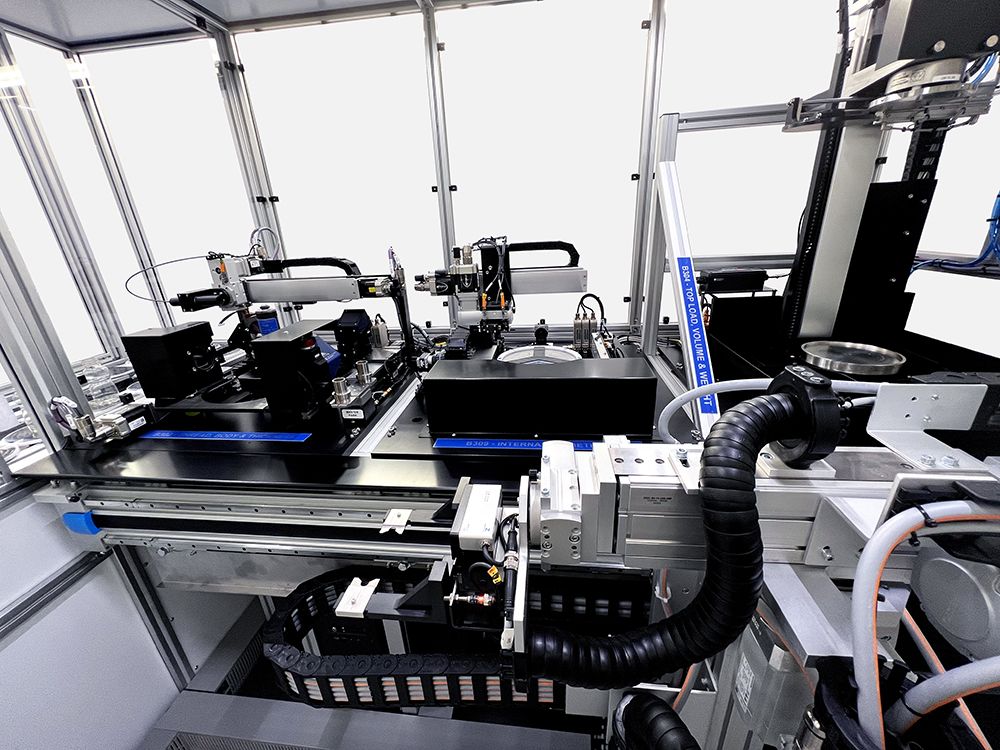

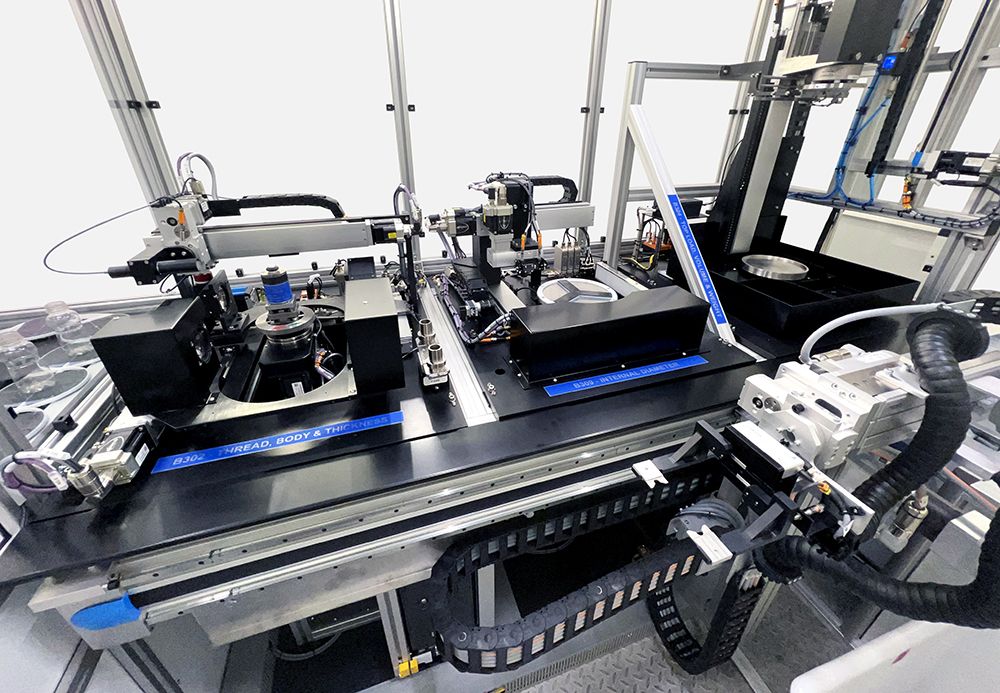

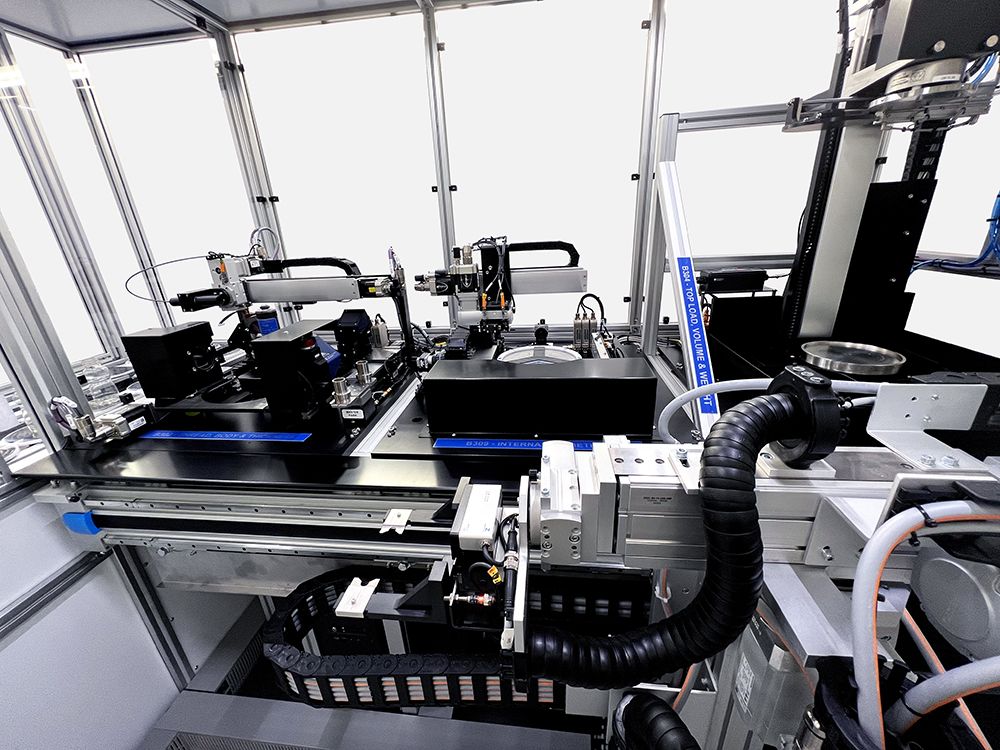

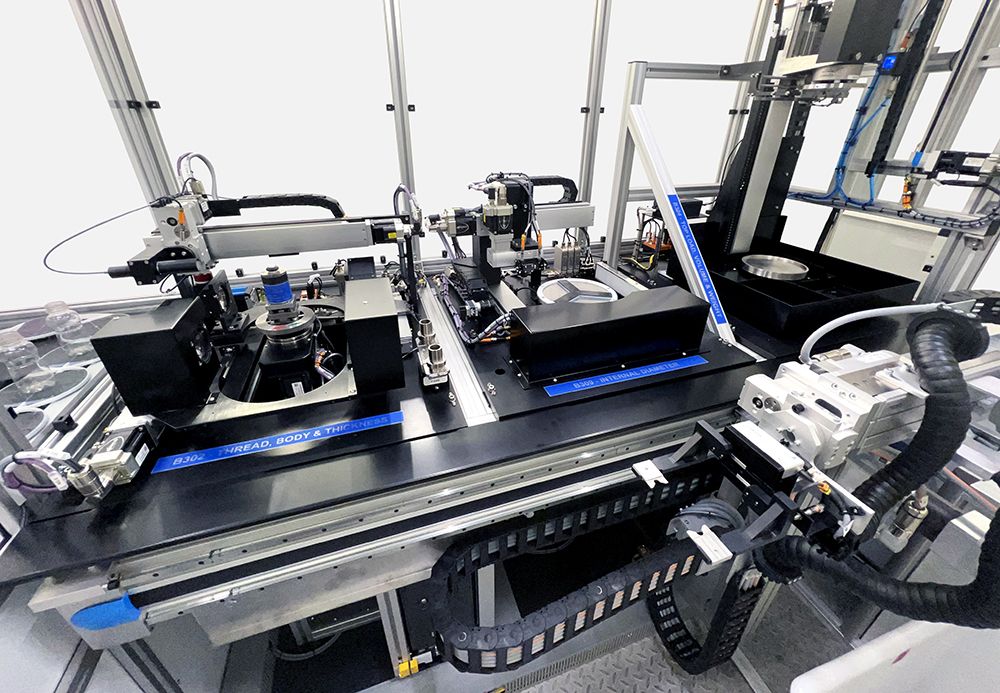

Torus’ TQ-Lab is a unique, total quality testing station for plastic packaging such as plastic bottles and jars, typically used for soft drinks, health supplements, cosmetics, and domestic cleaning products. Plastics packaging requires precision measurement of aspects such as material thickness, outer body and neck physical dimensions, neck diameter and volume as well as load testing for crushing and pressure. The TQ-Lab can undertake all the necessary tests on both empty and filled plastic containers or preforms in a single system. The multi-module concept improves accuracy and repeatability, reduces time and labour costs and saves on floor space in production environments. Once batches of plastic containers are placed onto the turnaround conveyor, the operator simply selects the relevant program and walks away.

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

Technical Specification

Measurement Features

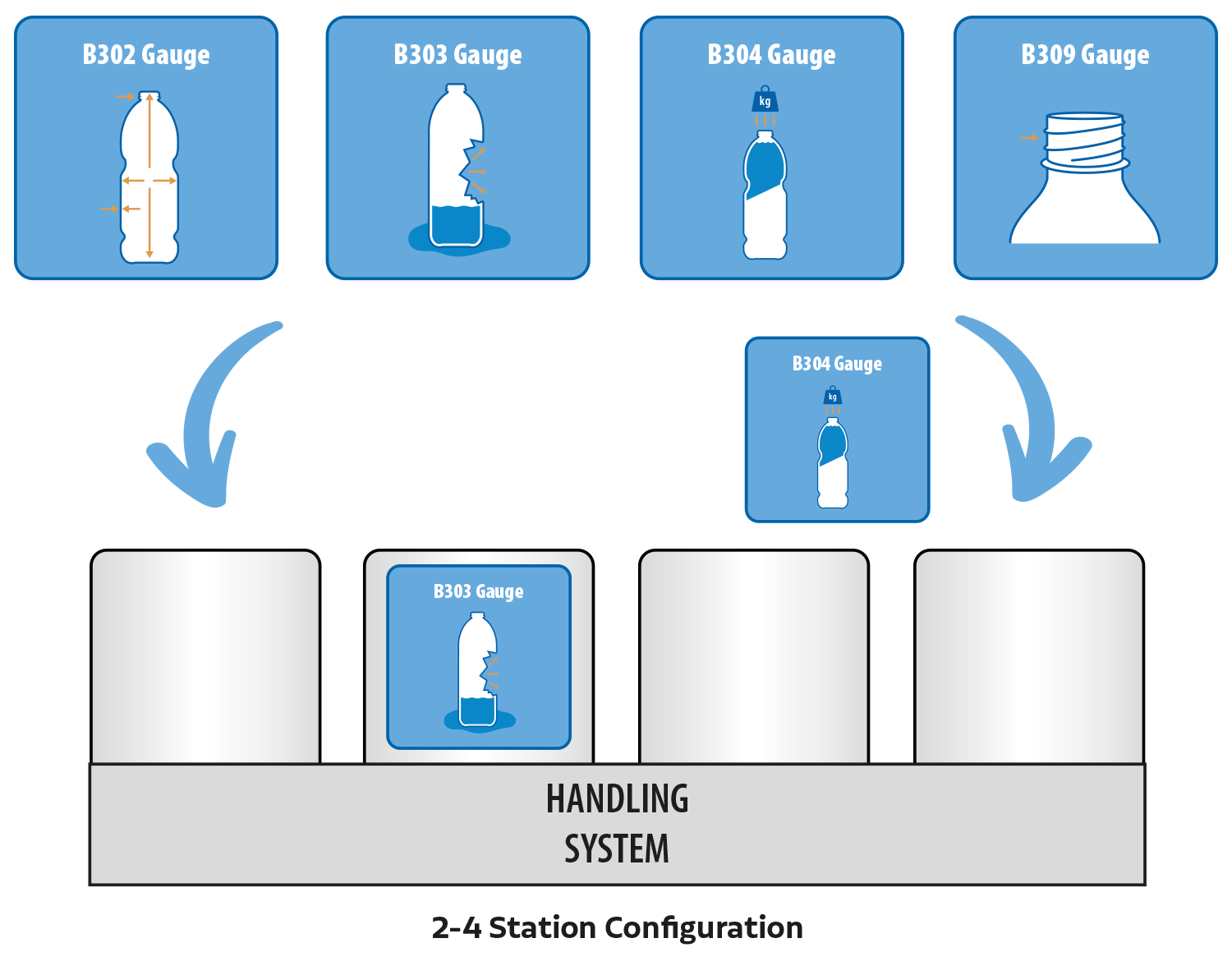

Choose from between 2 and 4 measurement modules to customise your TQ Lab:

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

Choose from a range of conveyor options, and finally choose your modules (a minimum of a 2 station configuration through to a maximum of 4).

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999