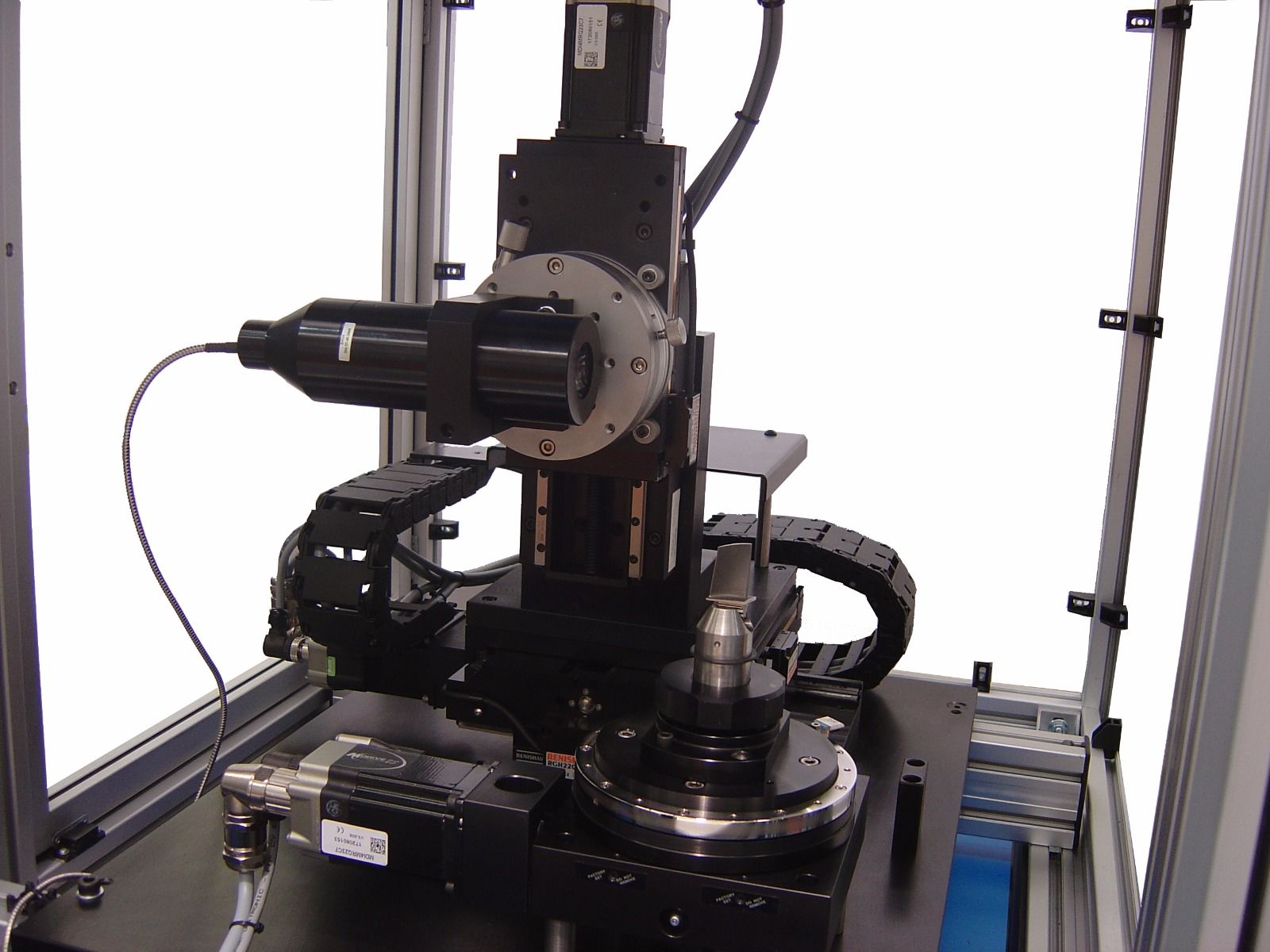

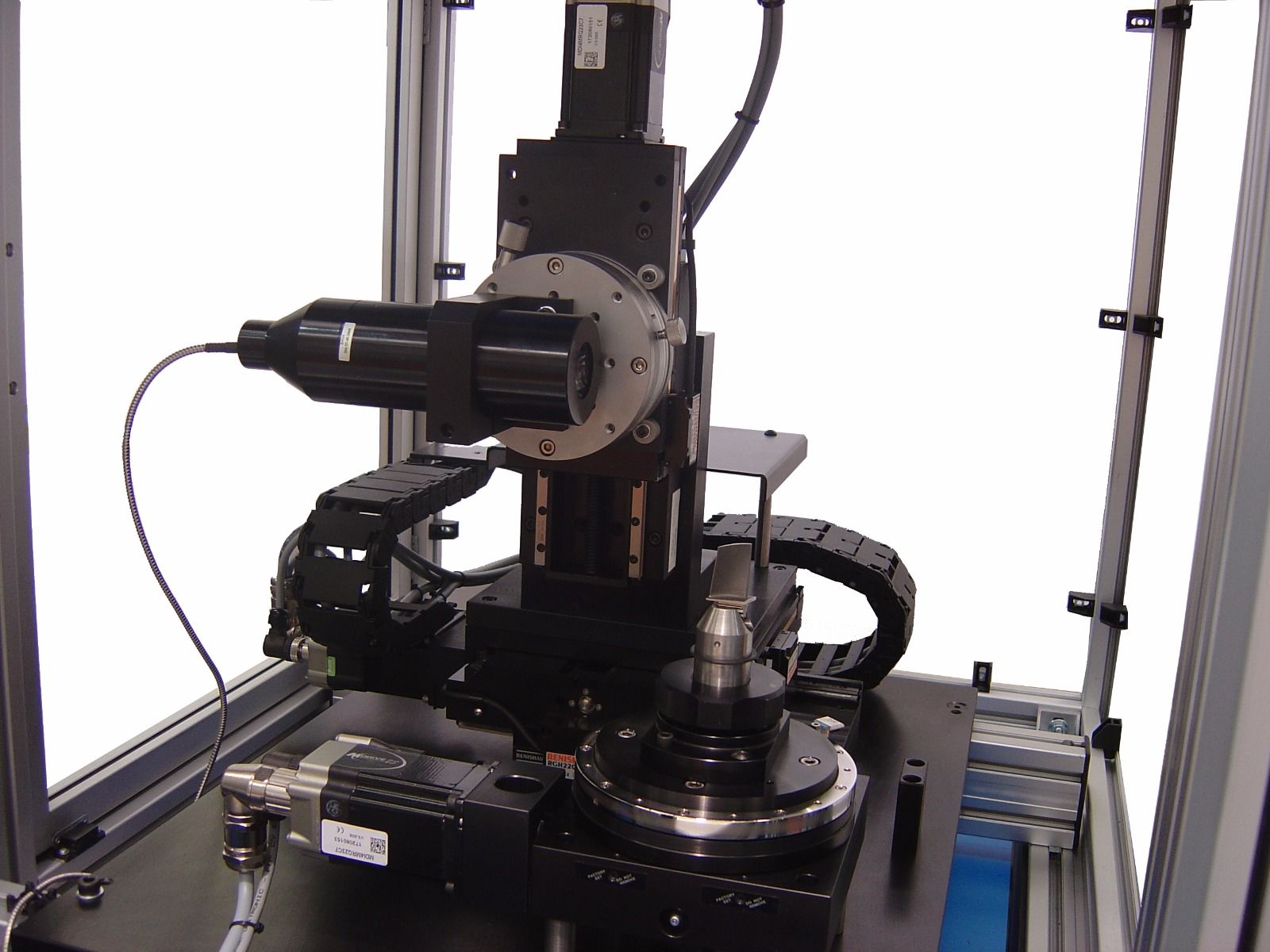

With the ever increasing need for Turbo Fan engine efficiency in mind, Torus Group developed the A521 CNC Fan Track Boring machine. The machine produces an accurate fan track bore in a fraction of the time of any other system whilst at the same time requiring fewer personnel for set-up and operation.

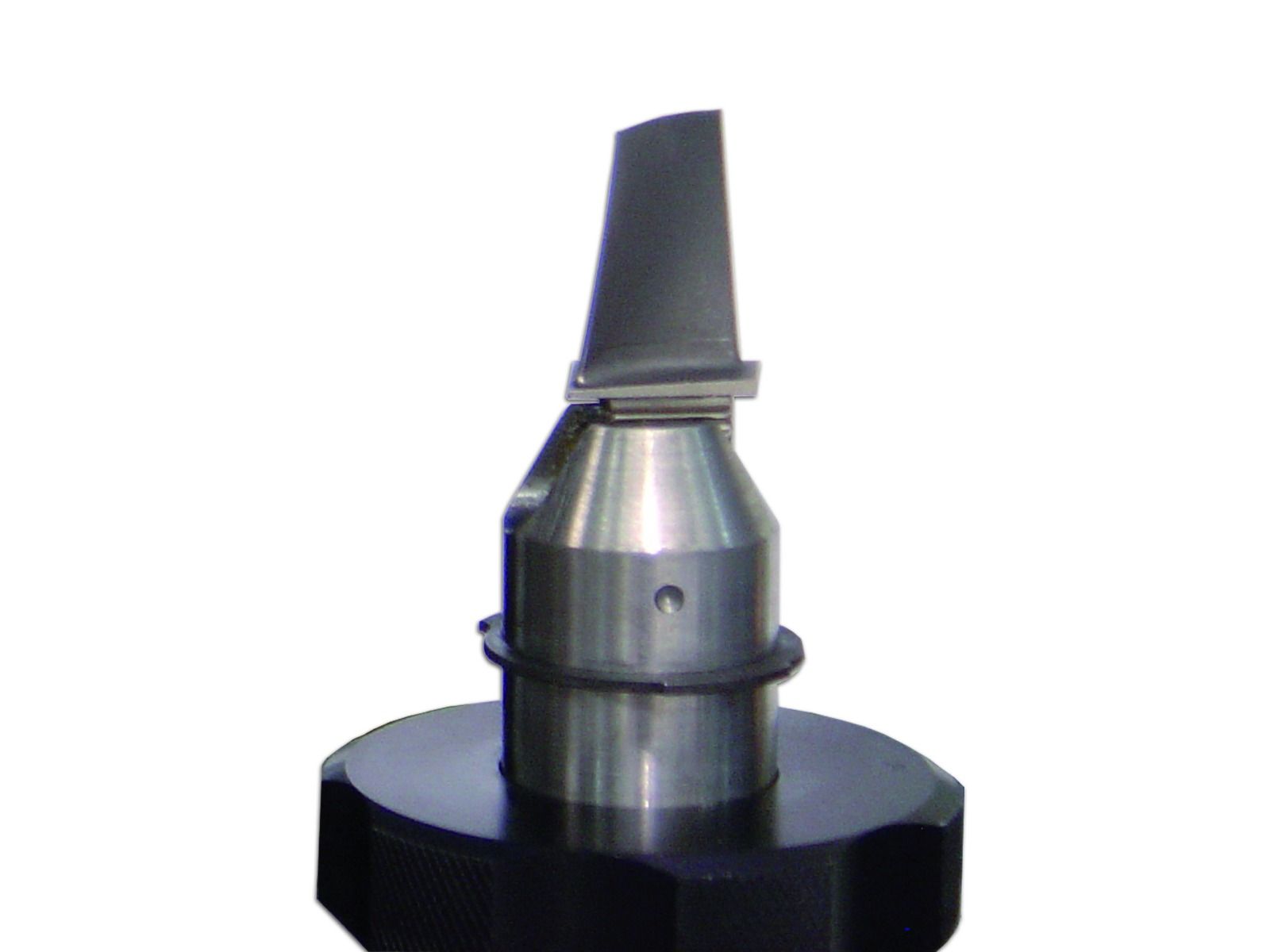

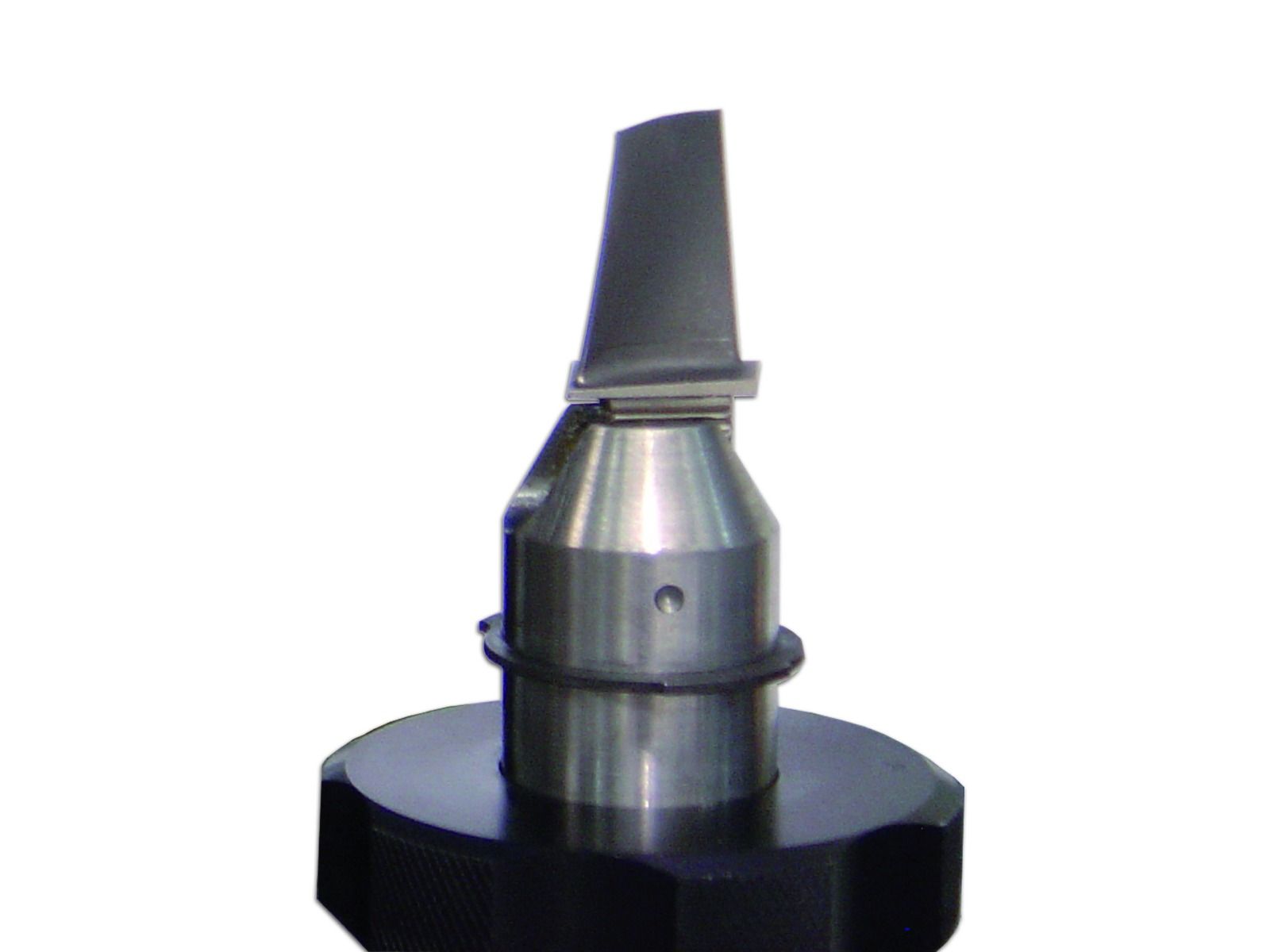

Polychromatic white light is focused onto the target surface by a multi-lens optical system. The lenses are arranged so that the white light is dispersed into monochromatic light by controlled chromatic aberration. Specific distance to the target is assigned to each wavelength which is exactly focused on the target is used for measurement. This light reflected from the surface is passed through a confocal aperture onto a spectrometer which detects and processes the spectral changes.

This unique measuring principle enables displacements and distances to be measured with high precision and extreme spatial resolution. Both diffuse and specular surfaces can be measured without the requirement for surface preparation.

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999