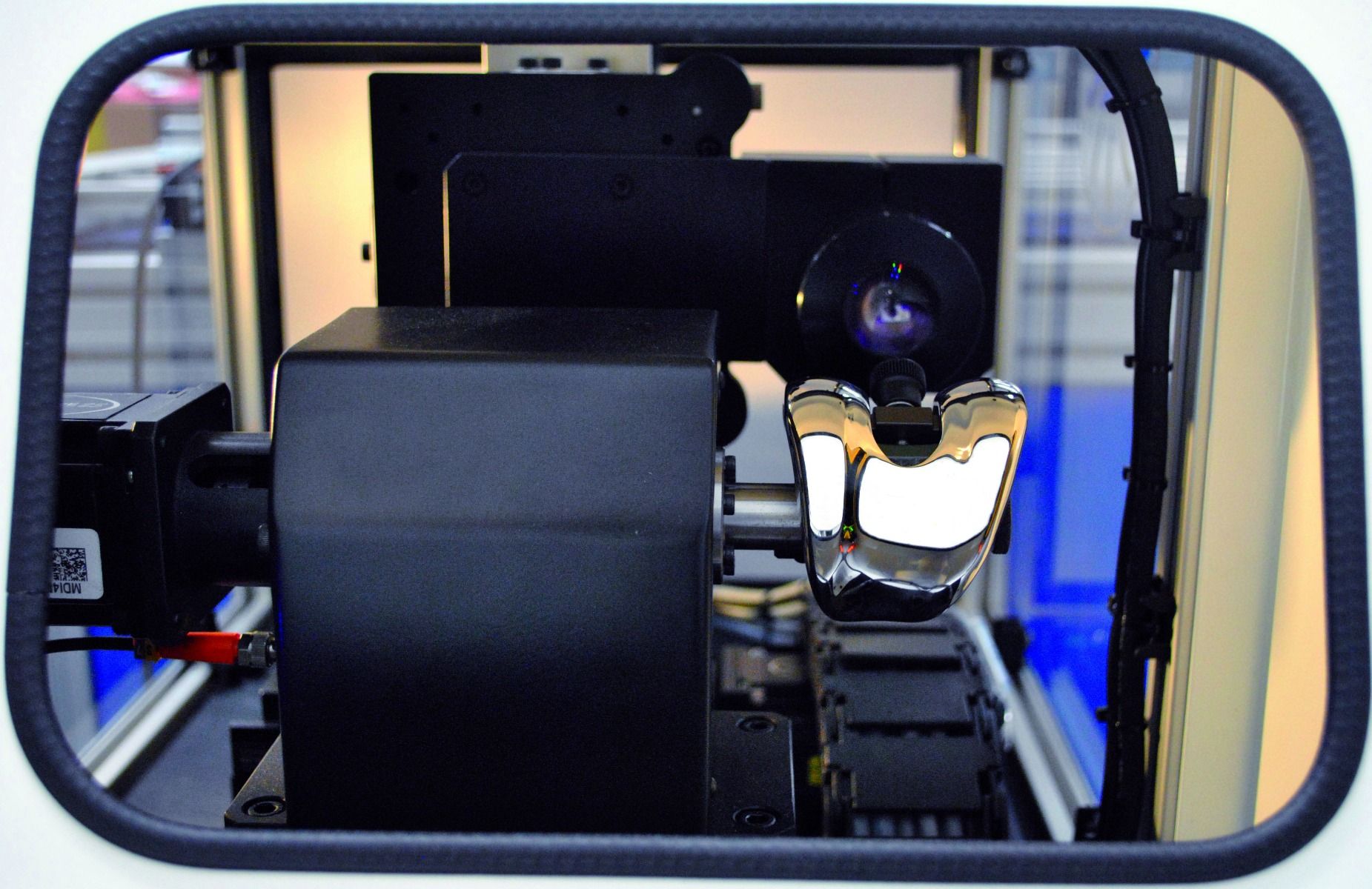

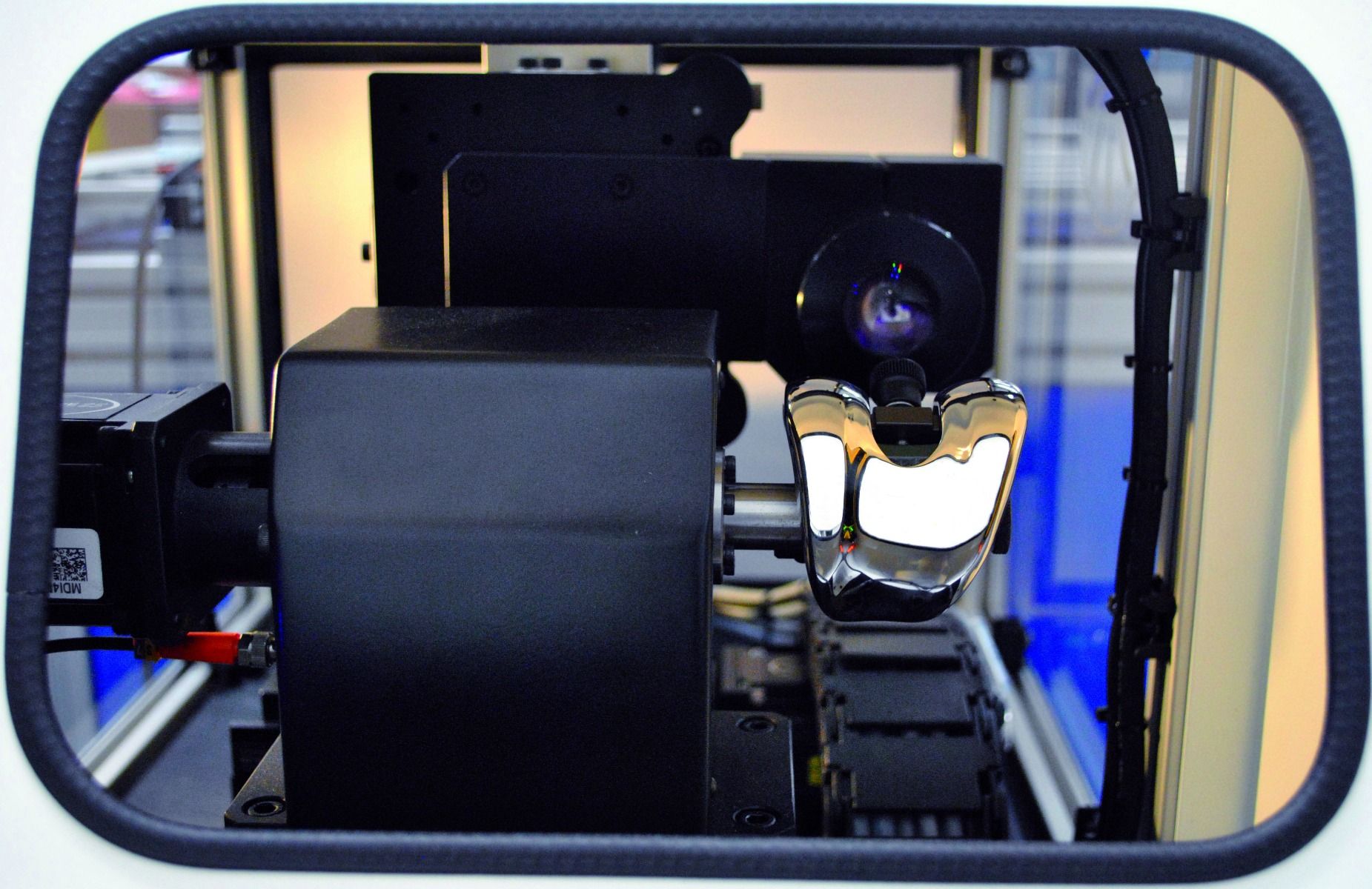

The Torus surface profiler measurement system utilises state-of-the-art confocal technology for rapid non-contact inspection of surface profiles on orthopaedic femoral knees, eliminating the need for handheld and subjective profile gauges and comparators

The system is designed for operational use on the shop floor therefore giving the machine tool operator a quick and repeatable measurement without having to go in to the inspection lab.

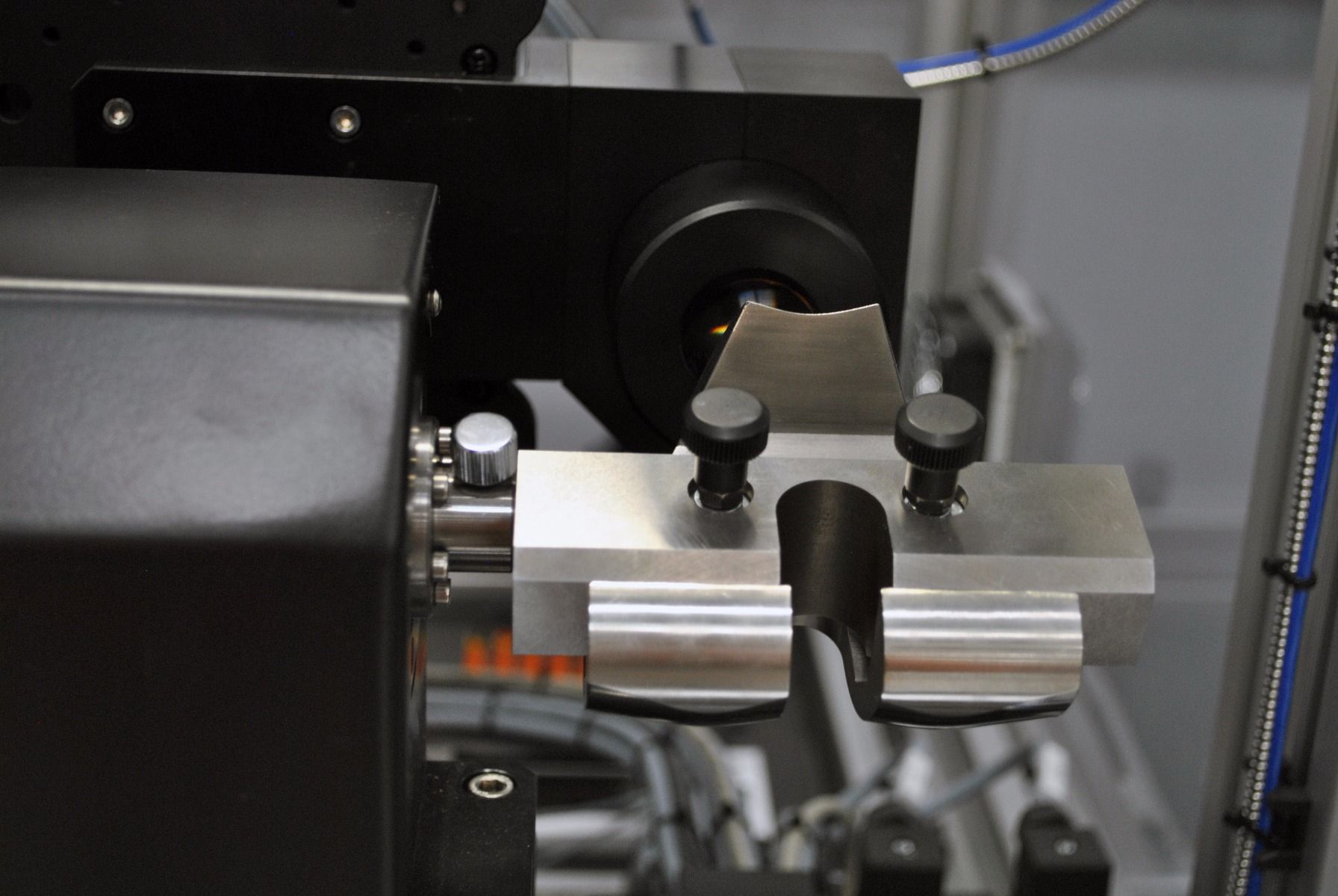

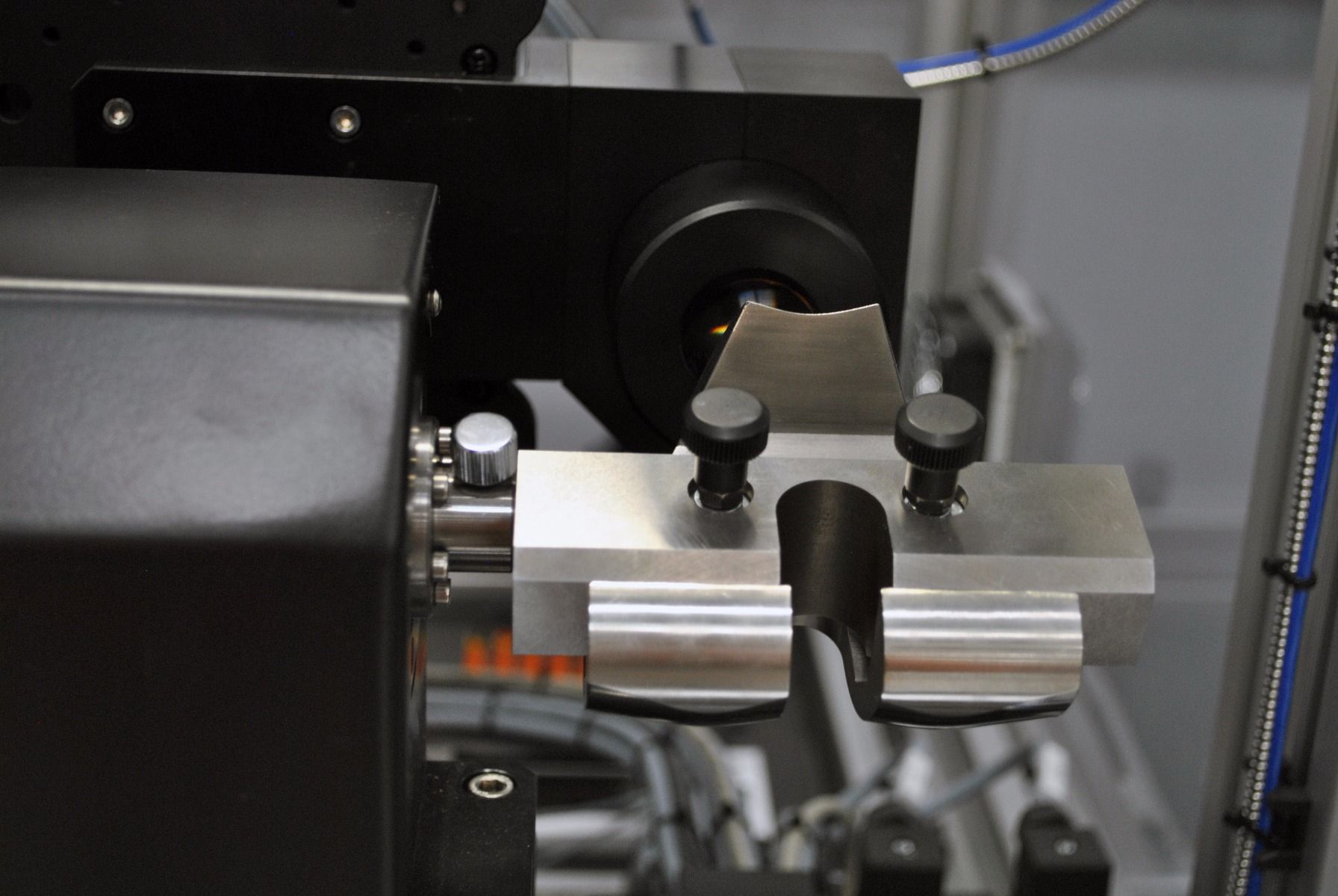

Polychromatic white light is focused onto the target surface by a multi-lens optical system. The lenses are arranged so that the white light is dispersed into monochromatic light by controlled chromatic aberration. Specific distance to the target is assigned to each wavelength which is exactly focused on the target is used for measurement.

This unique measuring principle enables displacements and distances to be measured with high precision and extreme spatial resolution. Cast, finished and highly polished surfaces can be measured without the requirement for surface preparation or machine adjustment.

Since the emitter and receiver are arranged in a single axis, shadowing is avoided, in contrast to conventional triangulation sensors.

The 4-axis motion control system is driven by high accuracy micro-stepping motors giving positional feedback, providing high resolution and high speed with stability and reliability.

Measurement Features

Feature

Technical Specification

Capabilities

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999