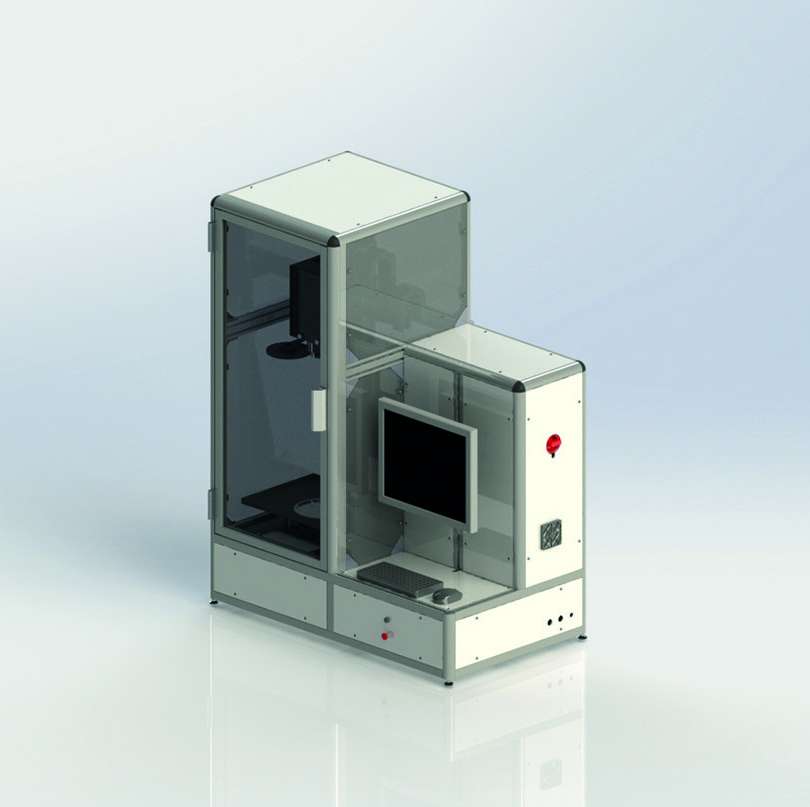

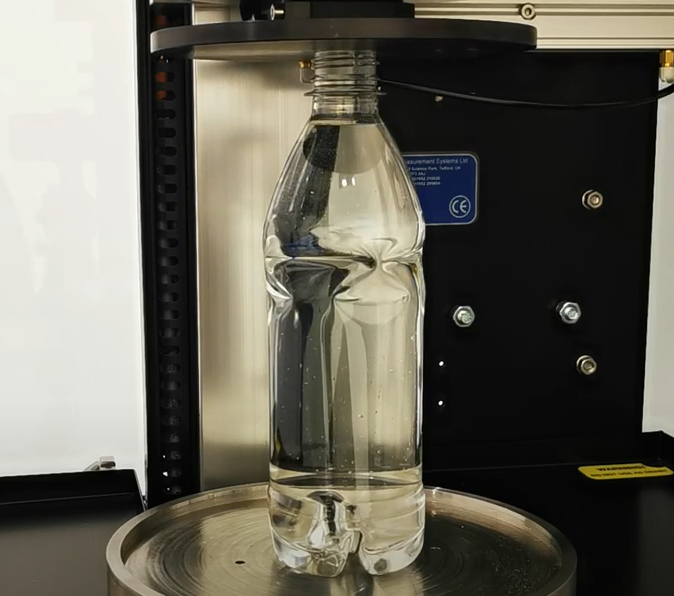

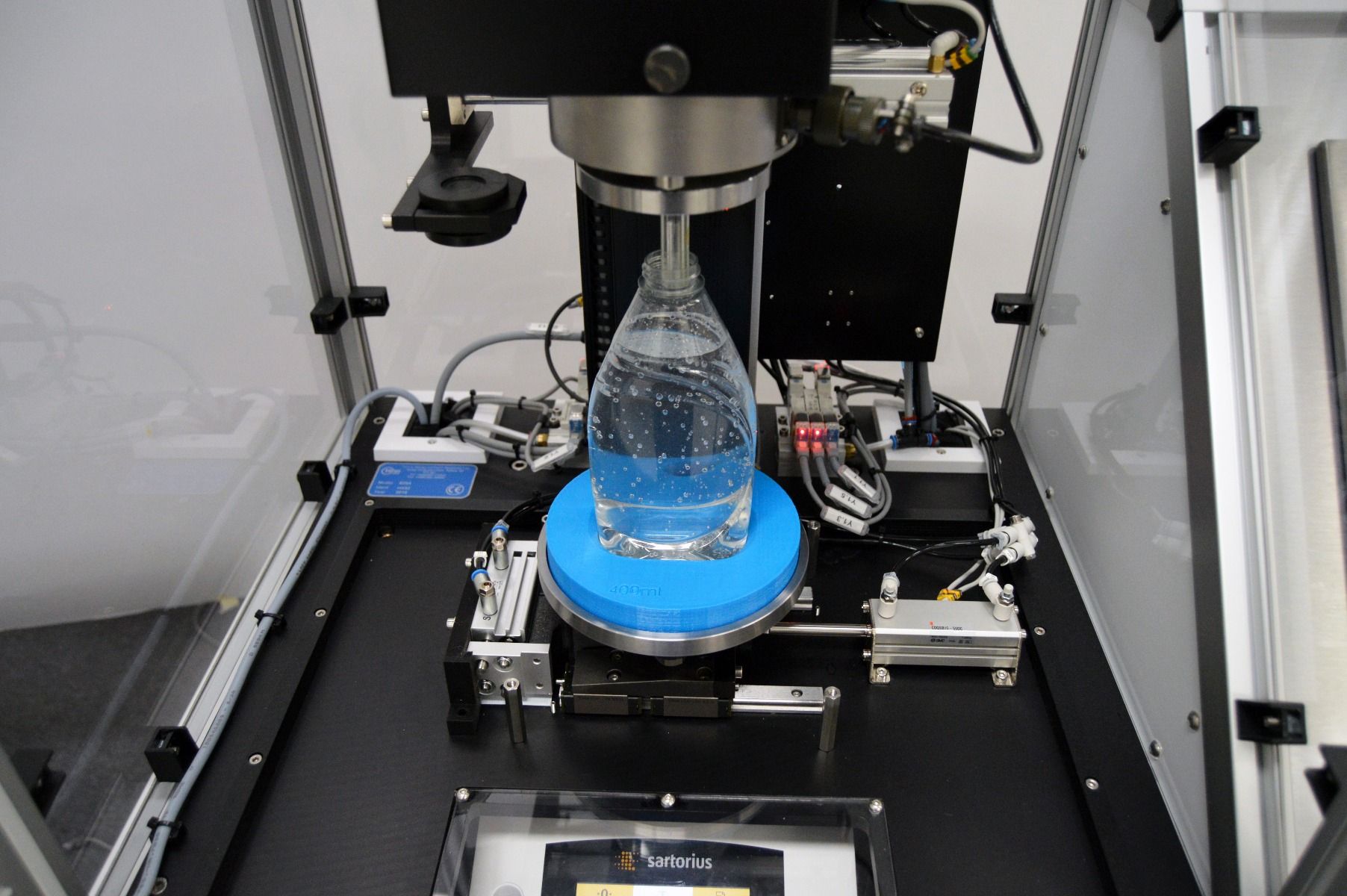

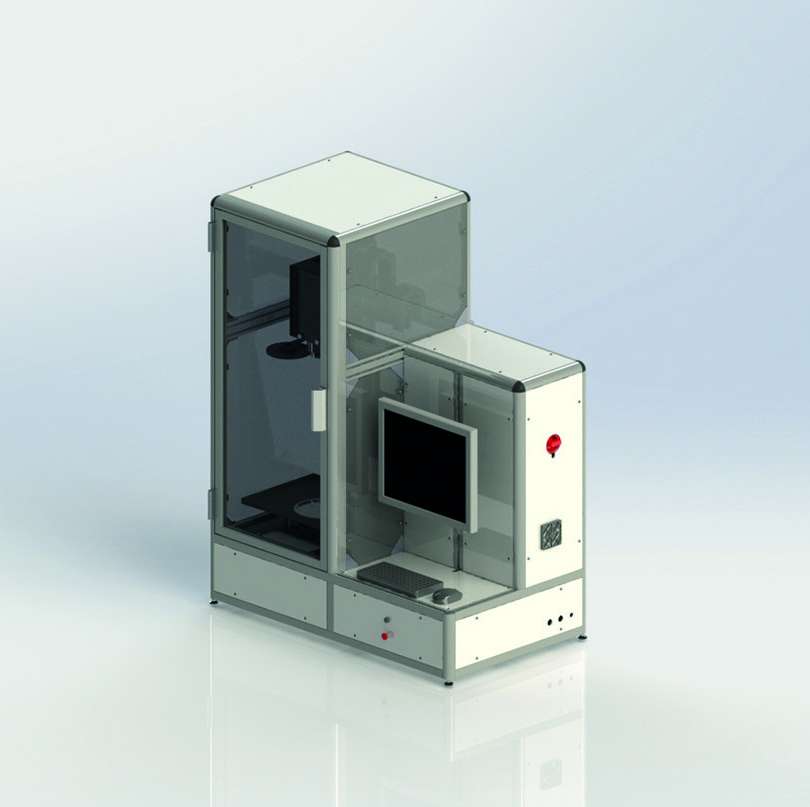

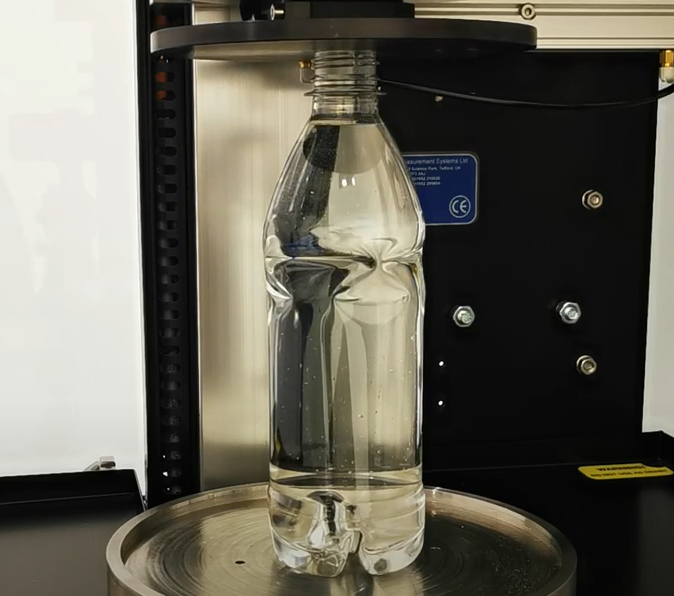

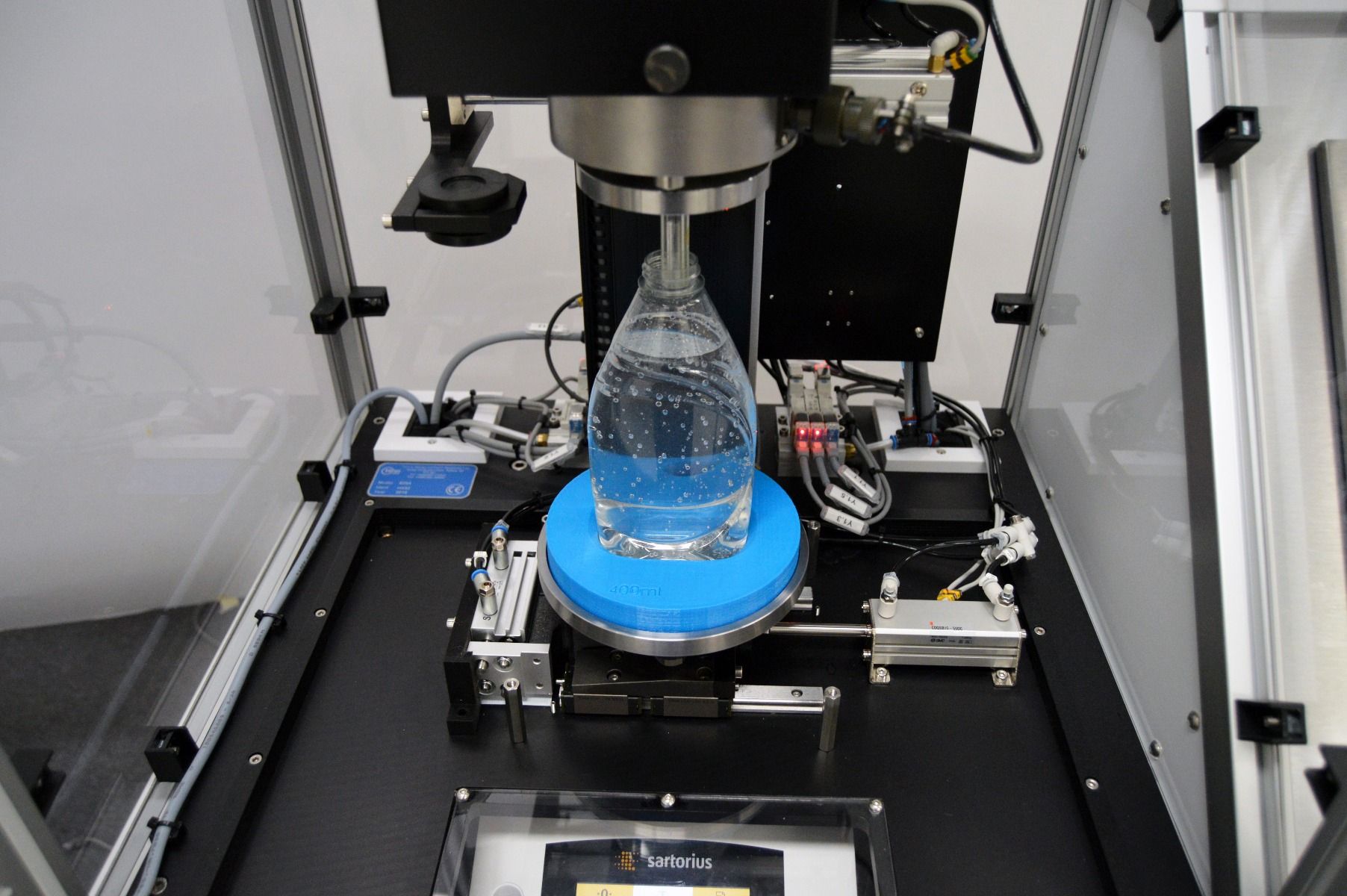

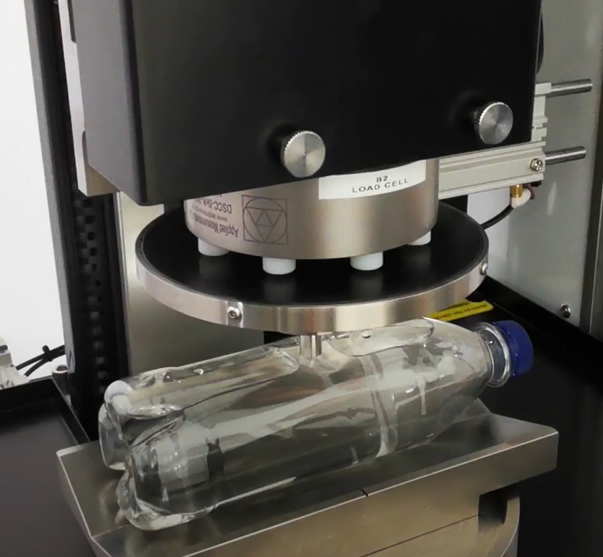

The B304 Top Load, Volume and Weight Gauge provides the worlds first in-line combination test for measuring vertical strength and capacity. Data can be presented numerically and graphically, creating a Max Load Vs Deflection signature as the ‘live’ bottle force is measured. A traceable batch setup function is provided for further blow moulder to cavity analysis. The test specifics adhere to ASTM D2659 Standards and offer selectable units of Force, adjustable compression speeds with a simple windows based programmable user interface.

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

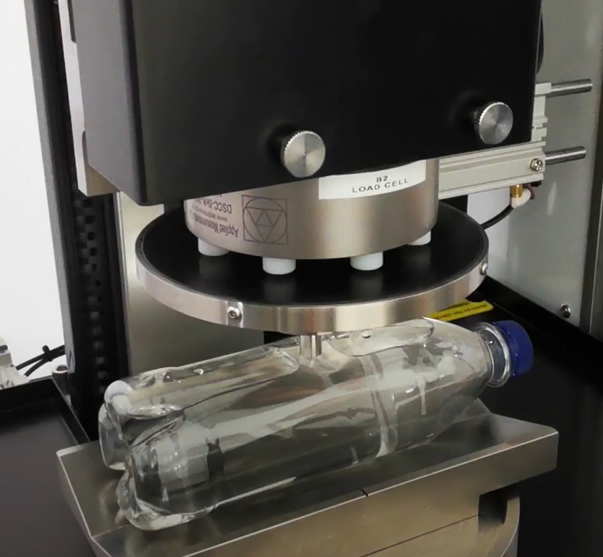

The latest update for the B304 introduces a side load horizontal test function, for both filled and empty containers, providing critical compression information.

Reporting options such as a standard CSV or Statistical Process Control (SPC)

Traceable to UKAS Standards.

Measurement Features

Technical Specification

Volume Inspection Options

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999