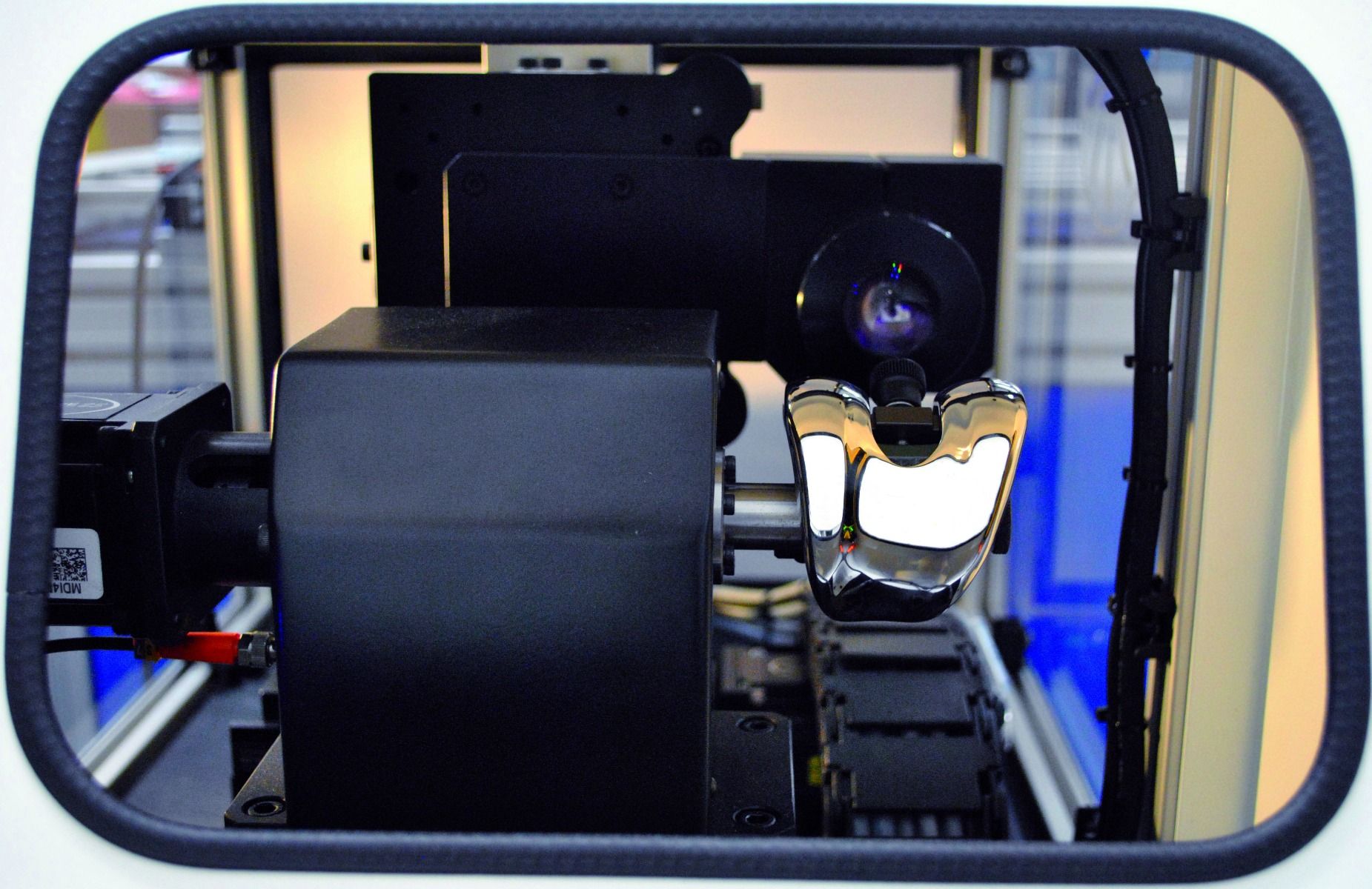

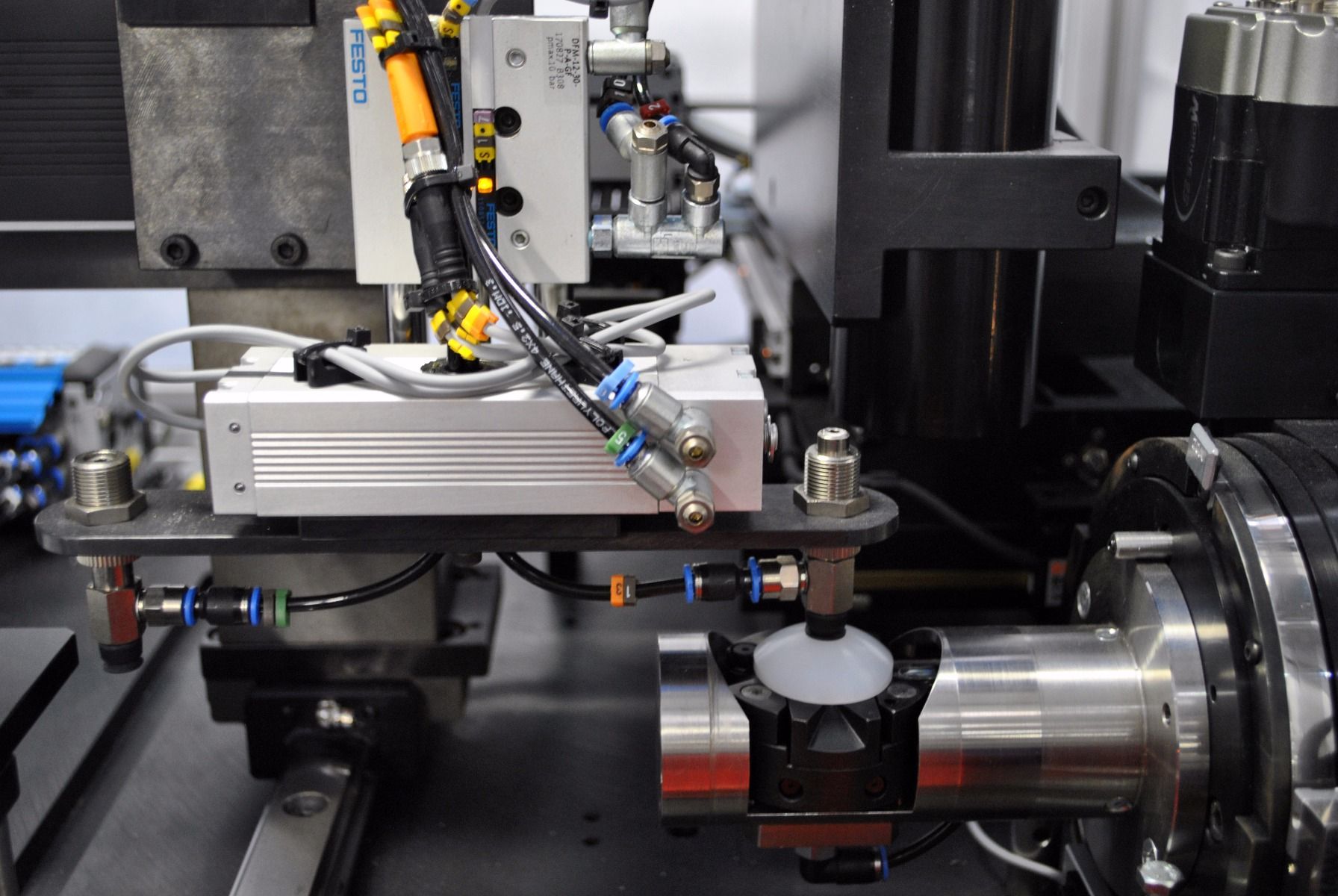

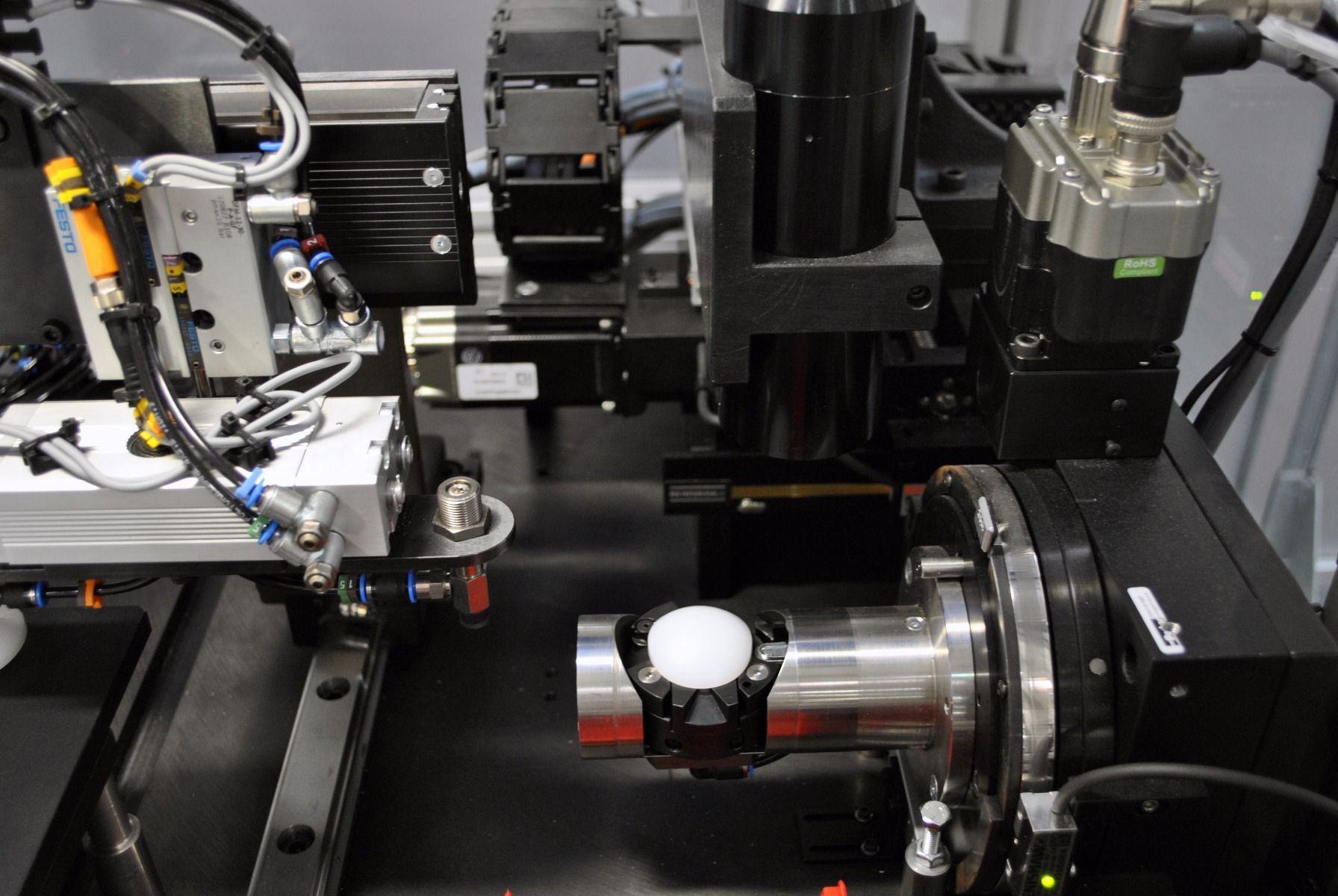

The 6-axis Torus TBT Gauge provides the ability to measure base & wall thickness with dimensional measurements in a single operation. This gauge has been designed with extended range to deal with the latest industry needs encompassing the scope to measure containers, jars and preforms as standard. Self centralising tooling delivers fast and repeatable container location, increasing throughput whilst achieving industry leading results. The latest confocal white light and optical technologies allow for unrivaled, non-contact measurements creating a new standard for plastic packaging quality control.

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

Reporting options such as standard CSV or Statistical Process Control (SPC).

Traceable to UKAS standards.

Measurement Features

Technical Specification

Thickness Sensor Options

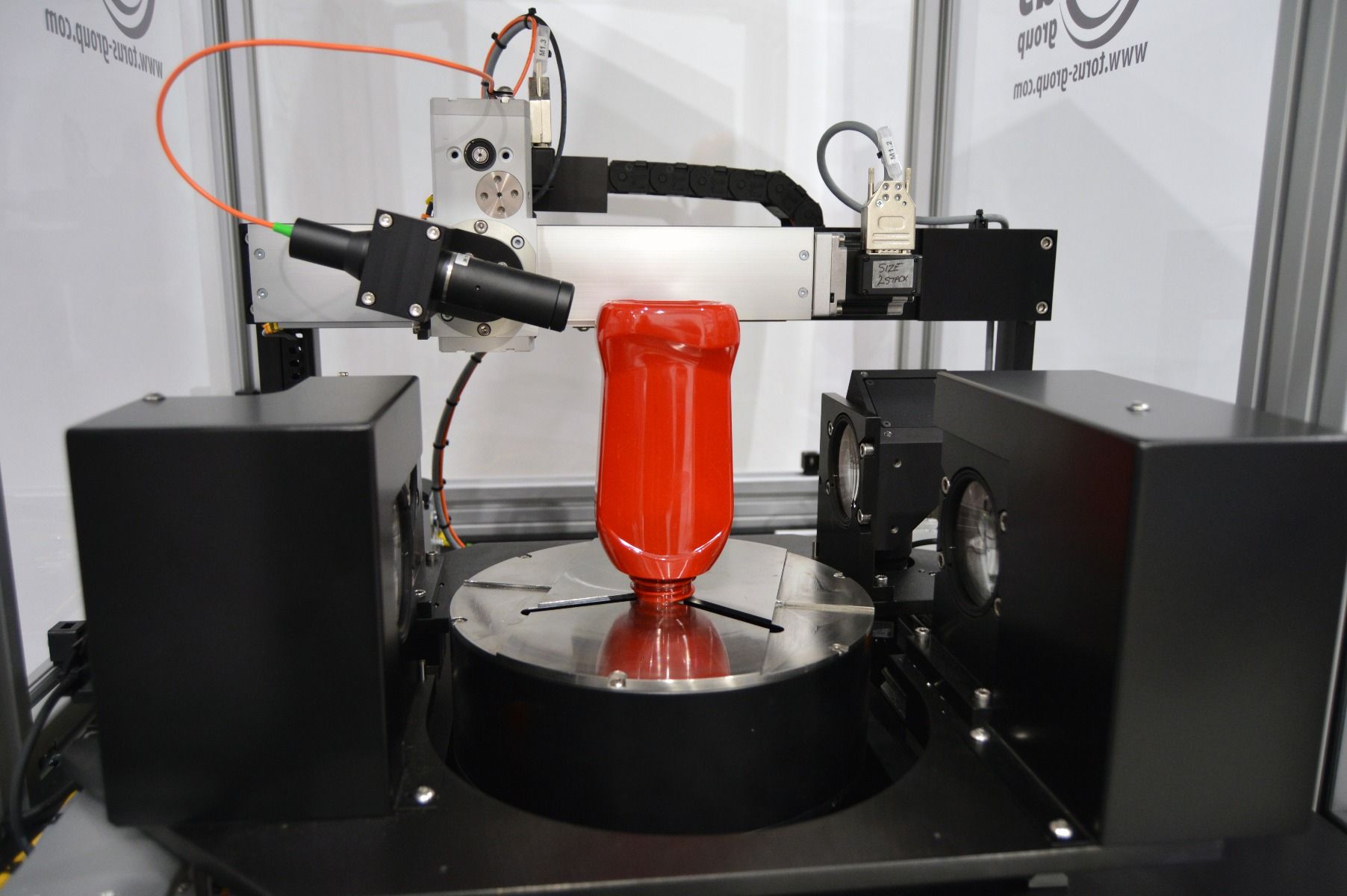

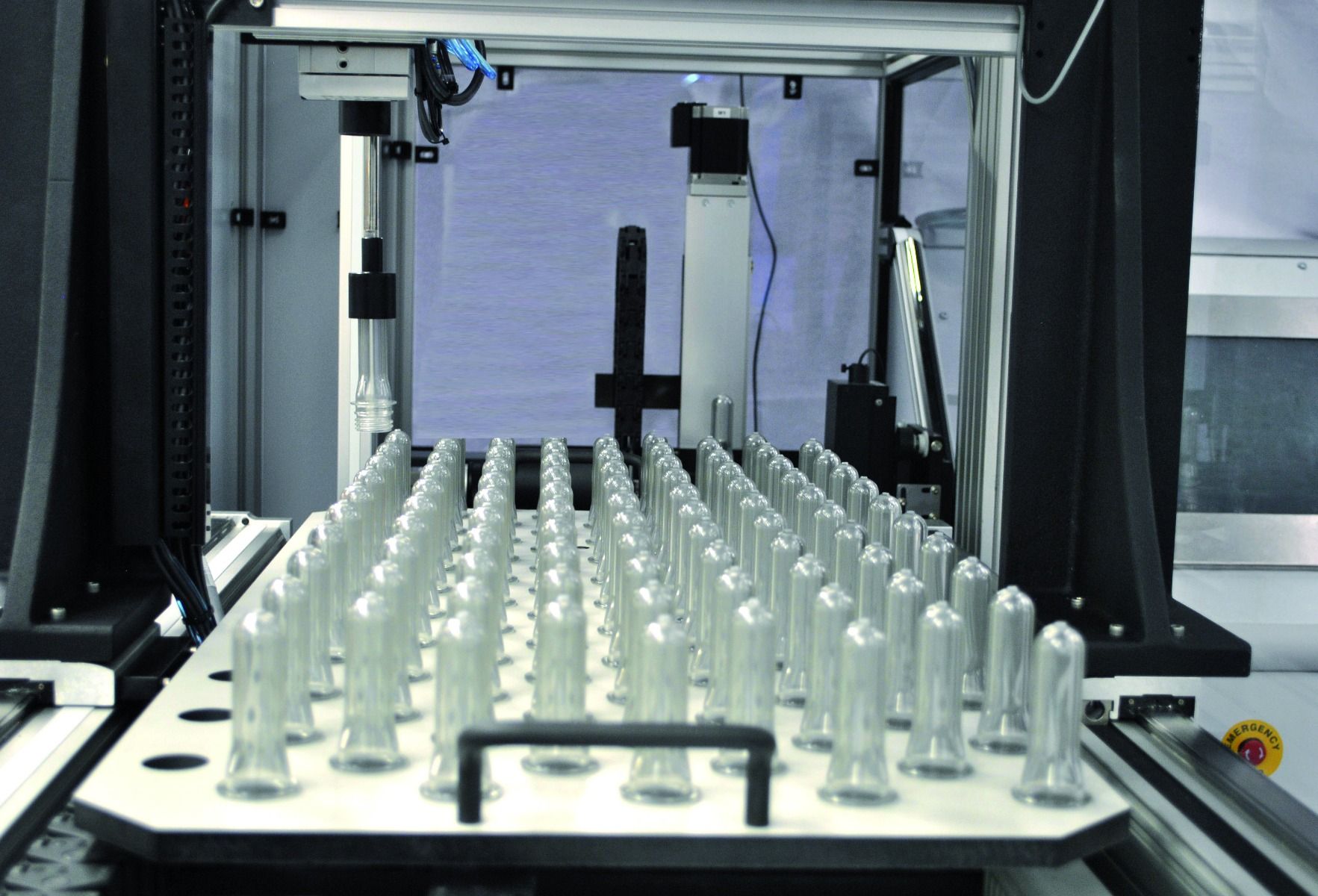

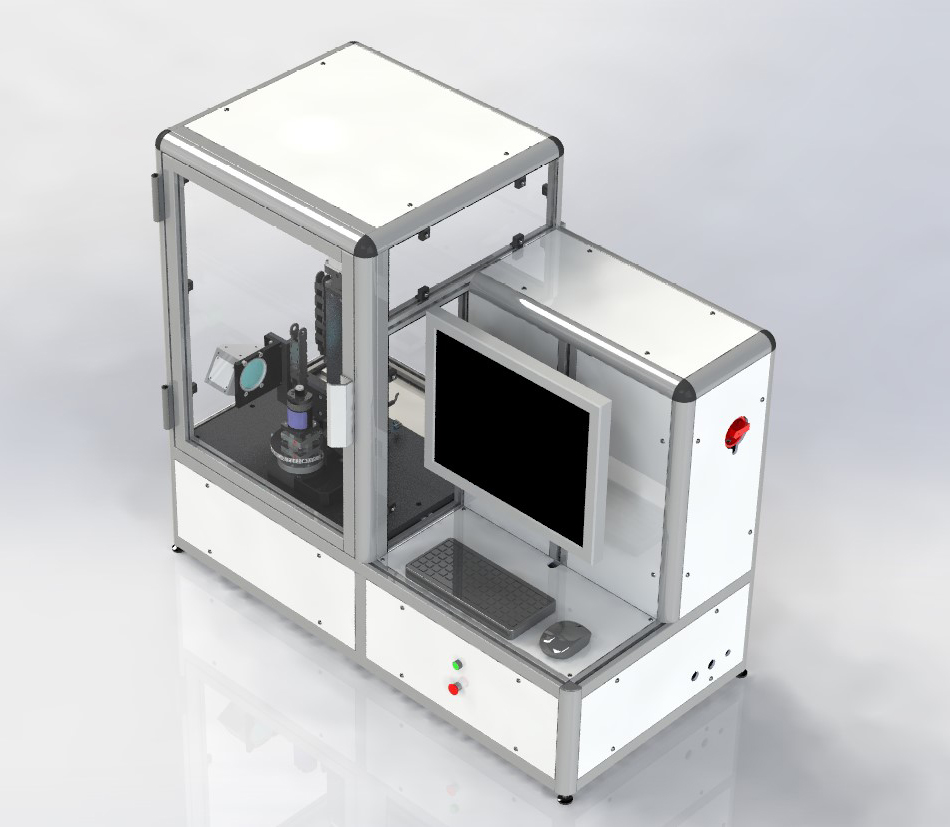

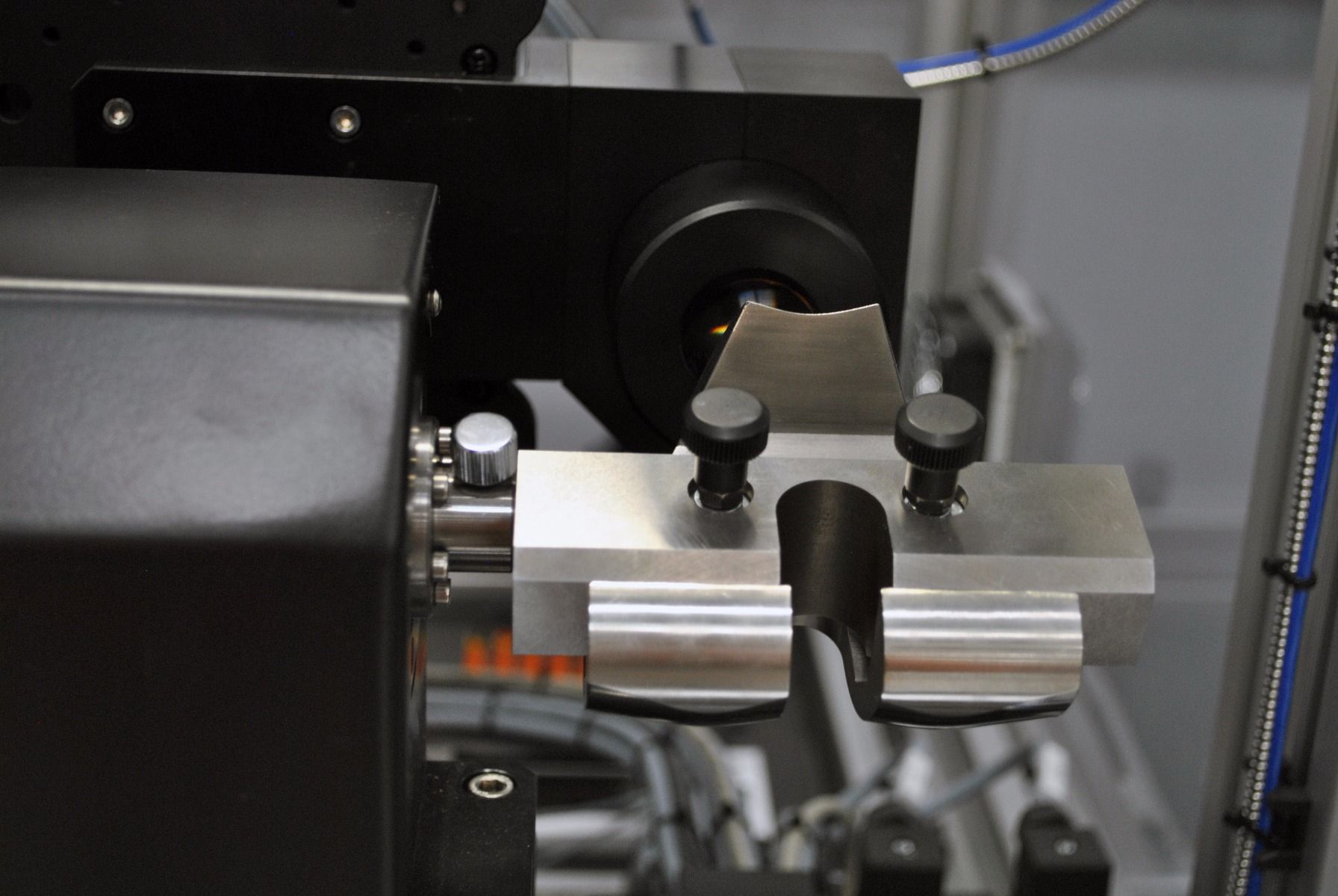

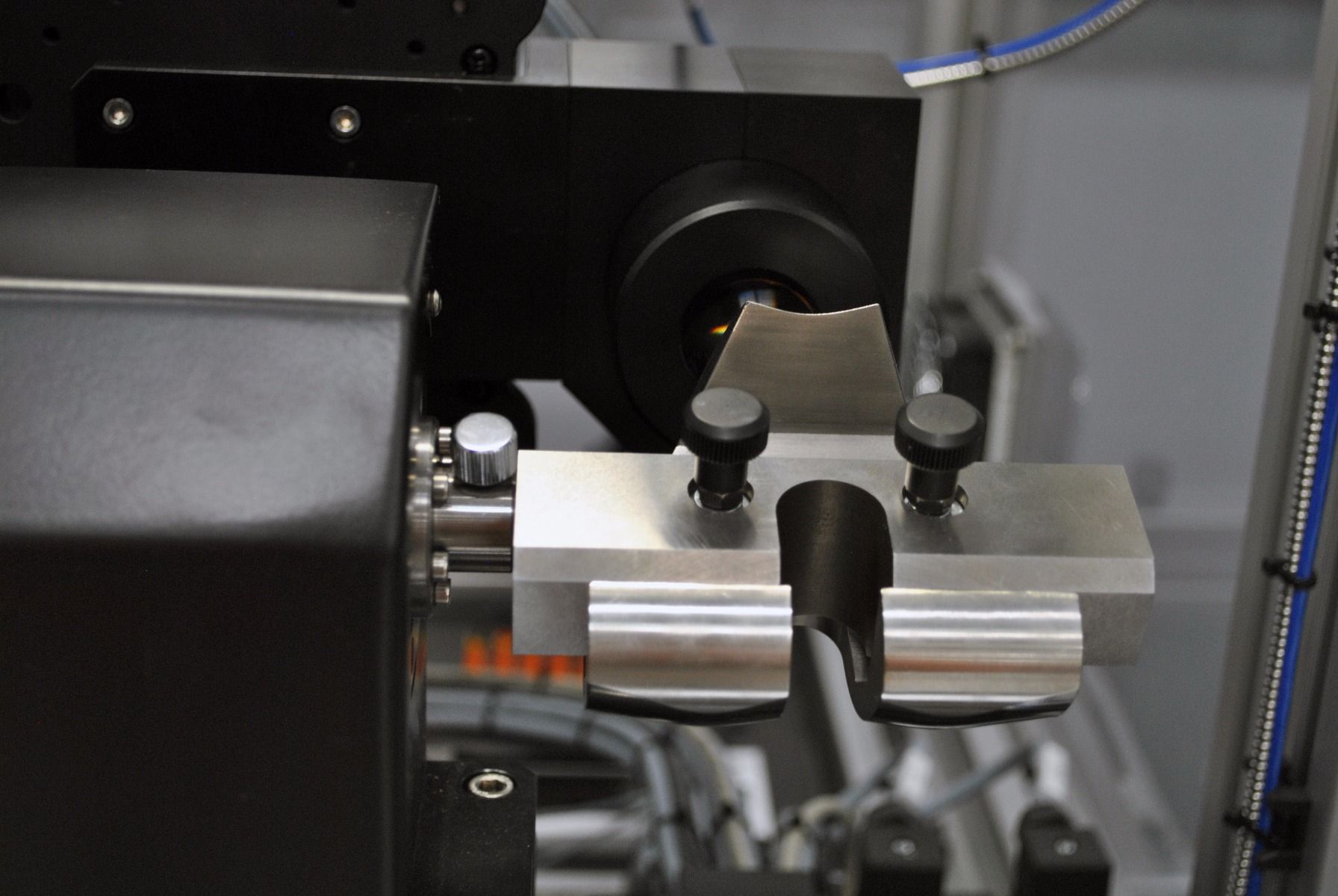

The B301 Semi-Automatic Optical Inspection Gauge has been developed to provide a fast, non-contact, traceable measurement solution for neck finish and body dimensions.

Using state-of-the-art optical telecentric lens technology, the system takes advantage of a self-teach profile function for part program generation.

Interchangeable location tooling provides the capability to perform dimensional inspection on a wide range of industry standard neck type finishes.

Automatic thread start alignment used to offer unmatched measurement repeatability and consistency from part-to-part measurement.

Reporting options as standard CSV or Statistical Process Control (SPC)

Traceability and Certification to UKAS Standards

Measurement Features

Technical Specification

The Torus surface profiler measurement system utilises state-of-the-art confocal technology for rapid non-contact inspection of surface profiles on orthopaedic femoral knees, eliminating the need for handheld and subjective profile gauges and comparators

The system is designed for operational use on the shop floor therefore giving the machine tool operator a quick and repeatable measurement without having to go in to the inspection lab.

Polychromatic white light is focused onto the target surface by a multi-lens optical system. The lenses are arranged so that the white light is dispersed into monochromatic light by controlled chromatic aberration. Specific distance to the target is assigned to each wavelength which is exactly focused on the target is used for measurement.

This unique measuring principle enables displacements and distances to be measured with high precision and extreme spatial resolution. Cast, finished and highly polished surfaces can be measured without the requirement for surface preparation or machine adjustment.

Since the emitter and receiver are arranged in a single axis, shadowing is avoided, in contrast to conventional triangulation sensors.

The 4-axis motion control system is driven by high accuracy micro-stepping motors giving positional feedback, providing high resolution and high speed with stability and reliability.

Measurement Features

Feature

Technical Specification

Capabilities

Torus’ A542 Actabular Cup Gauge gives critical measurement information on a variety of measurement features

Torus’ Floor Standing Acetabular Cup Gauge is designed specifically for Orthopaedic Hip manufacturers who need control their Acetabular Cups quickly, accurately and beside the machine tool. The gauge can accommodate the full range of Acetabular Cups and gives critical measurement information on inferred mouth diameter, internal taper angle, taper straightness and an accurate indication of rounds.

To operate, simply scan the batch card with a barcode reader and the software will automatically select the relevant component type from the menu and the powerful Windows software will prompt you to load the specific Acetabular Cup.

Important trace information can also be attributed, to ensure easy analysis and comparison to assist in process control.

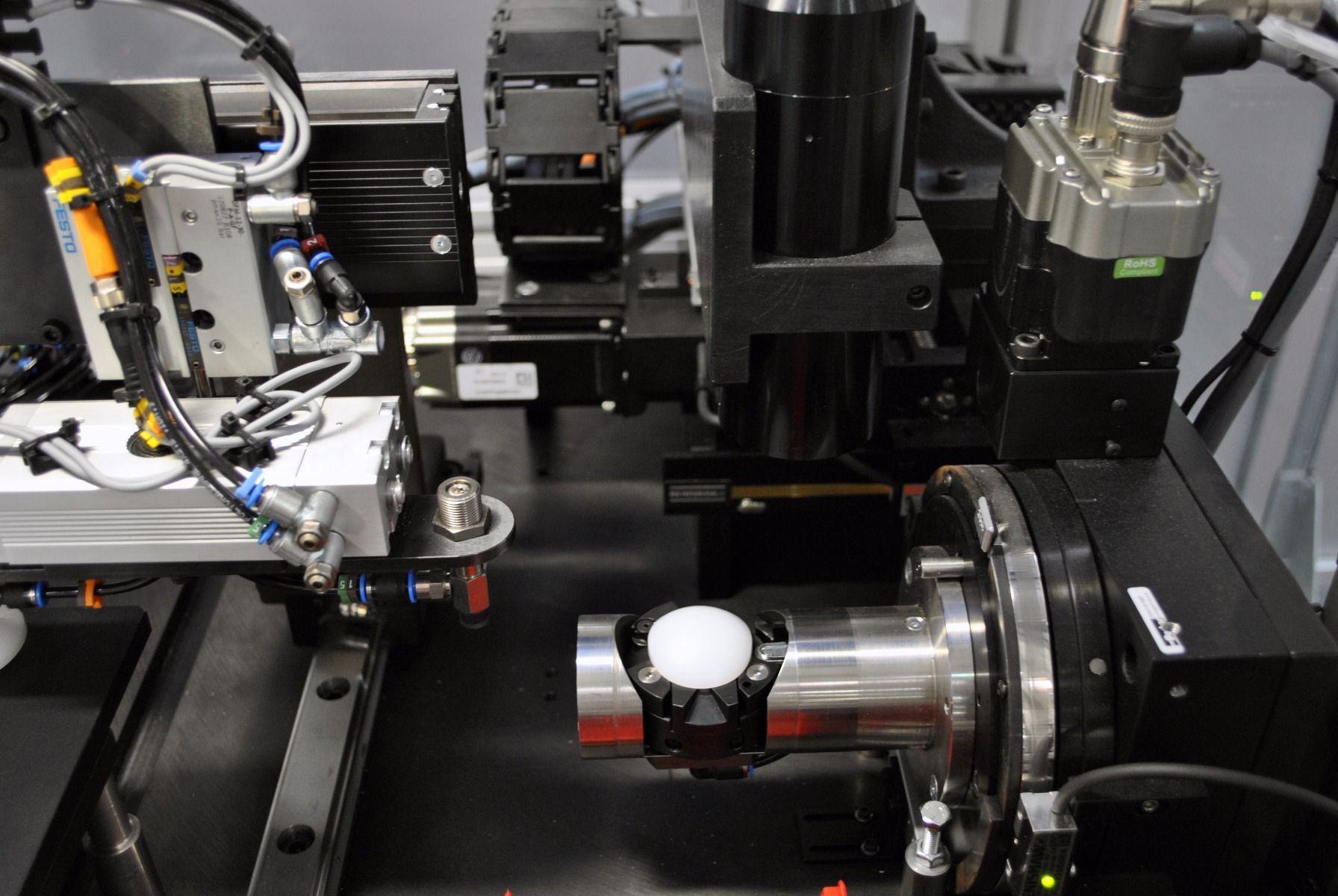

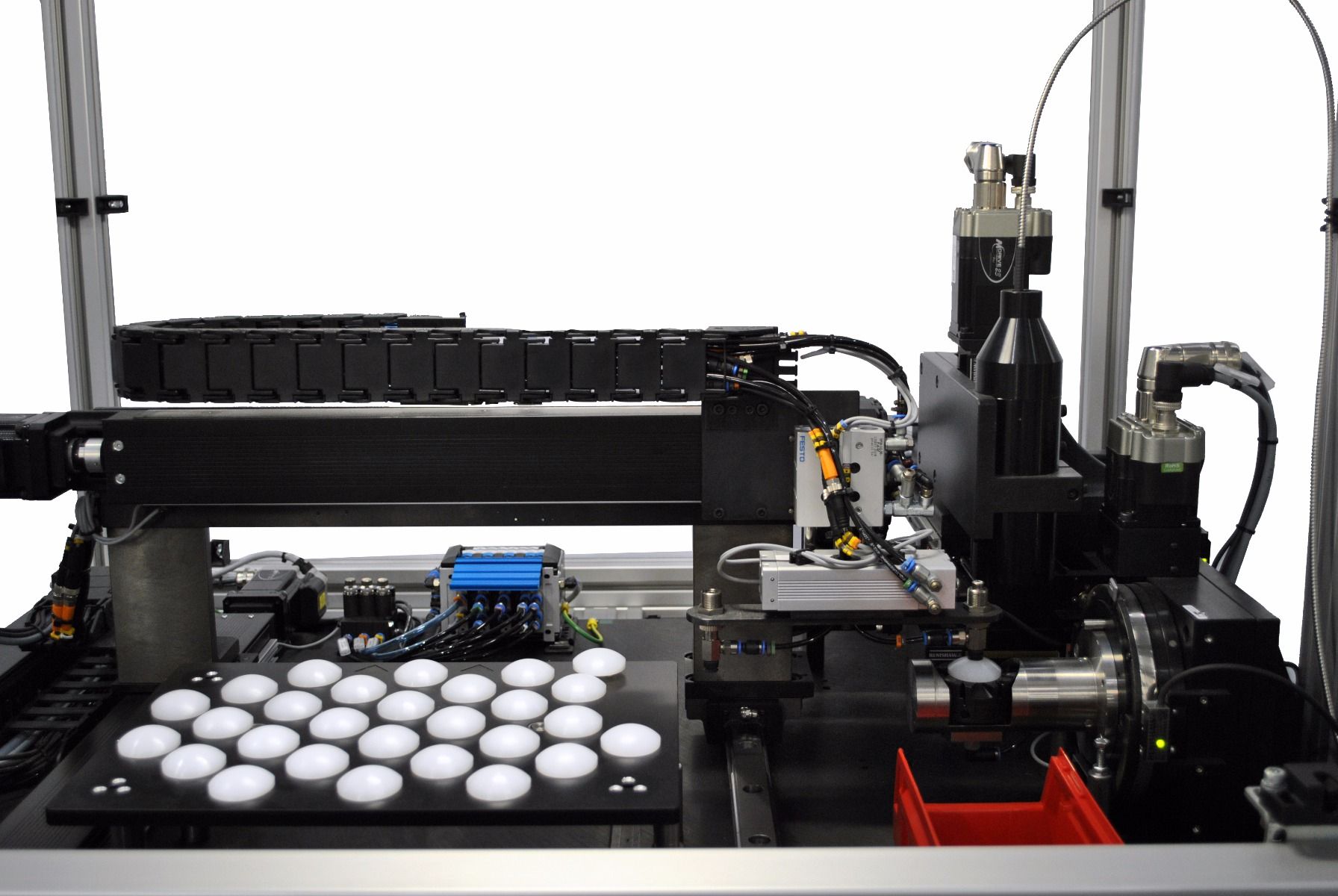

Eliminating the need for handheld and subjective profile gauges and comparators, Torus’ A540 Patella Insert Gauge utilises state of the art confocal technology for rapid non-contact inspection of surface profiles on orthopaedic patella inserts

Torus’ Polymer Patella Insert measurement system utilises state-of-the-art confocal technology for rapid non-contact inspection of surface profiles on orthopaedic patella inserts, eliminating the need for handheld and subjective profile gauges and comparators which can potentially mark the component and are less accurate. The system is designed for operational use on the shop-floor therefore giving the machine tool operator or quality control personnel a quick and repeatable measurement without having to go to the inspection lab.

Polychromatic white light us focused onto the target surface by a multi-lens optical system. The lenses are arranged so that the white light is dispersed into monochromatic light by controlled chromatic aberration. A specific distance to the target is assigned to each wavelength by a factory calibration. Only the wavelength which is exactly focused on the target is used for measurement. This light reflected from the surface is passed through a confocal aperture onto a spectrometer which detects and processes the spectral changes.

The 4-axis motion control system is driven by high-accuracy micro-stepping motors giving positional feedback, providing high resolution and high speed with stability and reliability.

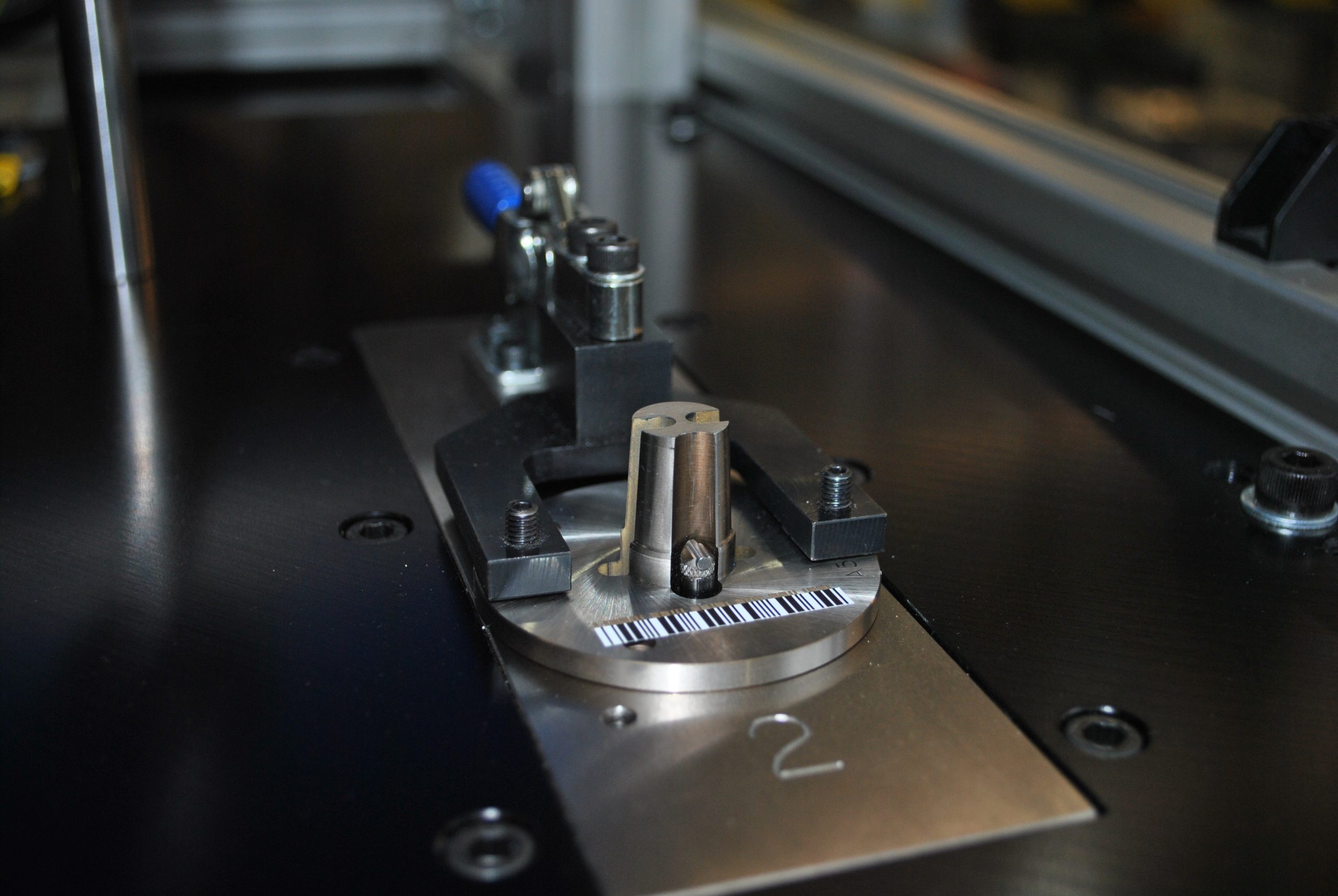

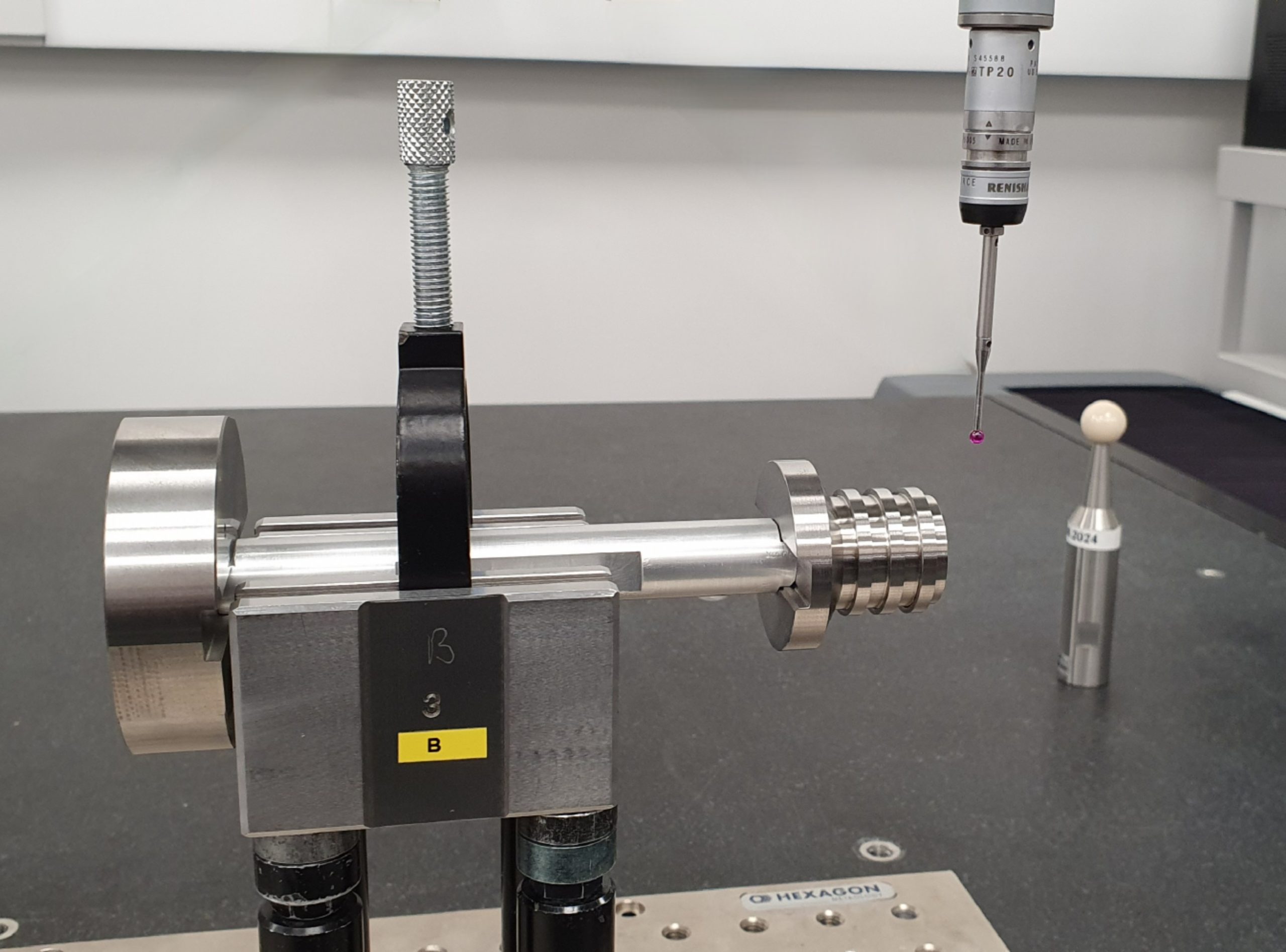

Torus’ A539 Mechanical Taper Gauge measures external and internal tapers and was developed and manufactured specifically to meet a demand in femoral head production.

The new floor standing taper gauge is the latest addition to Torus’ range of orthopaedic inspection systems. Designed specifically for orthopaedic hip manufacturers who need to control their femoral heads, this inspection gauge gives critical measurement information on the internal taper dimensions.

The gauge can accommodate the full range of femoral heads and measures a variety of different features.

To operate, simply scan the batch card with a barcode reader and the software will automatically select the relevant component type from the menu and the powerful Window software will prompt you to load the specific femoral head.

Measurement Features

Feature

Technical Specification

Capabilities

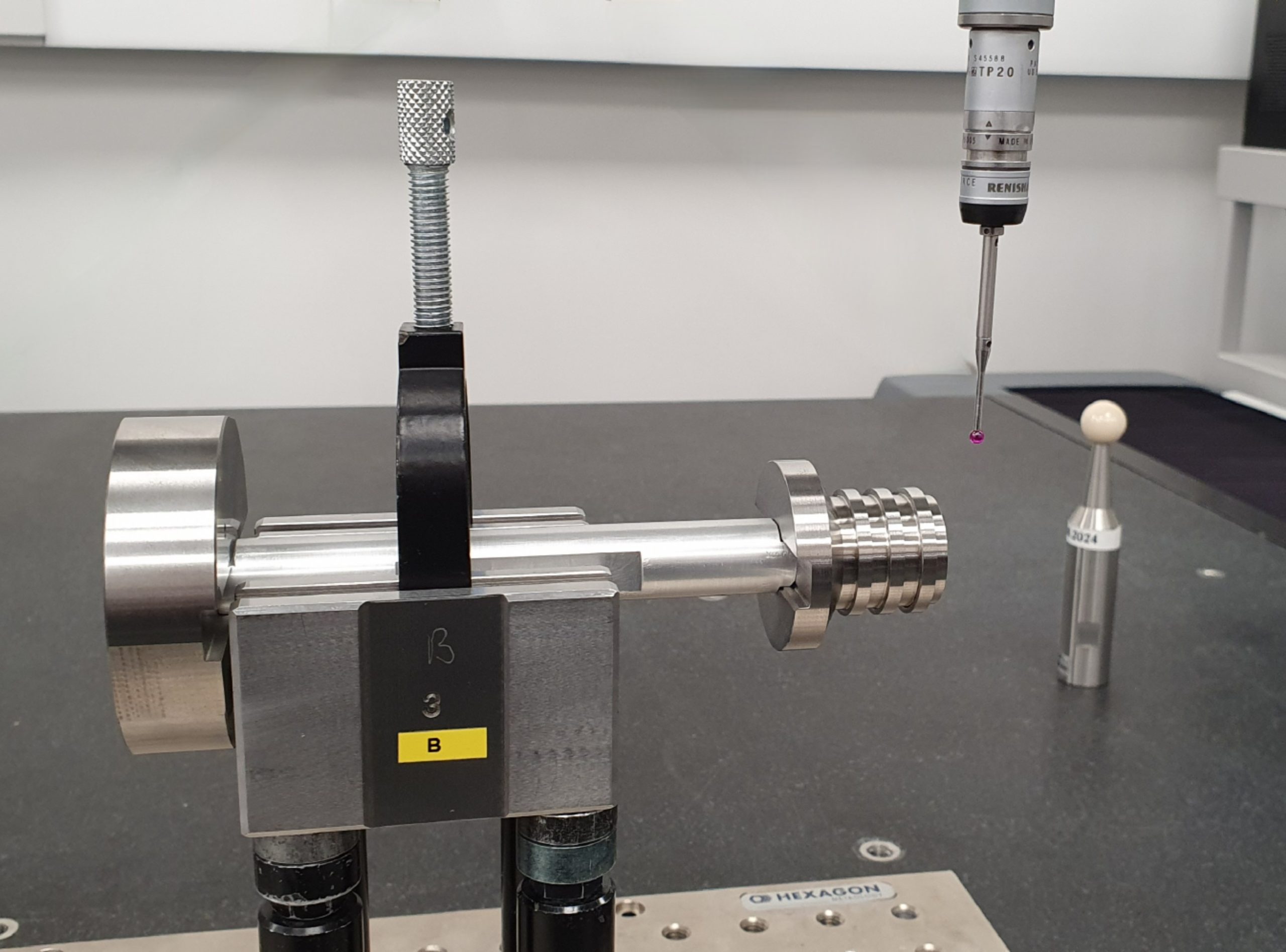

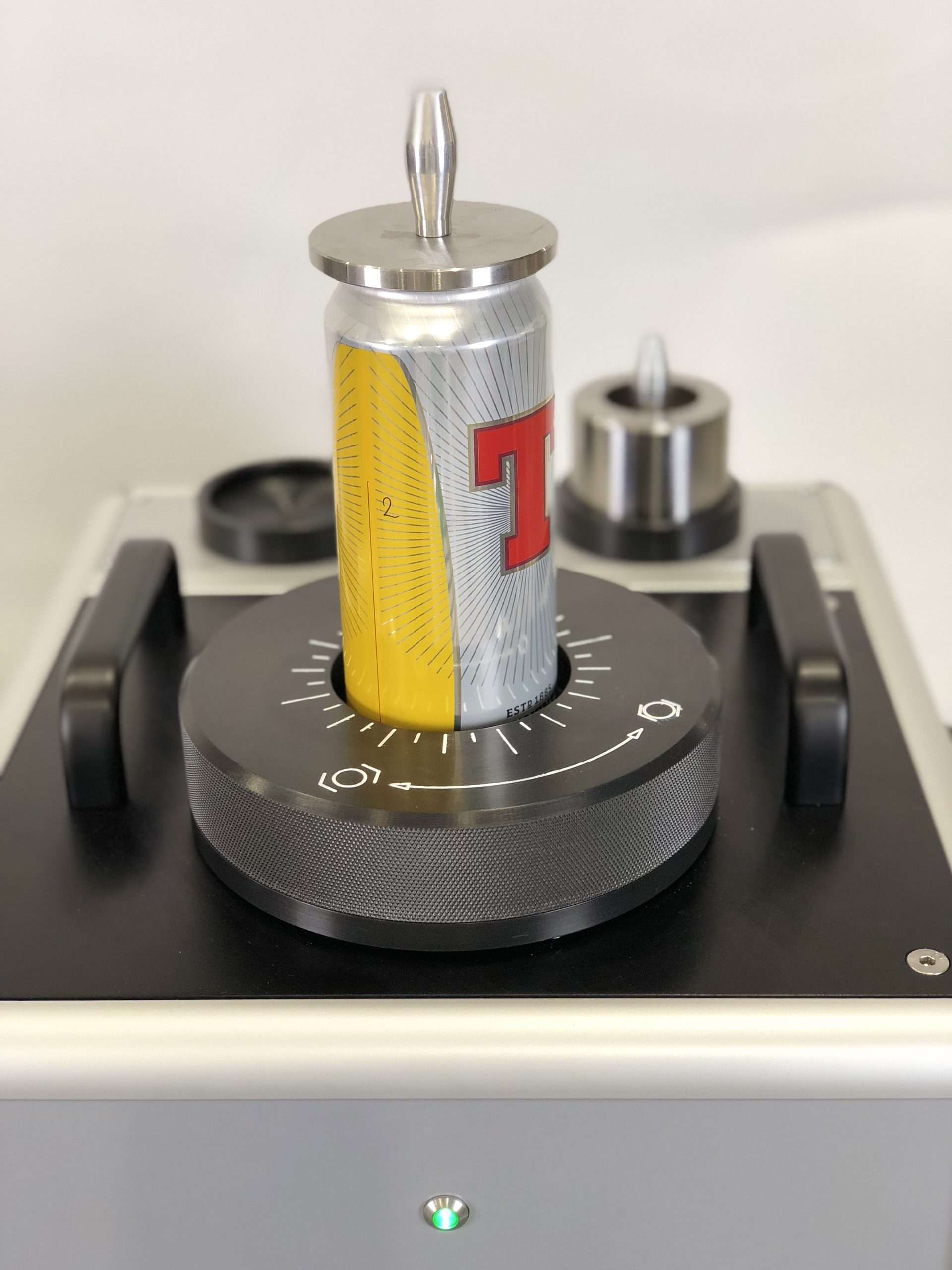

The Beverage Can Master supplied with your gauge is extremely important for the reliability of your measurement results.

As the original equipment manufacturer Torus Measurement Systems recommends that your Master is re-calibrated annually to continually assess for wear, damage and integrity. This ensures your product quality is never compromised.

Torus are a leading manufacturer in gauging systems for the packaging industry worldwide, with the expertise to understand the functionality and critical features of your master.

Torus Measurement Systems Master Calibration Service offers:

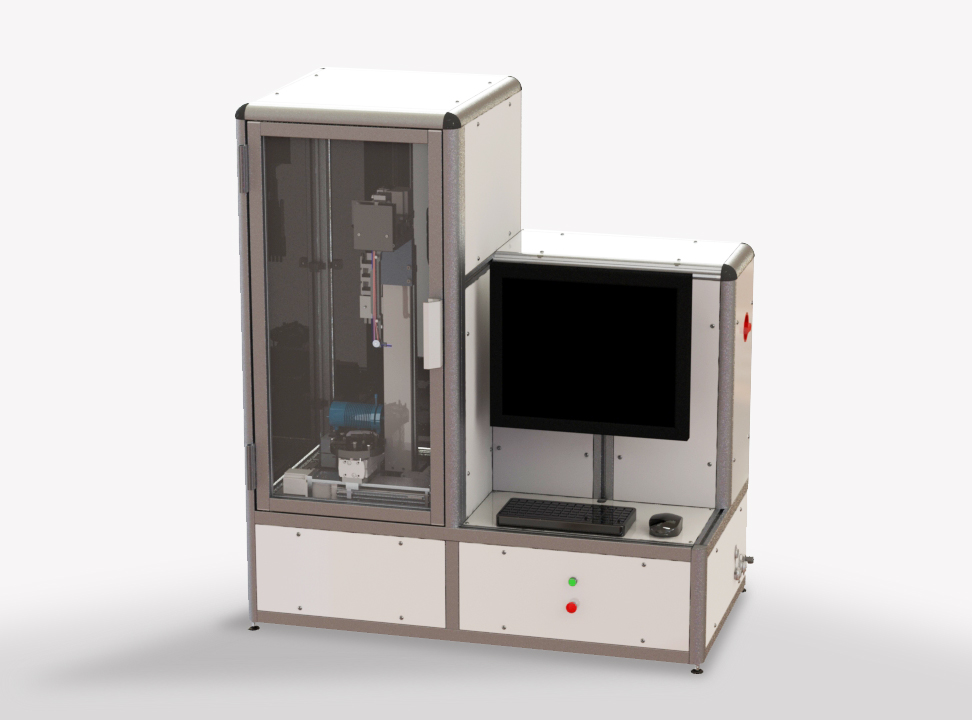

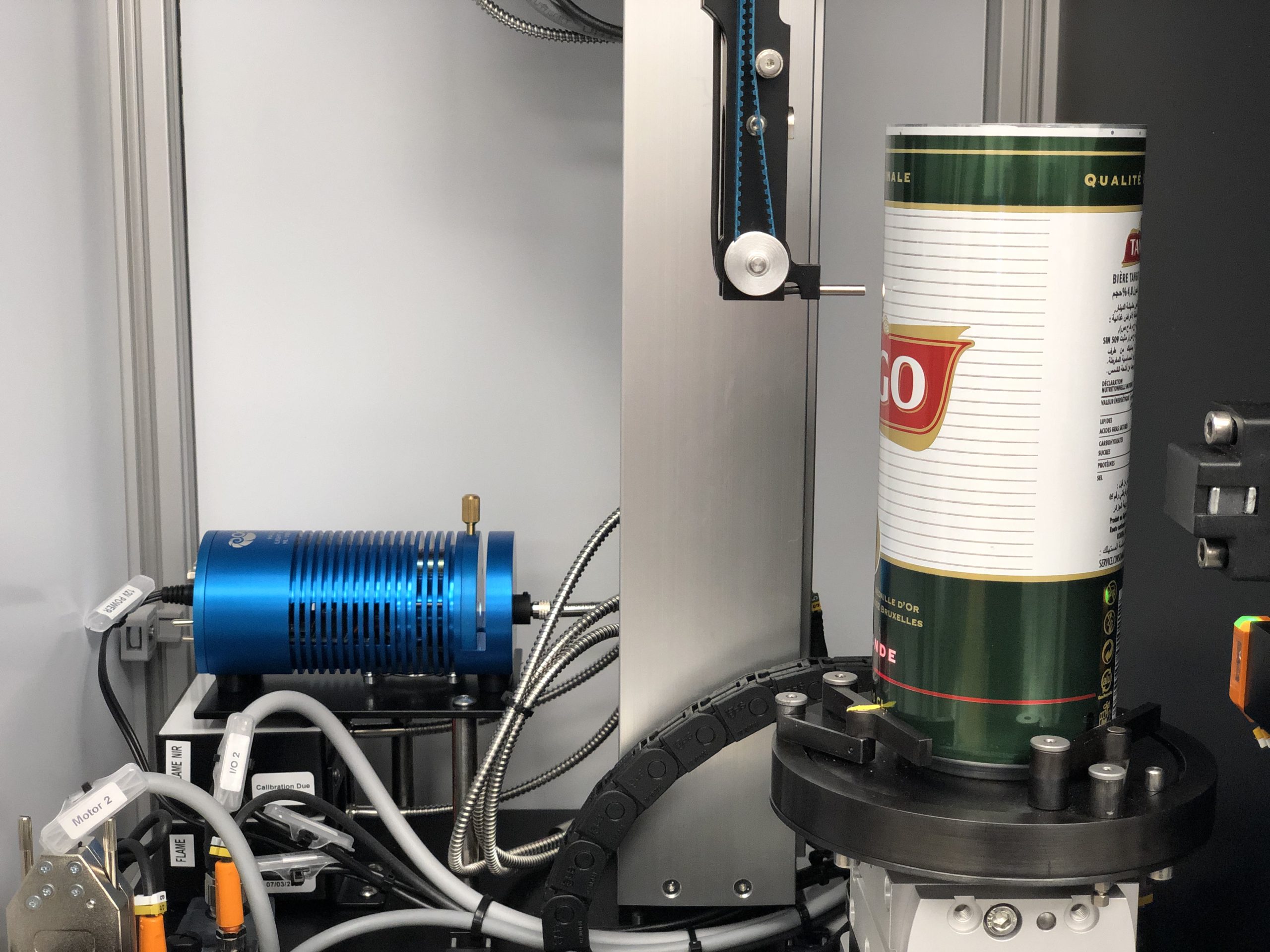

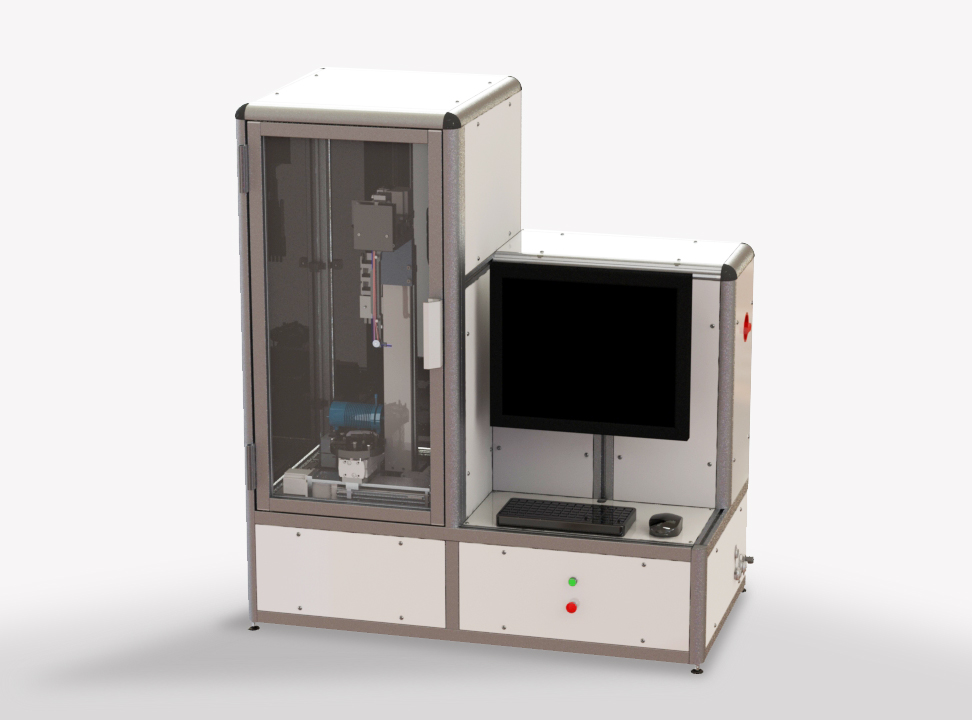

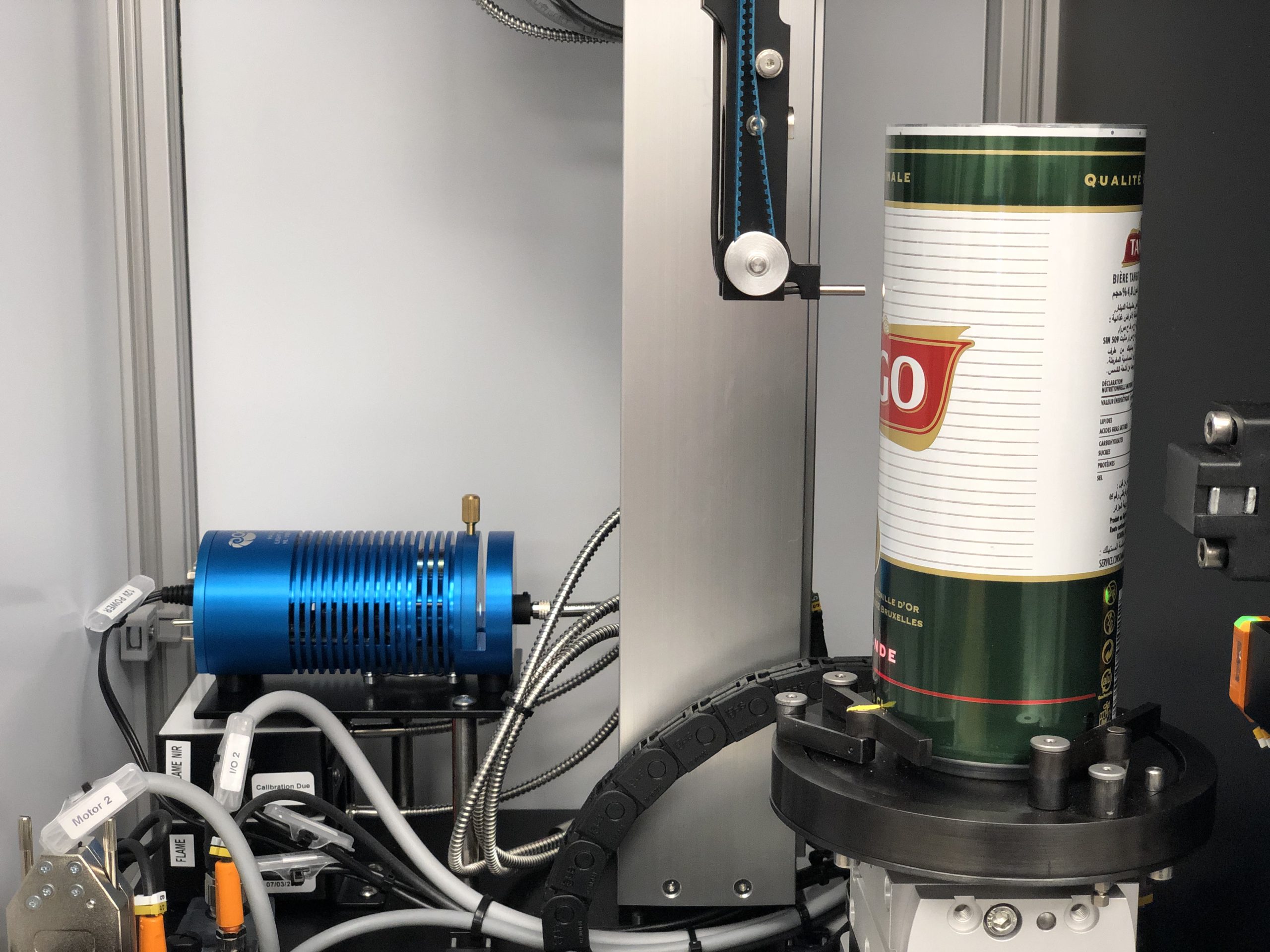

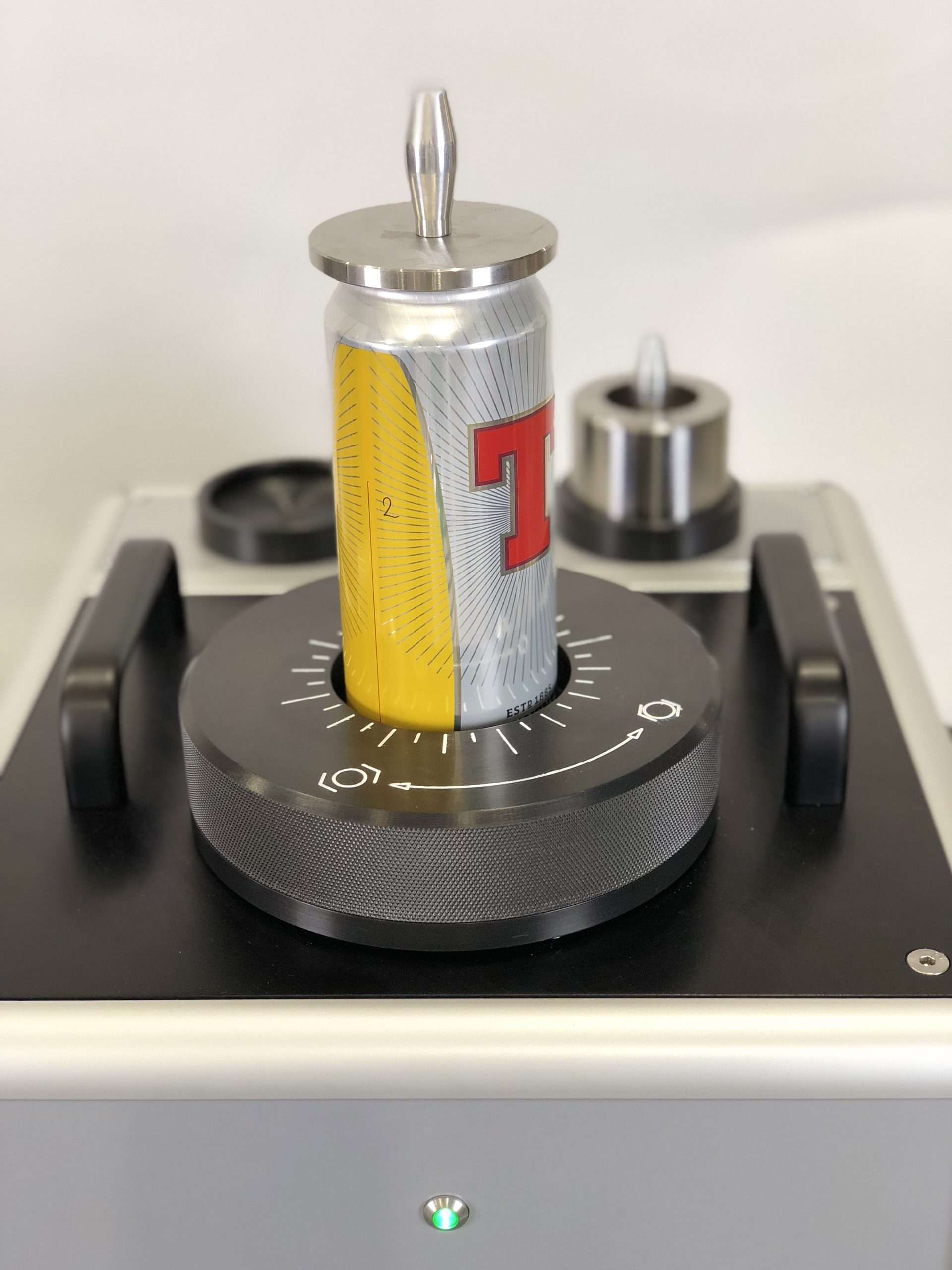

The Z340 Semi-Automatic Bench Top Coating Analyser has been developed to give detailed distribution analysis of the internal and external lacquer on a beverage can

The system utilises state-of-the-art non-contact spectroscopy techniques and is suitable for both aluminium and steel can inspection.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

Gauge Features

Start with the standard Z340 Semi-Automatic Bench Top Beverage Can Coating Analyser…

… add any of the below detailed optional modules at any time

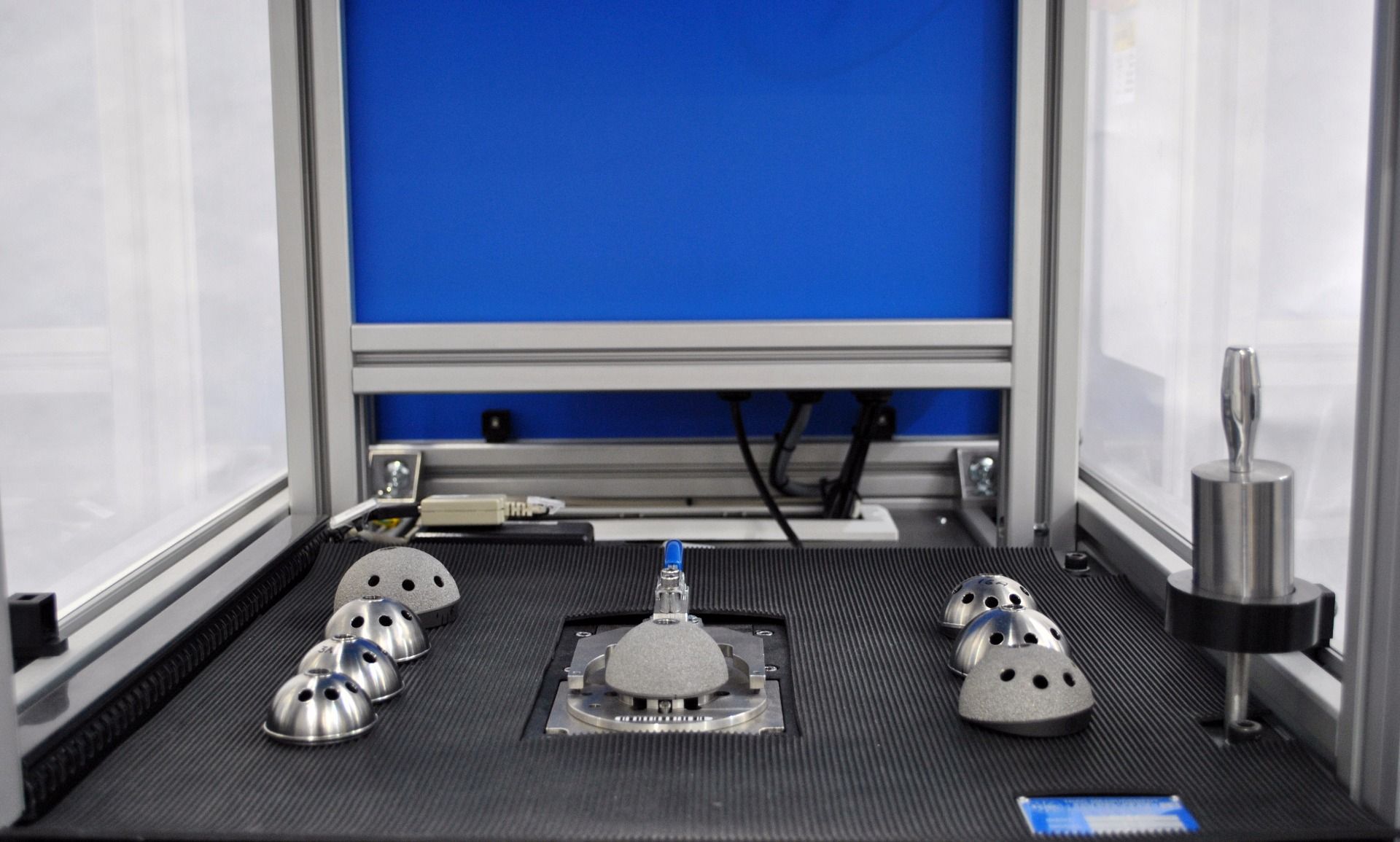

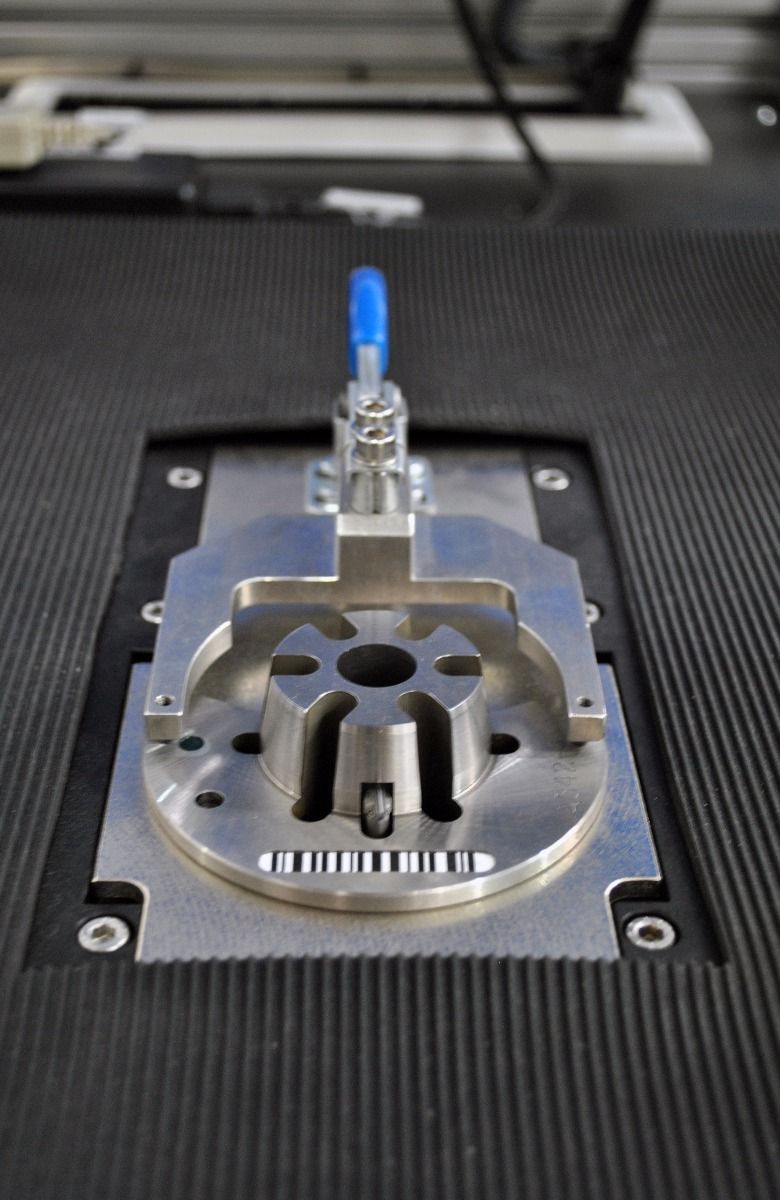

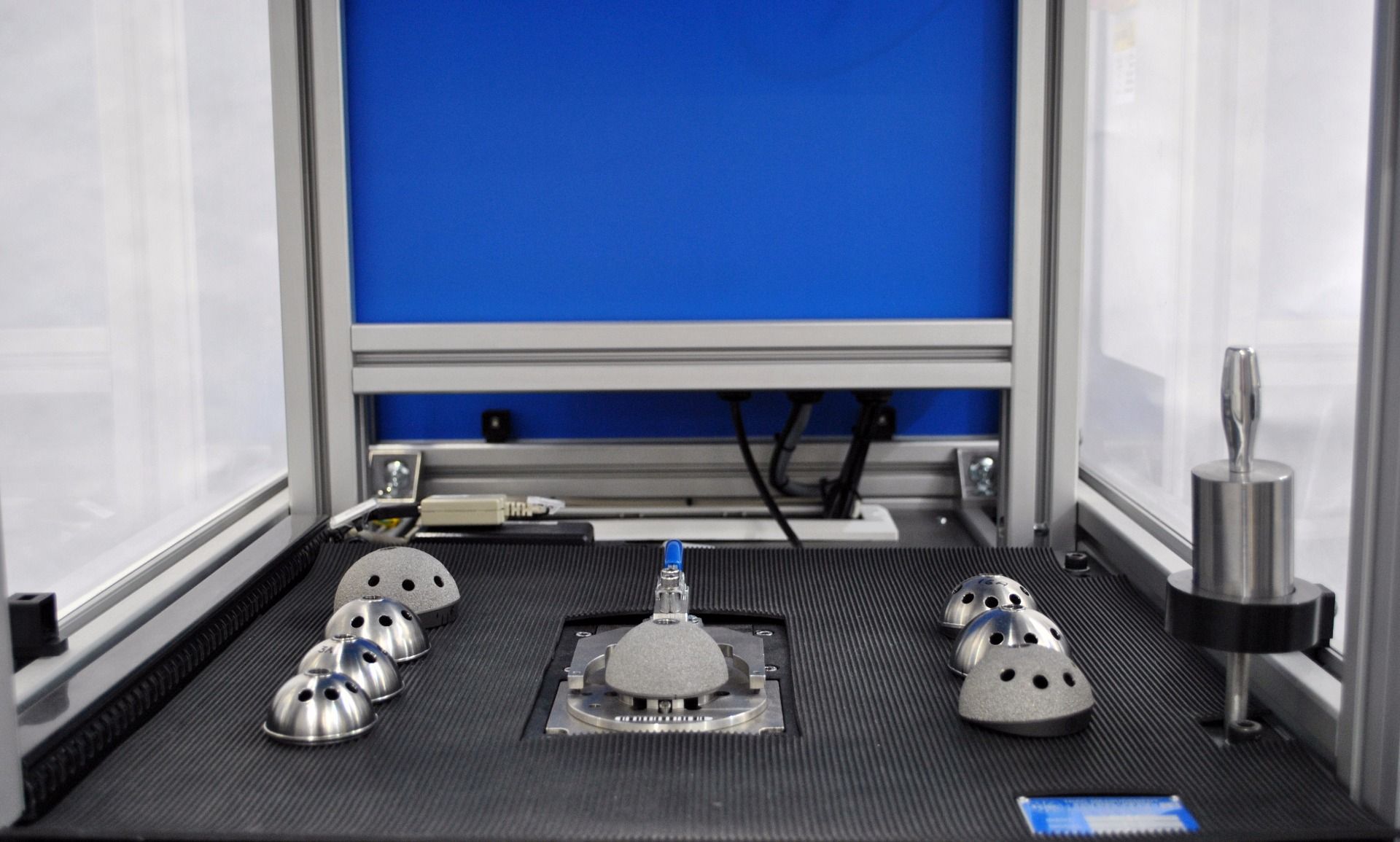

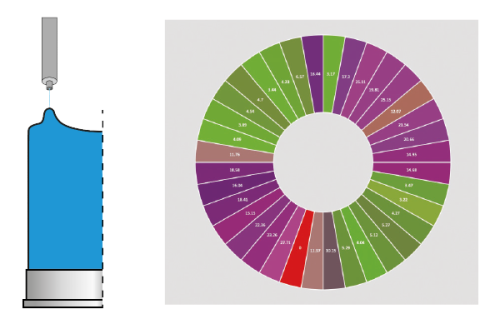

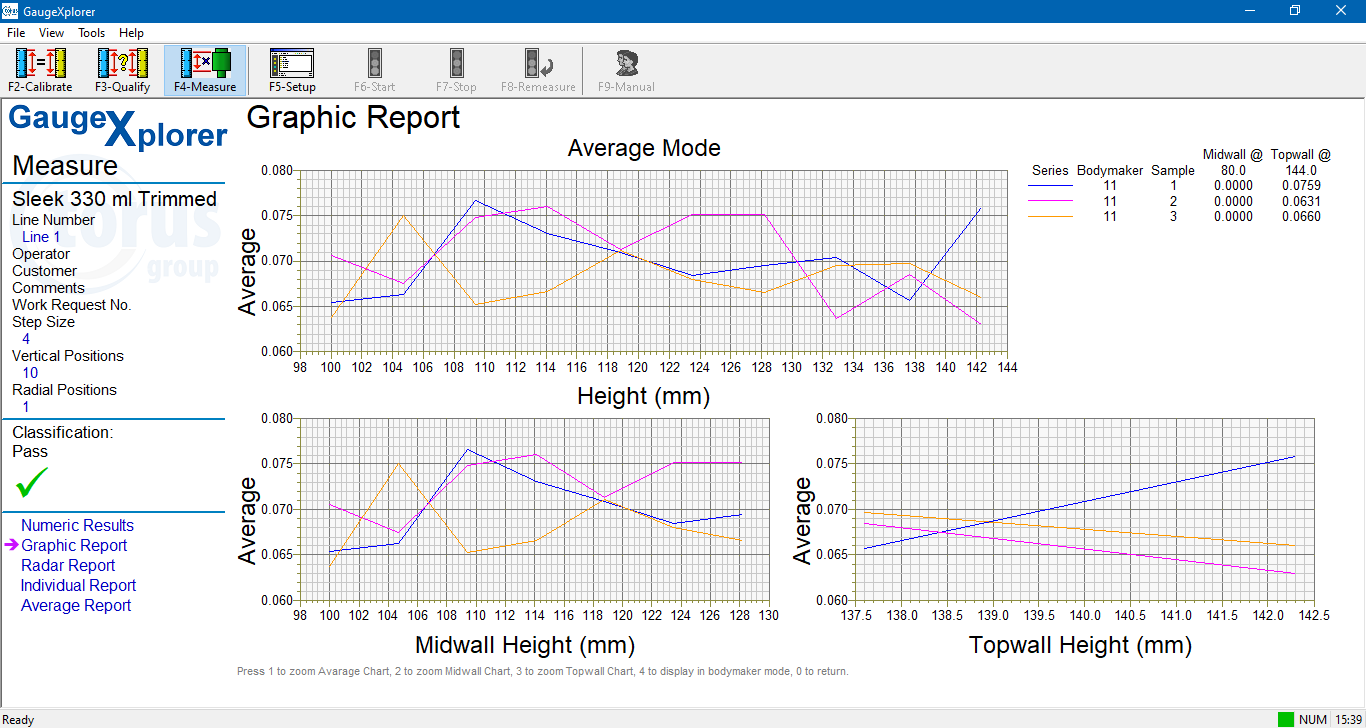

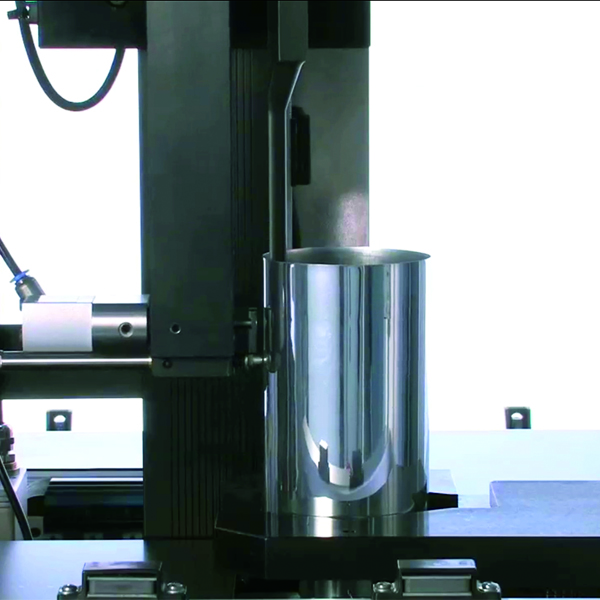

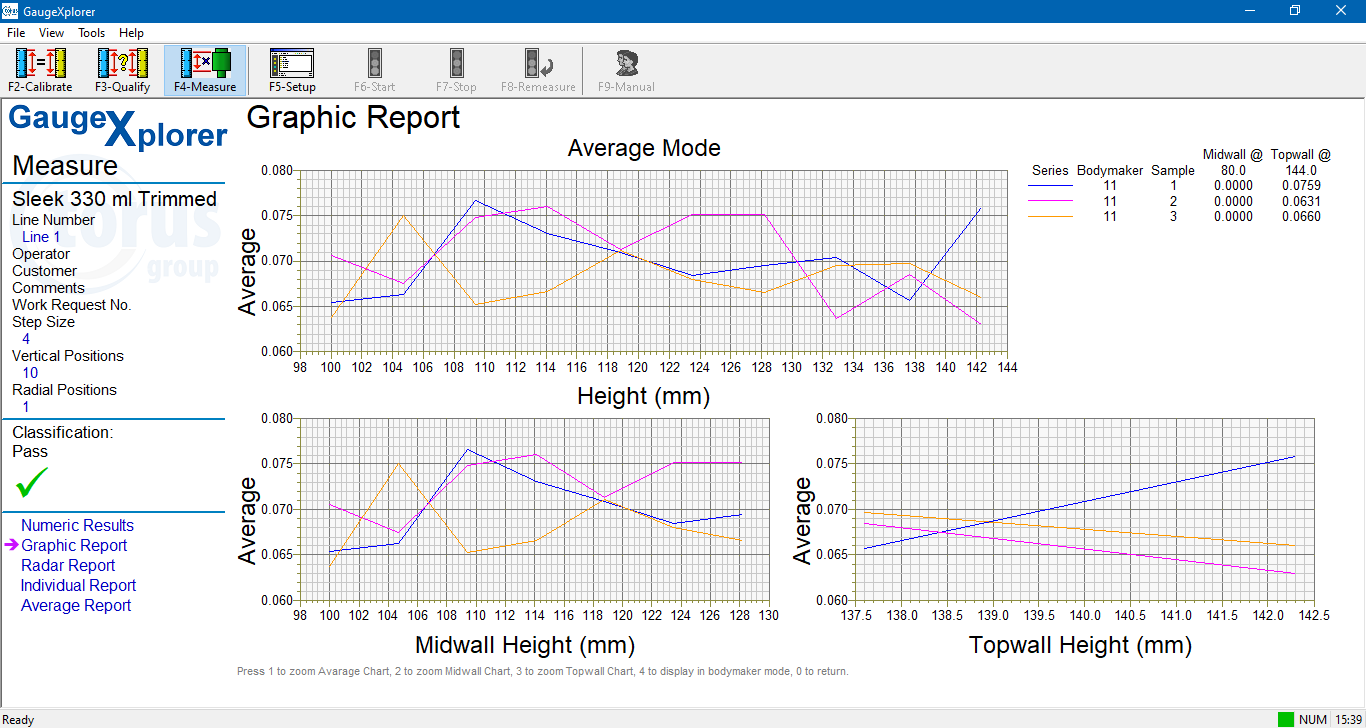

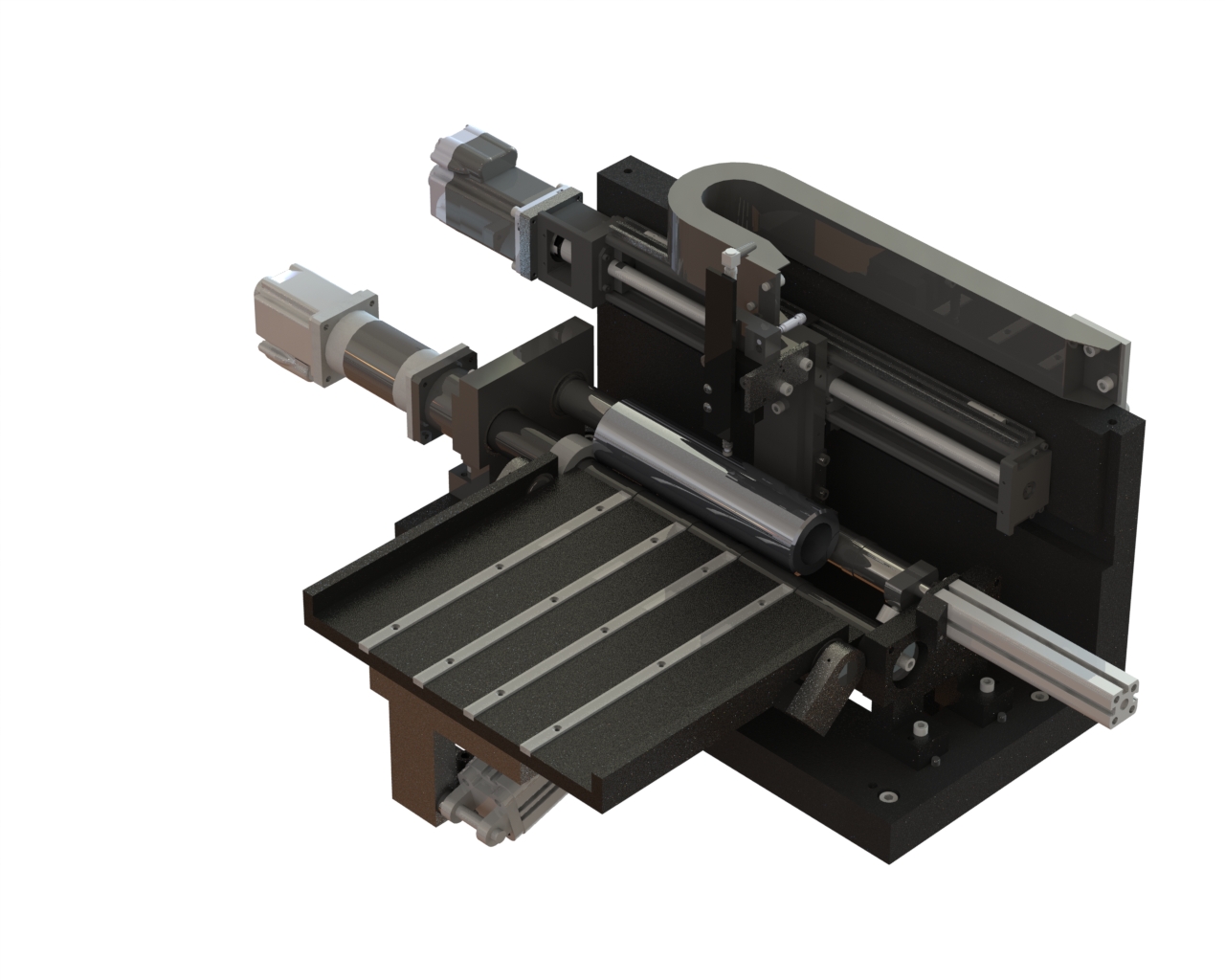

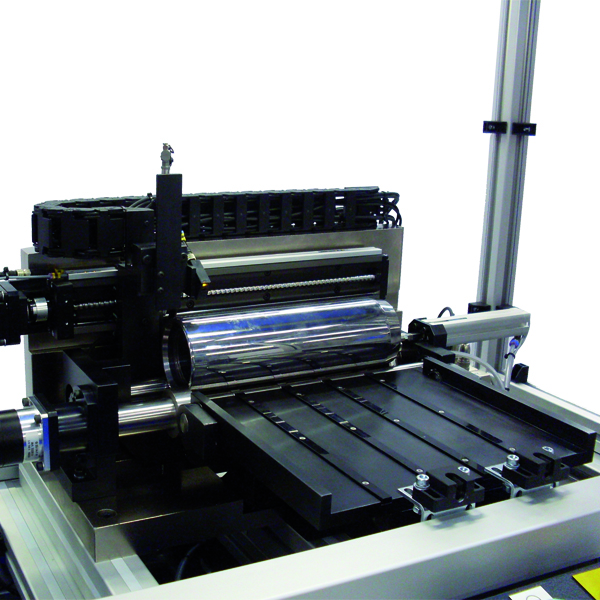

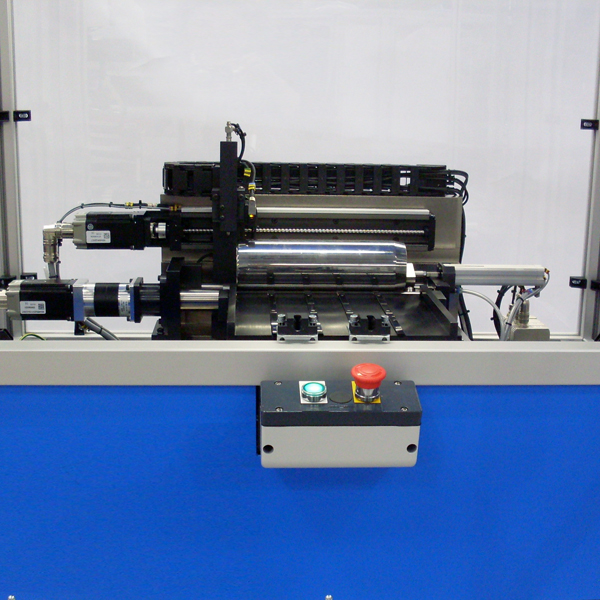

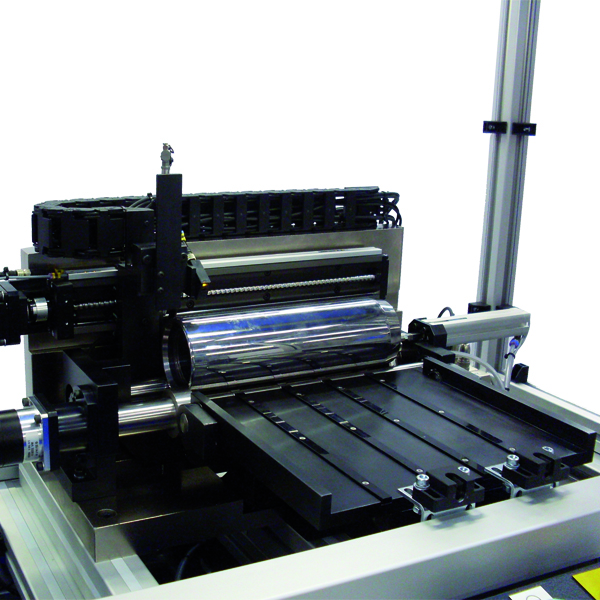

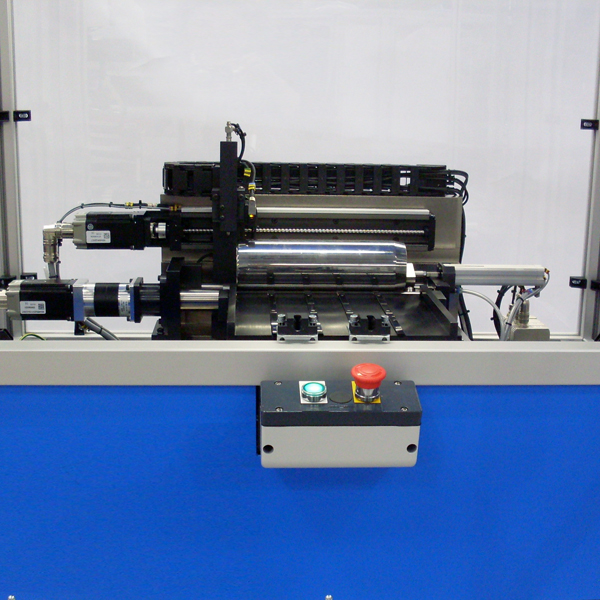

The Z314 Semi-Automatic Wall Thickness Analyser defines the standard for dimensional inspection

The Z314 measures cups and straight walled cans’ wall thickness. Utilising a single point wall thickness transducer based on industry standard Torus Z301 Front End Gauge.

The Z314 Wall Thickness Analyser ensures accurate wall thickness inspection of cups, straight walled cans or 2pc bottle cans with no need for tooling changeover.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

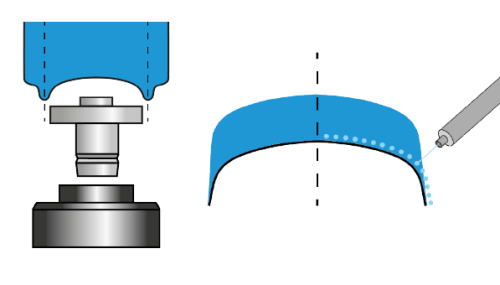

Designed specifically for 2 piece can manufacturers who “reform” their cans, this small inspection gauge gives critical measurement information on the setup of each head of your reformer

The scanner utilises proven contact measurement technology to scan the form of the reformed profile and incorporates a entering check to accurately locate Ø 202 – Ø 300 body cans.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

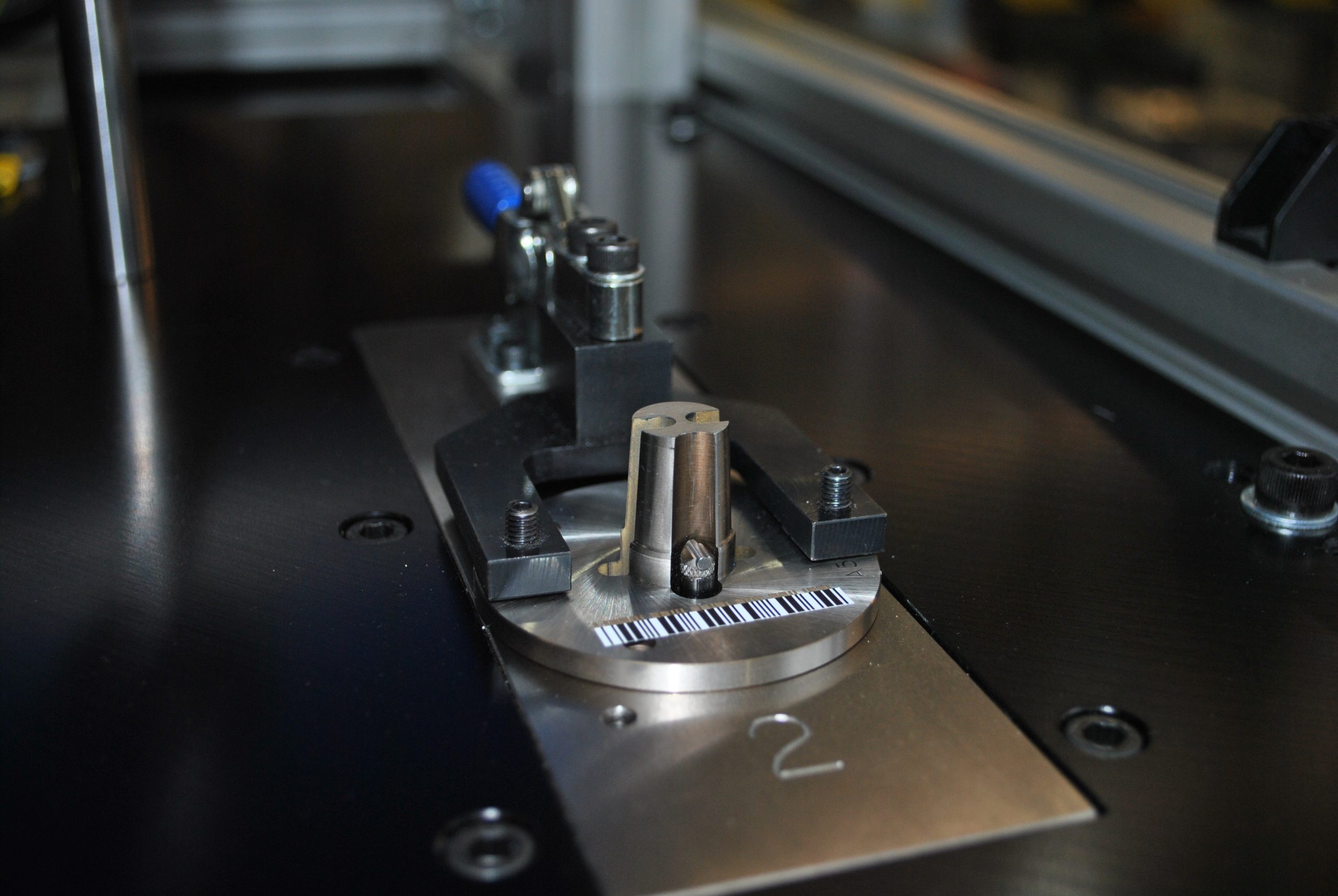

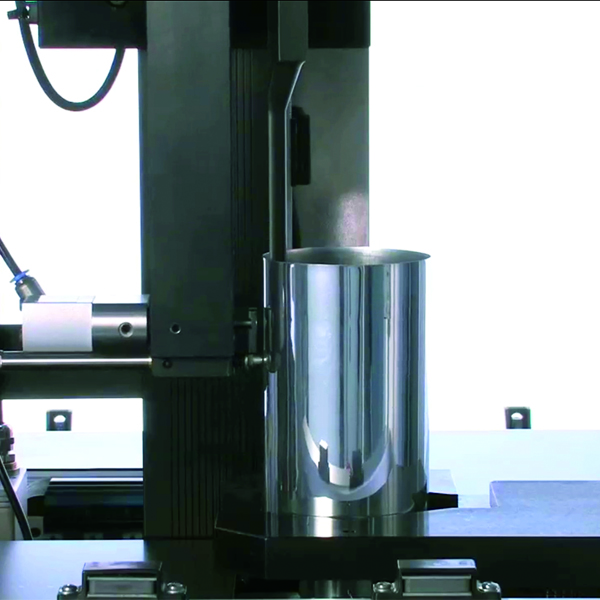

The Z311 Punch Inspection Gauge defines the standard for dimensional inspection of 2 piece beverage/beer can punch tooling

The Z311 Punch Gauge has been designed to measure a wide range of Punch sizes typically found in the metal container industry. Available as a semi-automatic (manually loaded) system, designed to measure a wide range of punch sizes typically found in the metal container industry.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

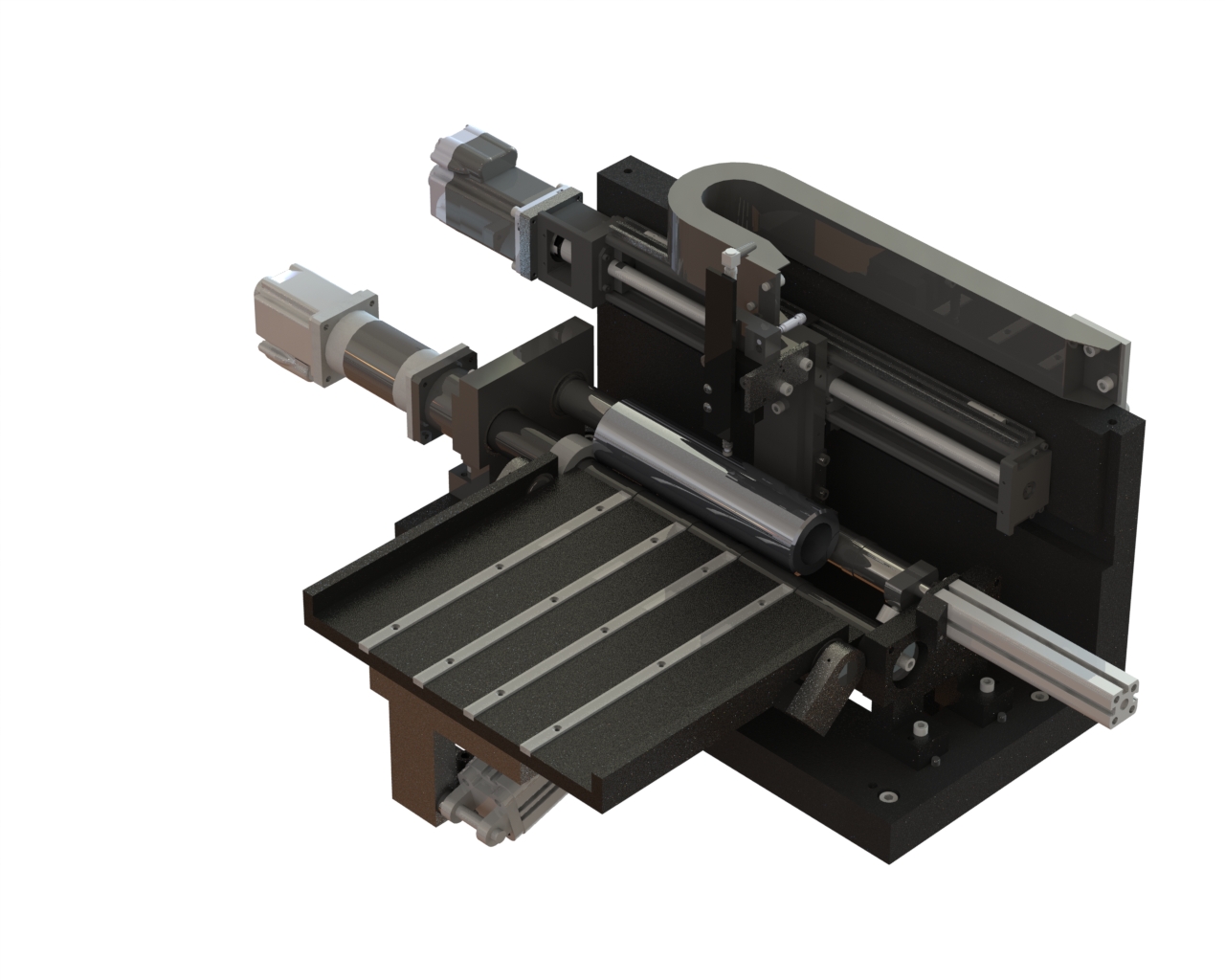

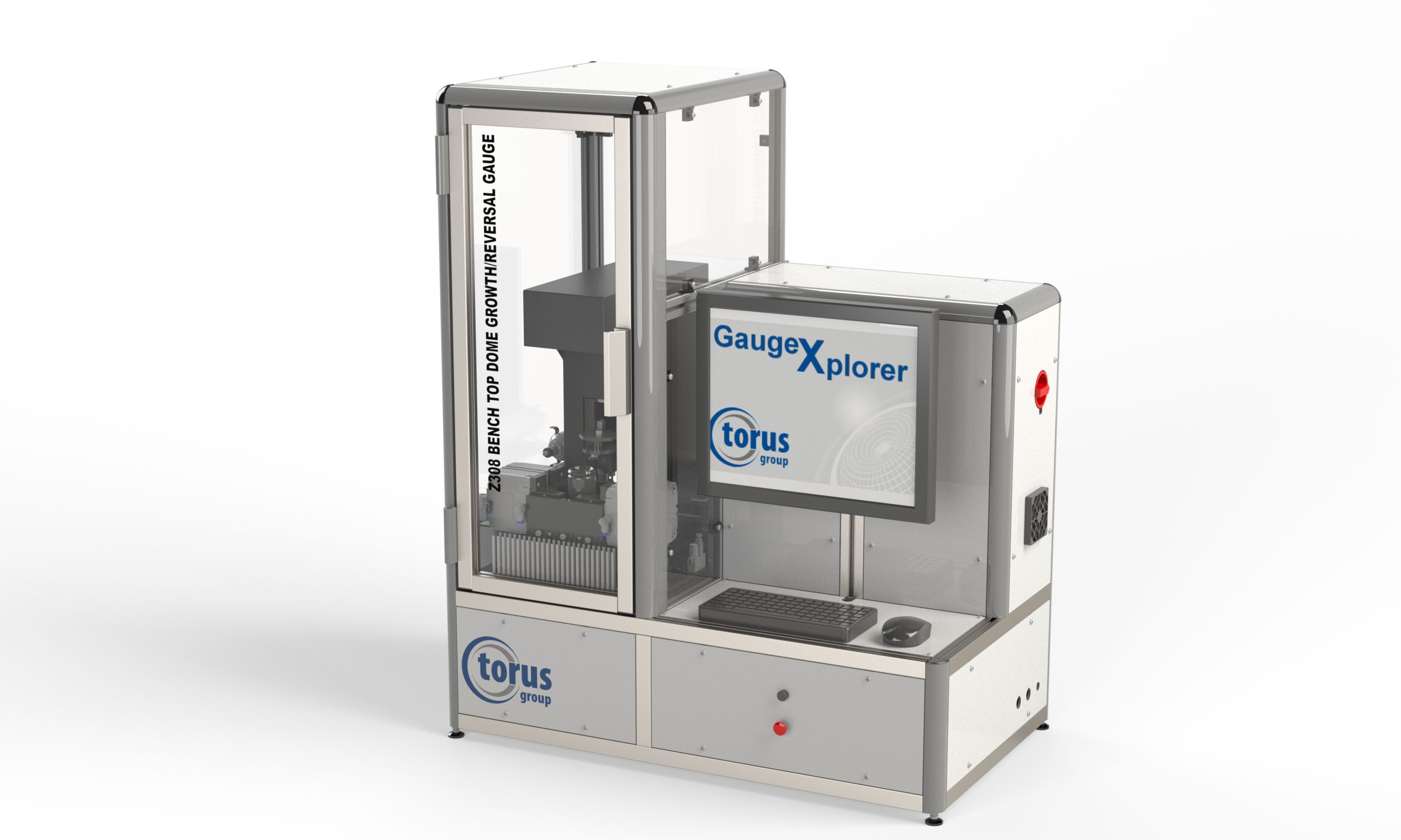

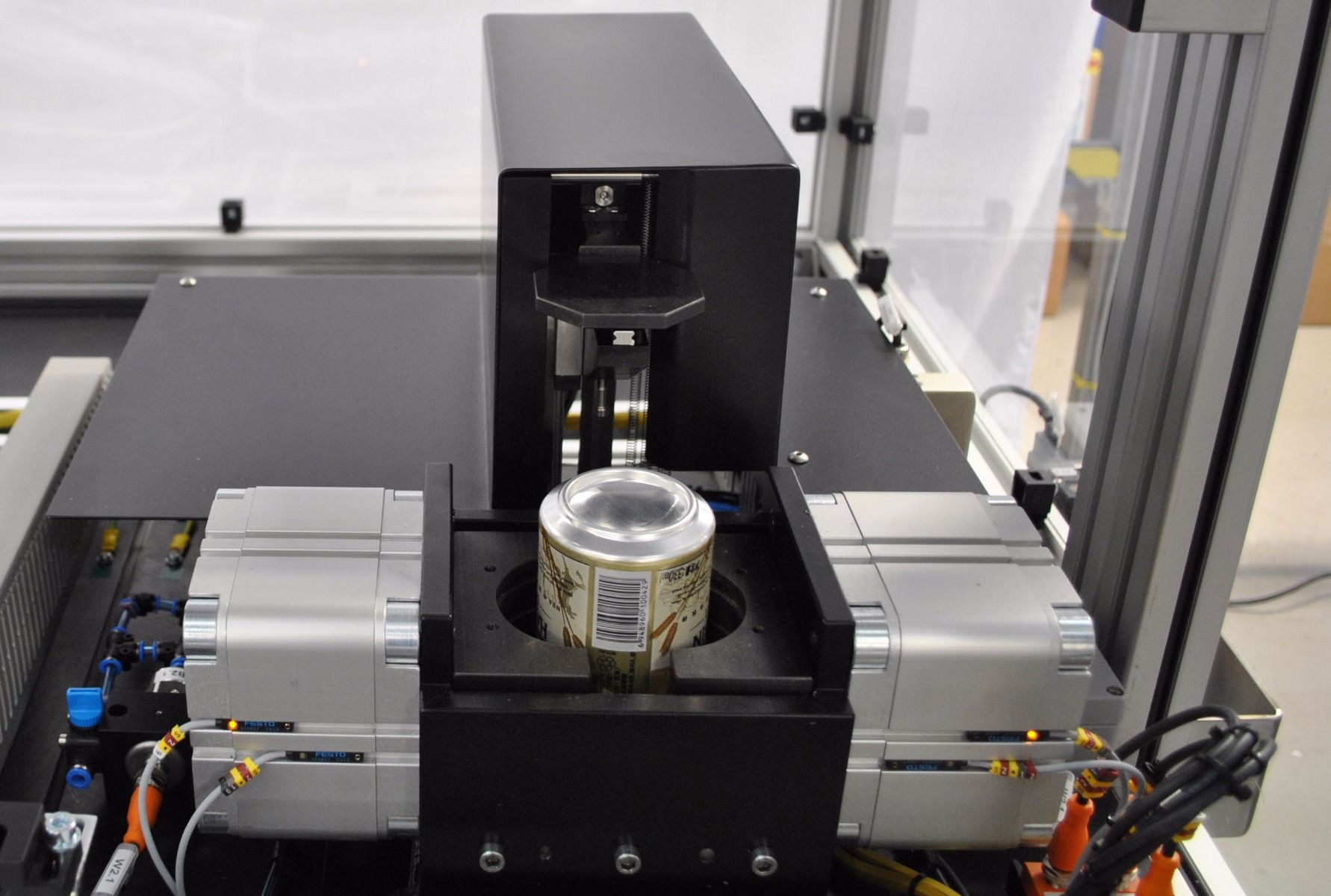

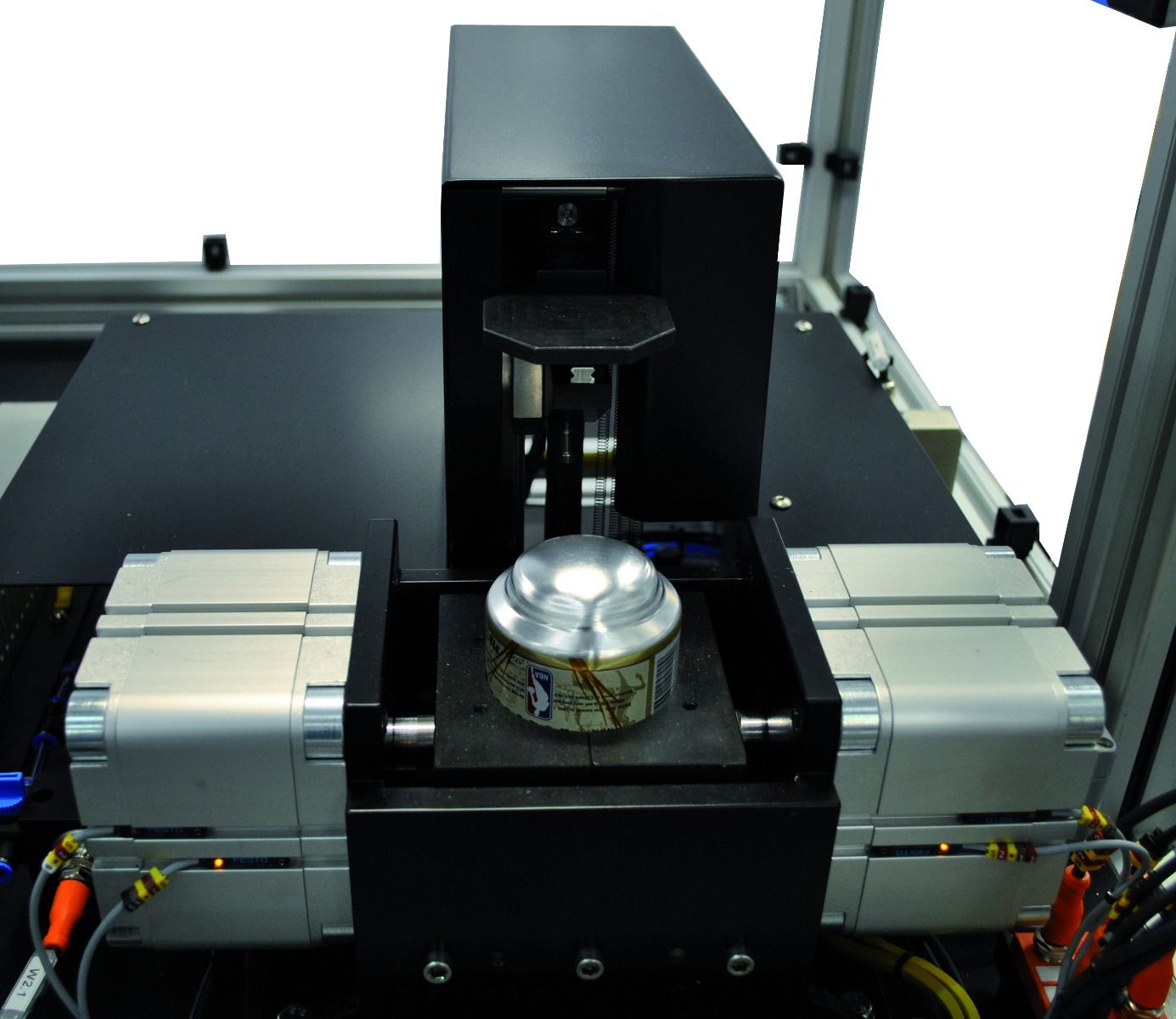

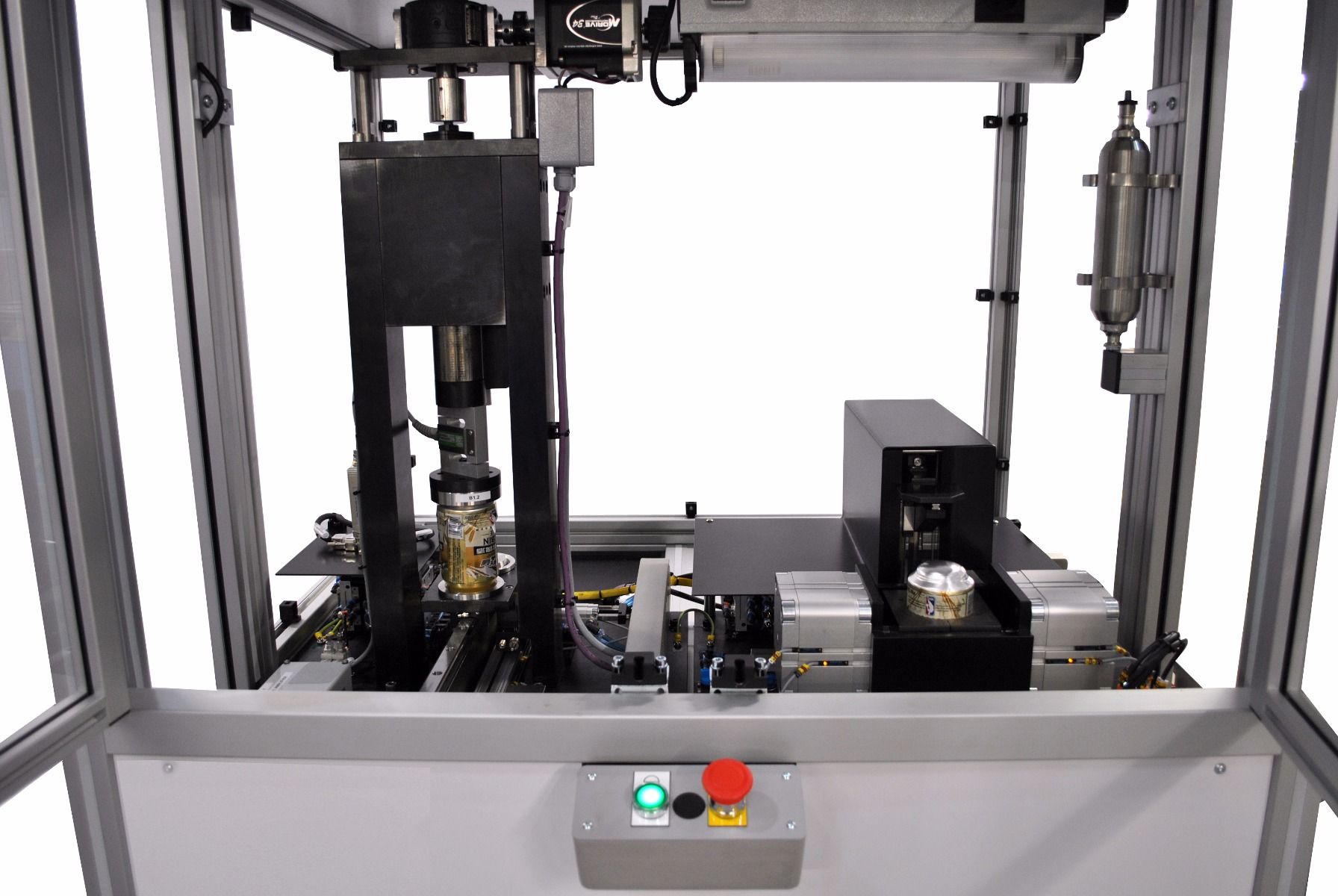

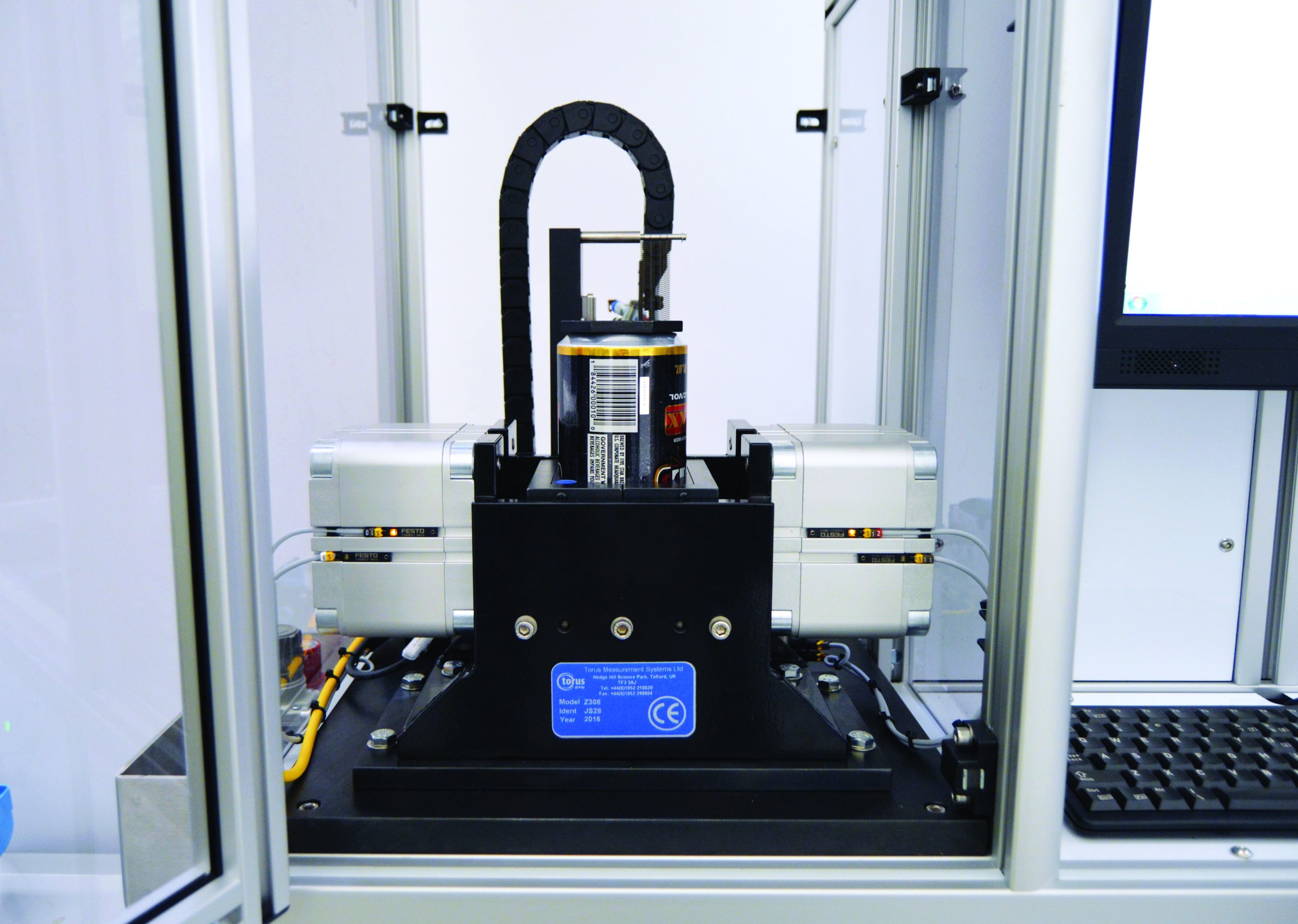

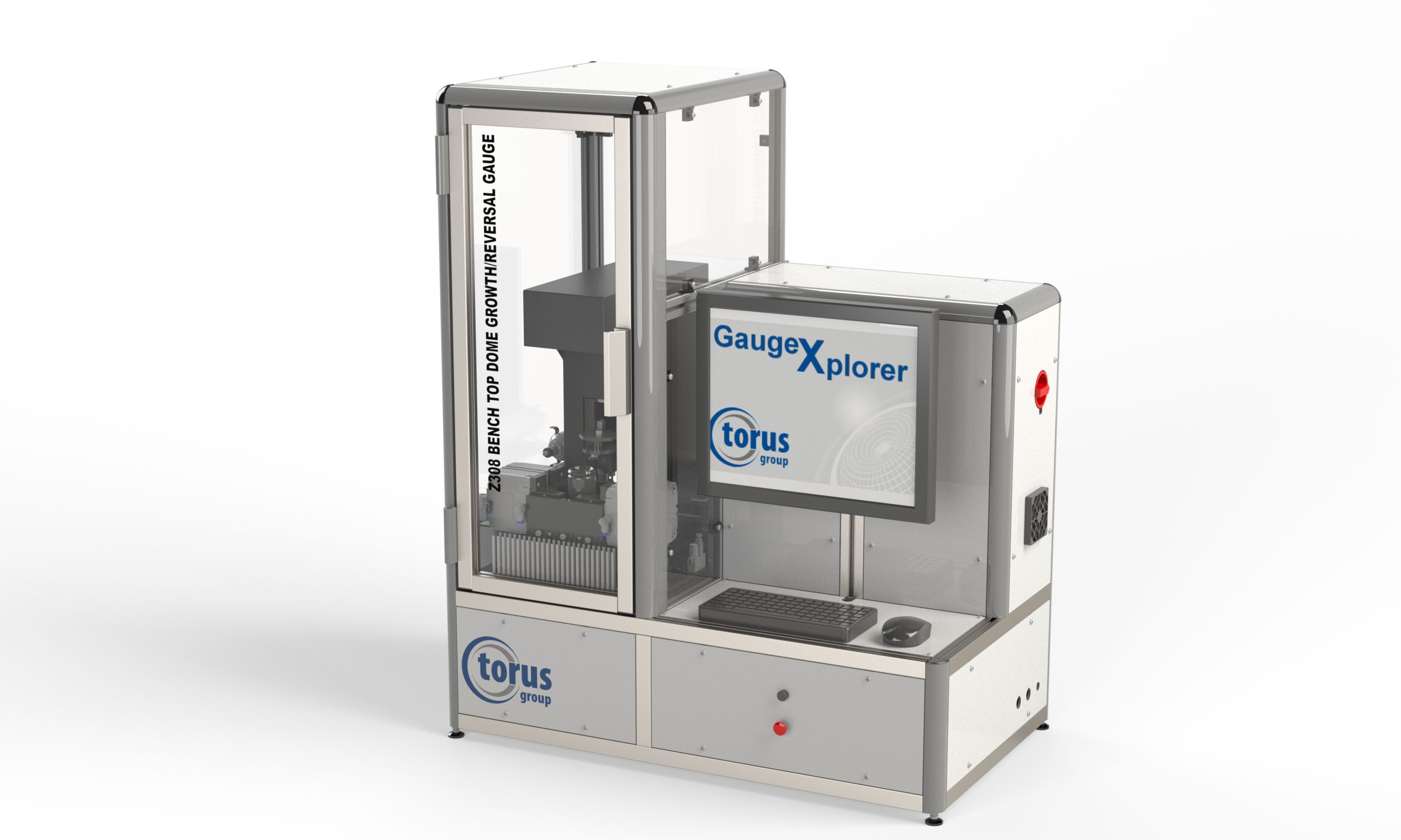

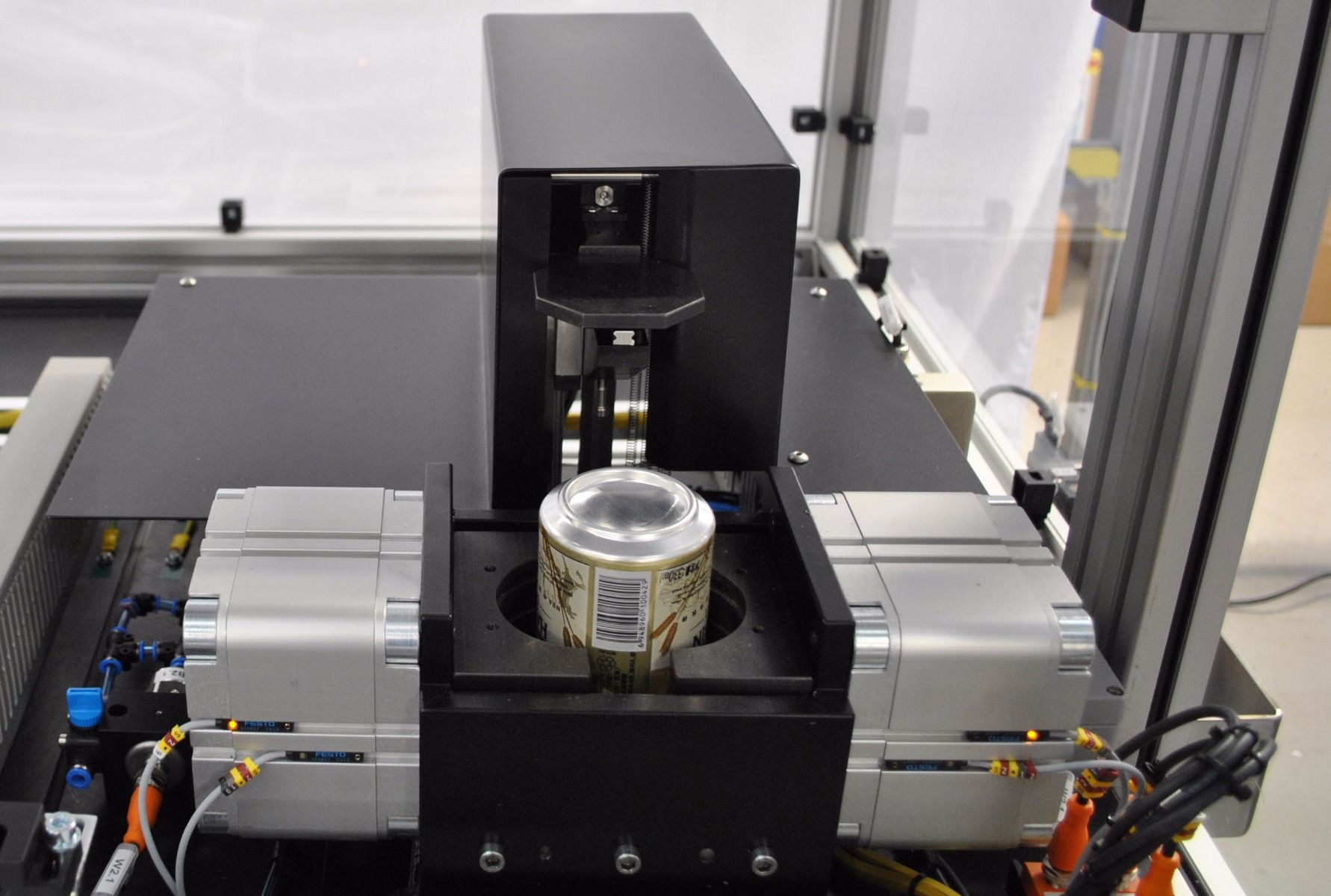

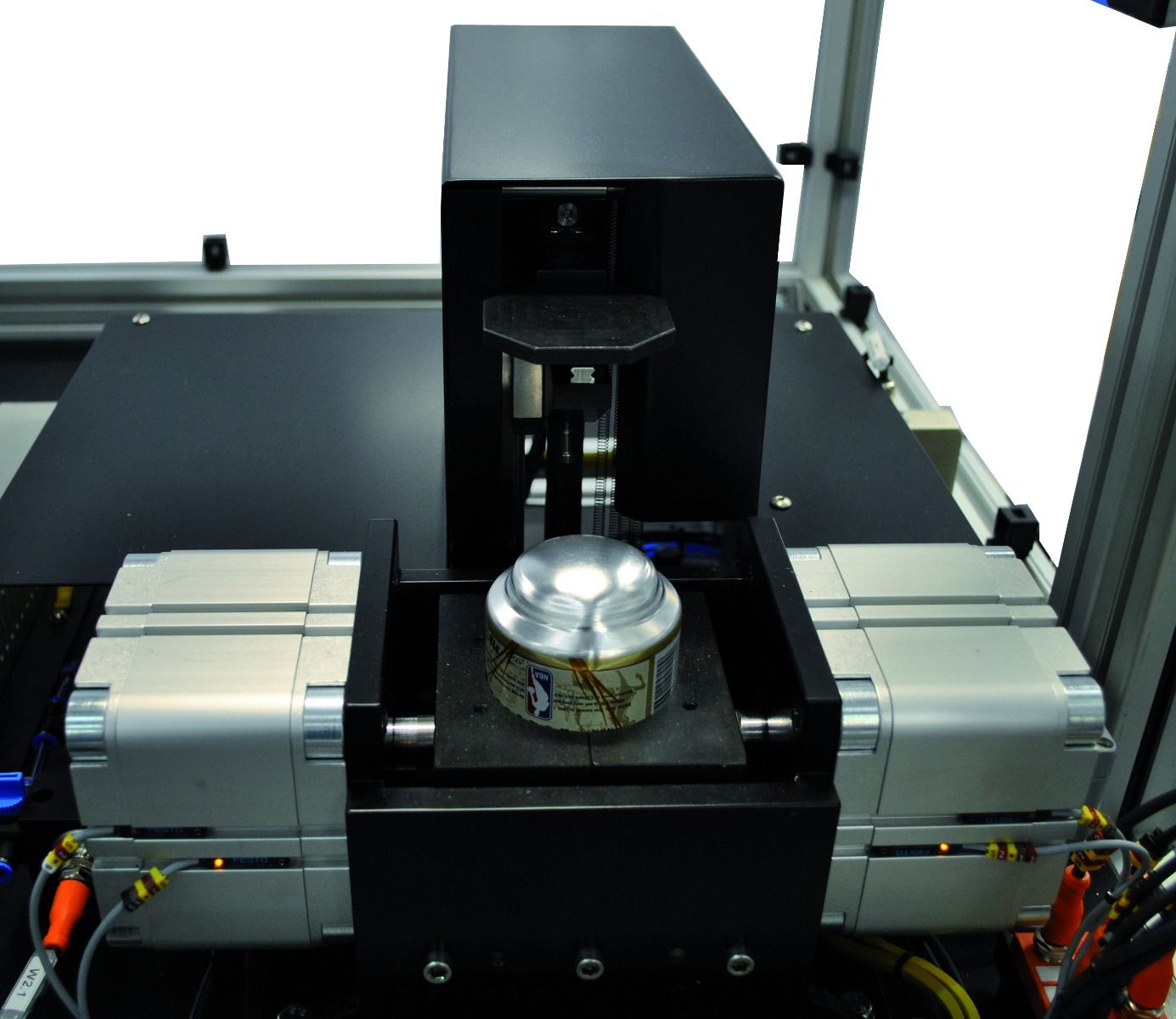

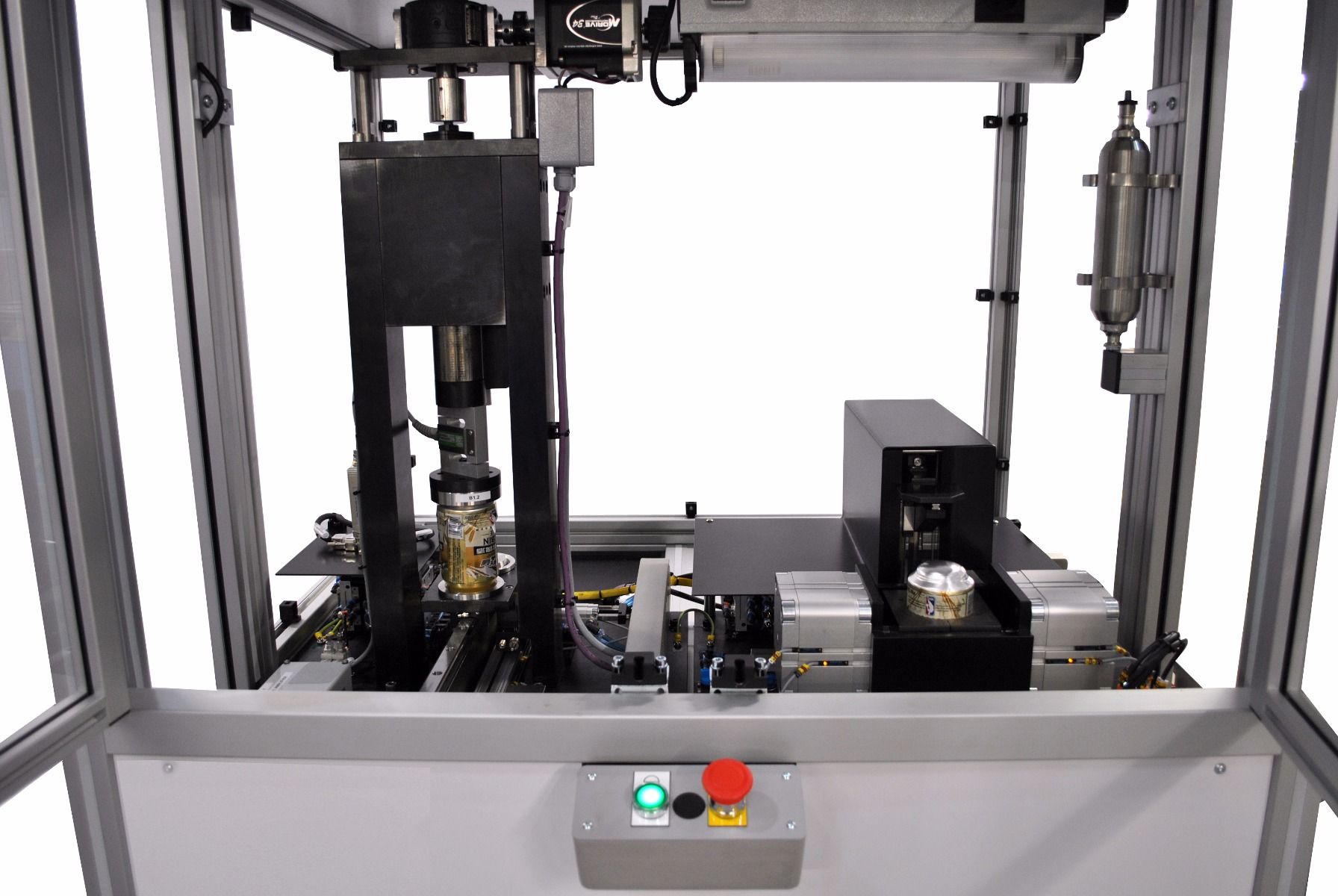

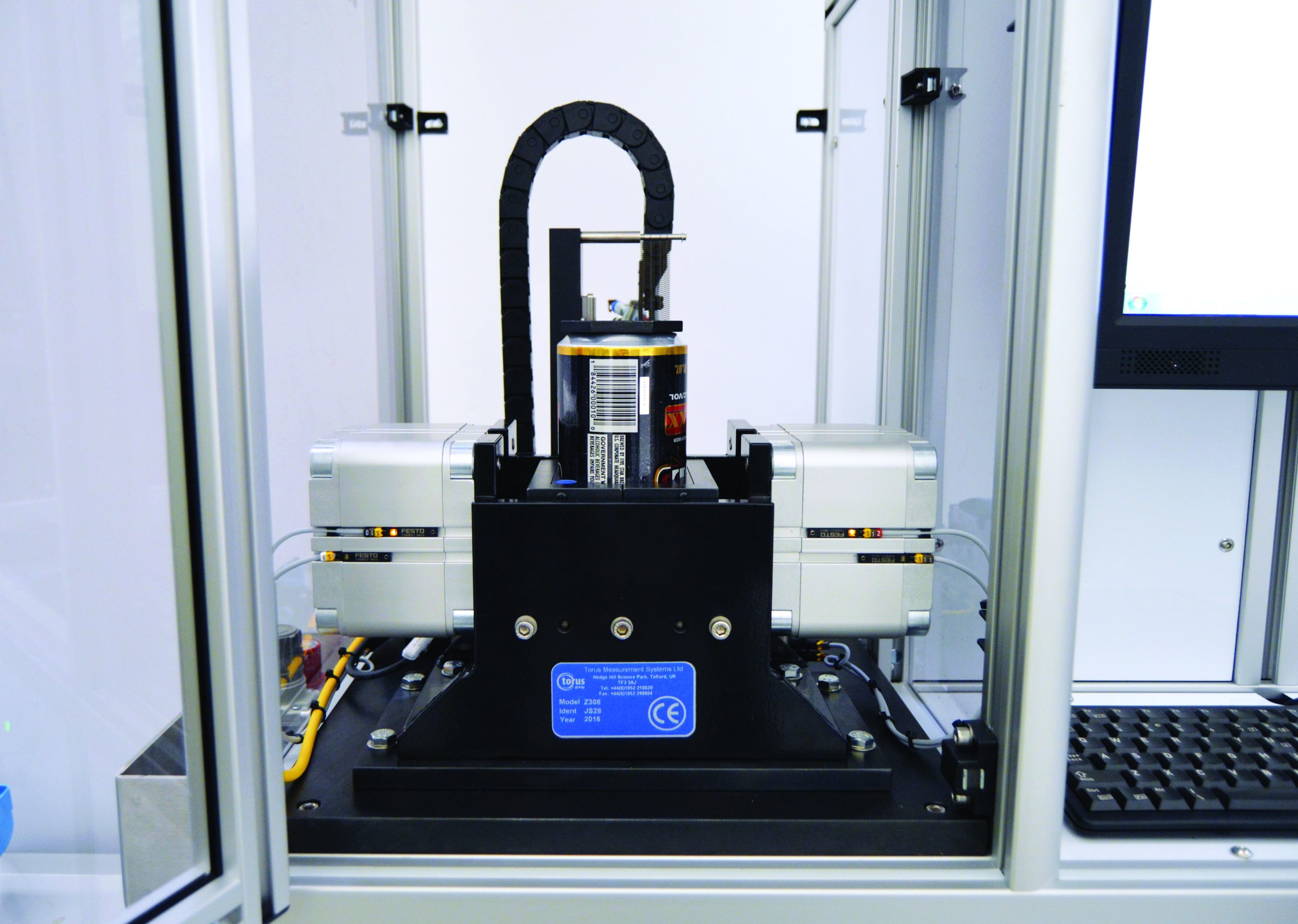

The Z308 Dome Reversal Gauge provides detailed information about the overall change in length of the can when pressure is applied and subsequently removed.

Measurement Features

Technical Specification

Gauge Features

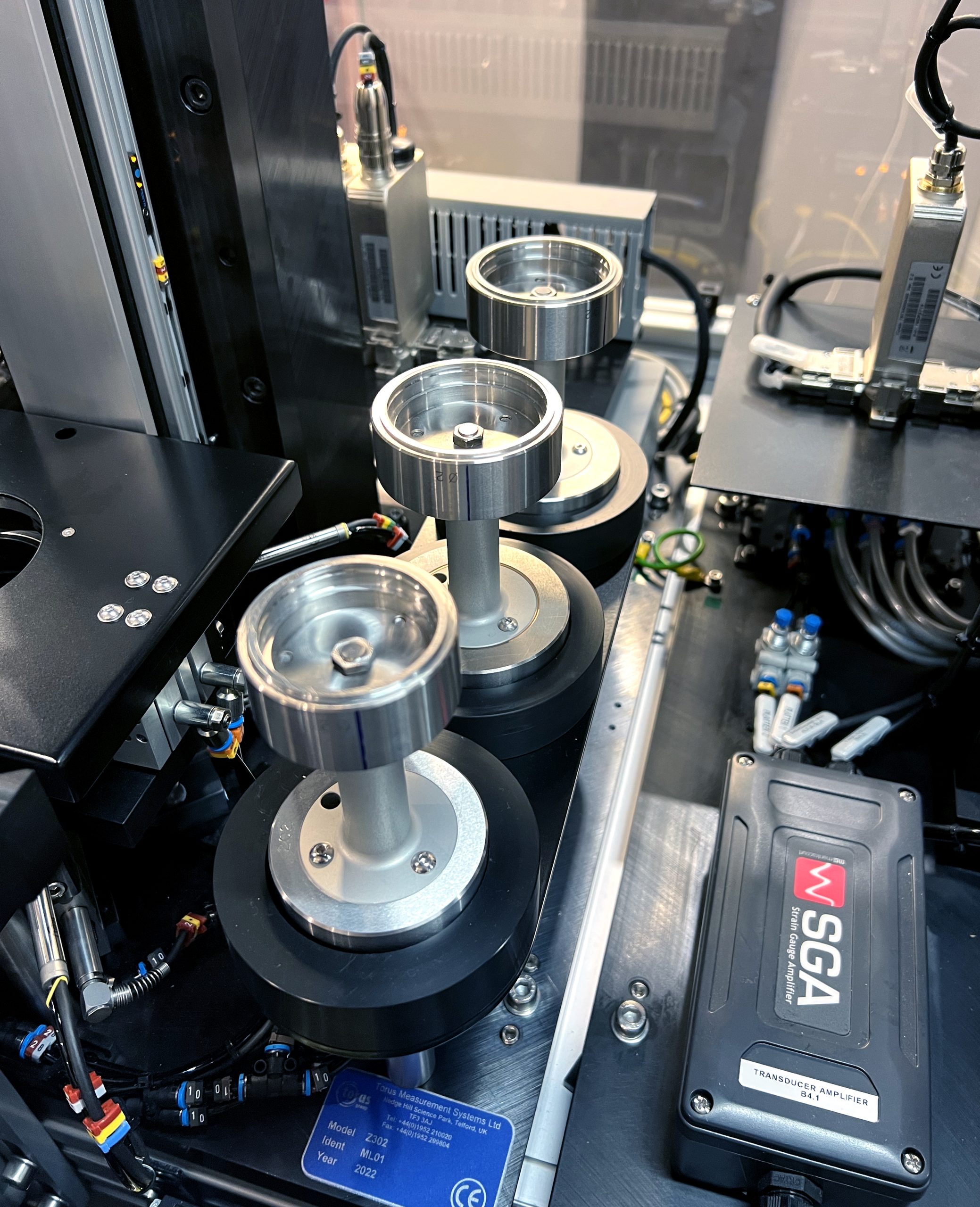

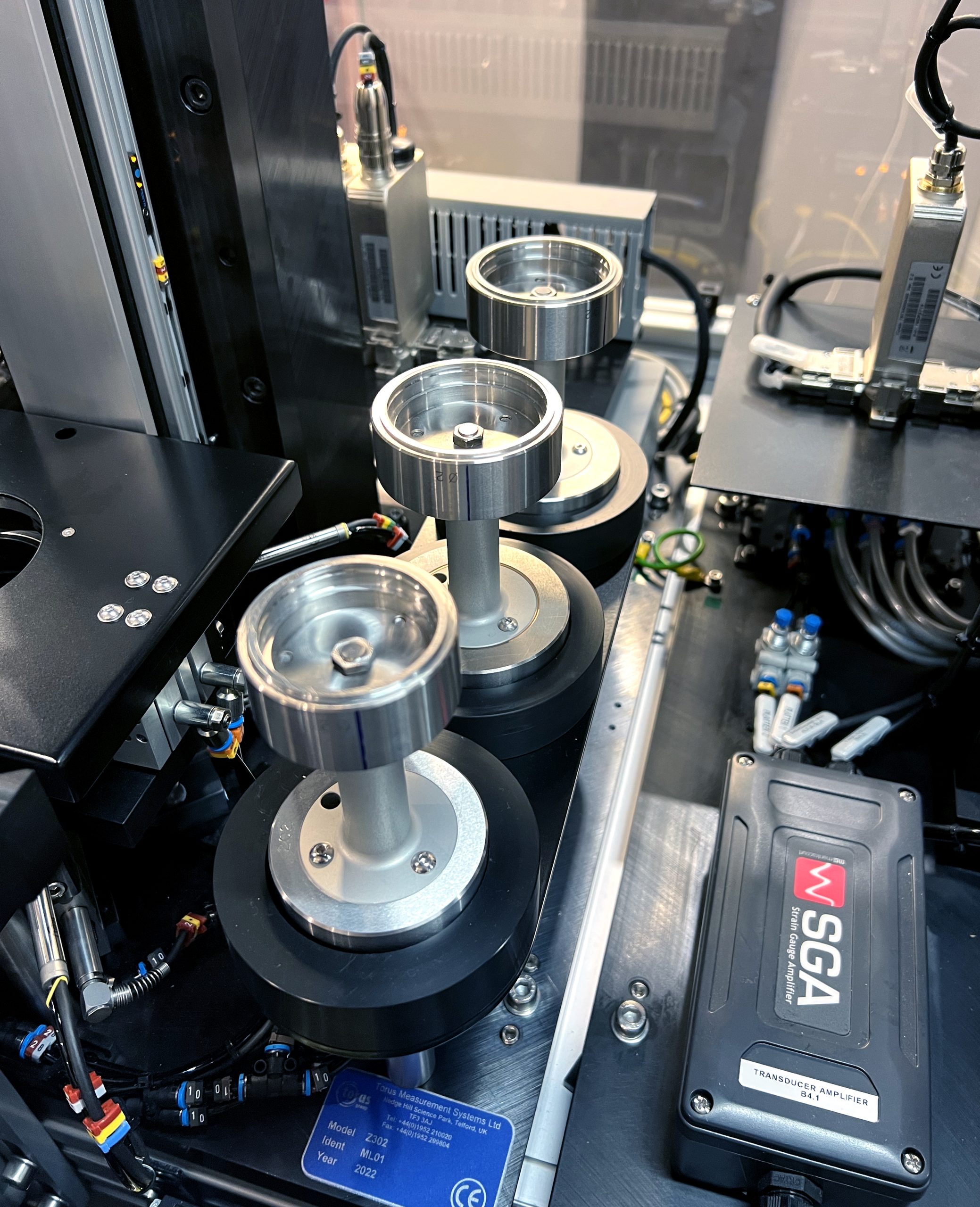

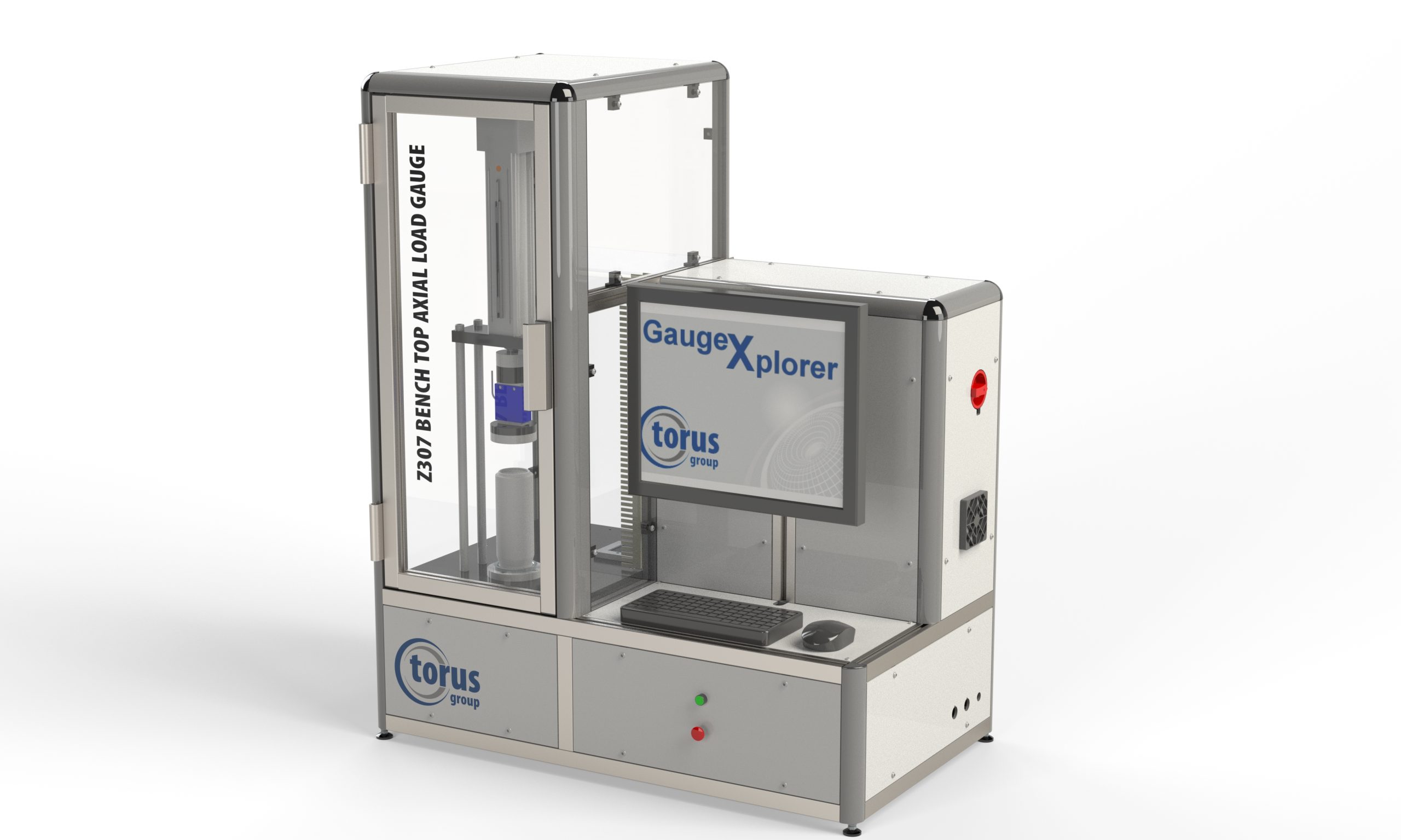

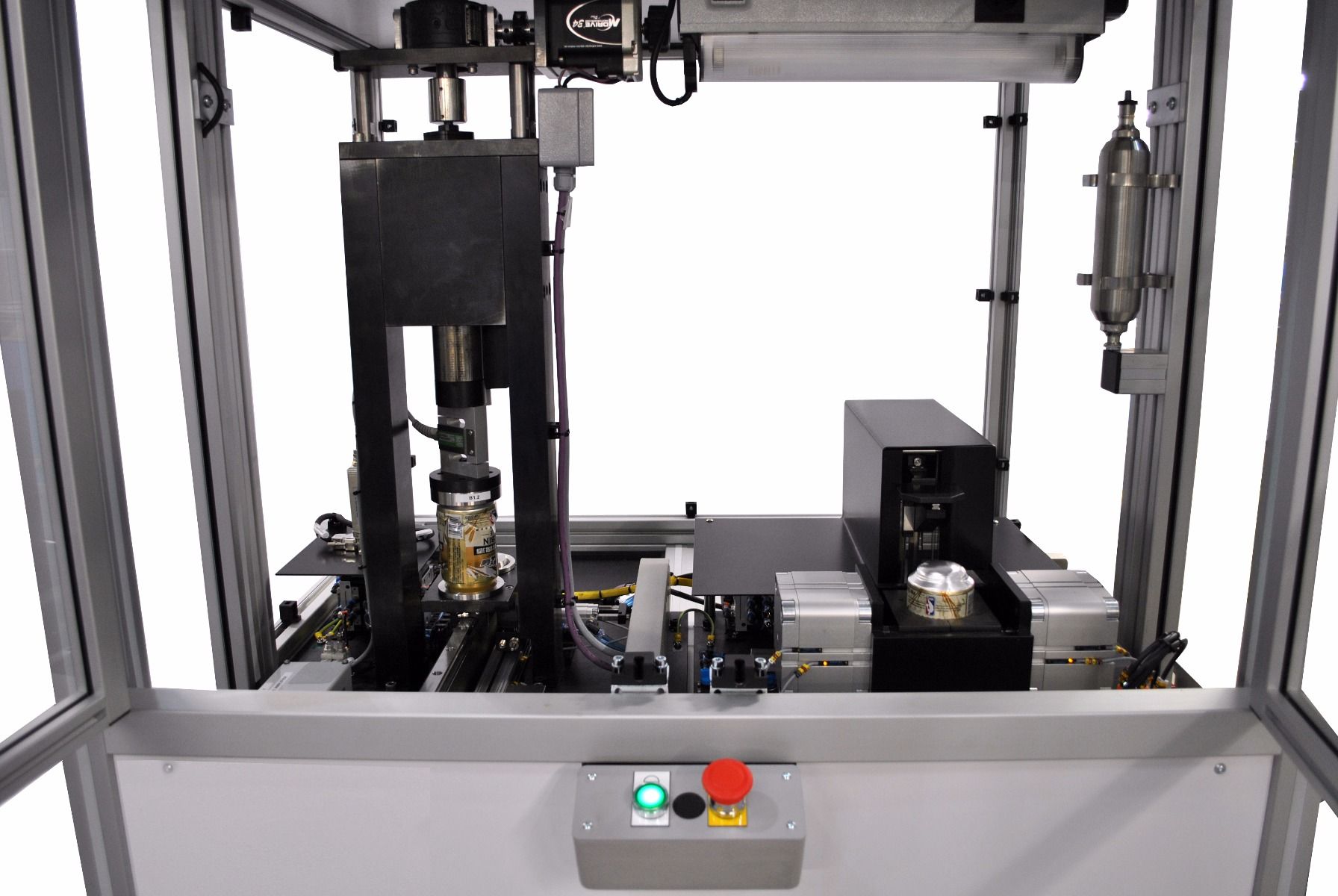

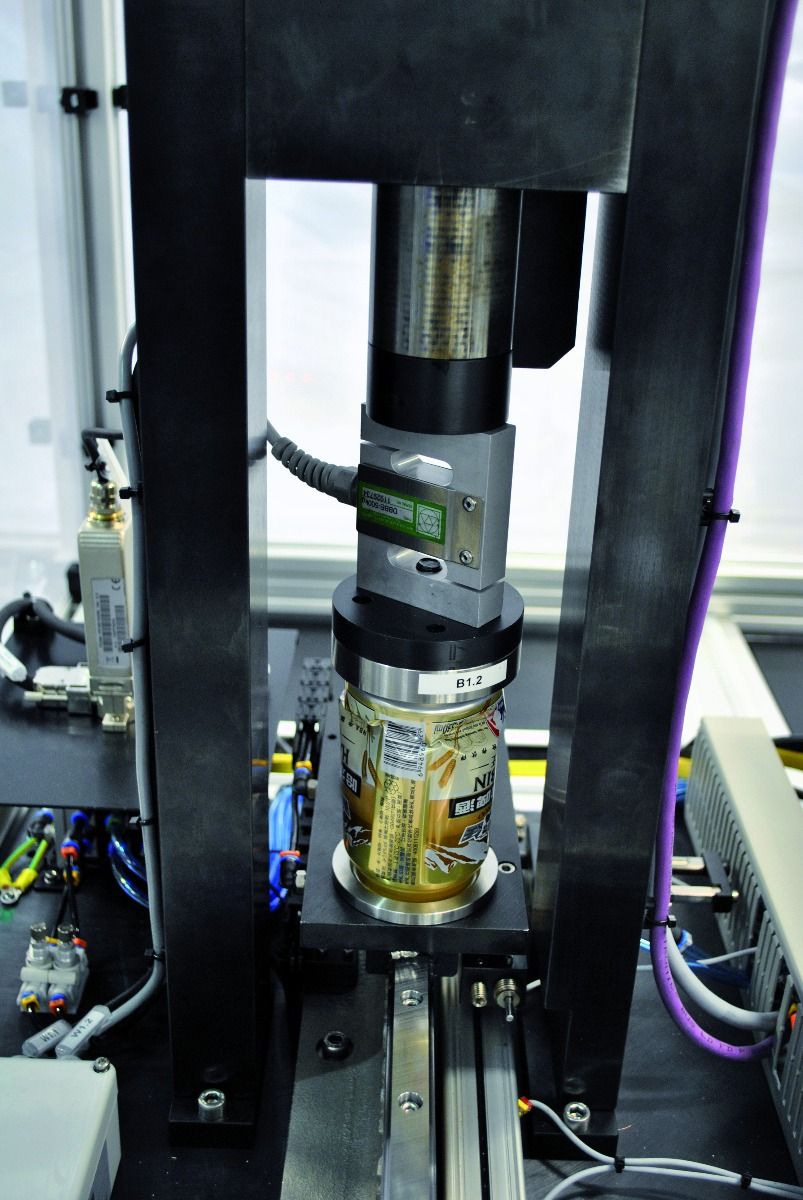

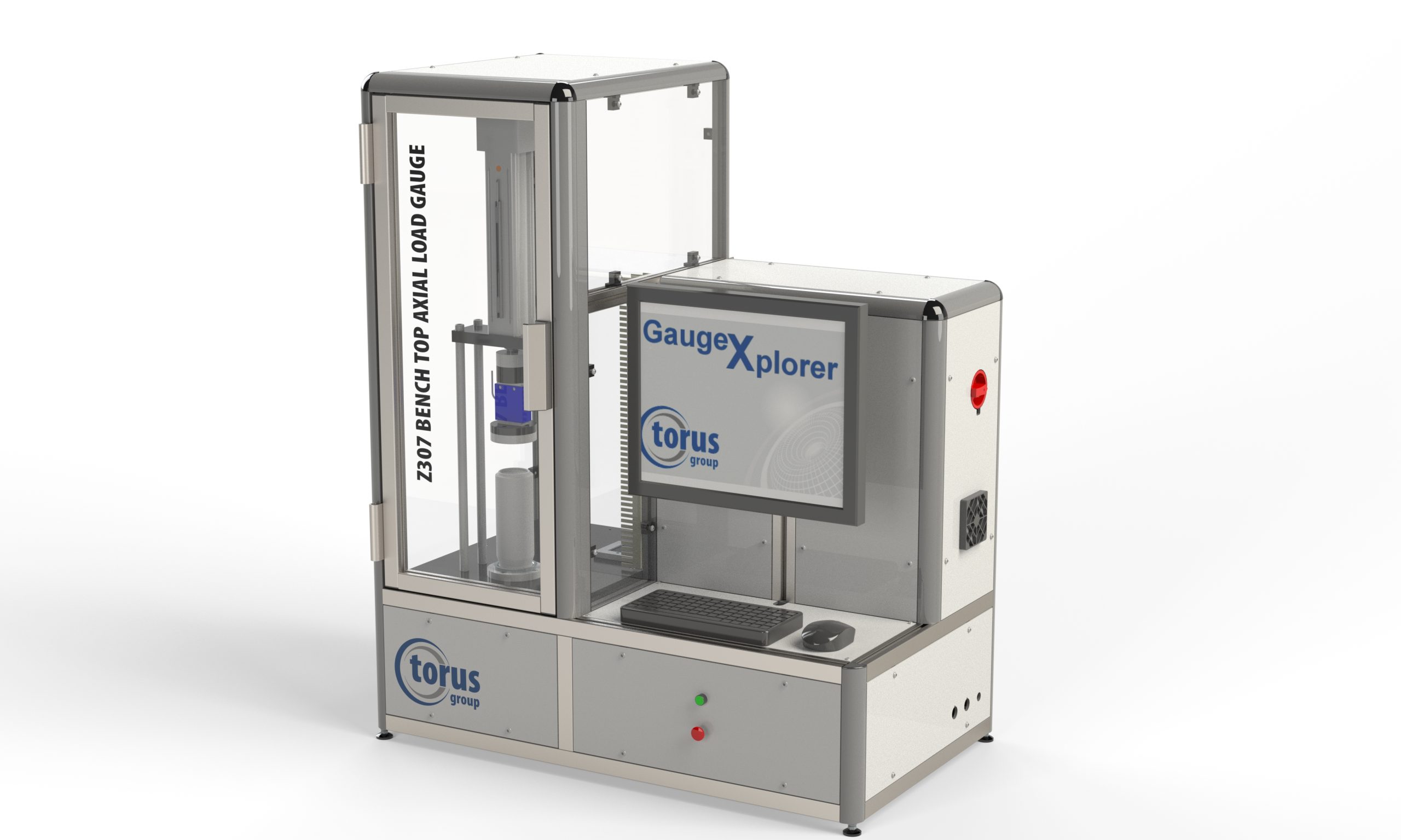

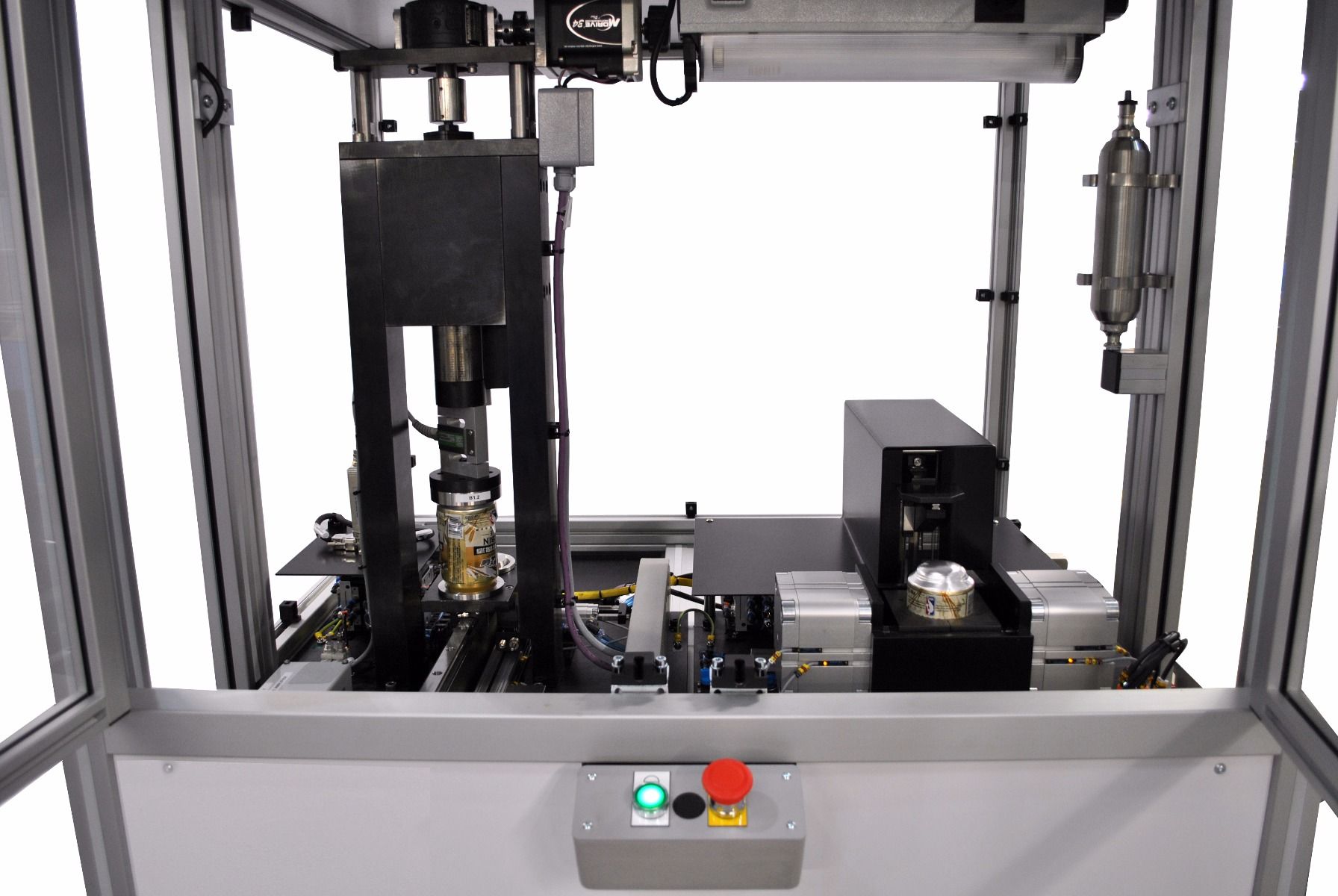

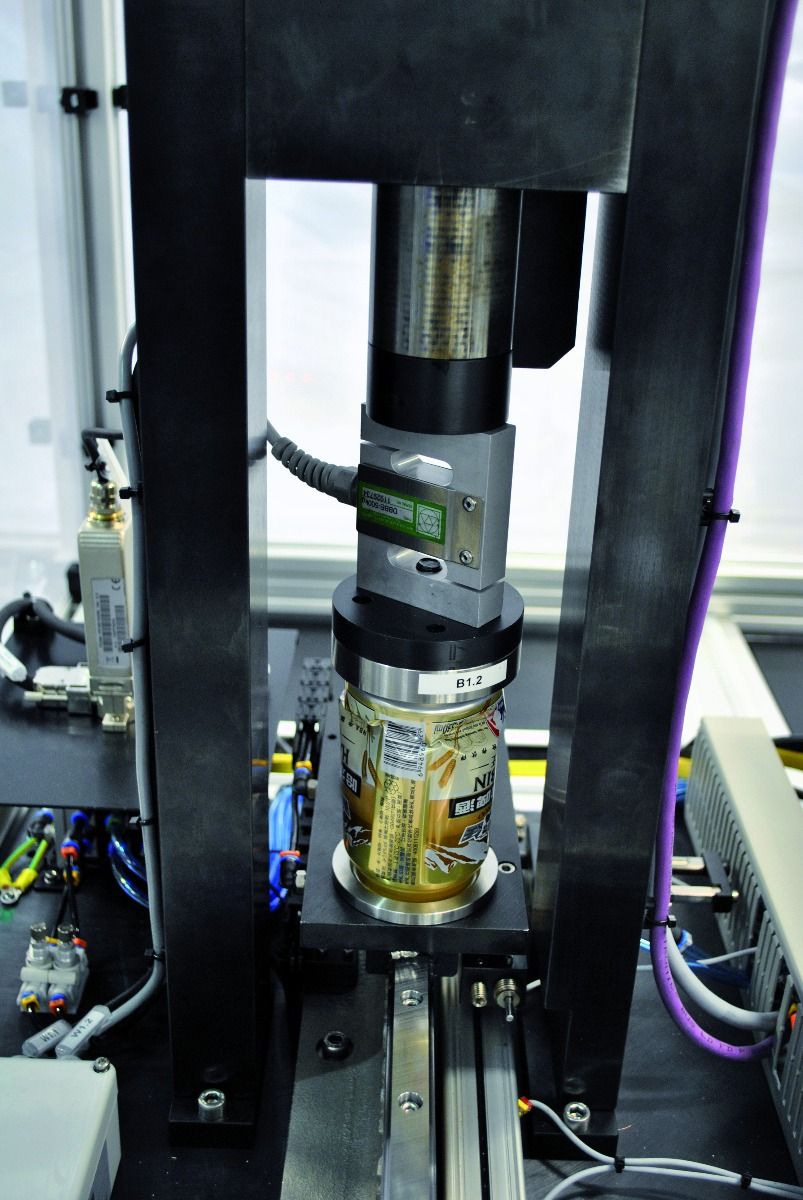

The Z307 Axial Load Gauge determines the maximum axial load force which can be applied prior to container failure, within a short cycle time.

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

Torus Beverage Can Gauging

Measurement Features

Axial Load – The maximum force at which the container fails/collapses | Accuracy: +/- 10 N

Technical Specification

Gauge Features

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999