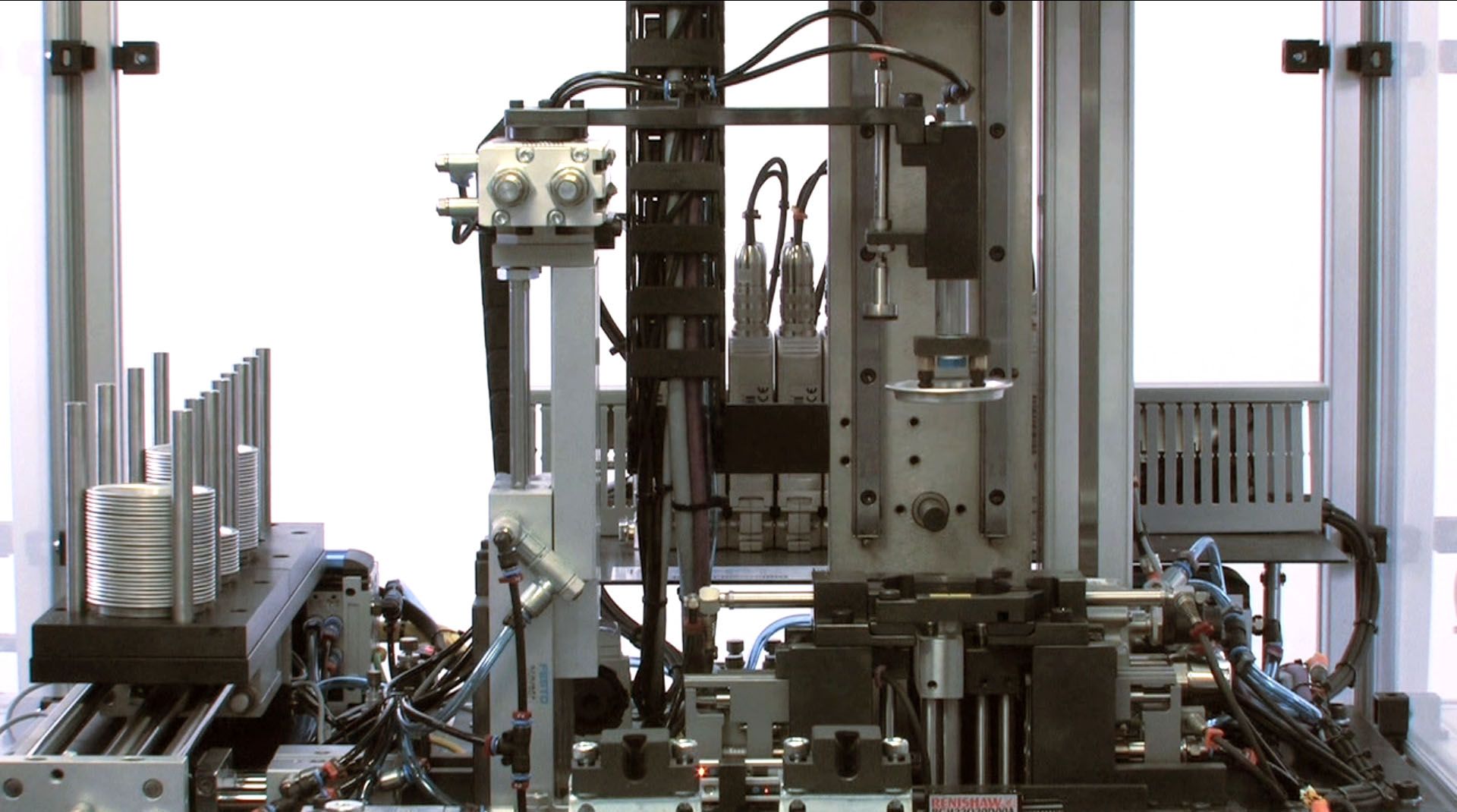

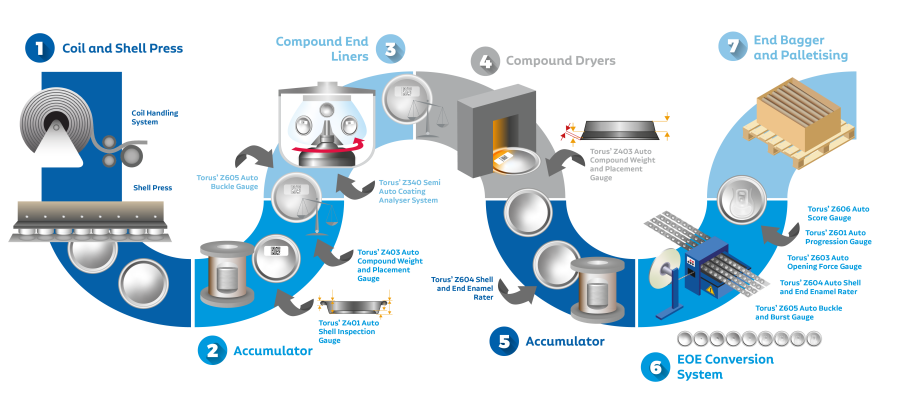

The Z401 Shell Inspection System from Torus Measurement Systems defines the standard for dimensional inspection of beverage / beer can shells.

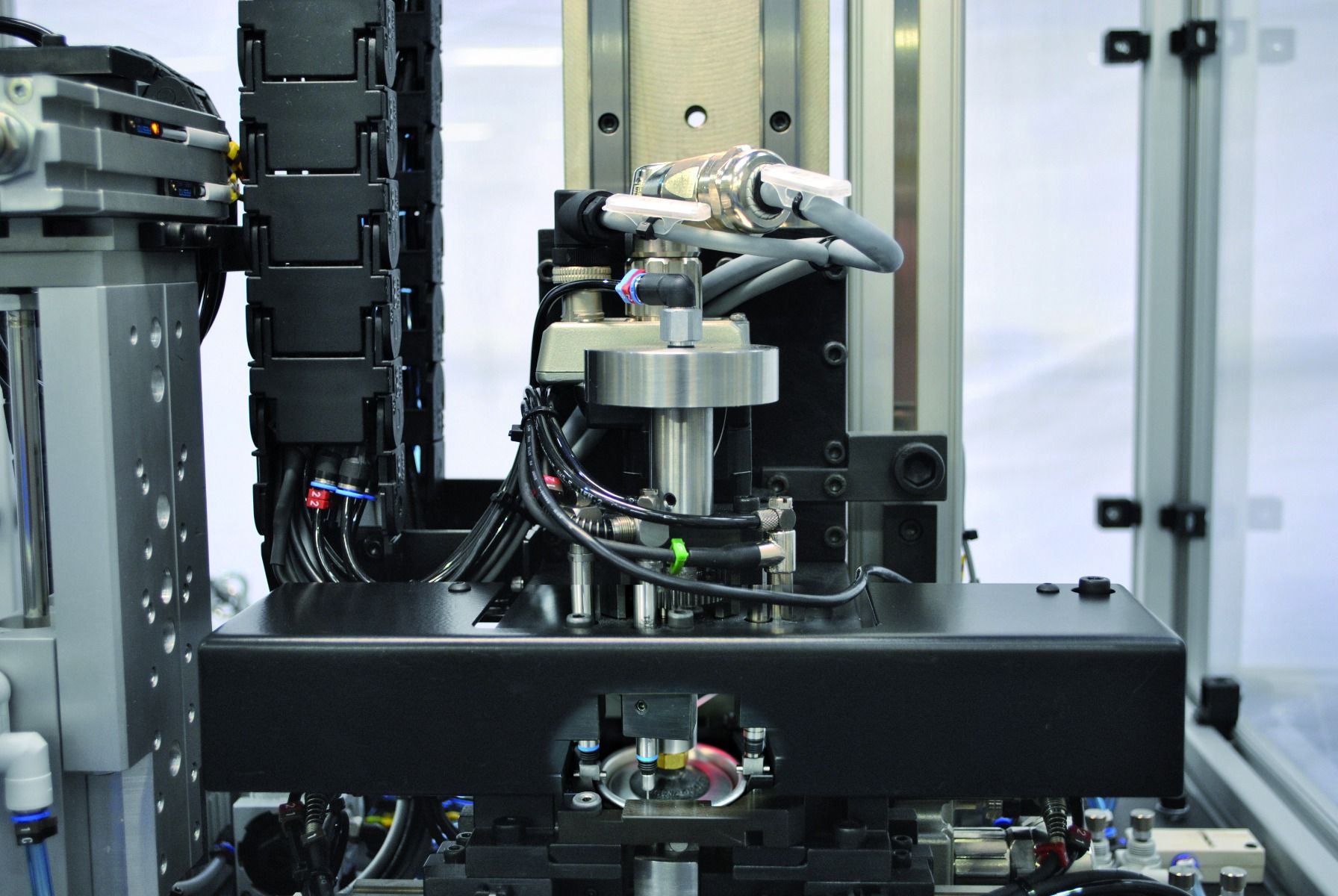

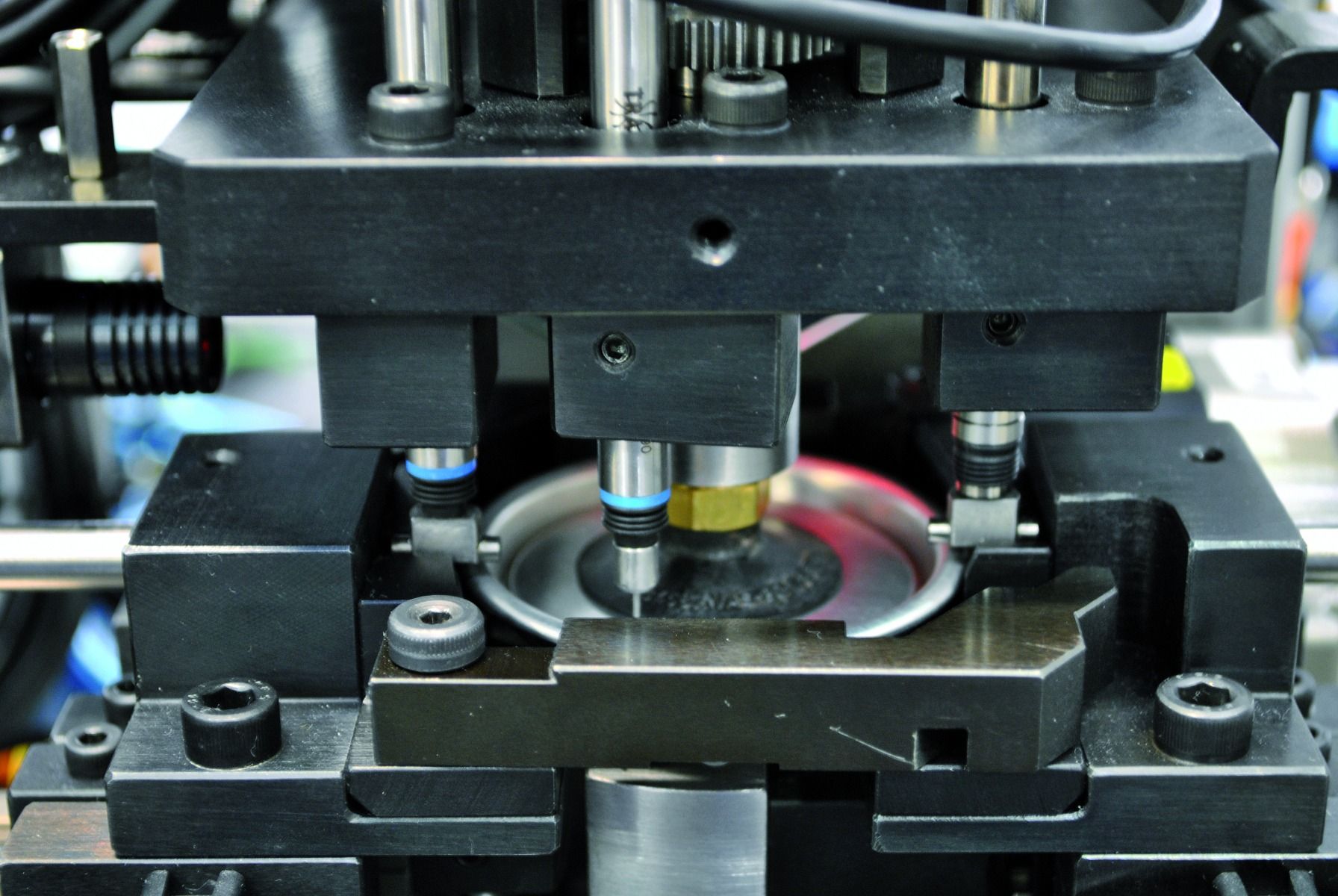

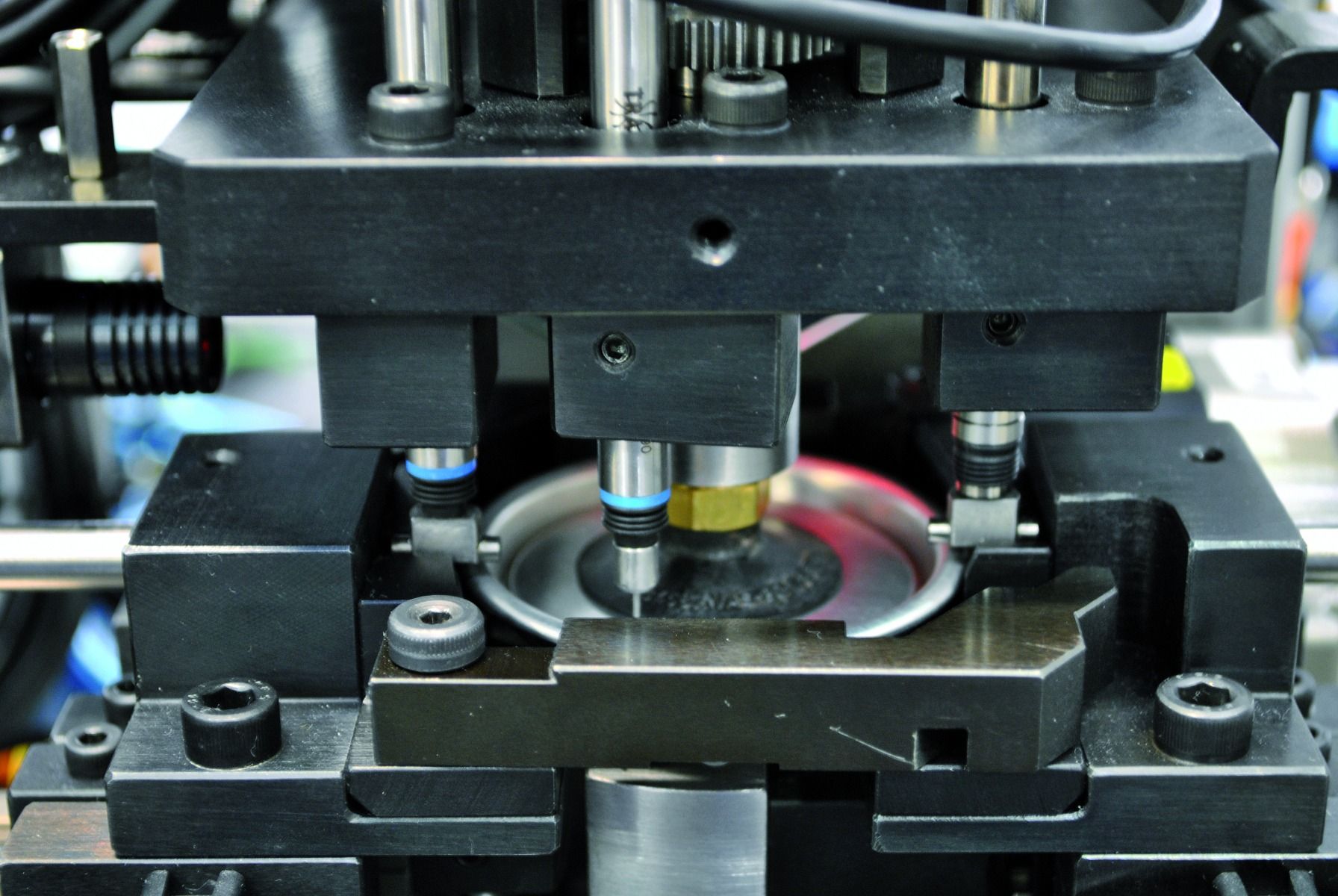

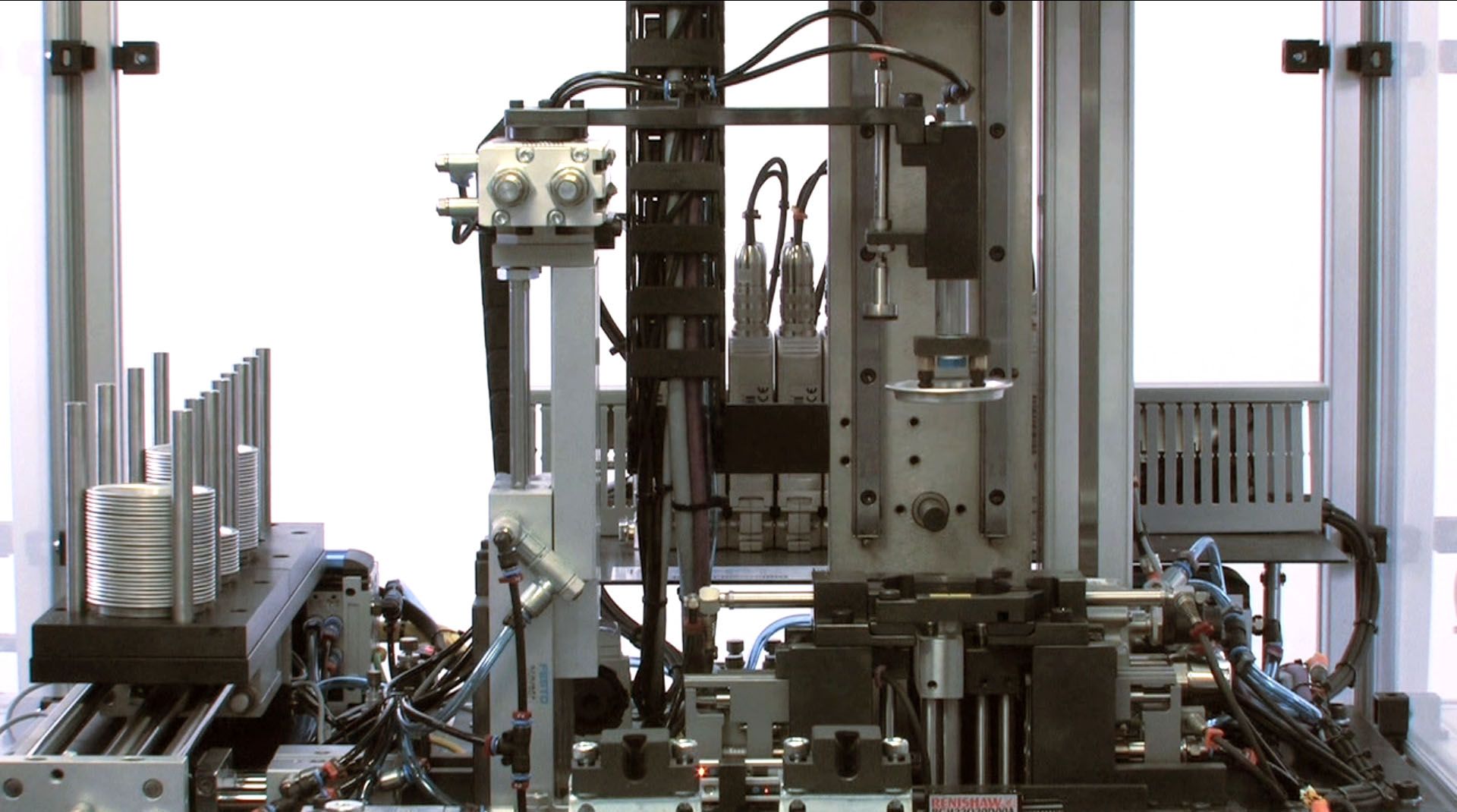

Each shell to be inspected is automatically collected from a ‘stack’ and loaded into the gauging module with an integrated pick and place system. The measurement cycle is then initiated via the PC running the TMS GaugeXplorer Measurement and Machine Control software.

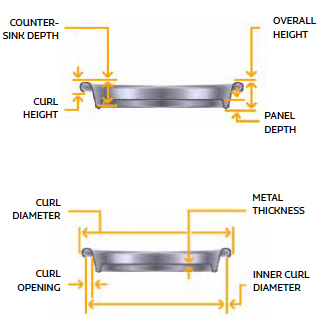

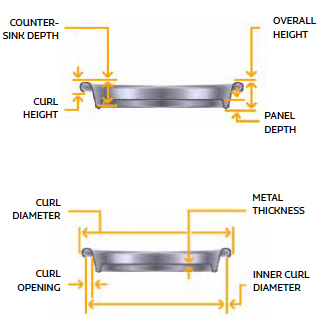

Measurement Features

*Curl Opening feature not supported on CDL style shells

Technical Specification

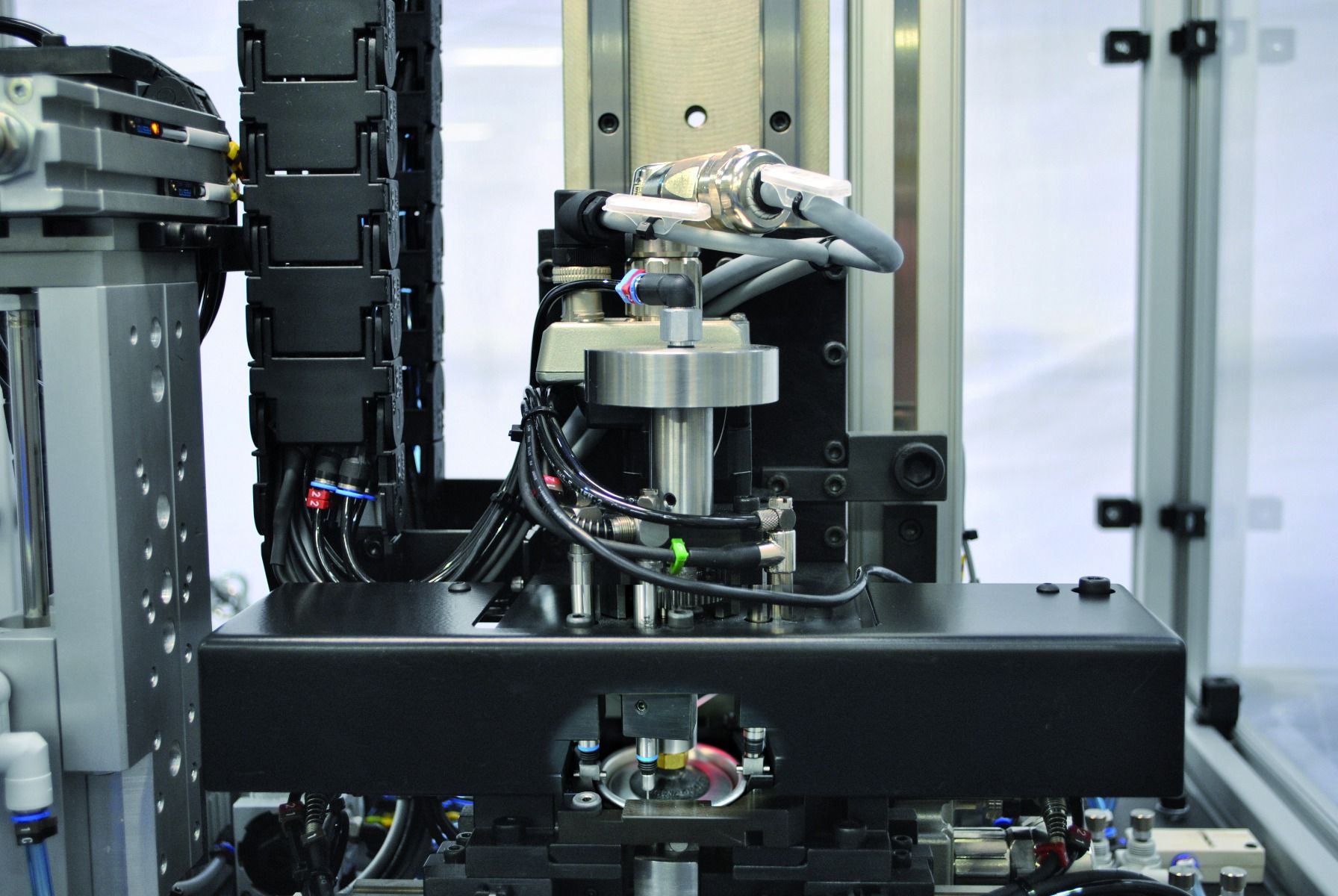

The Torus Measurement Systems modular design construction gives complete flexibility when specifying your requirements.

The below option Automatic Grain Alignment is available to add at anytime.

The Grain Alignment option allows operators to gain information of where exact measurement points are taken, allowing for precise tooling adjustment to be made when required.

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999