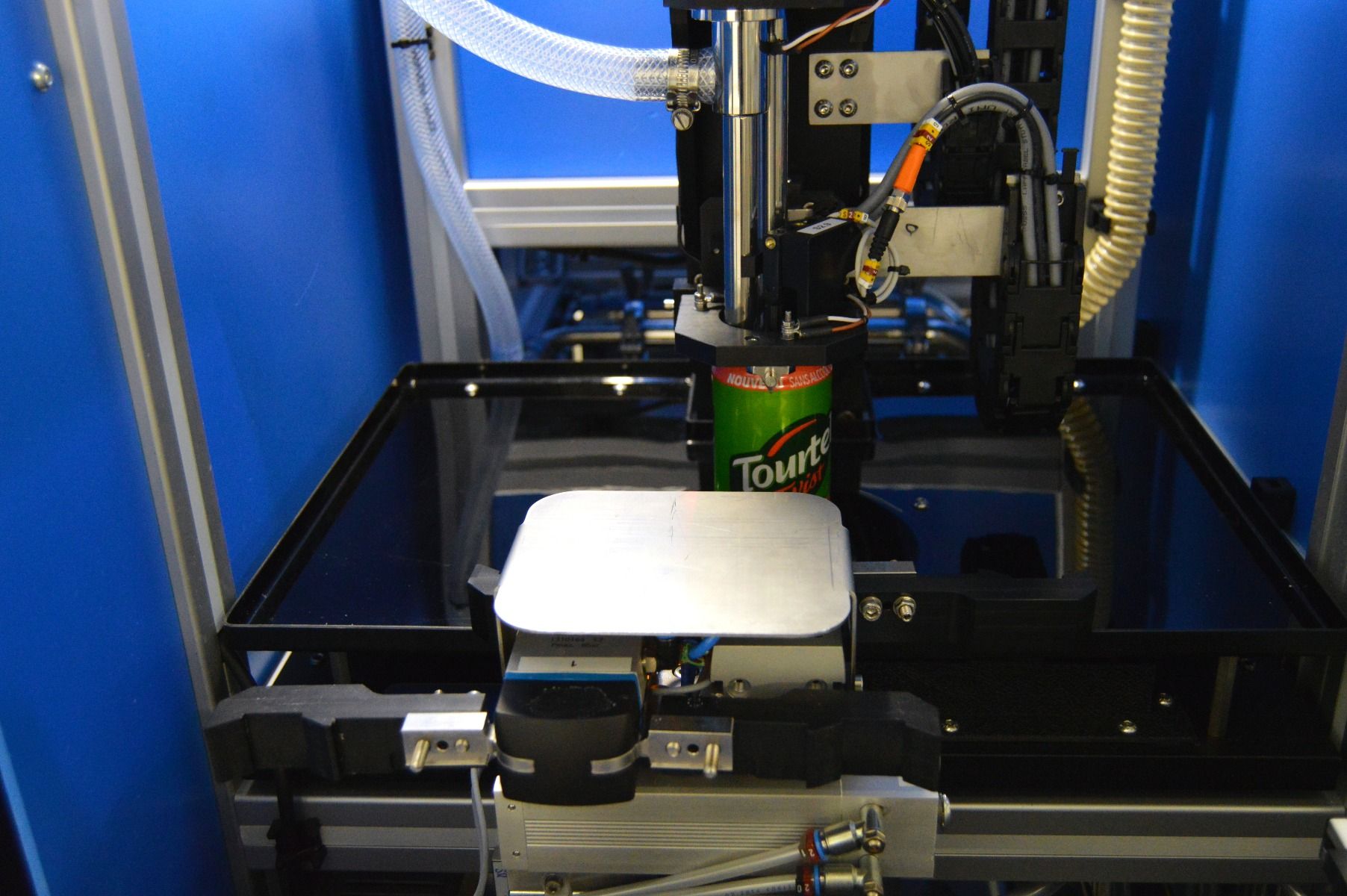

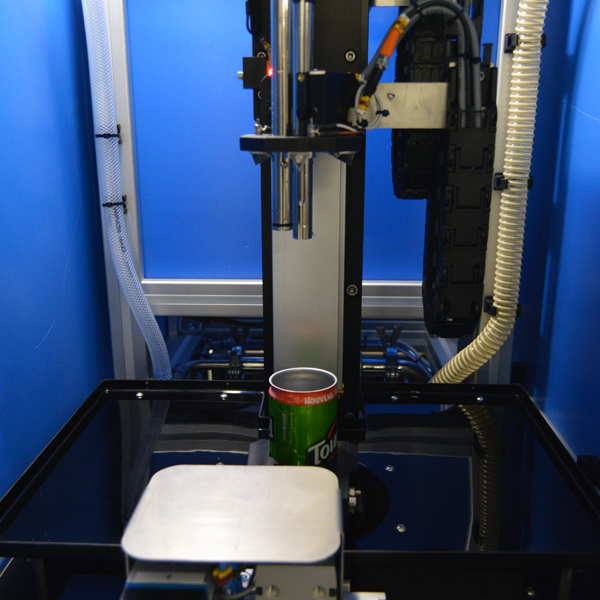

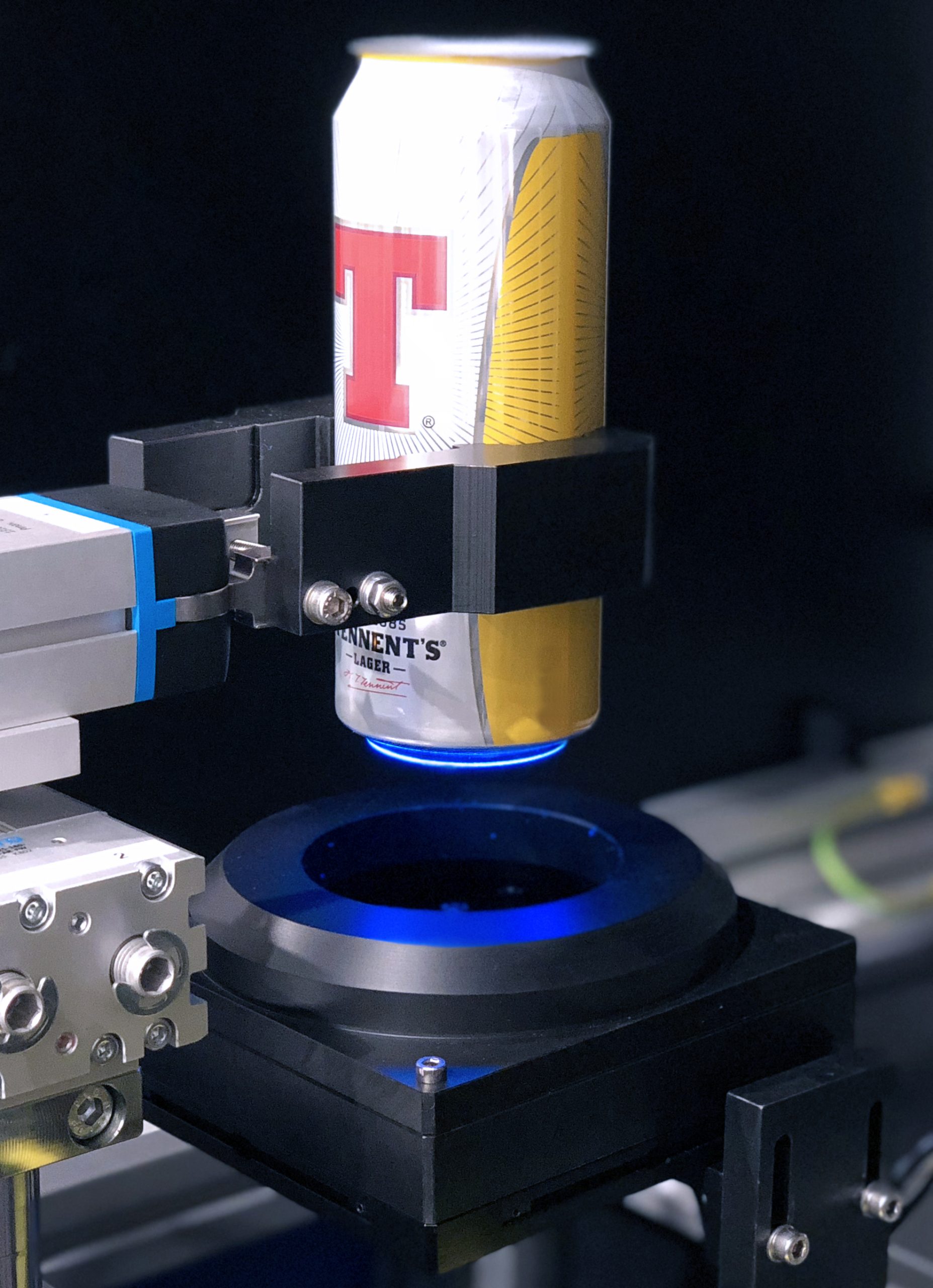

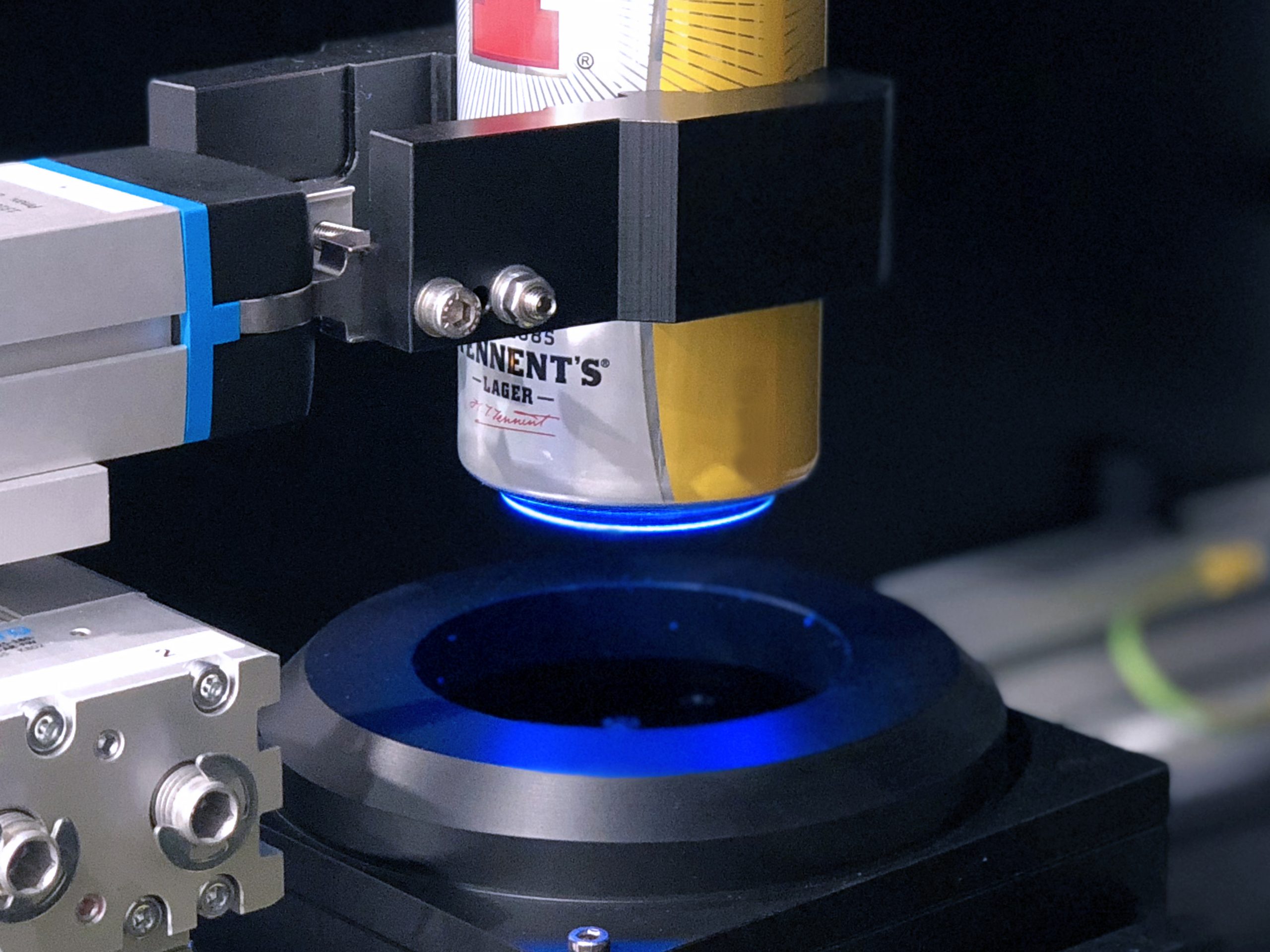

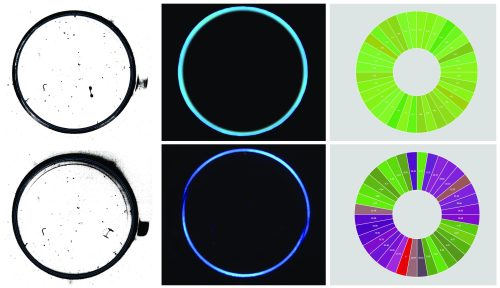

The Z340 Automatic Coating Analyser has been developed to give detailed distribution analysis of the internal lacquer on a beverage can

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

Torus Beverage Can Gauging

Measurement Features

Technical Specification

Gauge Features

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

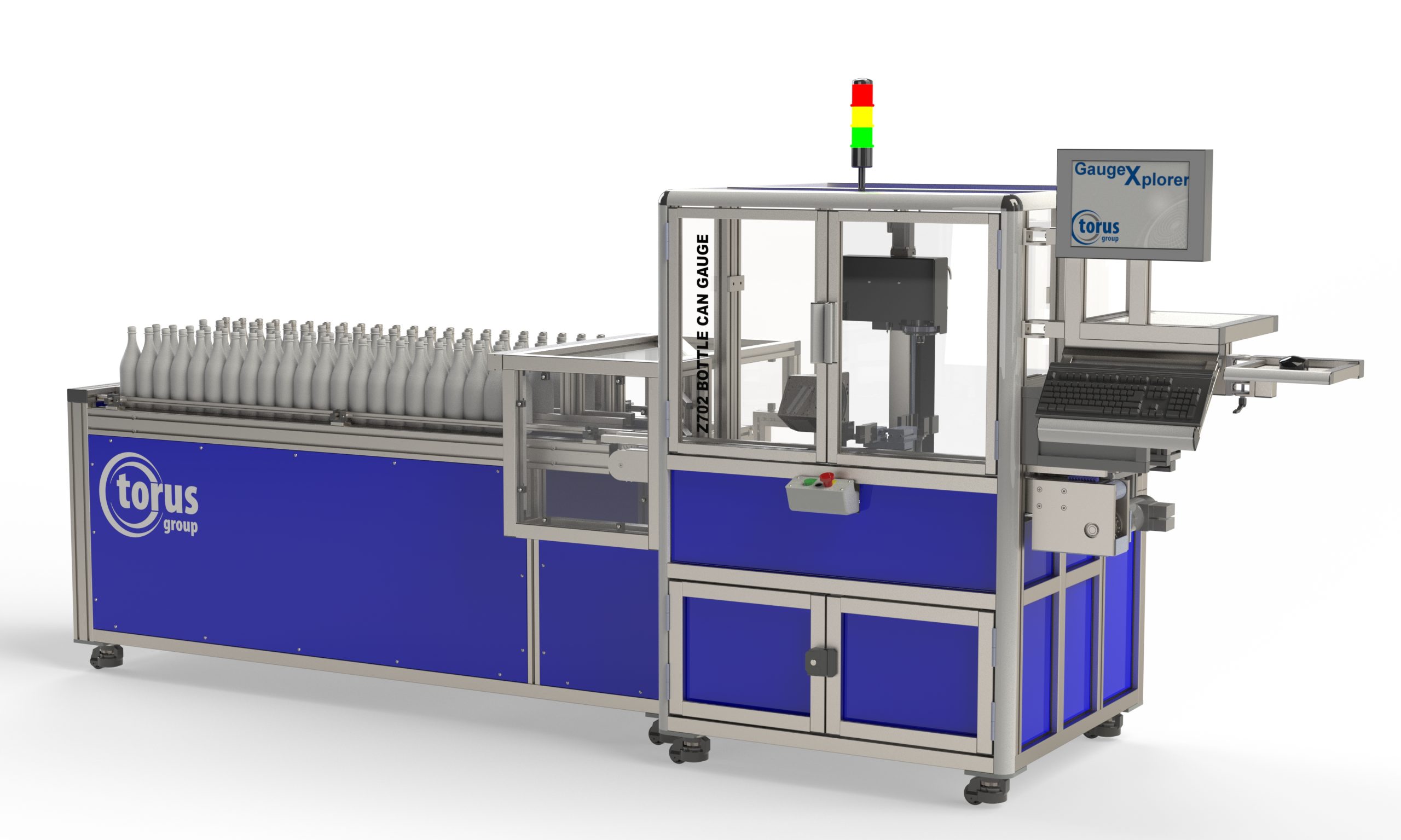

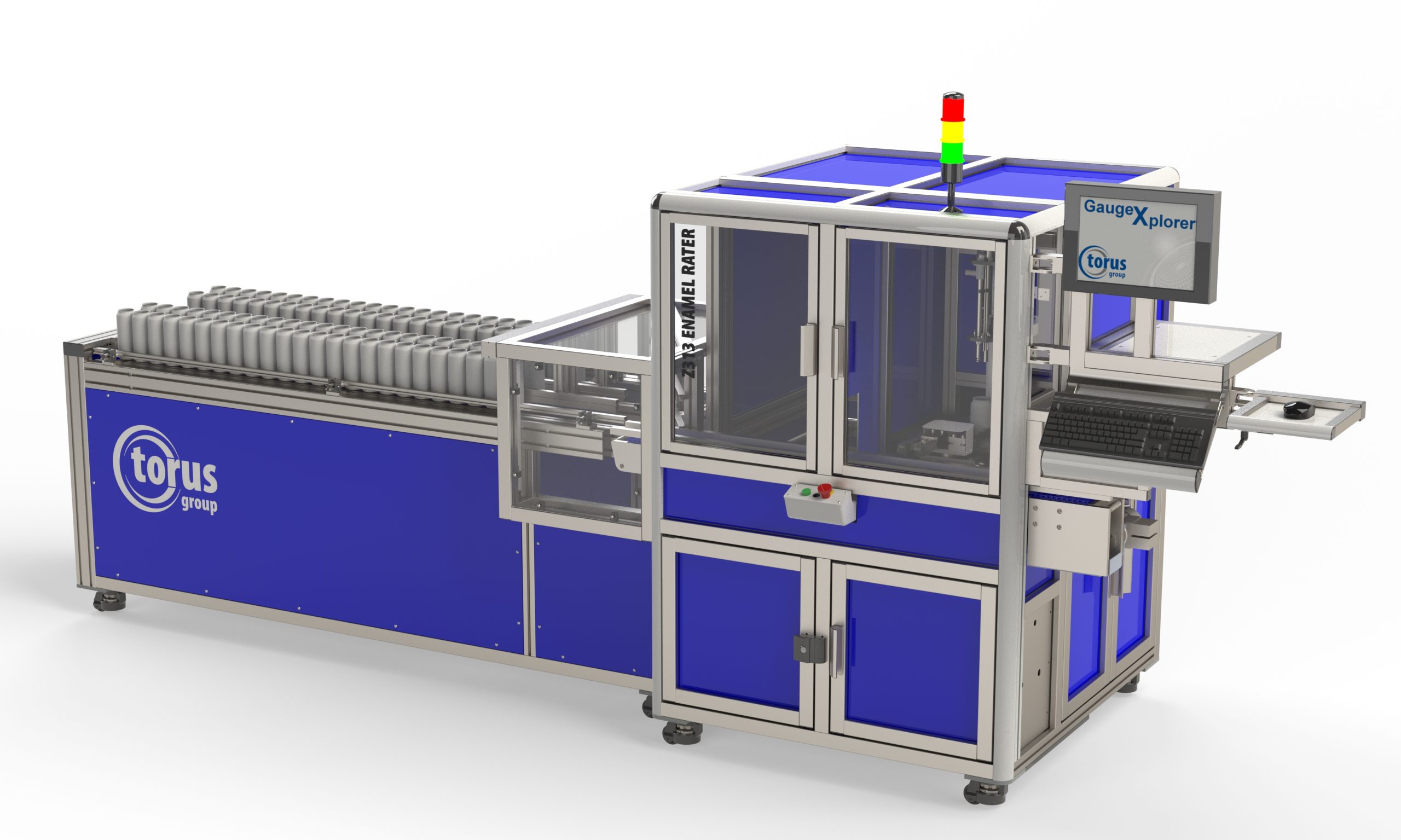

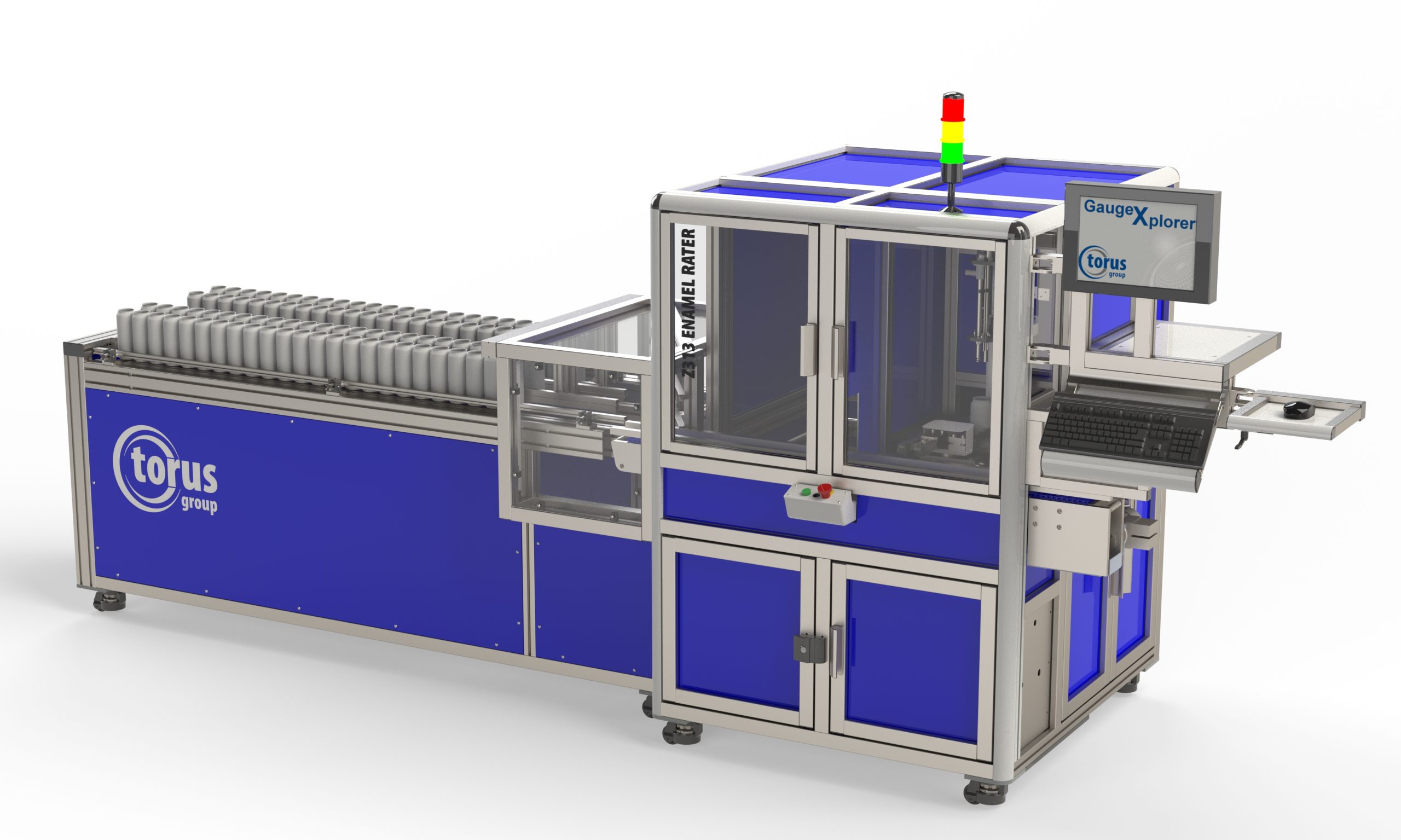

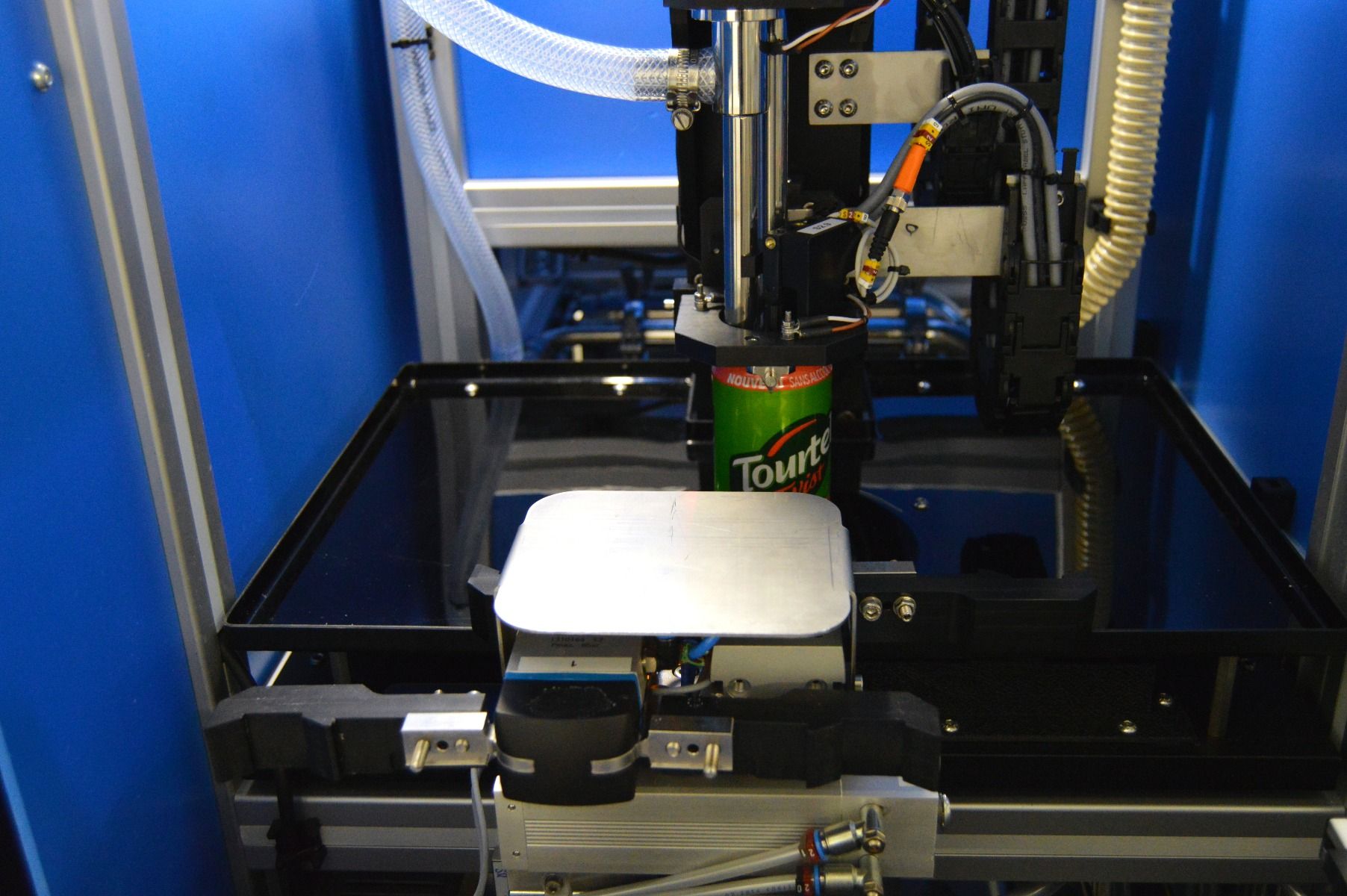

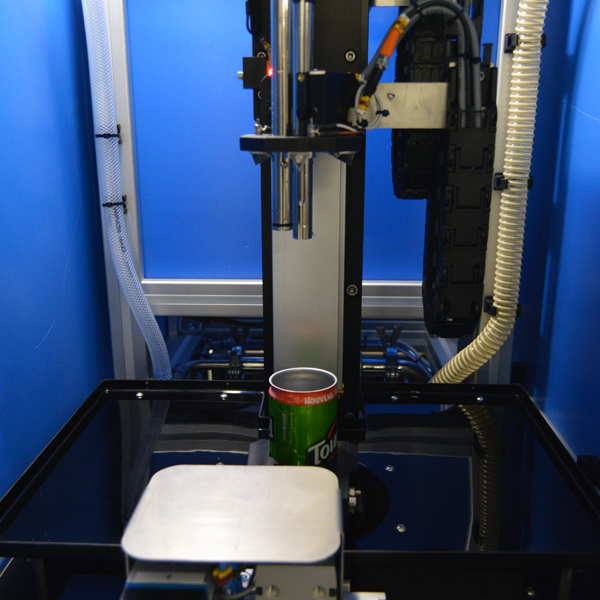

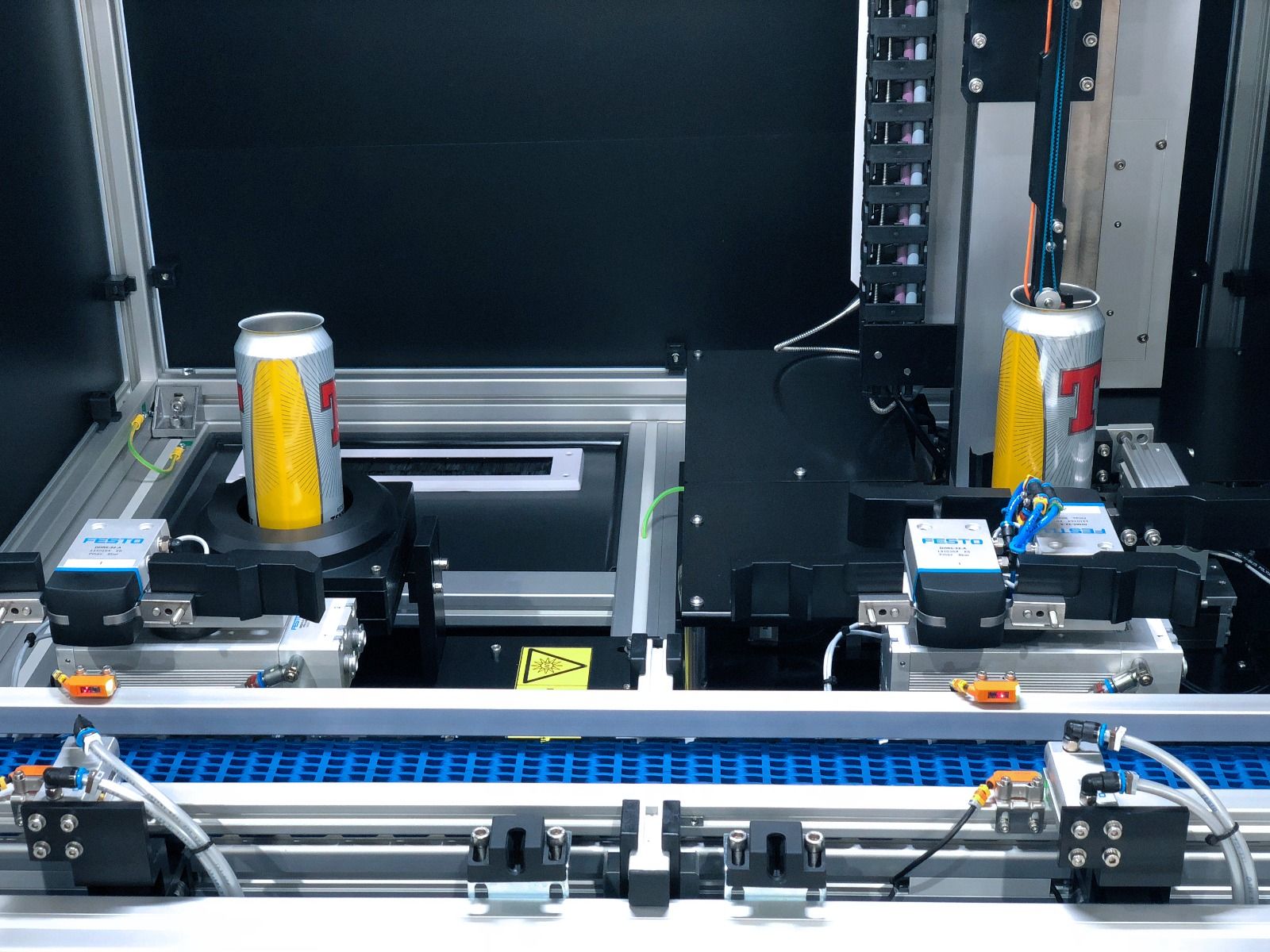

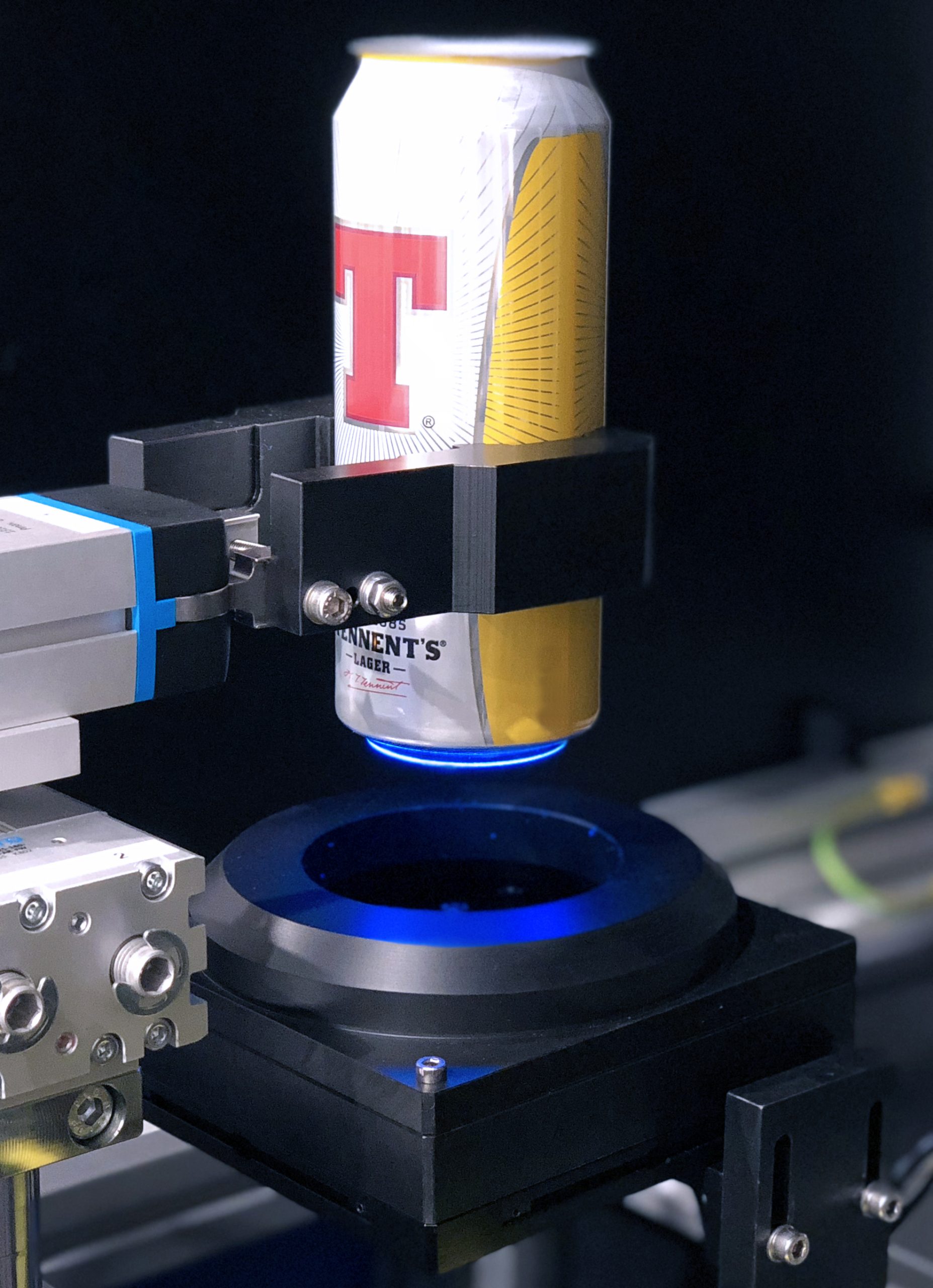

The Z313 Series Enamel Rater can be specified for conveyor loaded (automatic) or fully line fed (in-line) operation

The Z313 Enamel Rater measures the lacquer integrity of metal cans, with a typical throughput speed of 3 cans per minute.

The system can be specified with Torus’ optional LSM/ISG Recognition Camera Module, ensuring SPC data output is “tagged” with the relevant traceability for effective remedial actions.

Torus Beverage Can Gauging

Measurement Features

Standard

Measurement Features

Hi-Res (typically for plants running steel cans)

Technical Specification

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

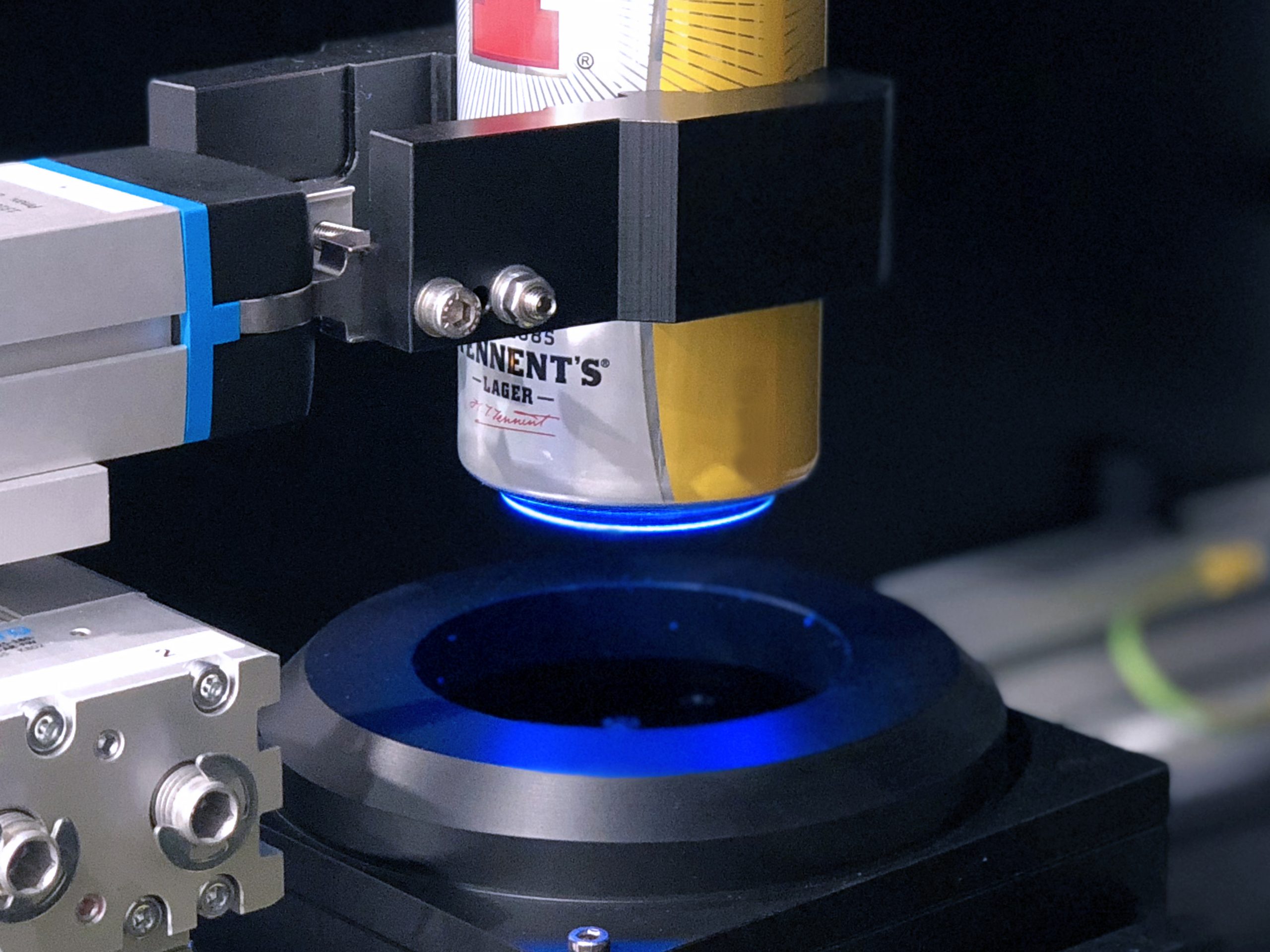

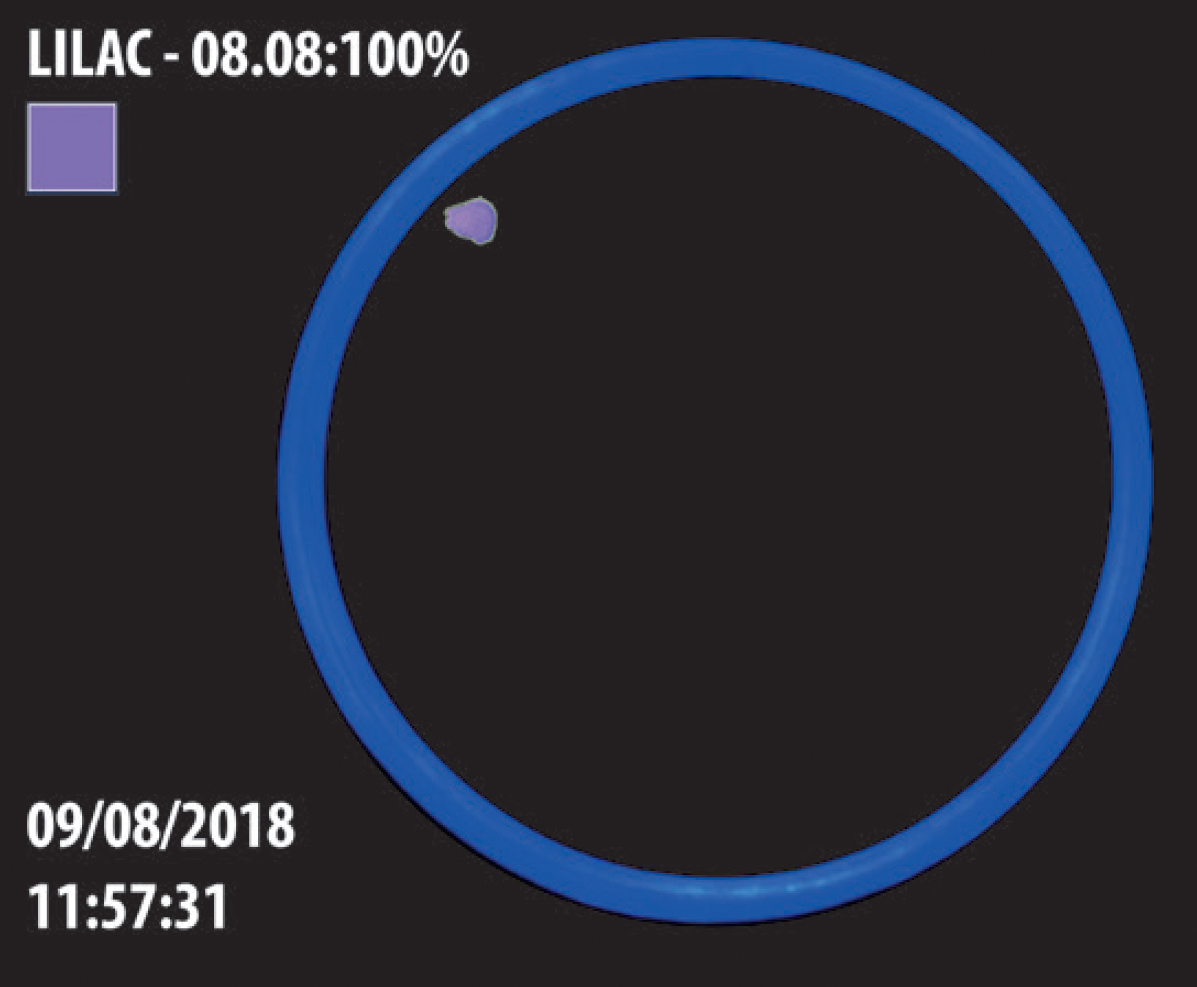

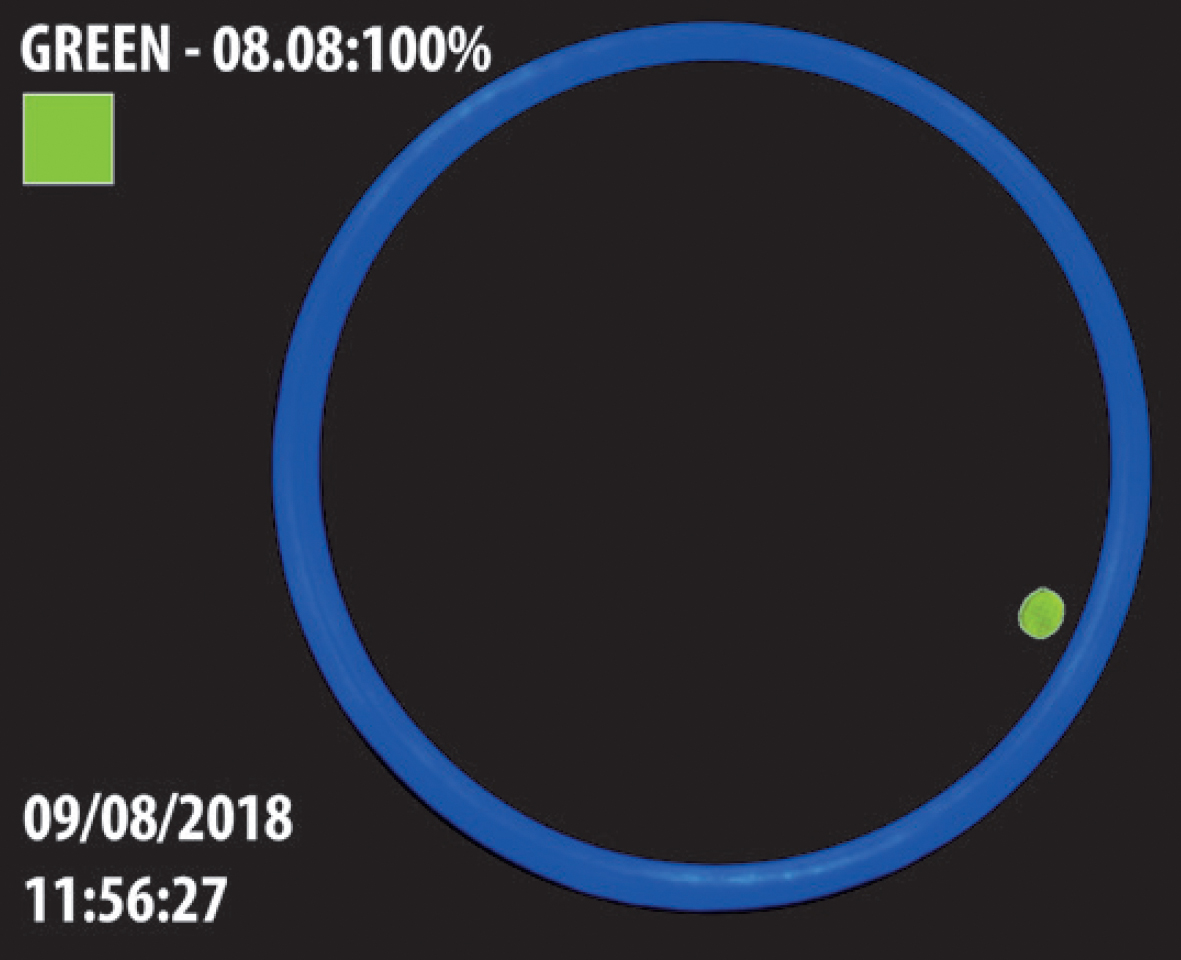

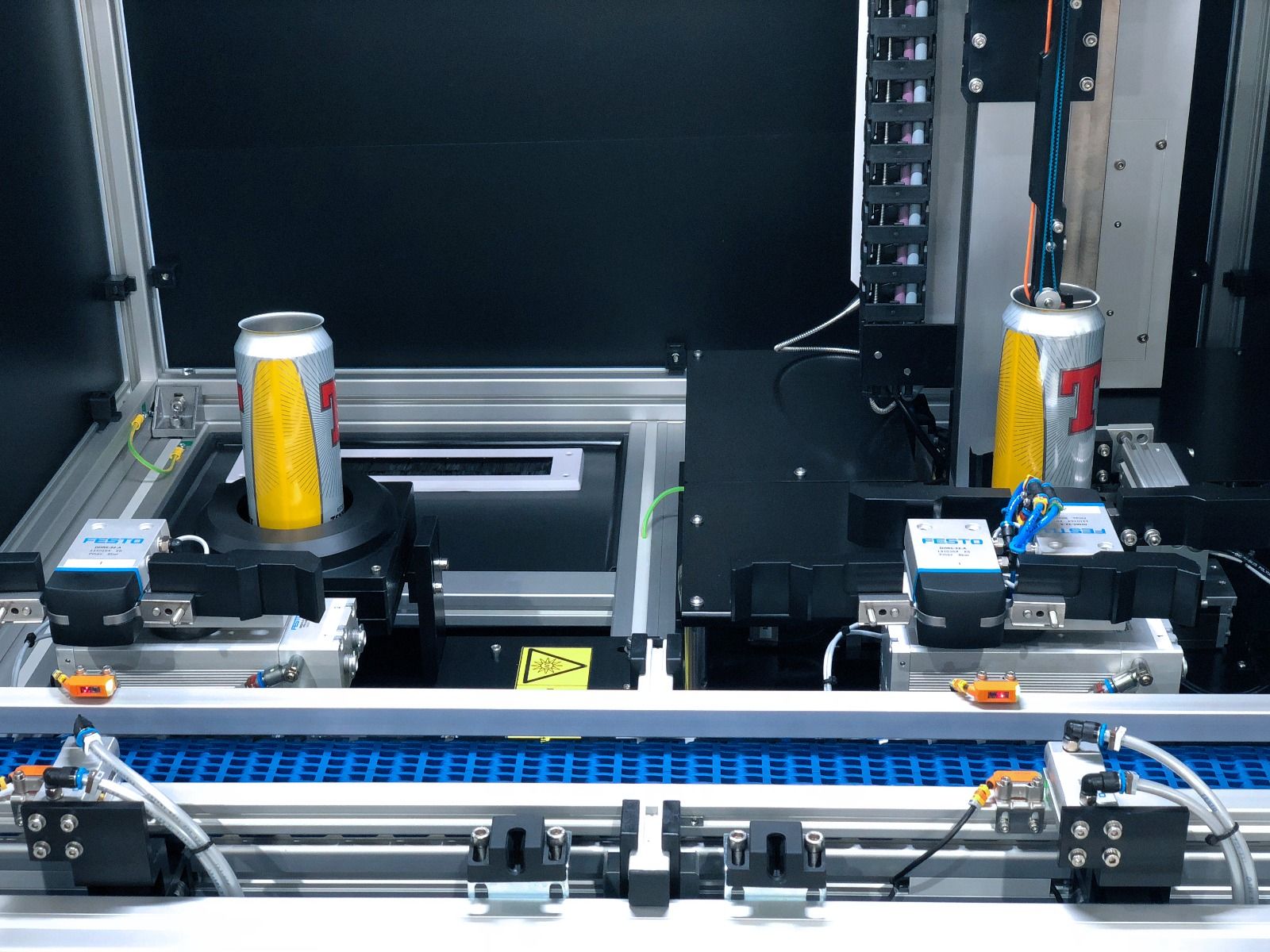

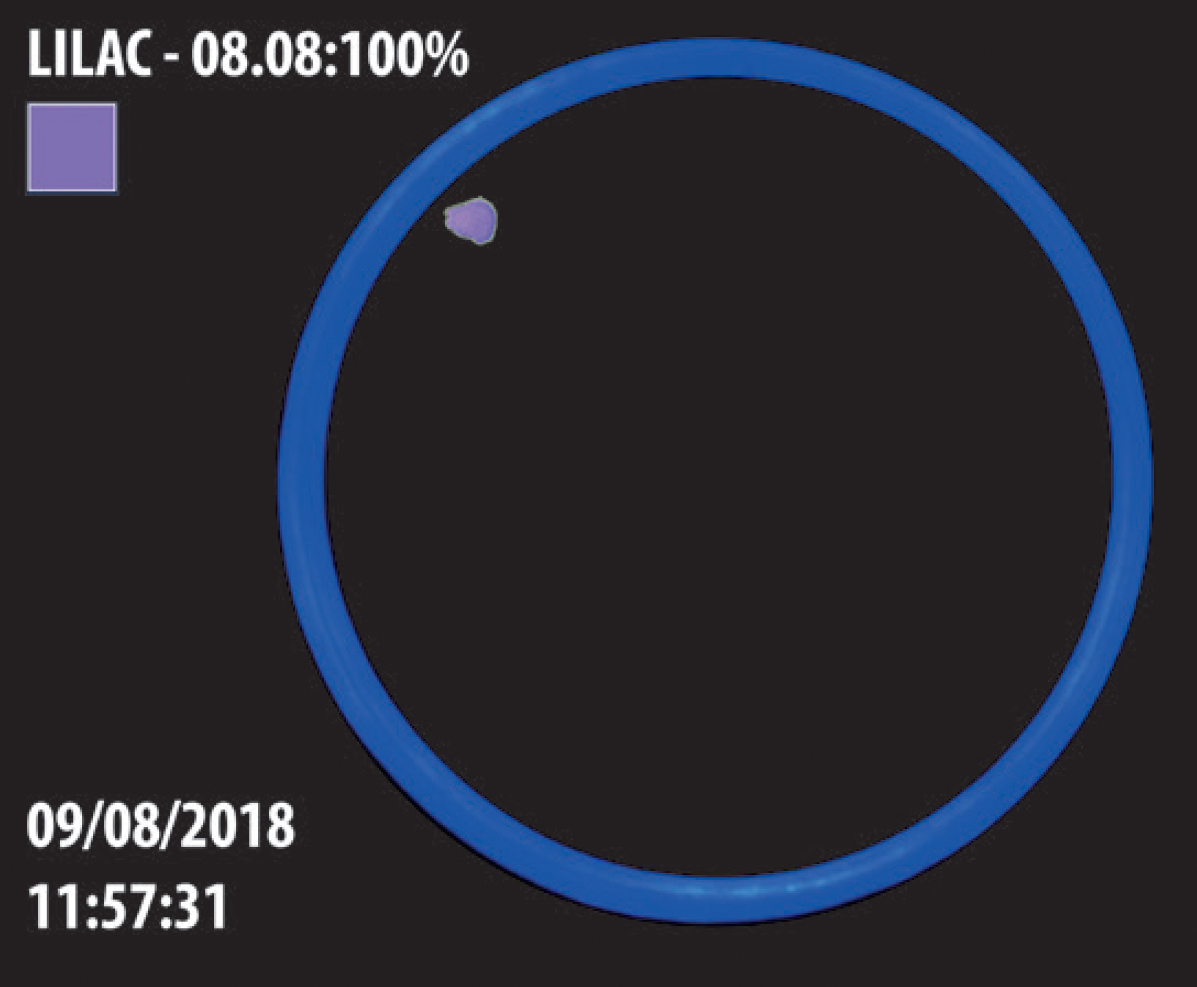

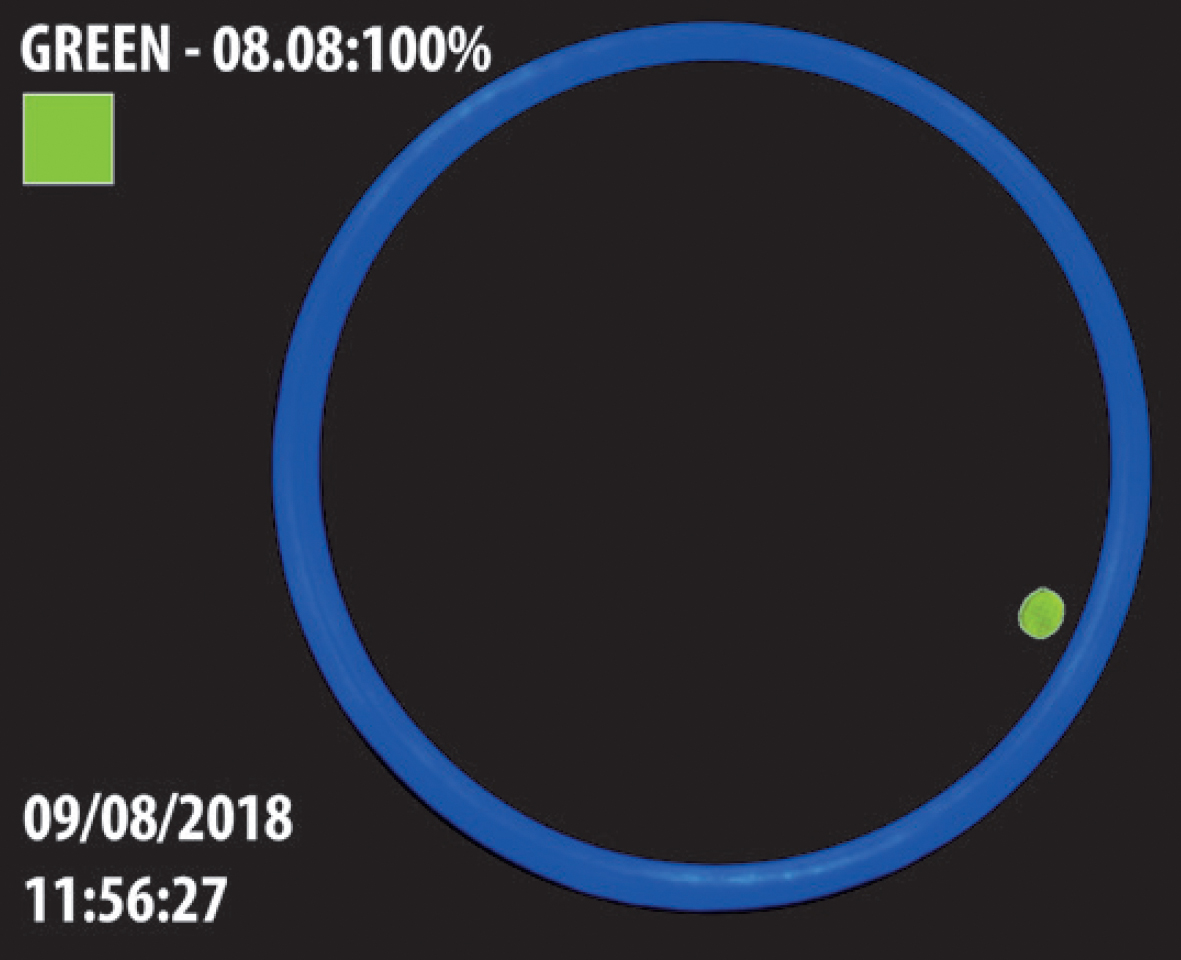

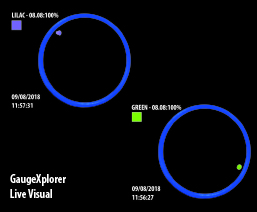

The Z312 Vision Module tests for all industry standard ISG recognition, including UV/BRC presence in one system.

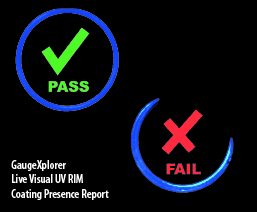

The Z312 Vision Module quickly identifies the application of UV base rim coat presence, indicating in split seconds a percentage coverage based on parameters set within Torus’ GaugeXplorer software. The live report instantly denotes if the rim coat has either been under applied or damaged.

Designed with flexibility in mind the Z312 module can be integrated into any new or existing Torus gauge, or alternatively supplied as a standalone system. The flexible module boasts multi size capability with no change parts allowing the system to be located anywhere on the shop floor.

Torus Beverage Can Gauging

Gauge Features

UV Base Rim Coat Presence (BRC)

• Visible Spray Dot

• UV Spray Dot

• 2 & 5 Digit Dot Matrix Character Code (Visible/UV)

The Z312 works together with and complements Torus’ Z340 Coating Analyser to provide Base Rim Coat Distribution Analysis, aimed to show operators how the BRC is distributed and thus showing up any potential areas to save resource.

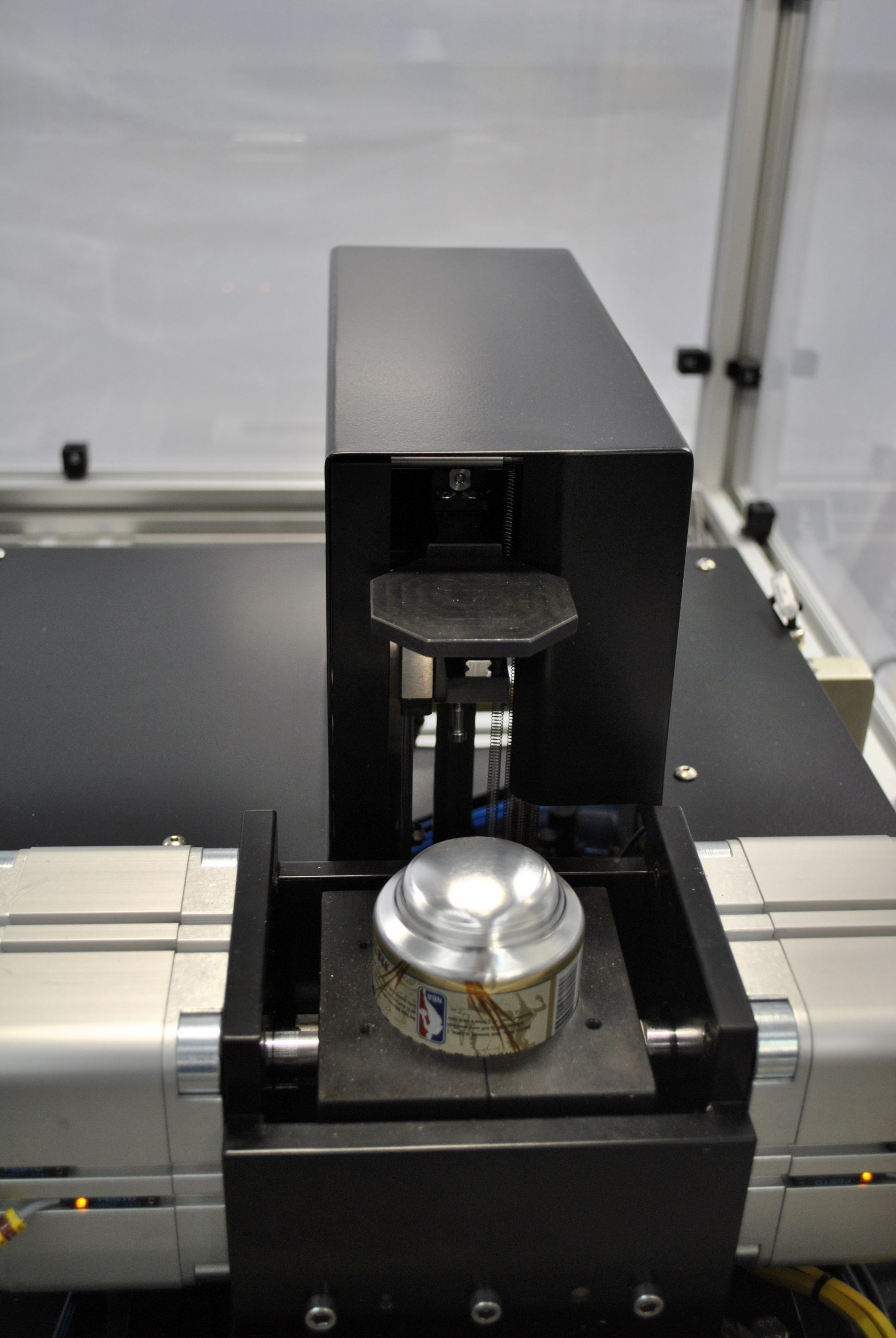

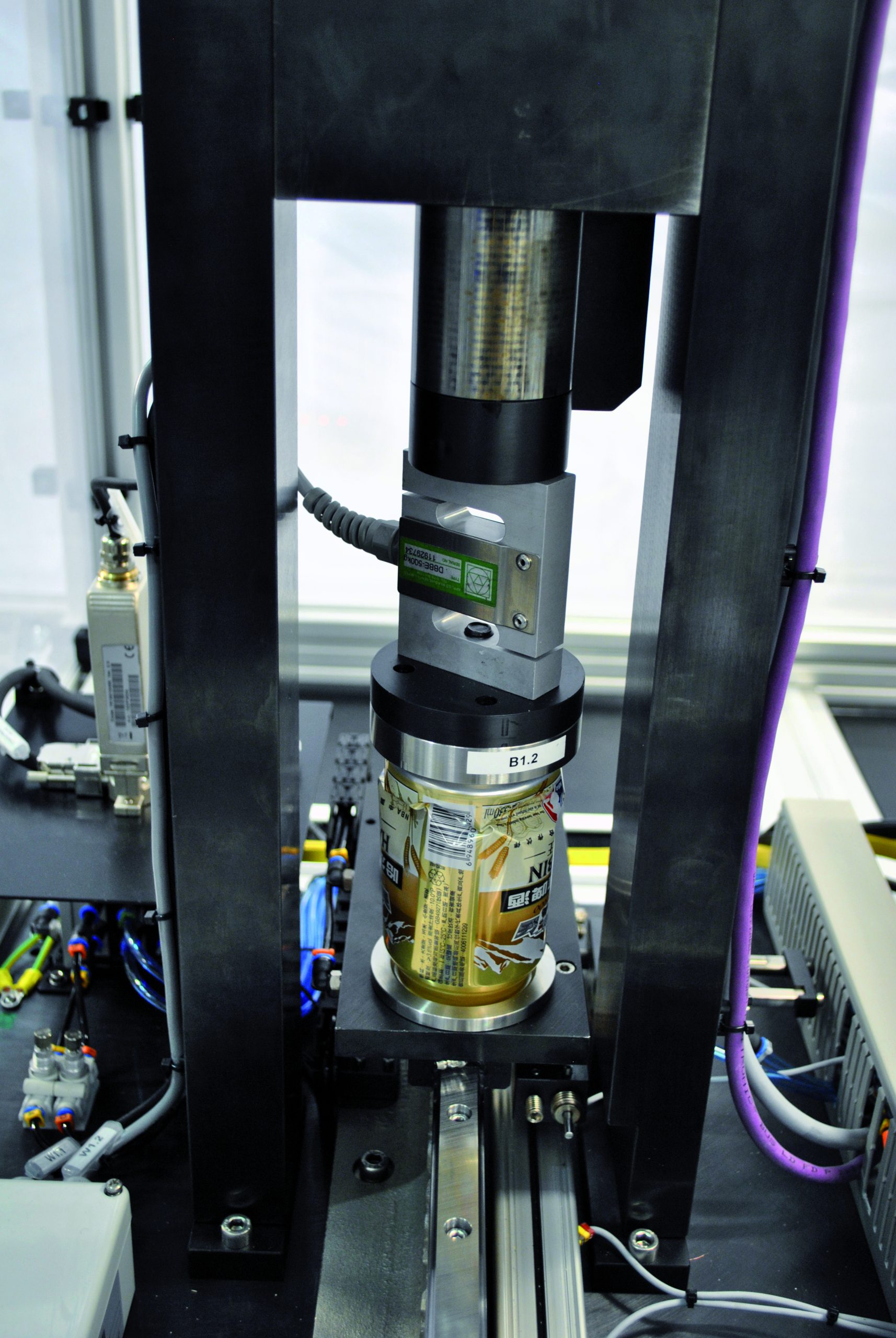

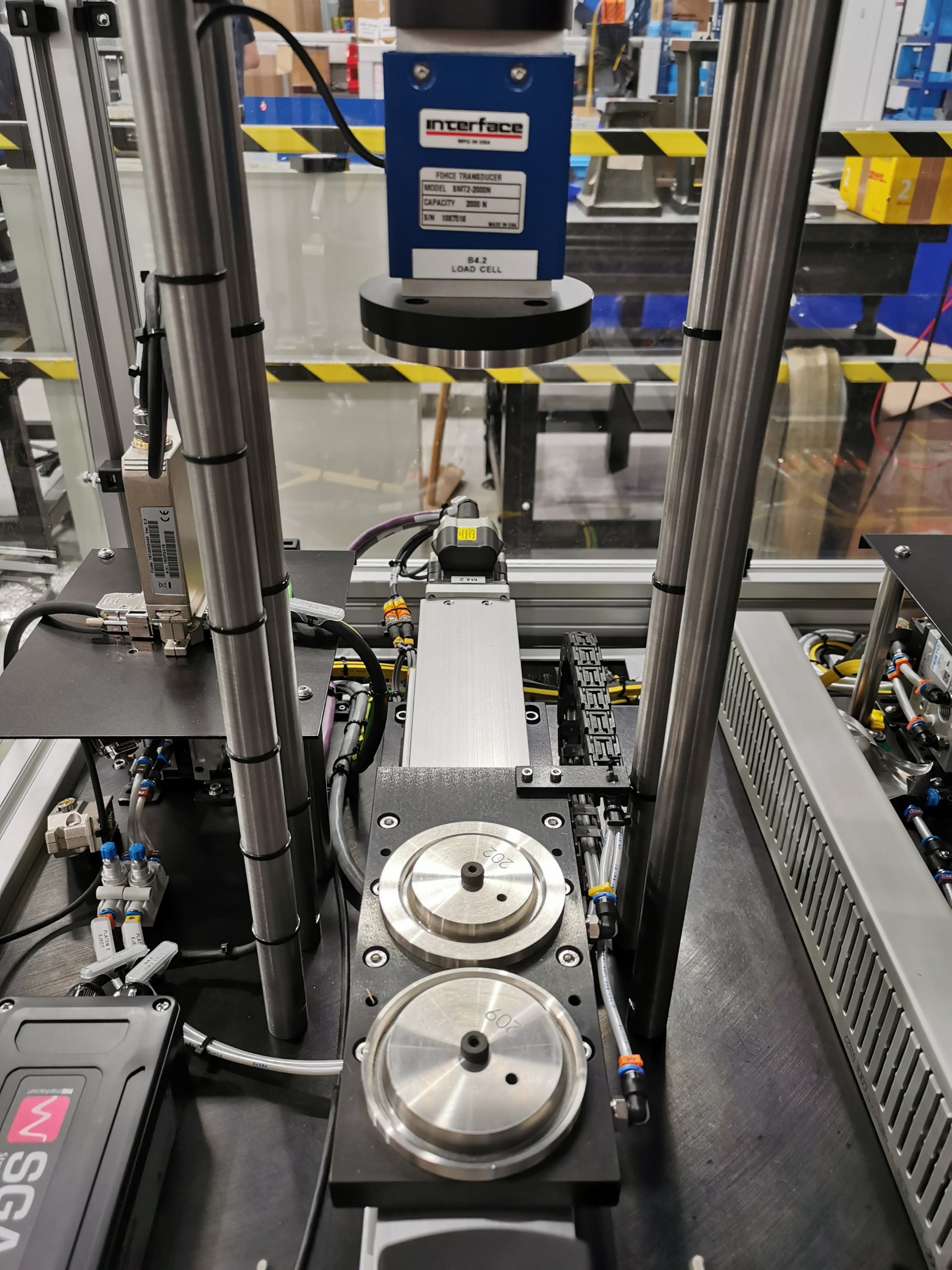

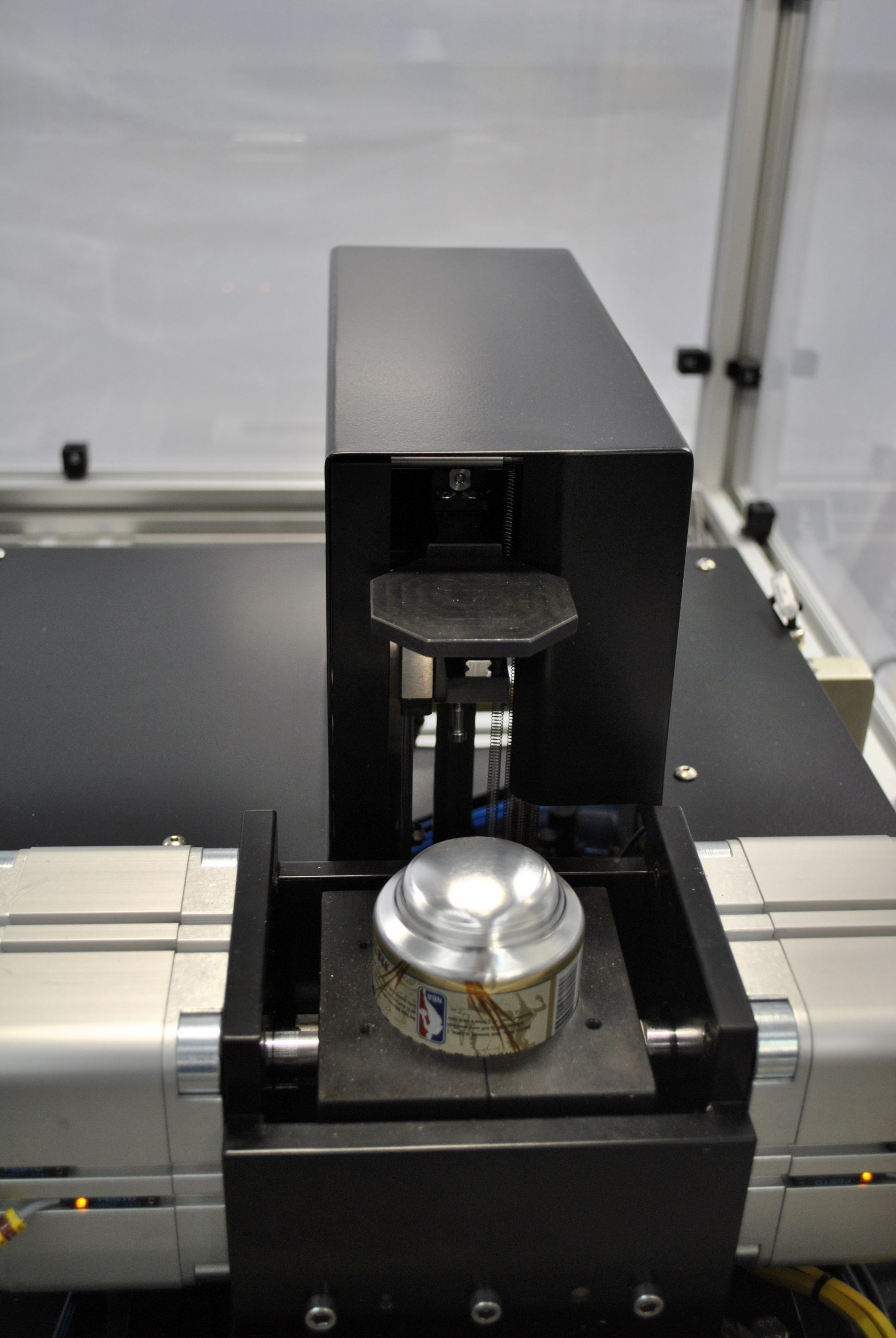

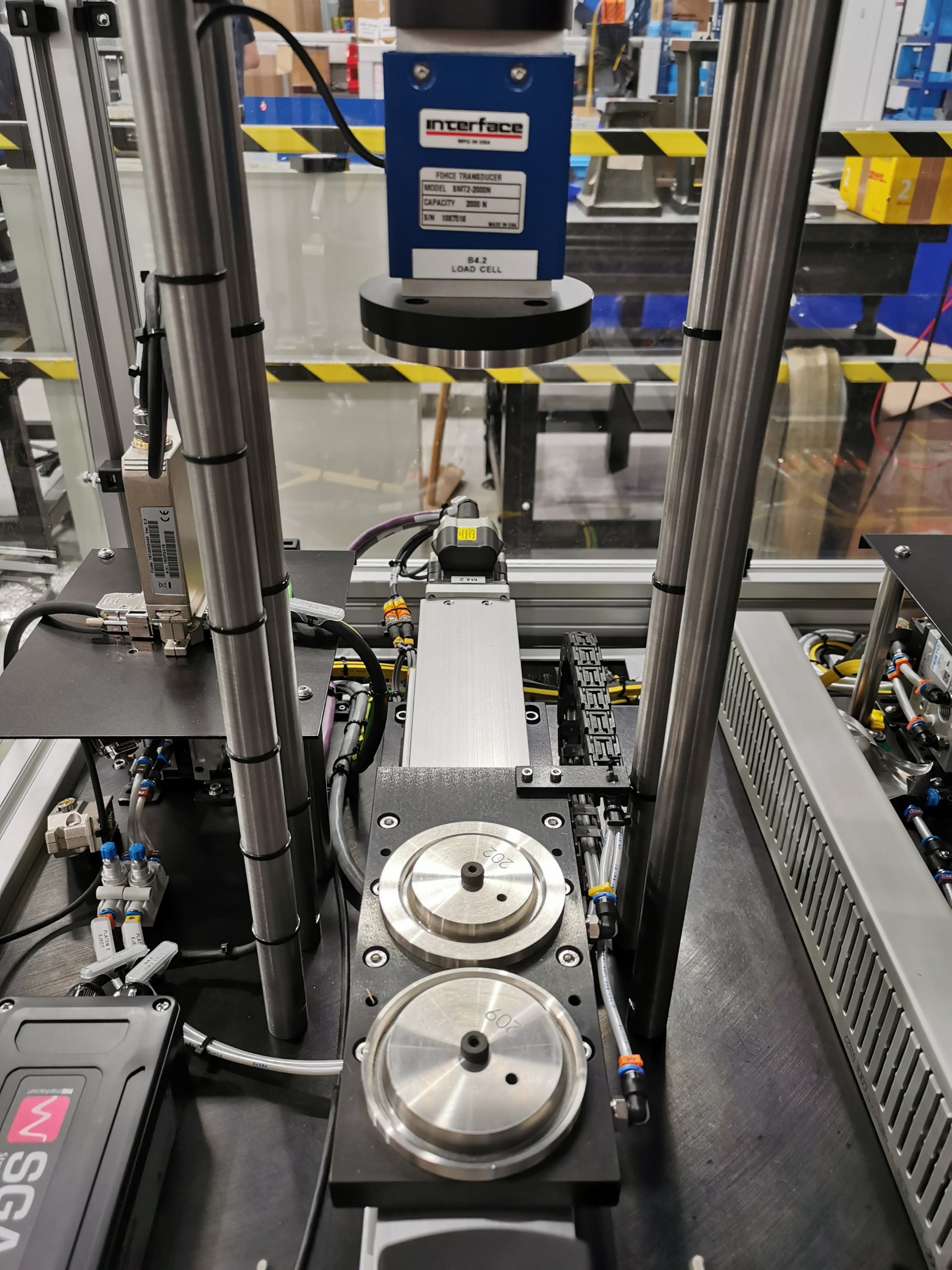

Torus’ Z307 series defines the standard for destructive testing and inspection

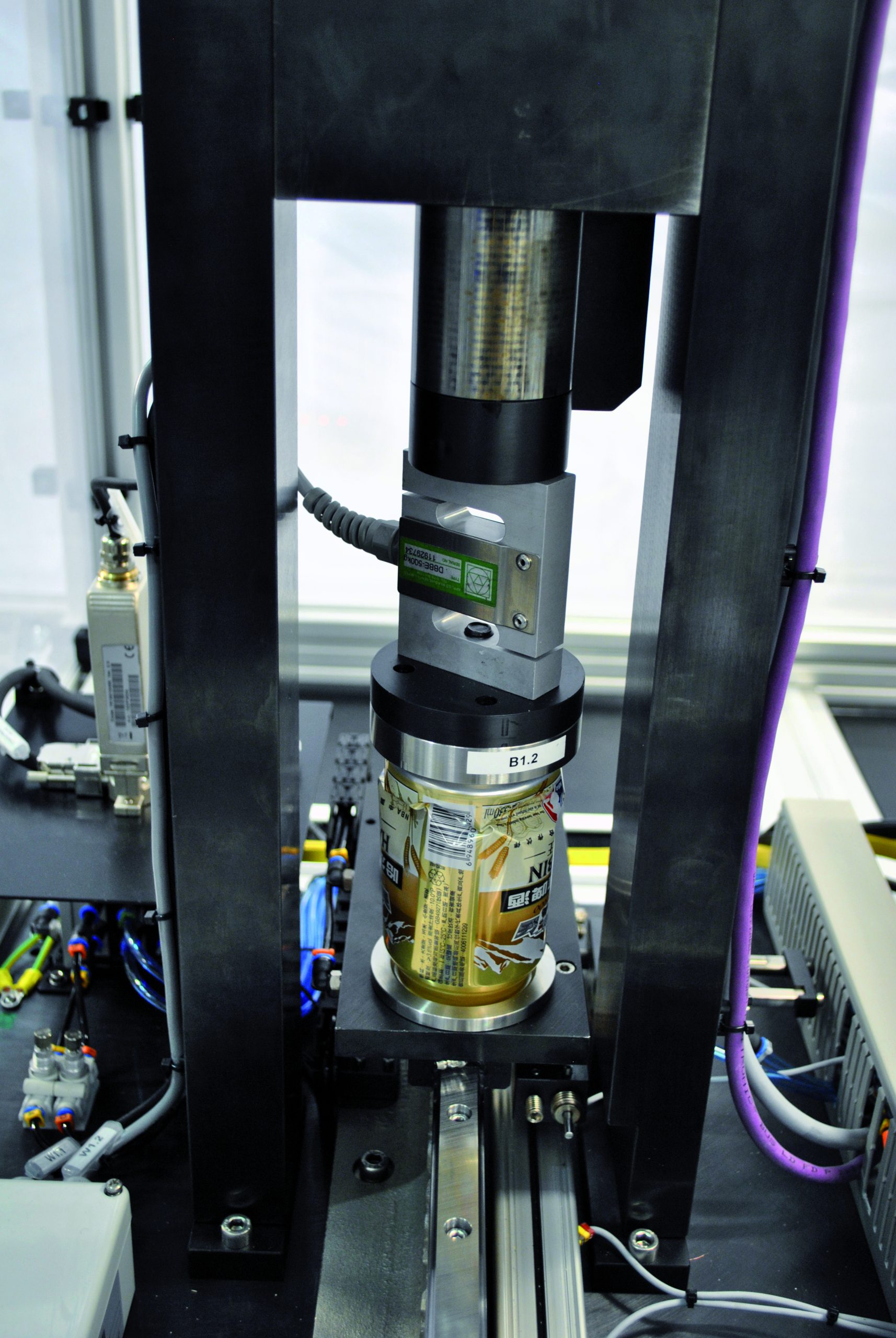

The Z307 Automatic Axial Load module determines the maximum axial load force that can be applied prior to container failure, within a short cycle time.

The Z308 Dome Growth/Dome Reversal module provides detailed information about the overall change in length of the can when pressure is applied and subsequently removed. The system has programmable internal pressure capability to meet each customer’s exact needs for dome growth. After dome growth, the can sample can be reversed to find the maximum pressure the sample is able to withstand before failure (dome reversal)

Torus Beverage Can Gauging

Measurement Features

Technical Specification

Gauge Features

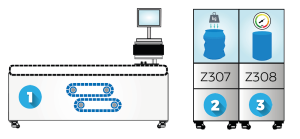

Option 1: Standard Setup

Z308 Option:

Interchangeable Jaws

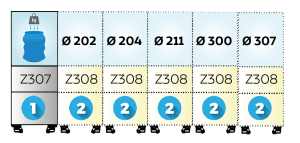

Option 2: Dedicated Body Diameters

For dedicated body diameter product lines, the Torus modular concept is able to cover Ø 202 – Ø 307 body diameters (up to but not limited to) with a dedicated module for each with no change parts.

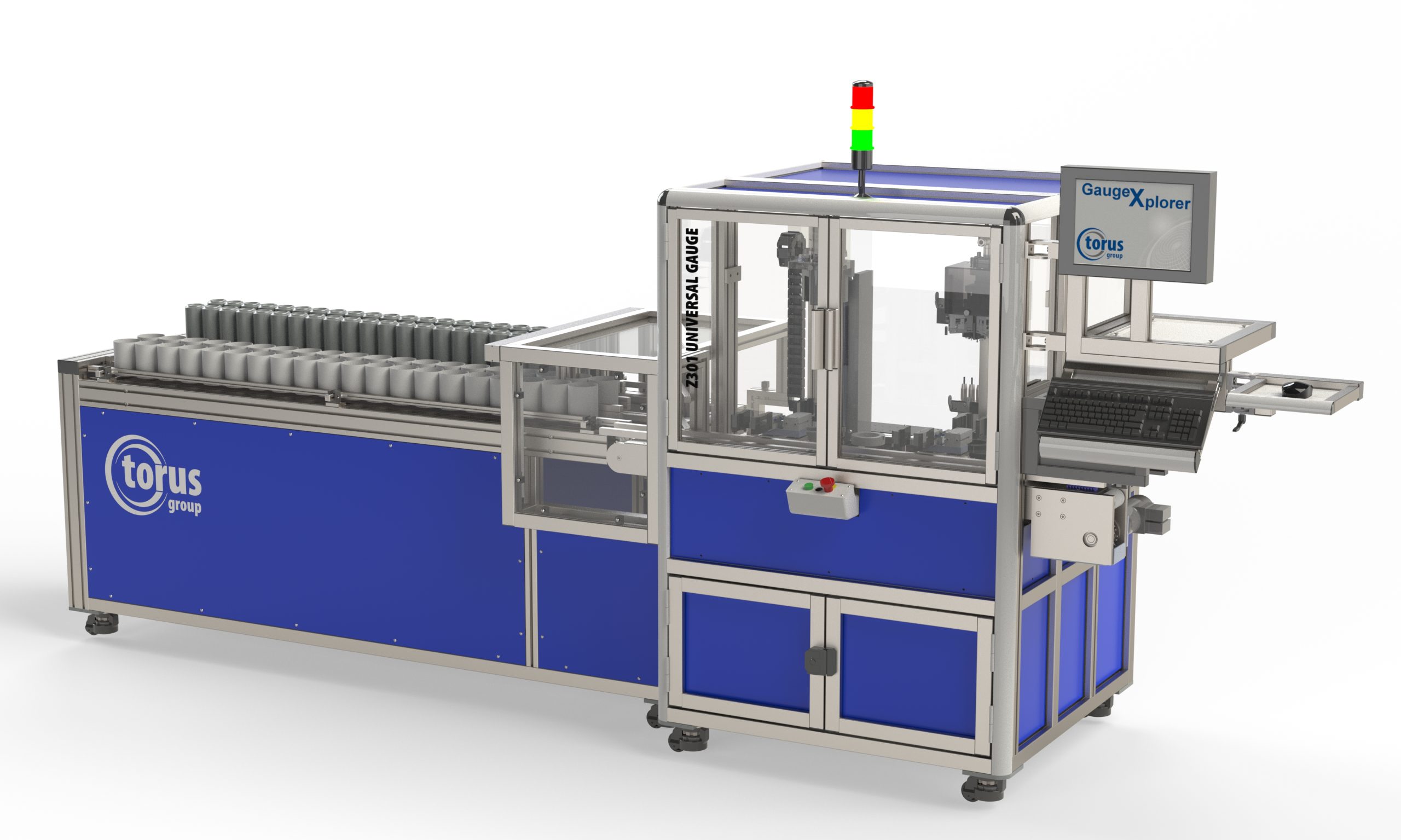

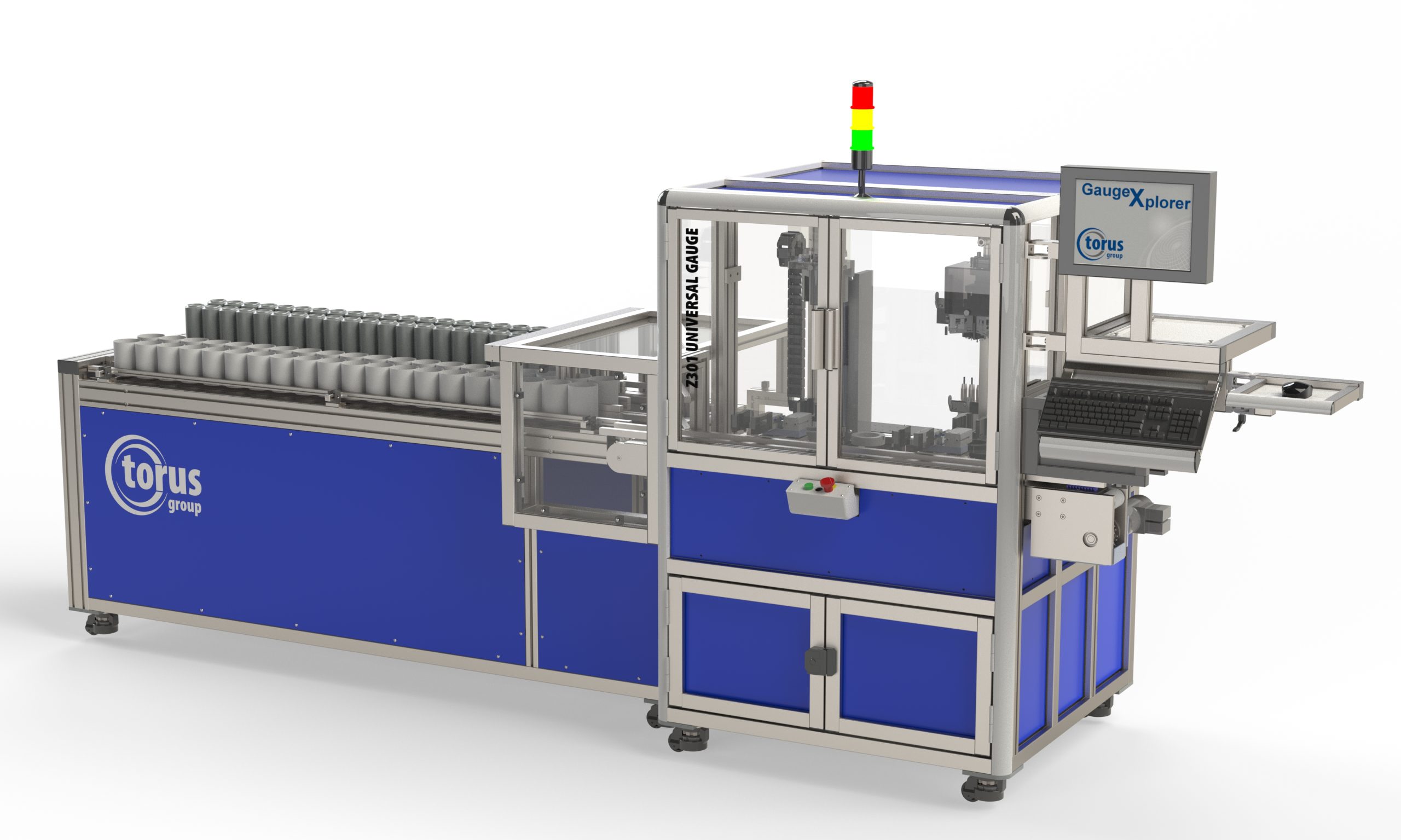

The Z301 Universal Gauge incorporates trimmed and finished can measurement into the same system, for full component measurement.

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

Torus Beverage Can Gauging

Measurement Features

Trimmed Can Features

Finished Can Features

Technical Specification

Trimmed Can Capabilities

Finished Can Capabilities

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999