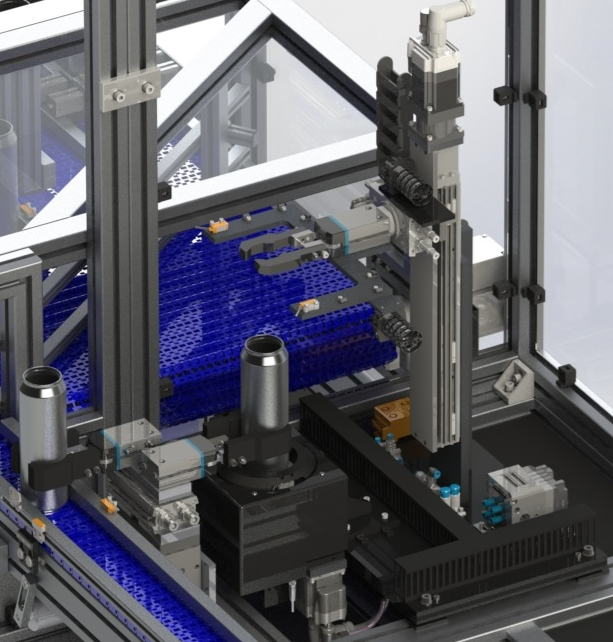

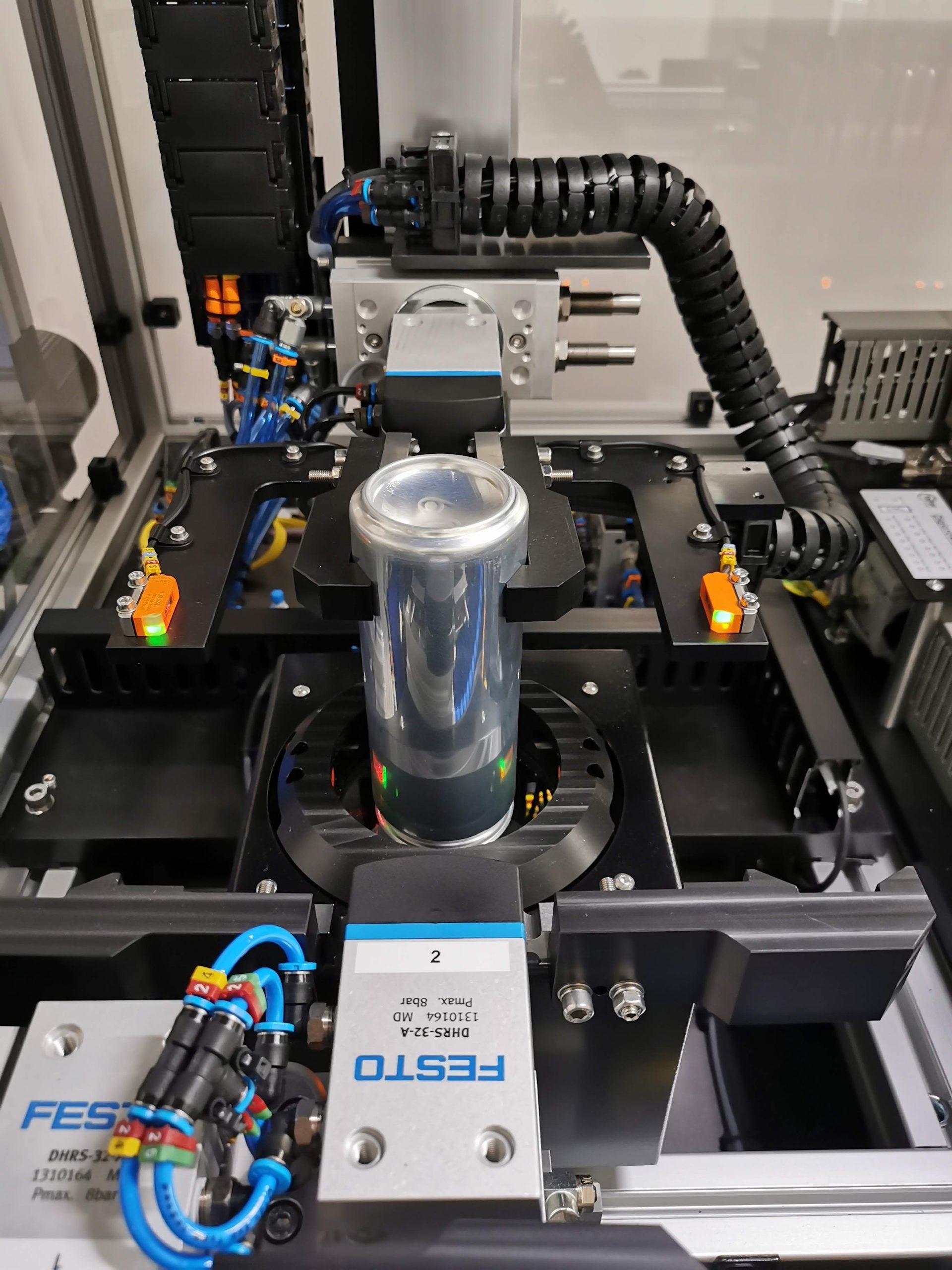

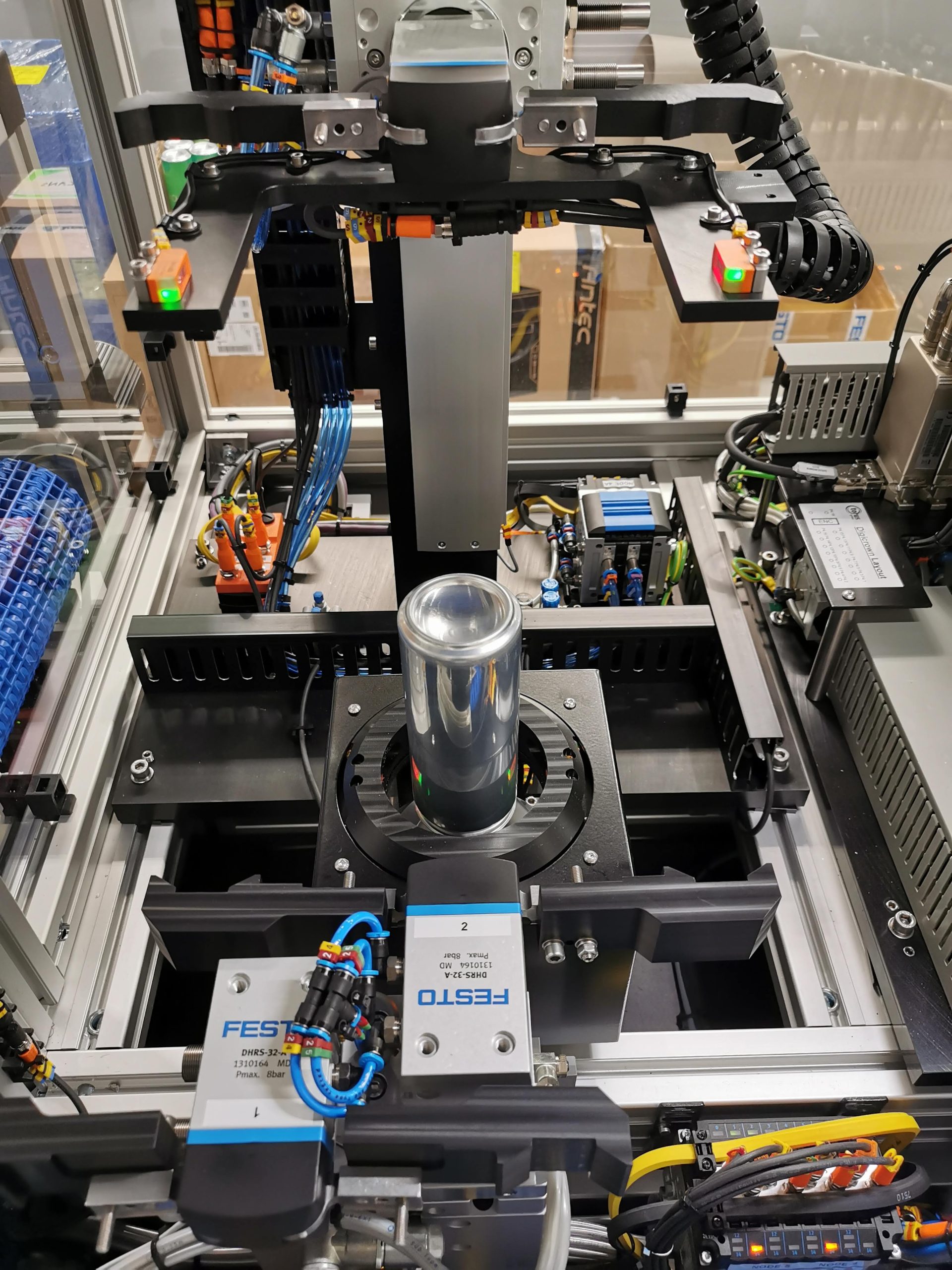

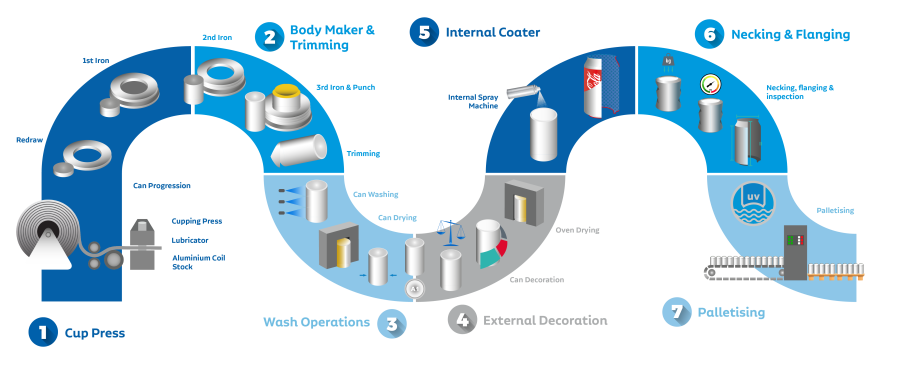

Designed to be integrated into all new and existing Torus gauging systems, unlike, its predecessor, the new Z705 Body Maker Module has an inbuilt turnover option, and can operate universally in conjunction with both Z301 Trimmed Can Inspection and Z302 Finished Can Inspection gauges, offering traceability on both trimmed and finished components within one measurement system.

The Z705 Body Maker Recognition Module operates both single and double-digit Alphaneumeric Code, without any influence from the application of Body Maker underlining, vent holes or spray head traceability markings.

Integrated with Torus’ GaugeXplorer software, the Z705 adds process traceability to components measured within additional gauging modules. With advanced through-put control, the sampling for each Body Maker can be set at a target rate, to ensure an equal distribution of measurement results.

Torus Beverage Can Gauging

Measurement Features

Feature

Technical Specification

Capabilities

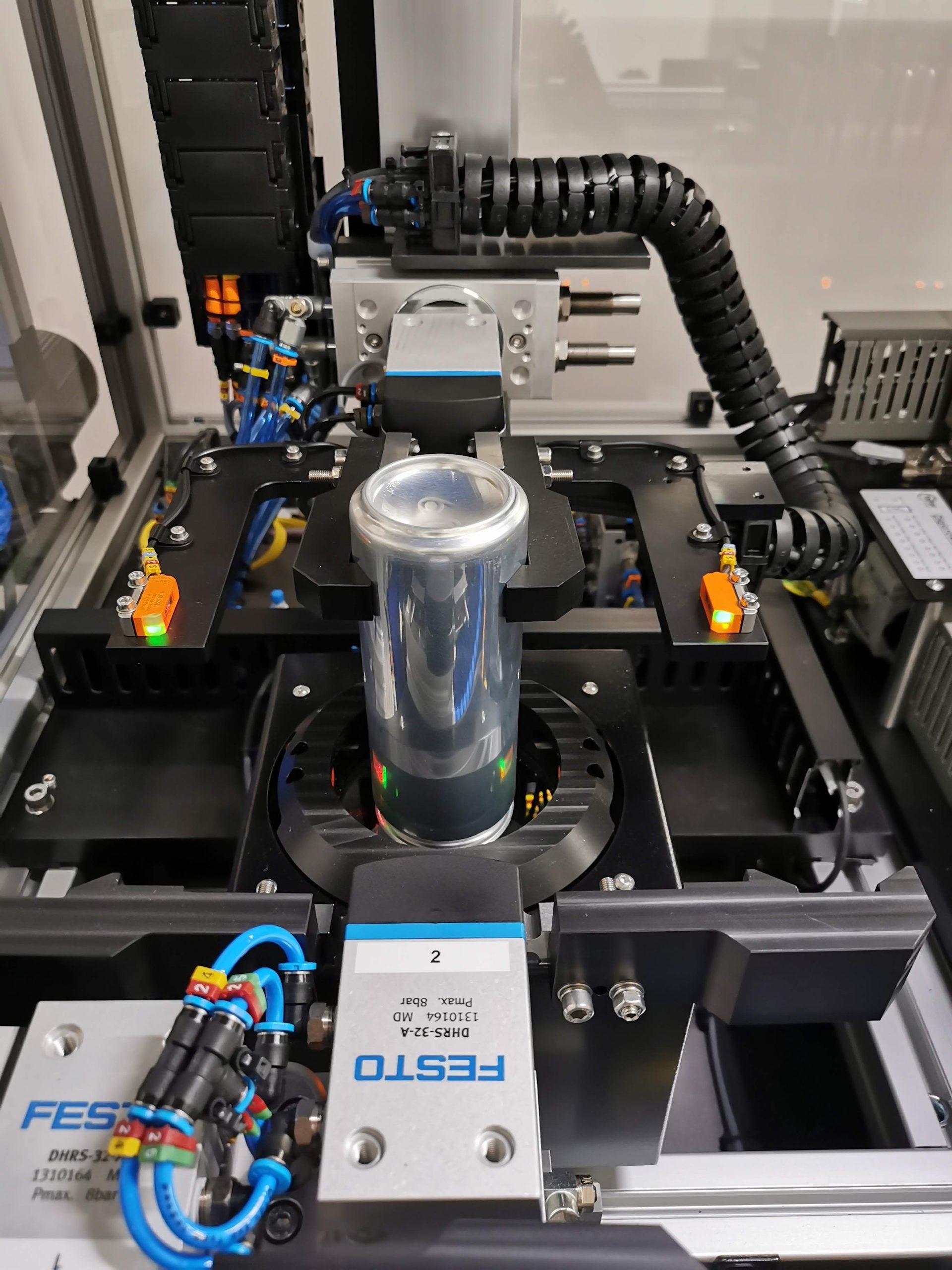

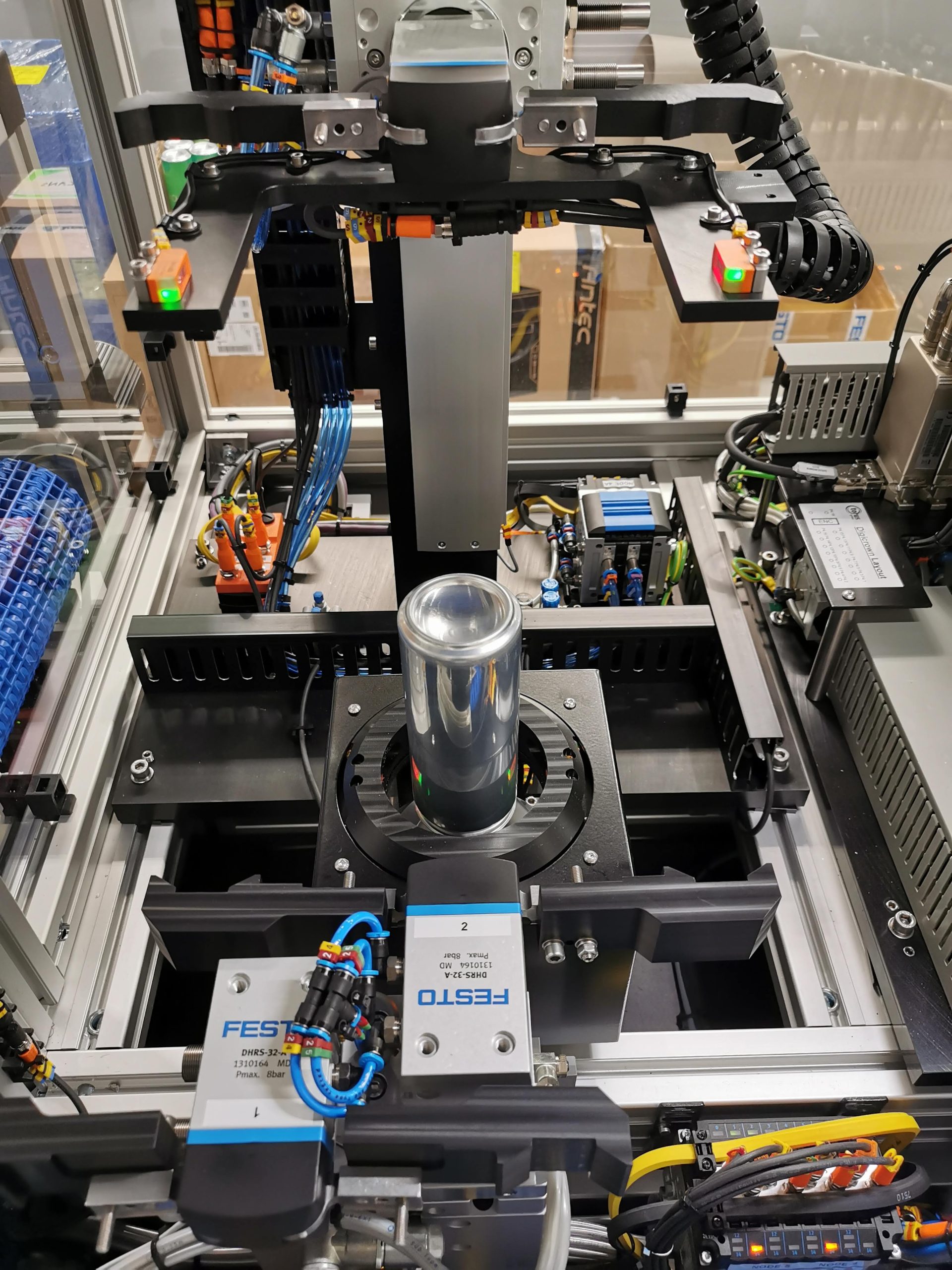

A multi-segment illumination source, operates simultaneously with image acquisition, rotating around an optimal search area, collecting multi-image captures throughout the range. Using latest photometric stereo post image control processing technology, a high-quality result against a pre-defined model is identified. The Body Maker Recognition result is then tagged to the component for measurement result traceability, reported in conjunction with measurement data results.

An example of the Body Maker results below:

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999