With the ever increasing need for Turbo Fan engine efficiency in mind, Torus Group developed the A521 CNC Fan Track Boring machine. The machine produces an accurate fan track bore in a fraction of the time of any other system whilst at the same time requiring fewer personnel for set-up and operation.

Torus’ A521 Fan Track Boring machine features a CNC control of the cutting path, negating the need for expensive fixed profile templates prone to inaccuracy and wear. Additionally, profiles can be easily edited from fan track profile CAD files giving unprecedented flexibility, dramatically reducing lead time and costs for new profile variants.

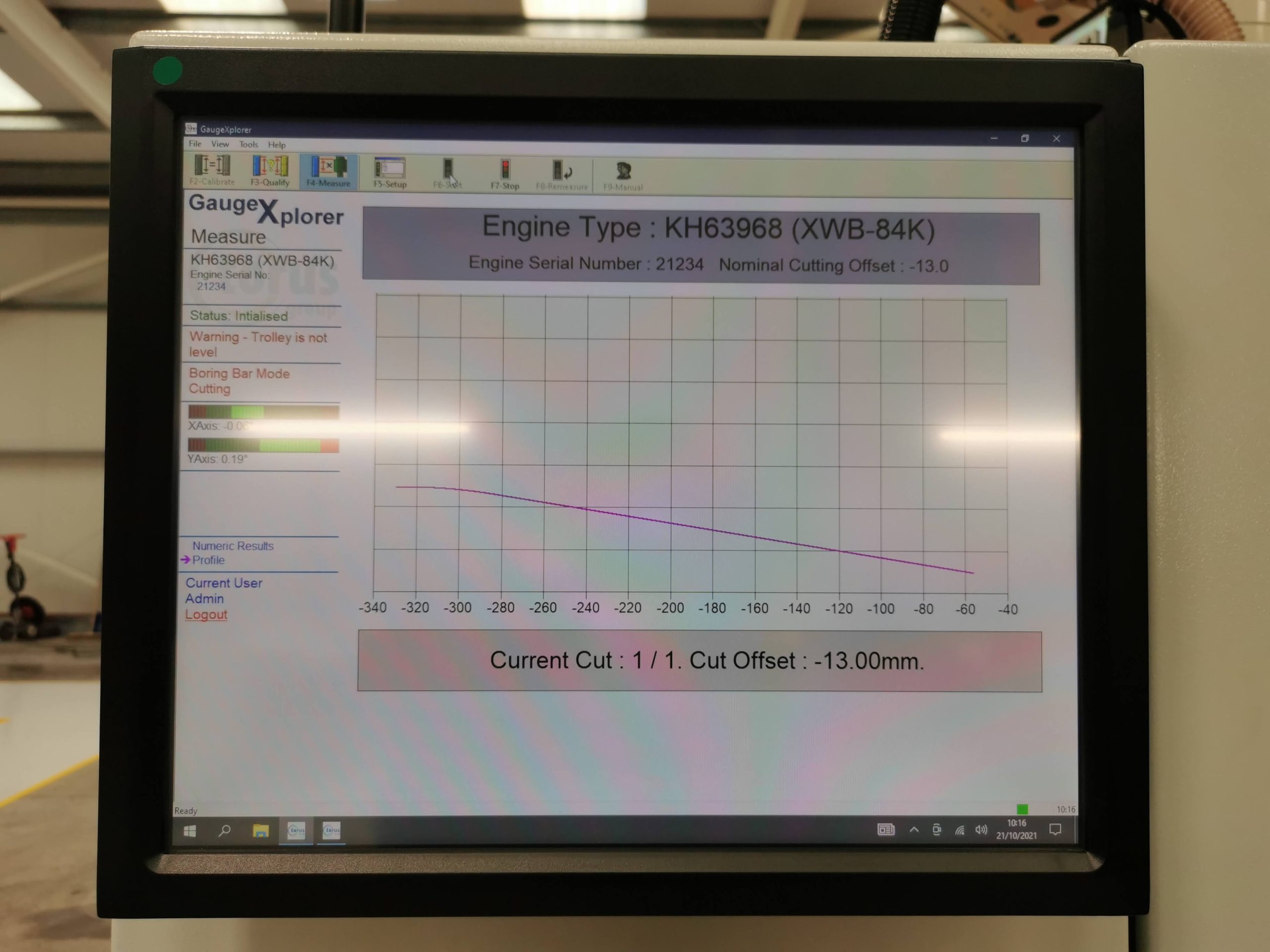

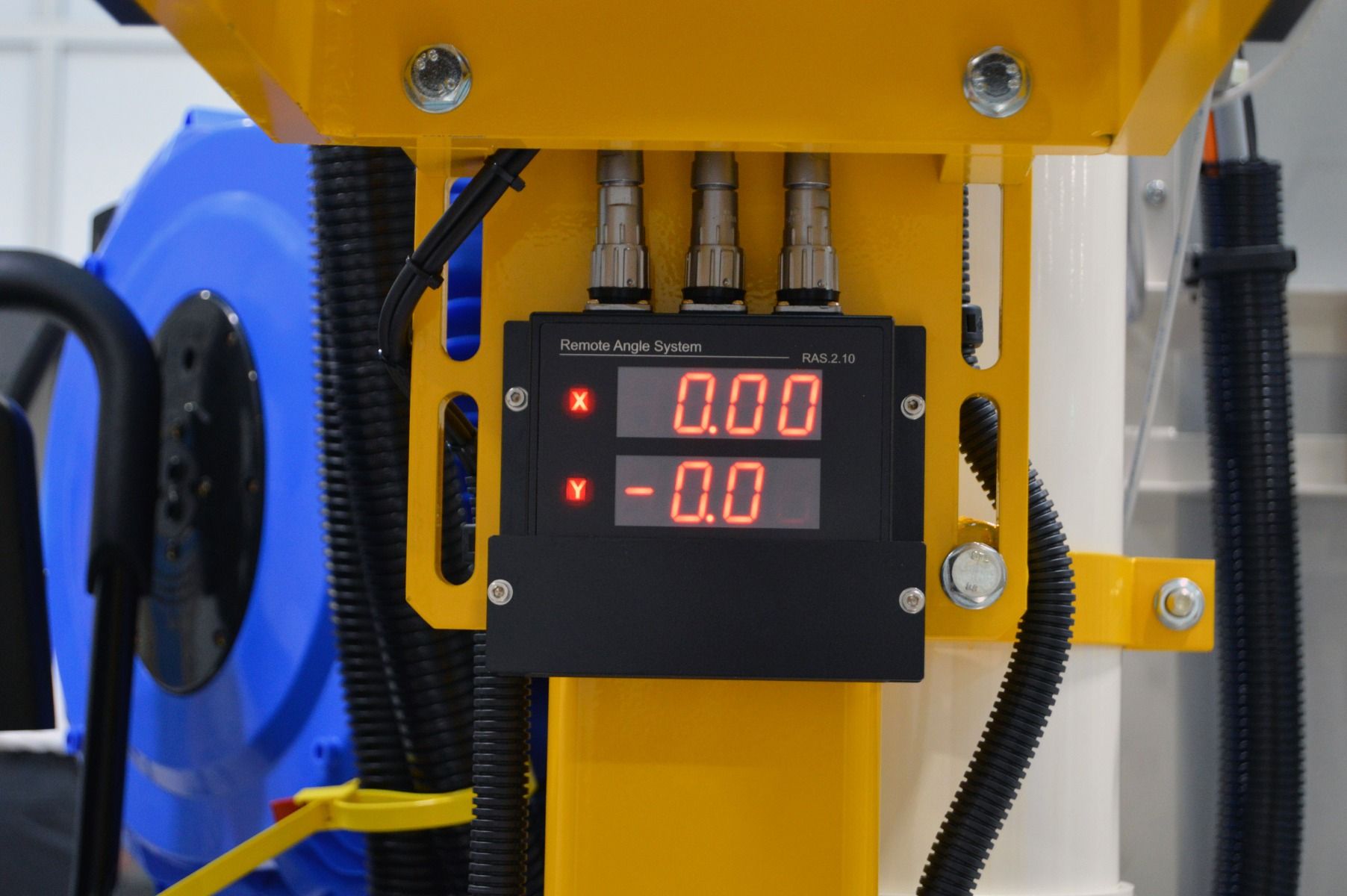

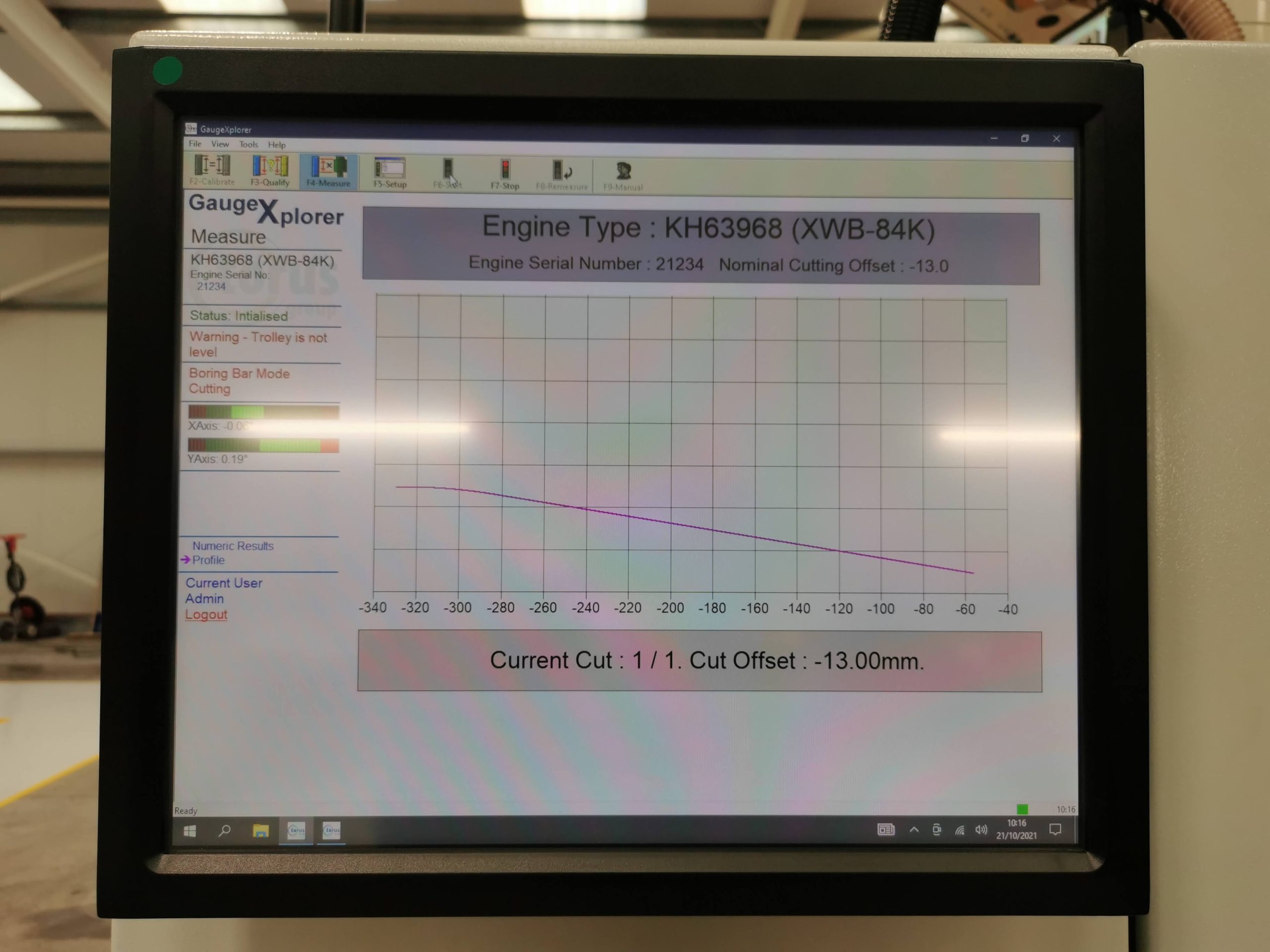

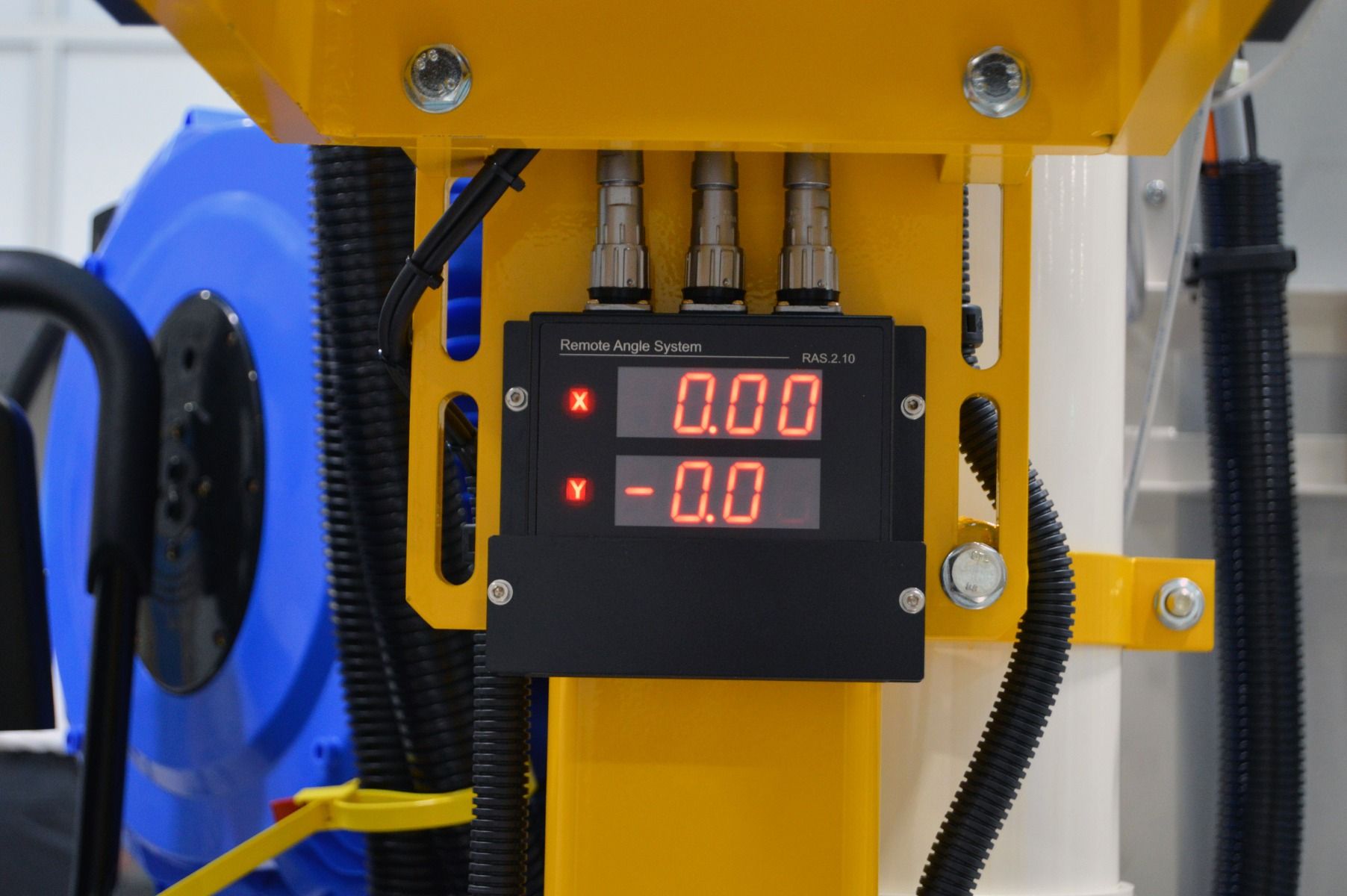

The integrated measurement system is utilised for pre-machining inspection, optimising the cutting sequence to give ultimate machining efficiency. Of course, the same system is also used for final inspection, producing a measurement report tailored to the end user’s requirement to include:

The reports can be networked for full traceability.

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999