Introducing Torus’ Z704 RemoteXplorer, offering remote visual global support from our head office

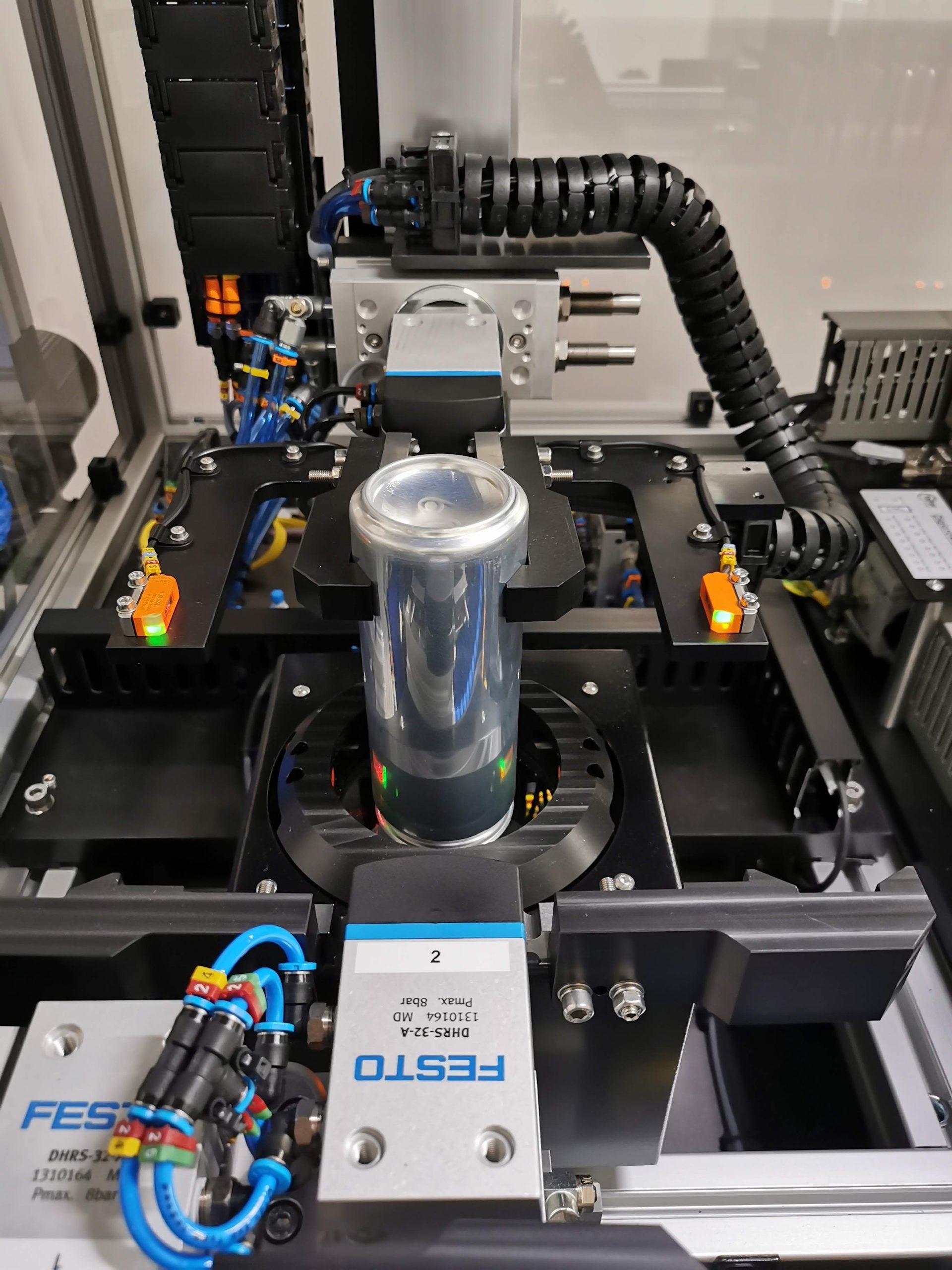

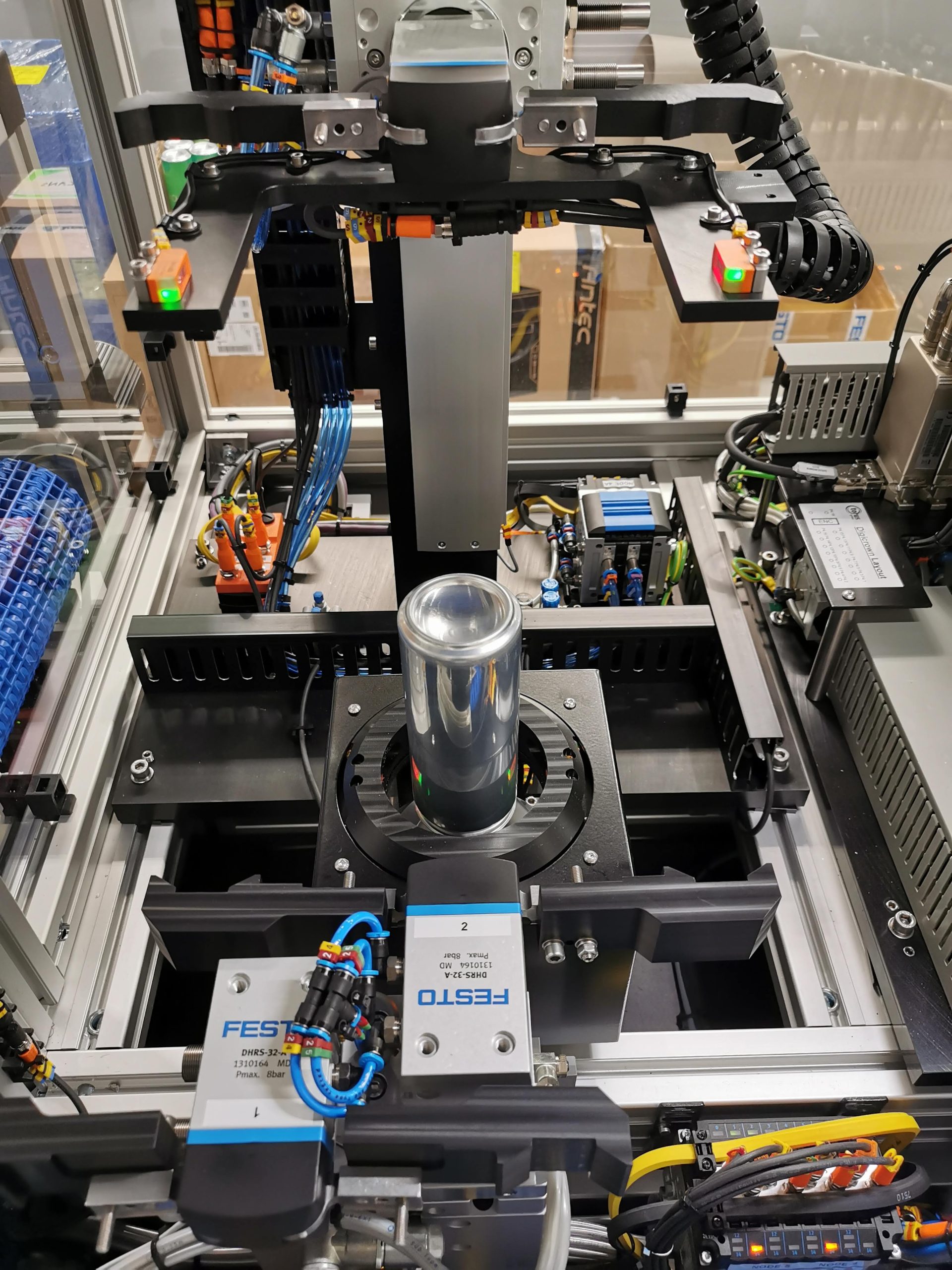

Remote support has been available for many years via Torus’ global helpdesk team, but only now can ‘eyes on’ support be offered via a new extension of Torus’ traditional GaugeXplorer software. RemoteXplorer, with the permission of customers, the gauges can now be monitored visually using RemoteXplorer’s newly developed pan and tilt camera system and software package.

How can we help you?

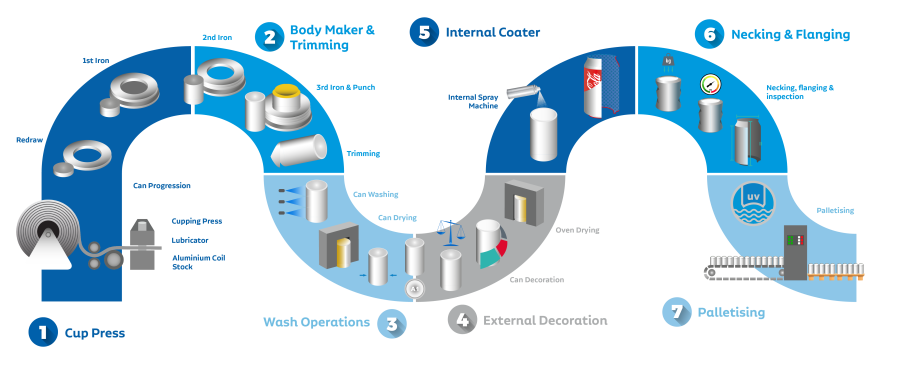

Using Industry standard database platforms, SPCXplorer is suitable for single station application, through to full factory database-centric network installations.Statistical Process Control (SPC) software is essential for manufacturing wide quality monitoring.

Upgrade Existing SPC Software Systems

With our database migration tools and backward compatibility architecture, users of the previous generation Repro2000 statistical process control software can upgrade with minimal disruption to their daily operation.

Designed with the needs of shop-floor data collection in mind, SPCXplorer can be interfaced to a large variety of manual instrumentation via RS232 connectivity, or for more complex gauging systems, can process bespoke ASCII data files via Ethernet.

The Reporting module ensures the data is displayed in the right format for your quality reviews, and with its simple and powerful administration functions, access to the management and configuration areas of the software is password protected for assured security.

Reliable & Professional SPC Software for Industry – SPCXplorer

Statistical Process Control software helps prevent business relative issues before they occur, via the use of data driven quality analysis. This enables you to monitor your production process by utilising visual diagrams such as Control Charts, customers have the ability to create specific control boundaries for all of their process monitoring needs. SPCXplorer detects manufacturing issues before they occur.

Using statistical process control software and knowing how efficient your processes are running, helps give the operators valuable information on whether to instigate or adjust their manufacturing processes or whether to carry on with the current process.

Want to know more about our SPC software? Contact us today.

How can we help you?

GXP software is fundamental to all Torus Measurement Systems gauges, providing smooth reliable gauge operation, including state of the art intuative diagnostic tools, allowing the operators and our TMS support team easy access to the gauge where ever in the world you are.

GXP software has a range of features for your specific industry requirements to help improve productivity & meet quality requirements.

How can we help you?

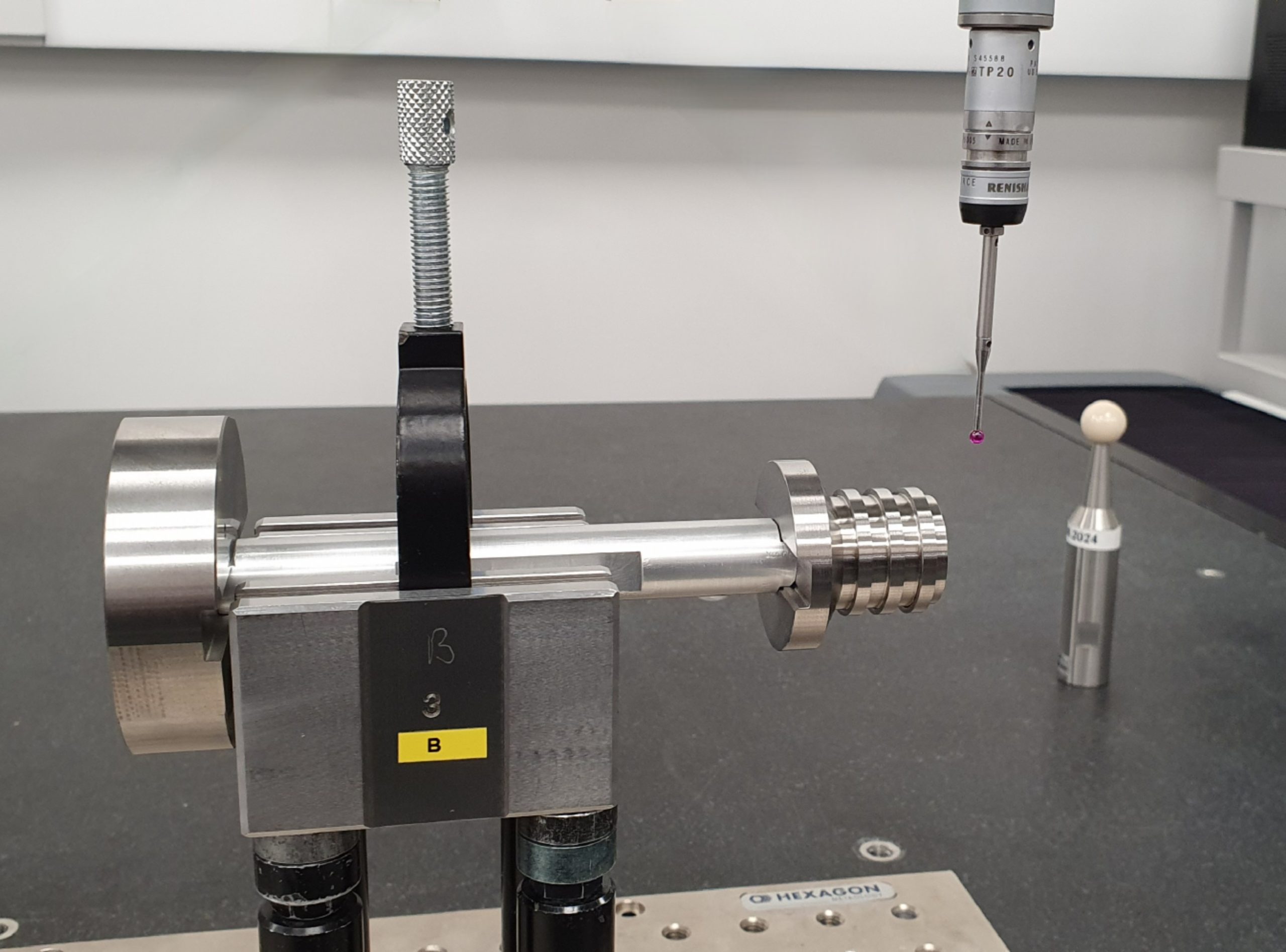

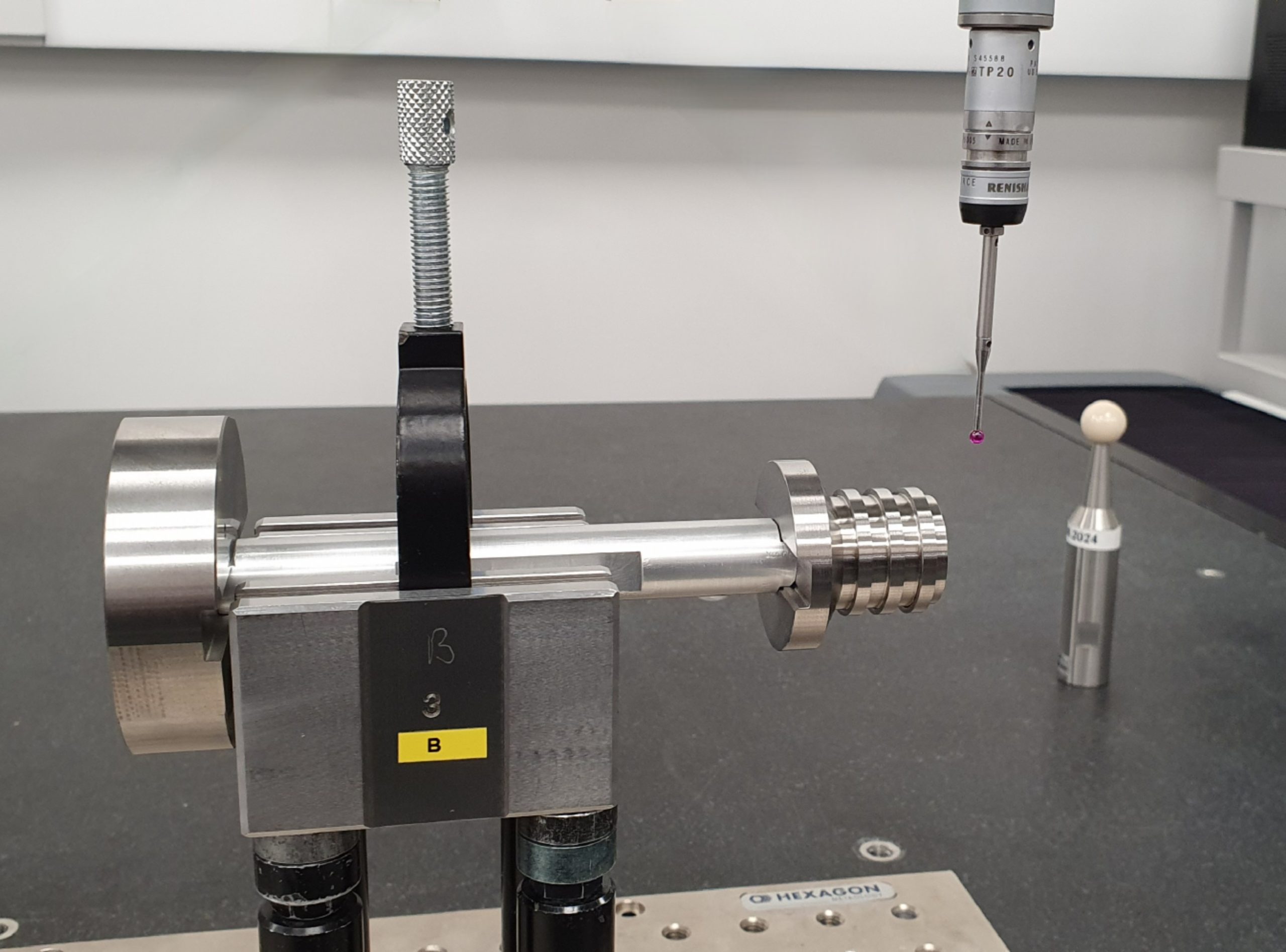

The Beverage Can Master supplied with your gauge is extremely important for the reliability of your measurement results.

As the original equipment manufacturer Torus Measurement Systems recommends that your Master is re-calibrated annually to continually assess for wear, damage and integrity. This ensures your product quality is never compromised.

Torus are a leading manufacturer in gauging systems for the packaging industry worldwide, with the expertise to understand the functionality and critical features of your master.

Torus Measurement Systems Master Calibration Service offers:

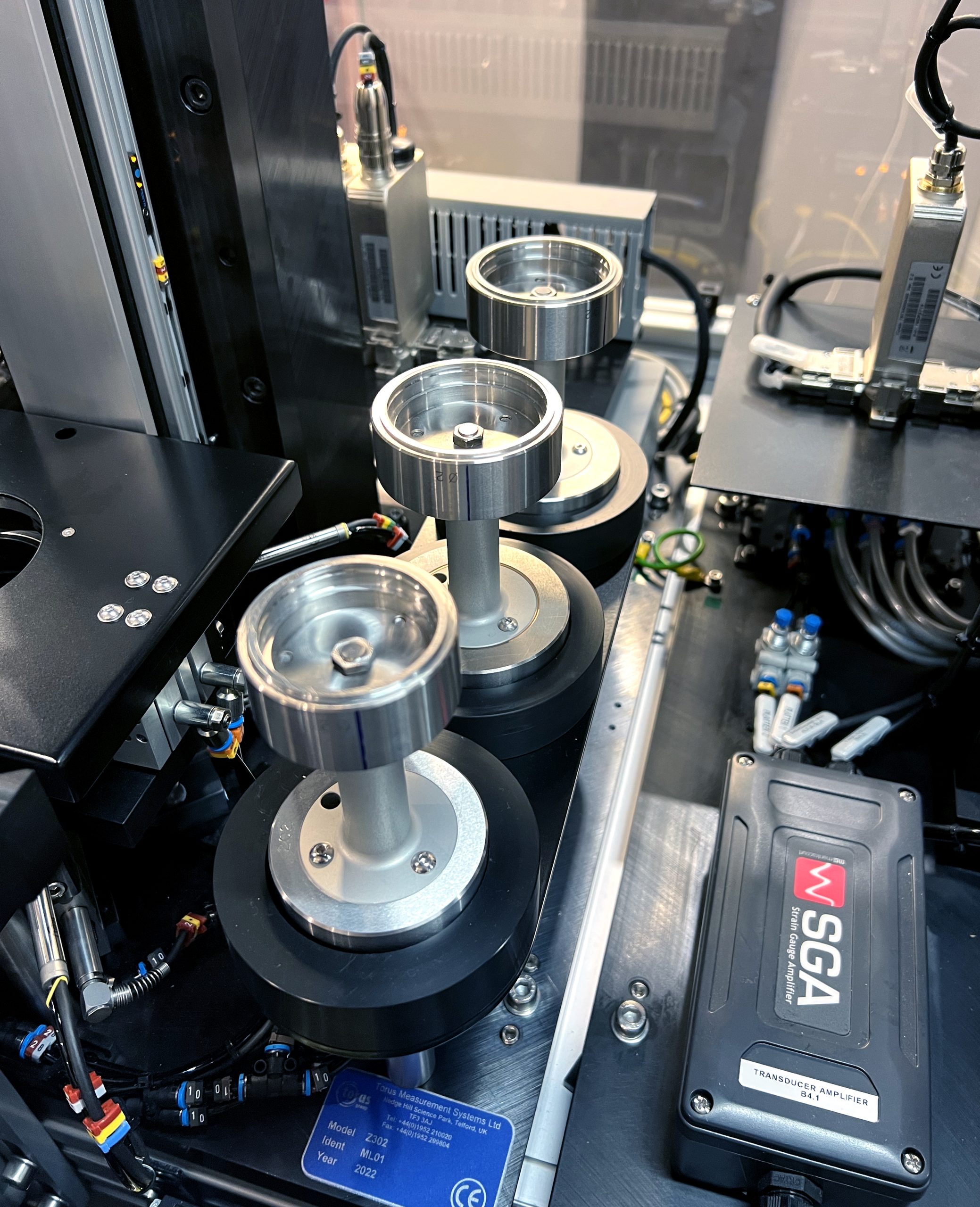

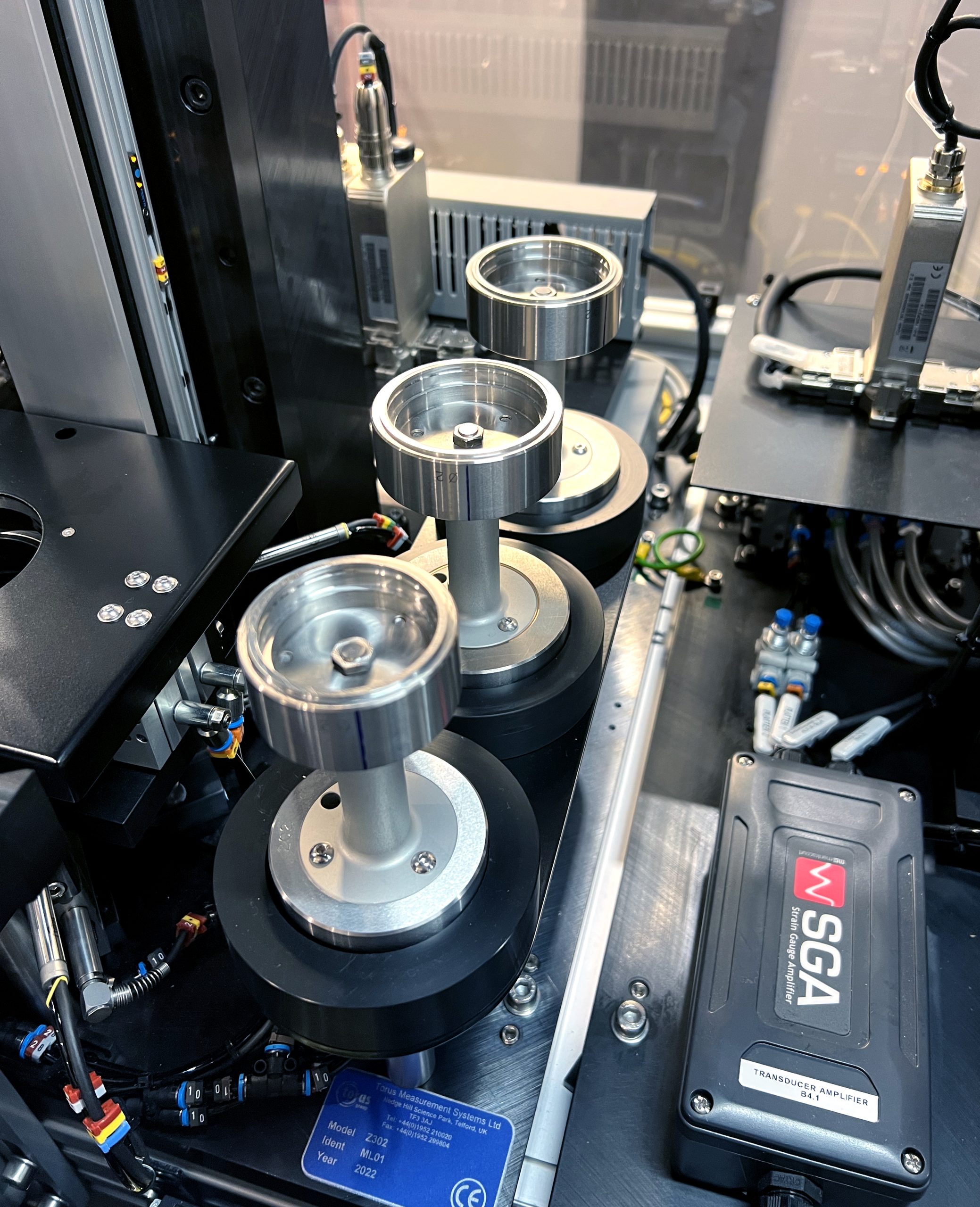

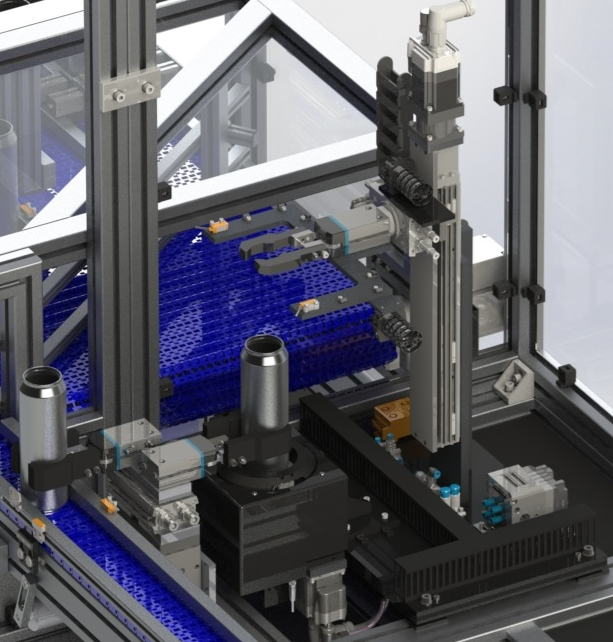

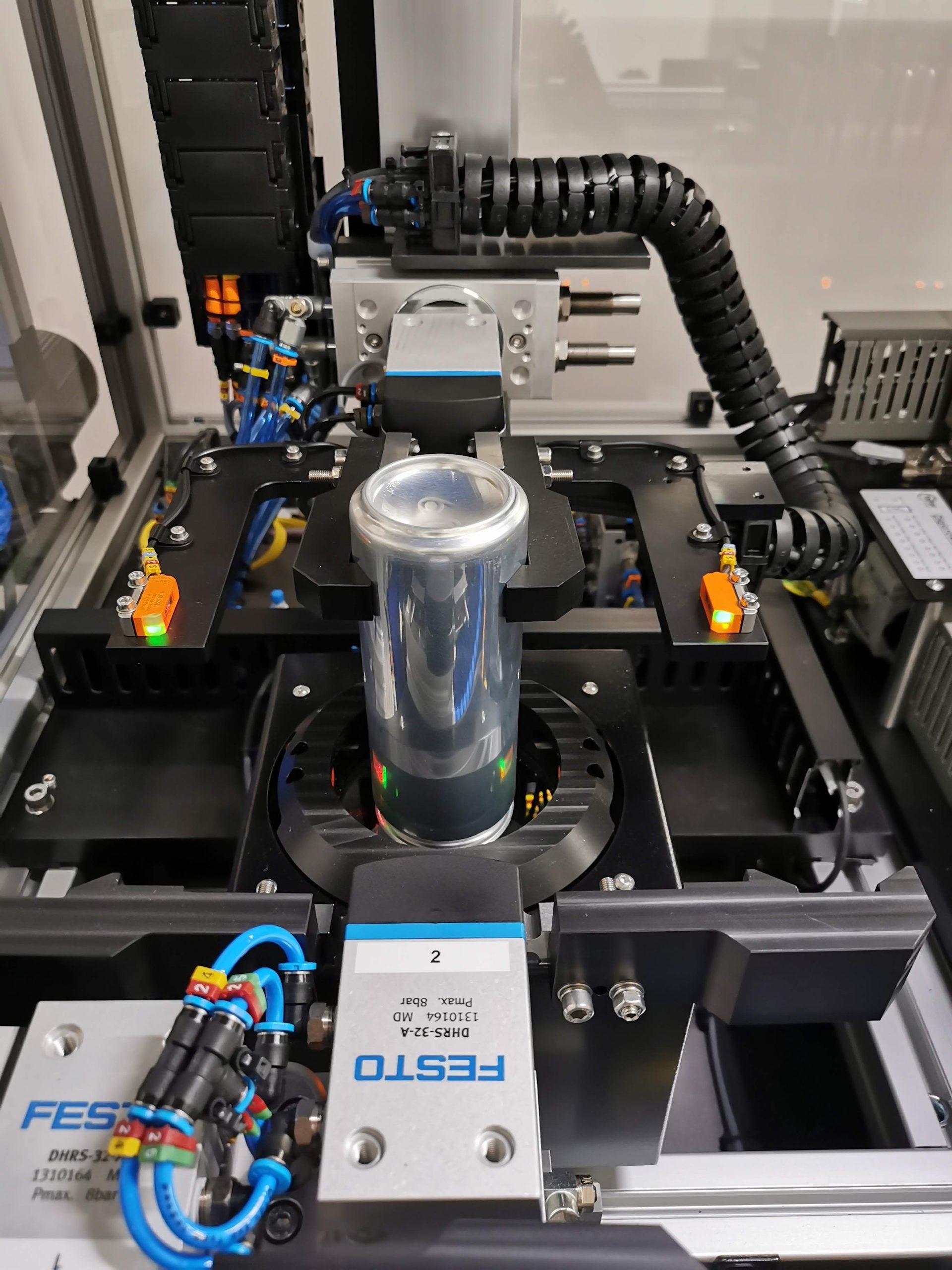

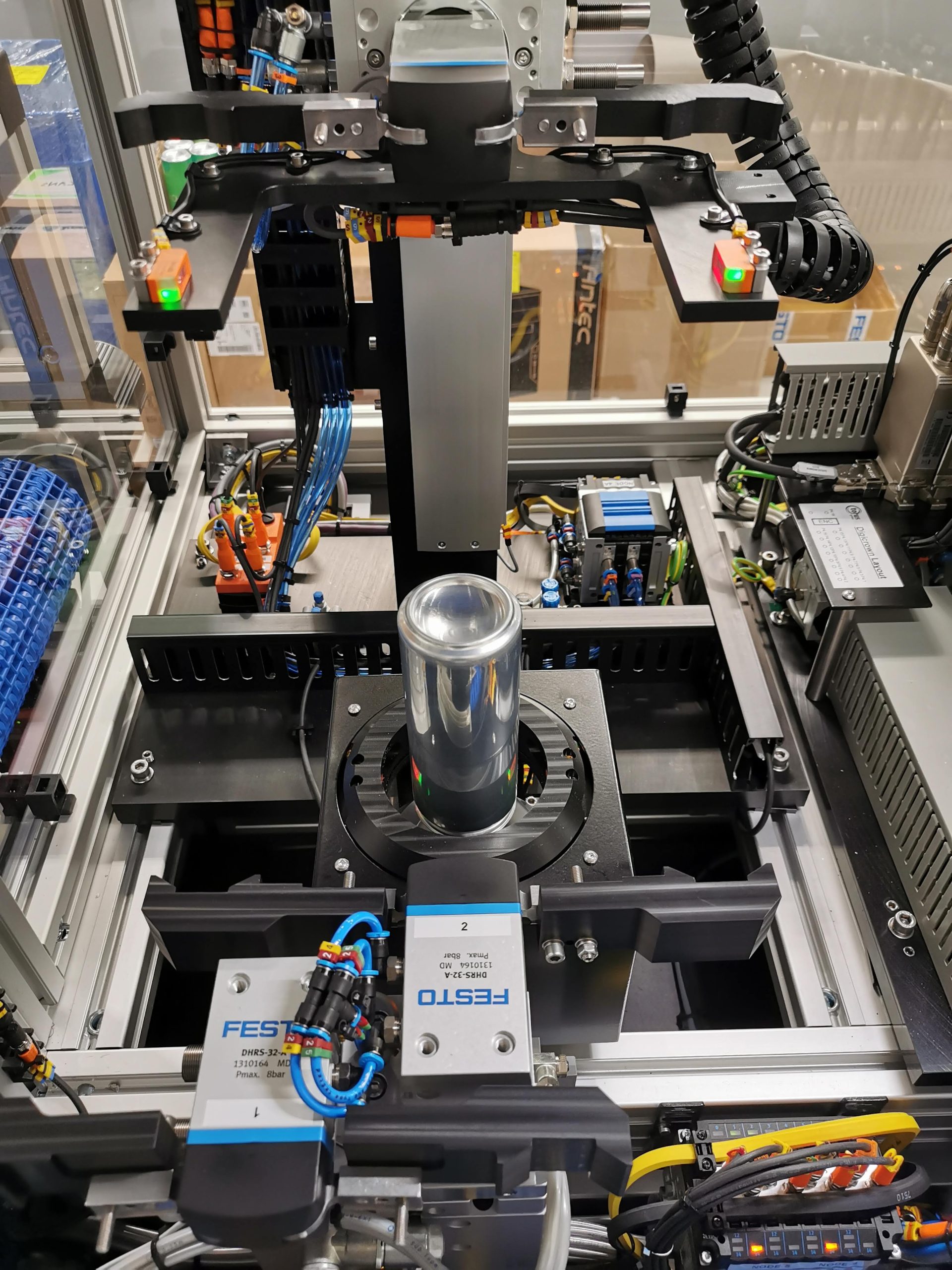

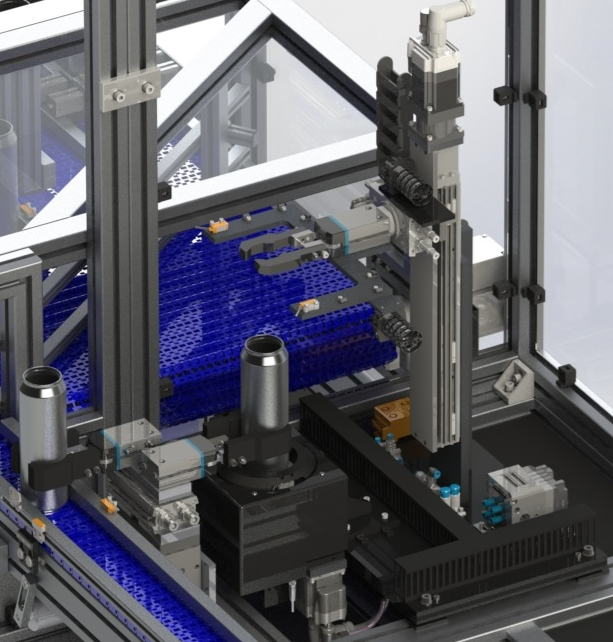

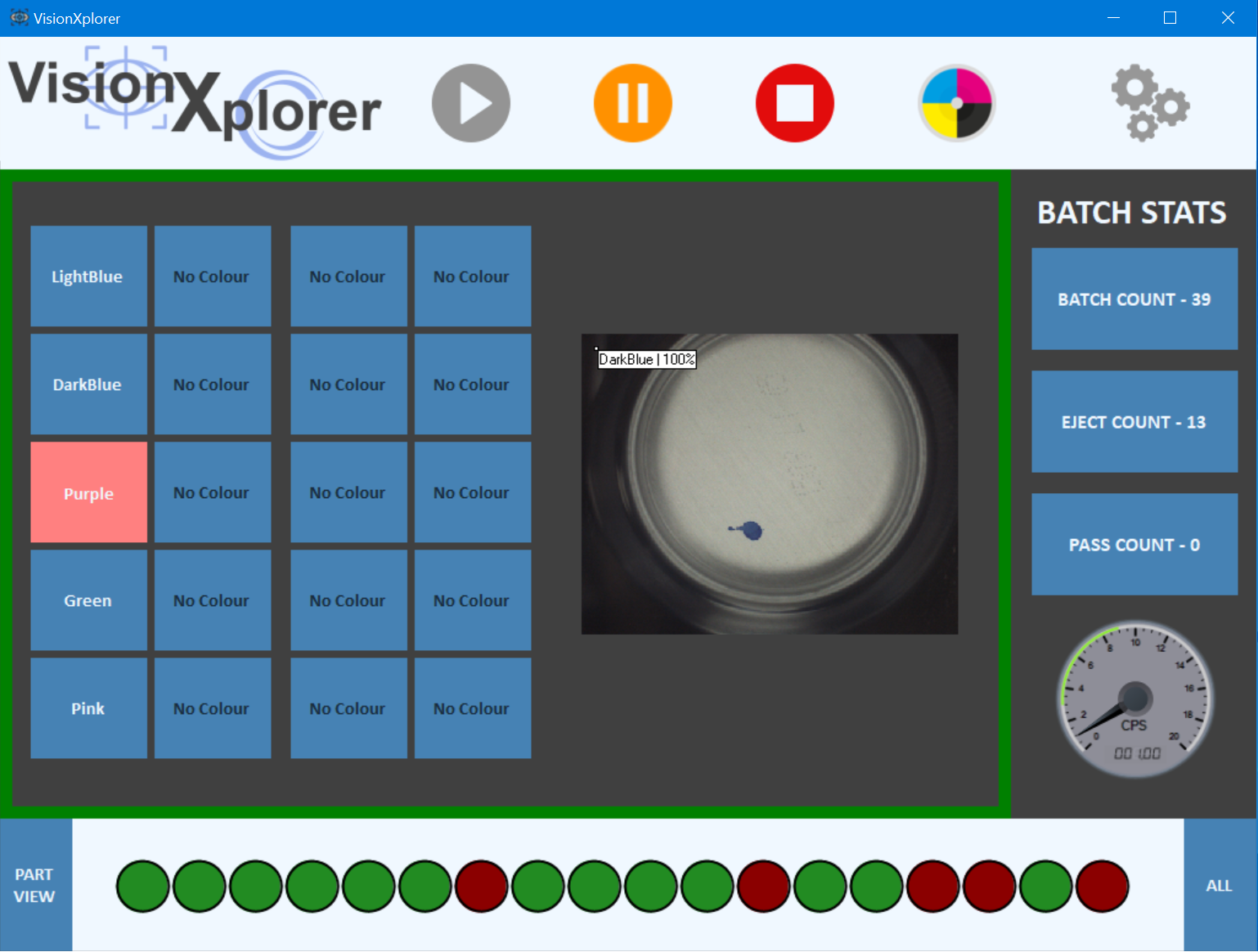

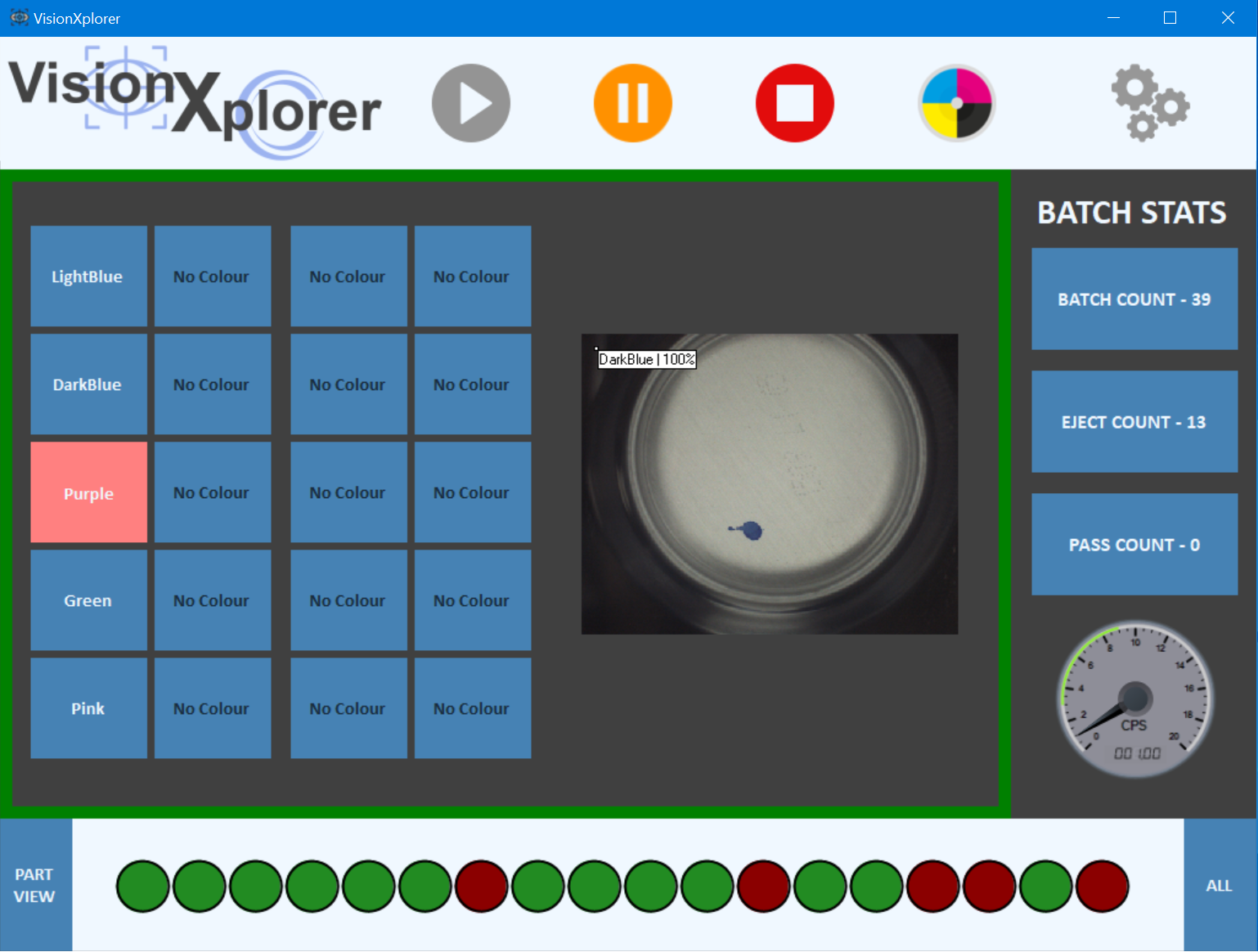

Designed to be integrated into all new and existing Torus gauging systems, unlike, its predecessor, the new Z705 Body Maker Module has an inbuilt turnover option, and can operate universally in conjunction with both Z301 Trimmed Can Inspection and Z302 Finished Can Inspection gauges, offering traceability on both trimmed and finished components within one measurement system.

The Z705 Body Maker Recognition Module operates both single and double-digit Alphaneumeric Code, without any influence from the application of Body Maker underlining, vent holes or spray head traceability markings.

Integrated with Torus’ GaugeXplorer software, the Z705 adds process traceability to components measured within additional gauging modules. With advanced through-put control, the sampling for each Body Maker can be set at a target rate, to ensure an equal distribution of measurement results.

Torus Beverage Can Gauging

Measurement Features

Feature

Technical Specification

Capabilities

A multi-segment illumination source, operates simultaneously with image acquisition, rotating around an optimal search area, collecting multi-image captures throughout the range. Using latest photometric stereo post image control processing technology, a high-quality result against a pre-defined model is identified. The Body Maker Recognition result is then tagged to the component for measurement result traceability, reported in conjunction with measurement data results.

An example of the Body Maker results below:

The Z701 Vision Sorting System has been developed specifically to meet customer end of line sorting requirements to facilitate sorting of HFI (Hold for Inspection) pallets to reduce manual work.

Torus Beverage Can Gauging

Measurement Features

Key Features

The Z701 integrates directly into an existing end of line sorter with minimal adjustments required. The system can be integrated into an existing or new sorter – Torus work closely with the customer’s chosen integrator to ensure a successful installation. A site survey is carried out by both parties to agree the suggested location for the integration.

The camera will be located on your existing sorting line

The Vision System can be positioned up to 10m away from the camera

The 2nd monitor can be positioned up to 10m away from the Vision System, enabling the user to measure results from elsewhere in the facility

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999