Introducing Torus’ Z704 RemoteXplorer, offering remote visual global support from our head office

Remote support has been available for many years via Torus’ global helpdesk team, but only now can ‘eyes on’ support be offered via a new extension of Torus’ traditional GaugeXplorer software. RemoteXplorer, with the permission of customers, the gauges can now be monitored visually using RemoteXplorer’s newly developed pan and tilt camera system and software package.

How can we help you?

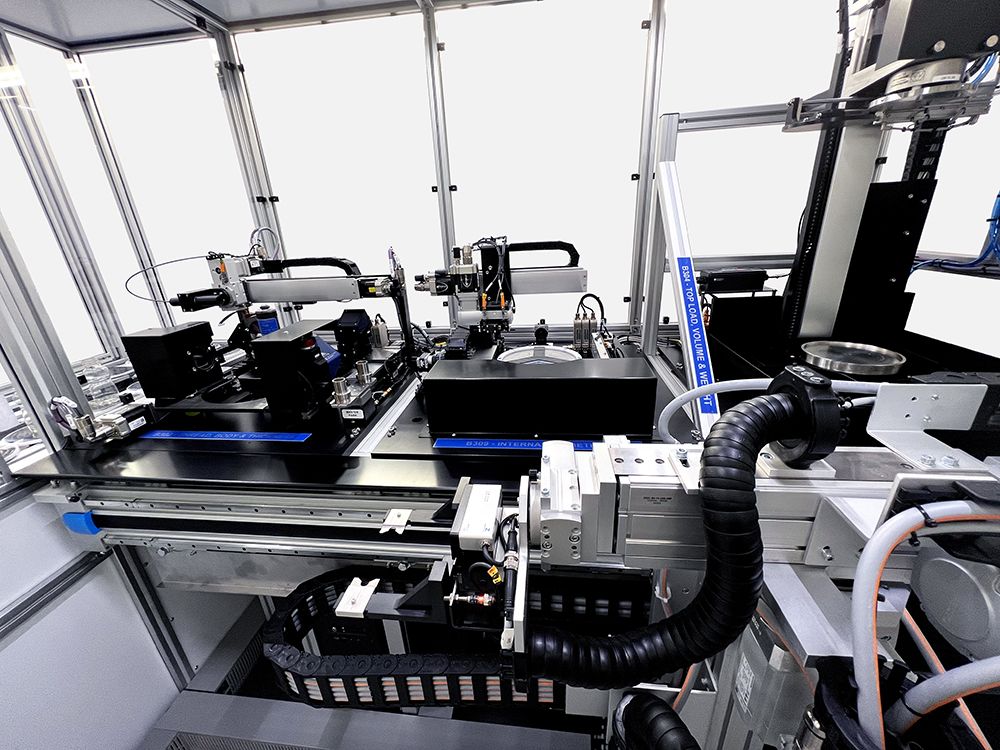

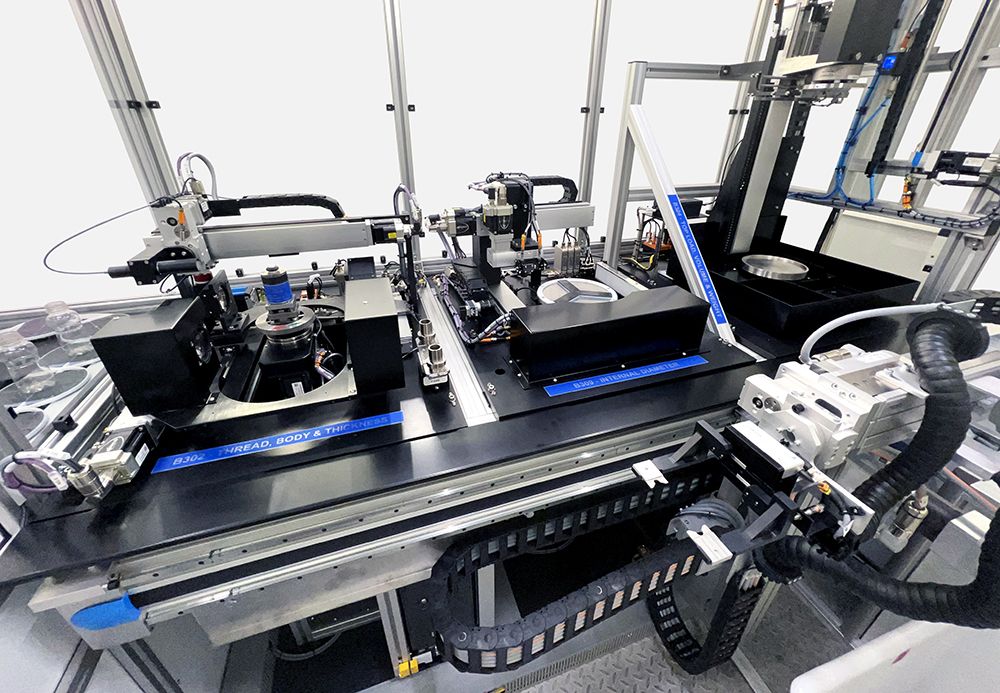

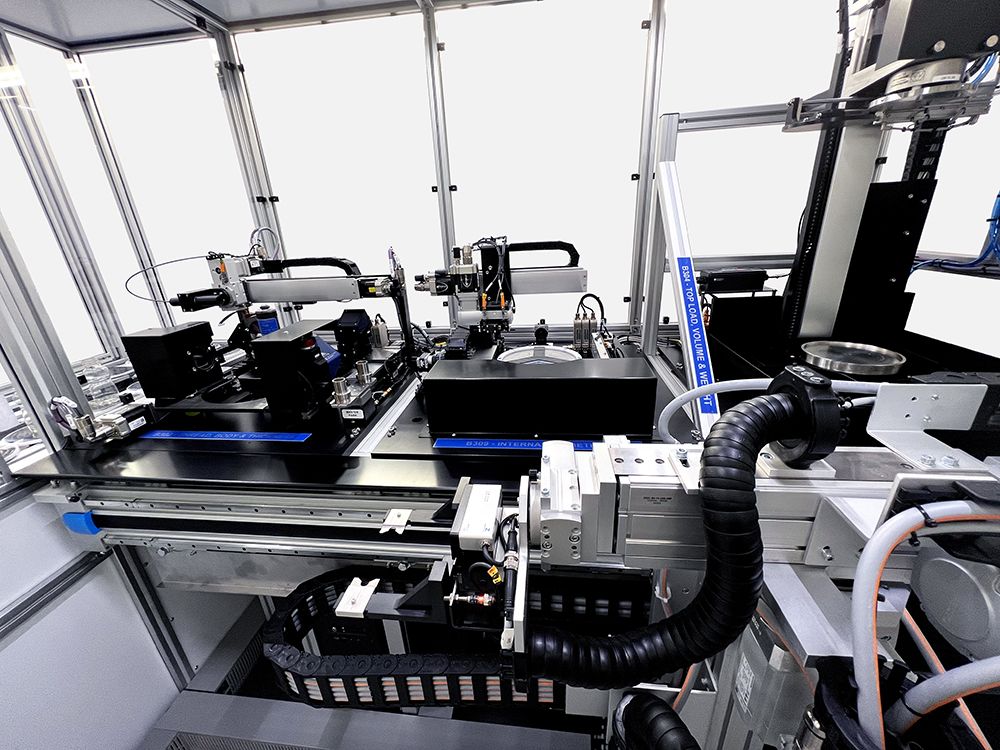

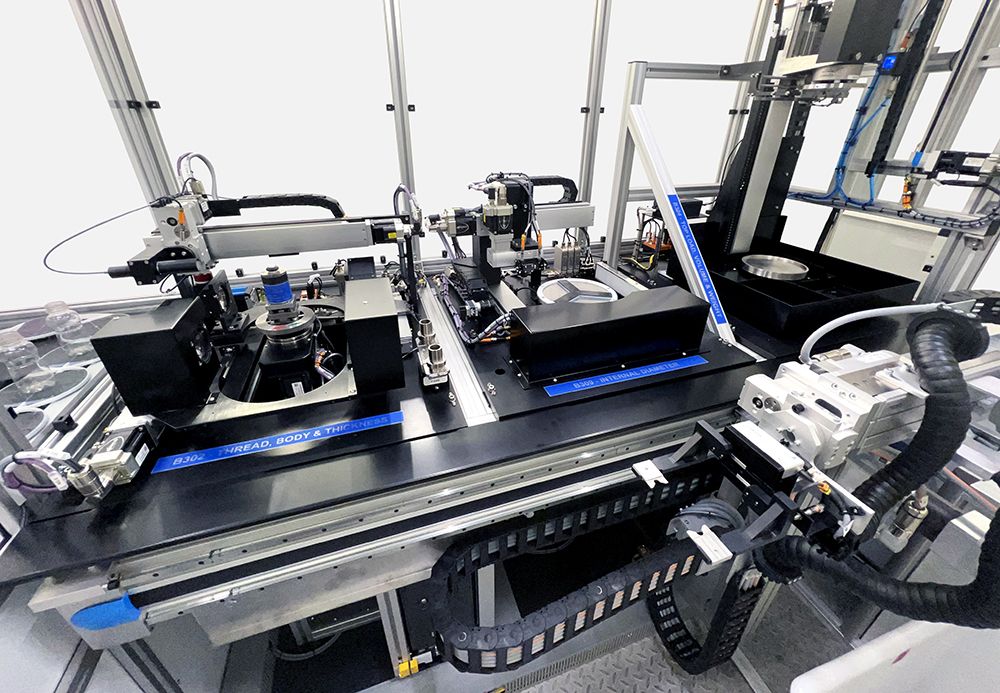

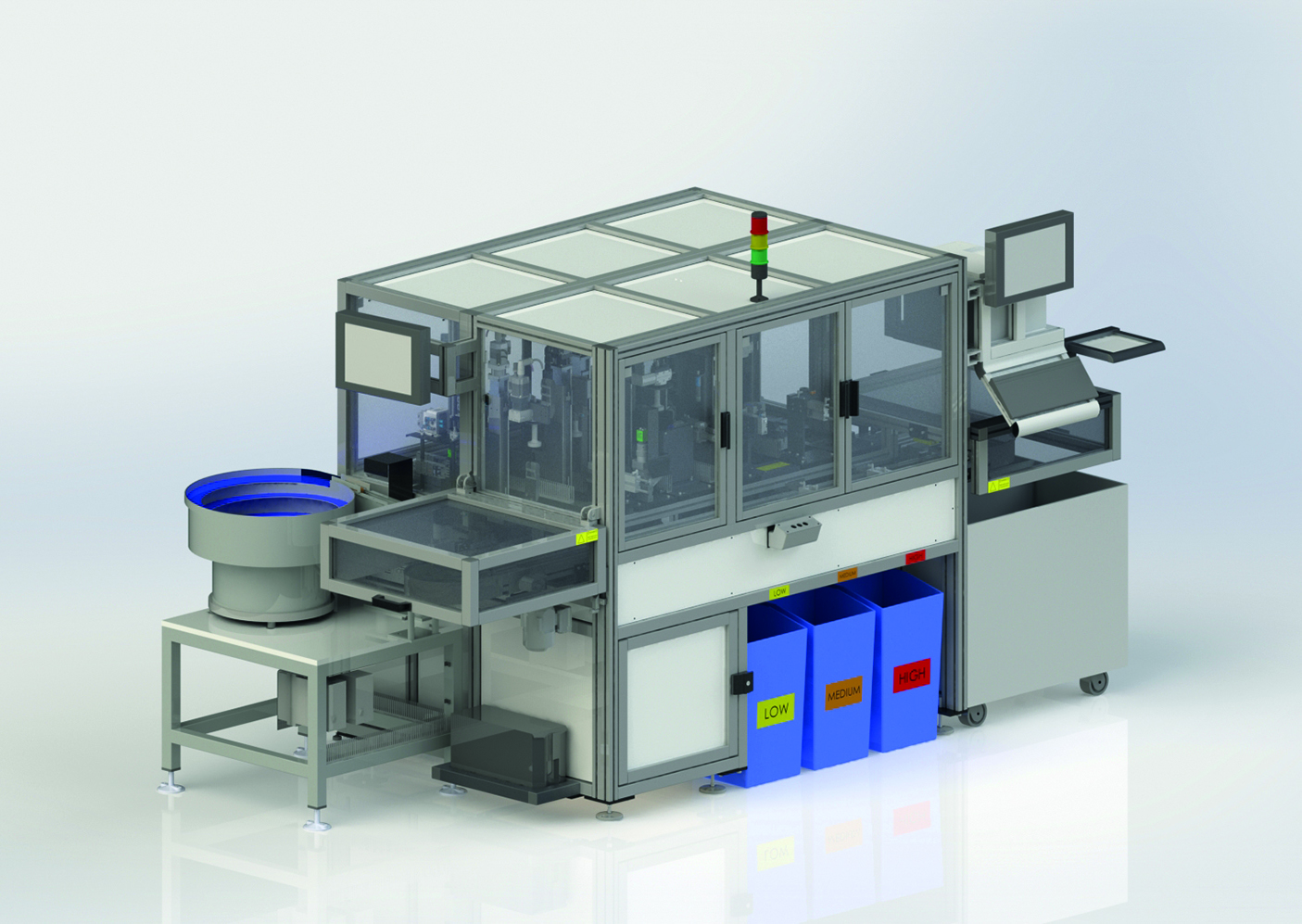

Torus’ TQ-Lab is a unique, total quality testing station for plastic packaging such as plastic bottles and jars, typically used for soft drinks, health supplements, cosmetics, and domestic cleaning products. Plastics packaging requires precision measurement of aspects such as material thickness, outer body and neck physical dimensions, neck diameter and volume as well as load testing for crushing and pressure. The TQ-Lab can undertake all the necessary tests on both empty and filled plastic containers or preforms in a single system. The multi-module concept improves accuracy and repeatability, reduces time and labour costs and saves on floor space in production environments. Once batches of plastic containers are placed onto the turnaround conveyor, the operator simply selects the relevant program and walks away.

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

Technical Specification

Measurement Features

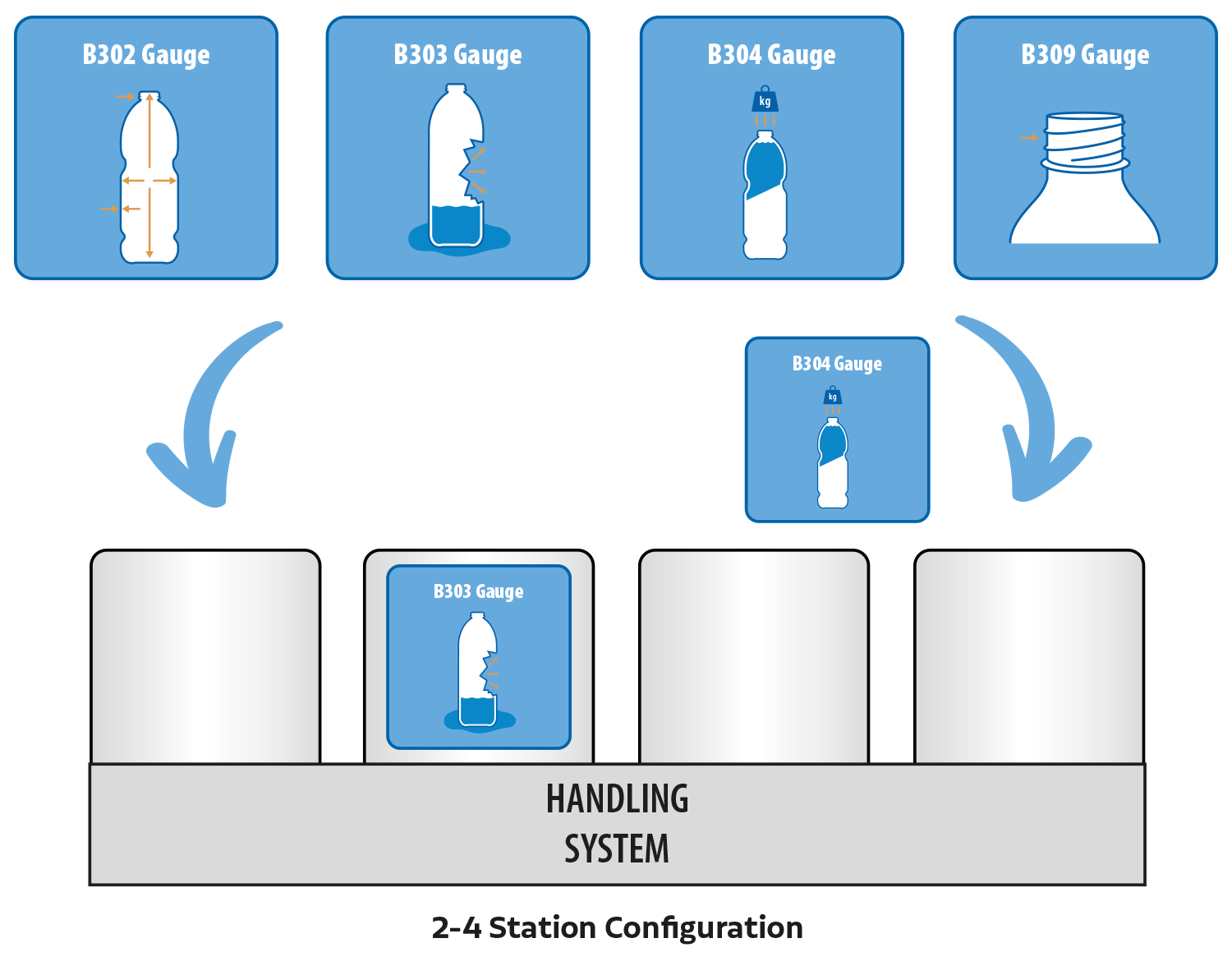

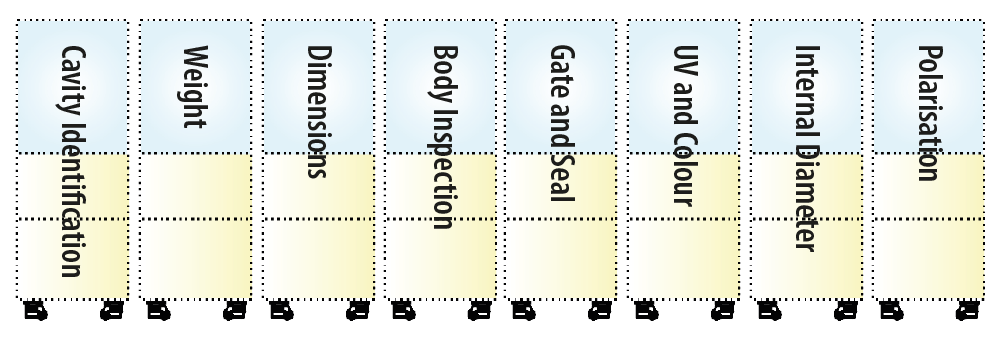

Choose from between 2 and 4 measurement modules to customise your TQ Lab:

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

Choose from a range of conveyor options, and finally choose your modules (a minimum of a 2 station configuration through to a maximum of 4).

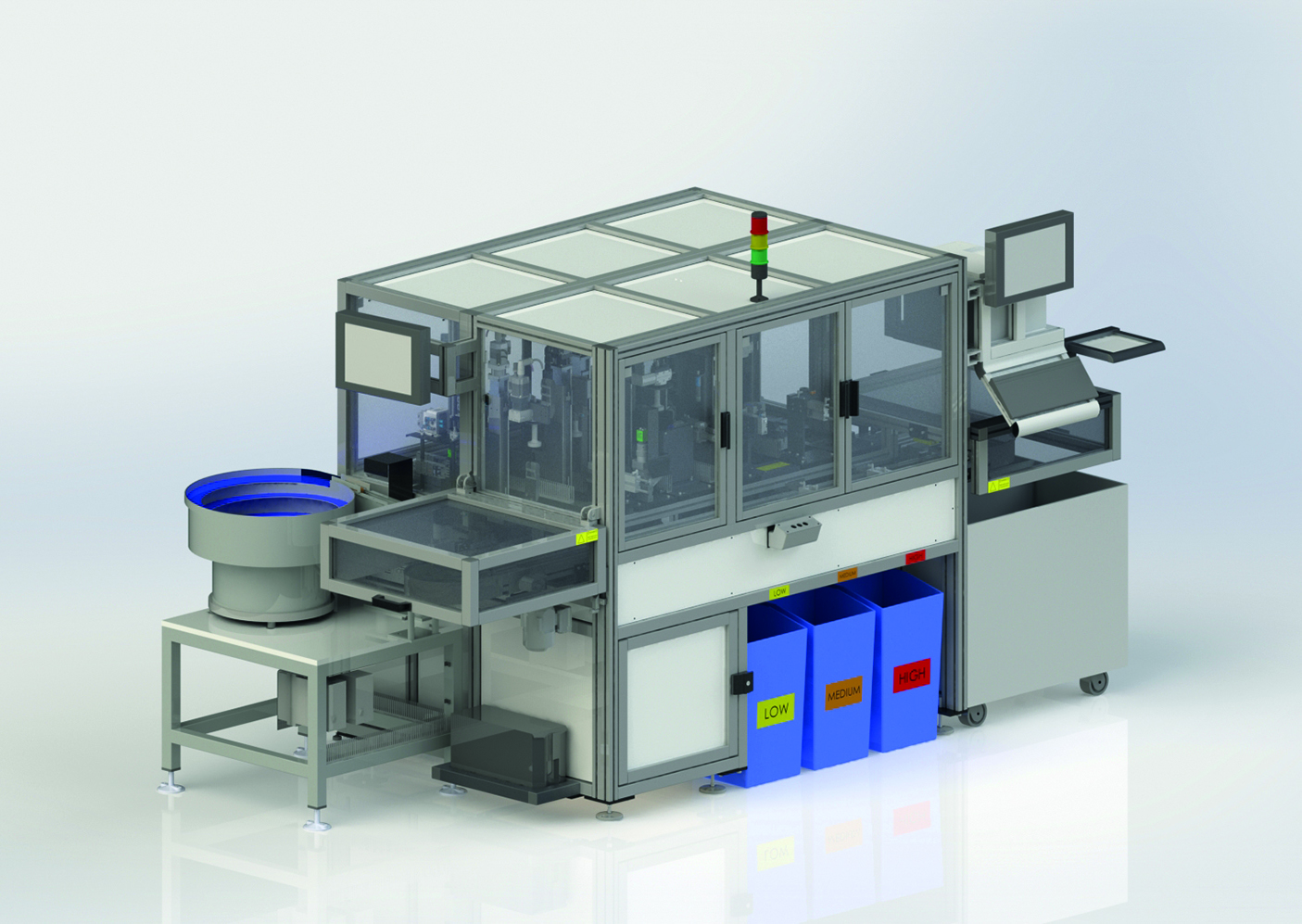

The B305 gauge is a modular system that can inspect and measure to find all of your preform defects. Each module can be selected by the customer allowing the configuration to suit your quality control needs. Dimensional measurements are calibrated automatically and can be traced to UKAS standards giving the user a full shot quality overview in approximately 15 minutes.

A full range of modular inspection station options, enables the customer to identify the inspection requirements and configure a system to suit the needs of the production facility.

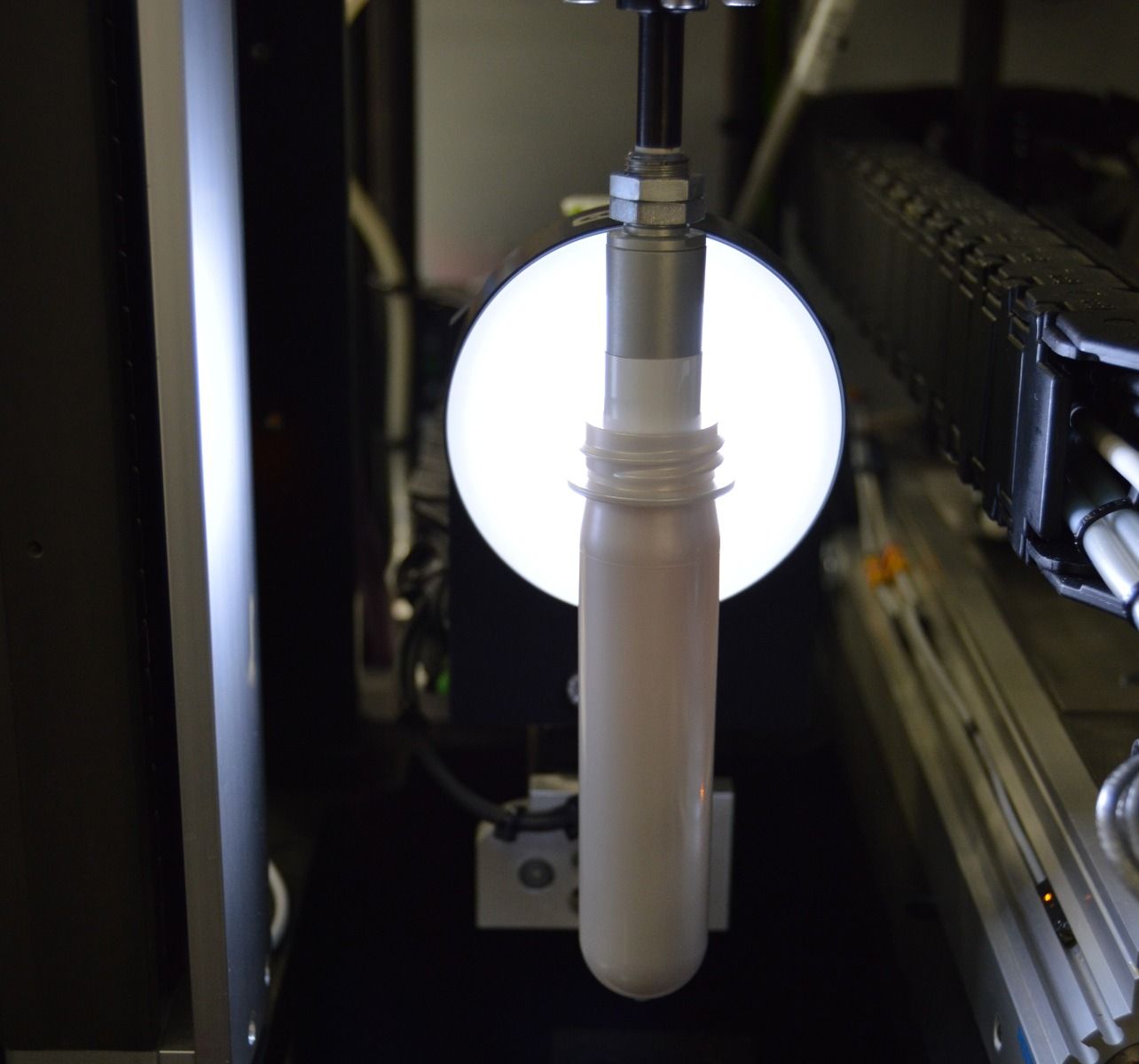

Automatic thread start alignment provides unrivalled ‘absolute’ dimensional measurement system performance, for both Neck and Body features, traceable and certified to UKAS Standards.

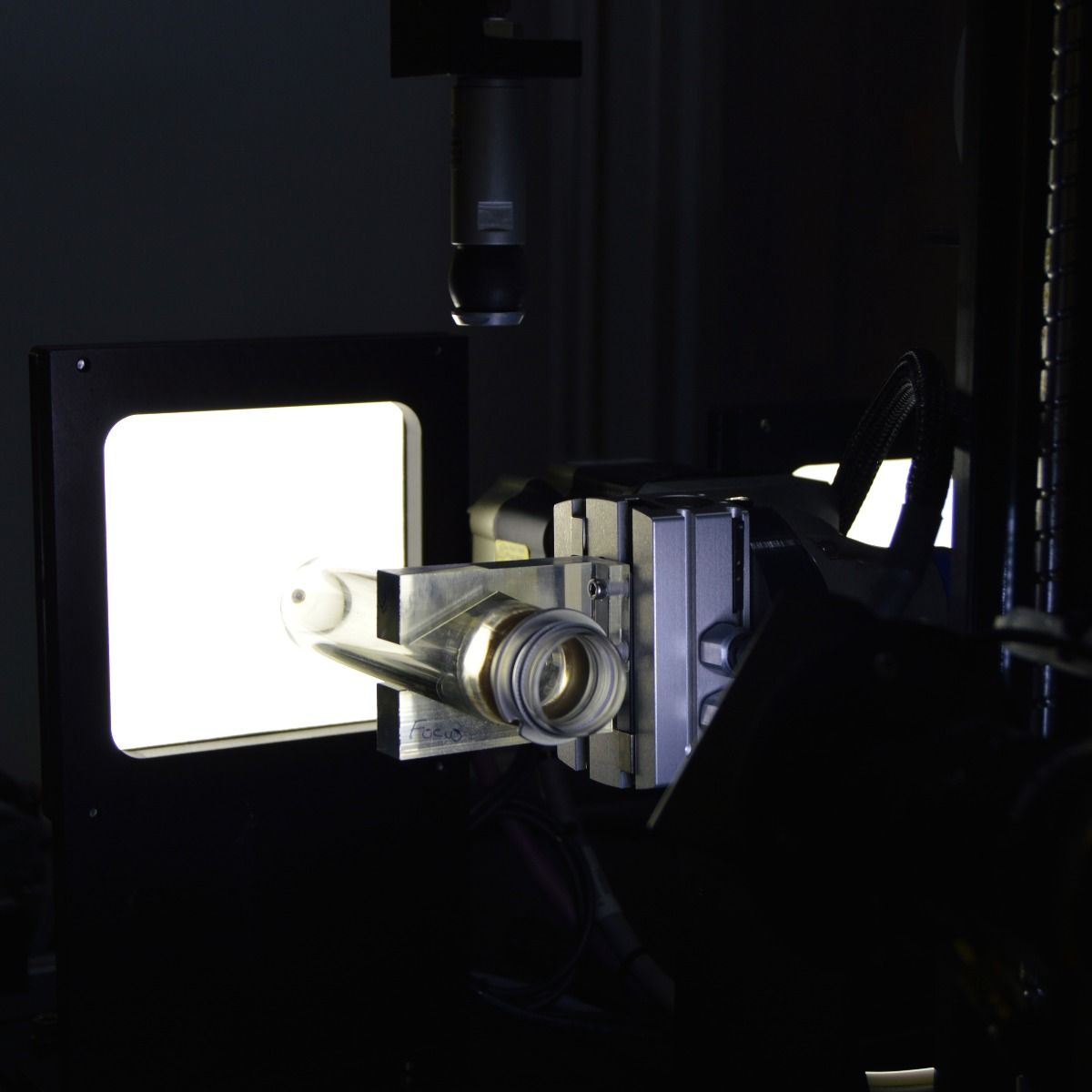

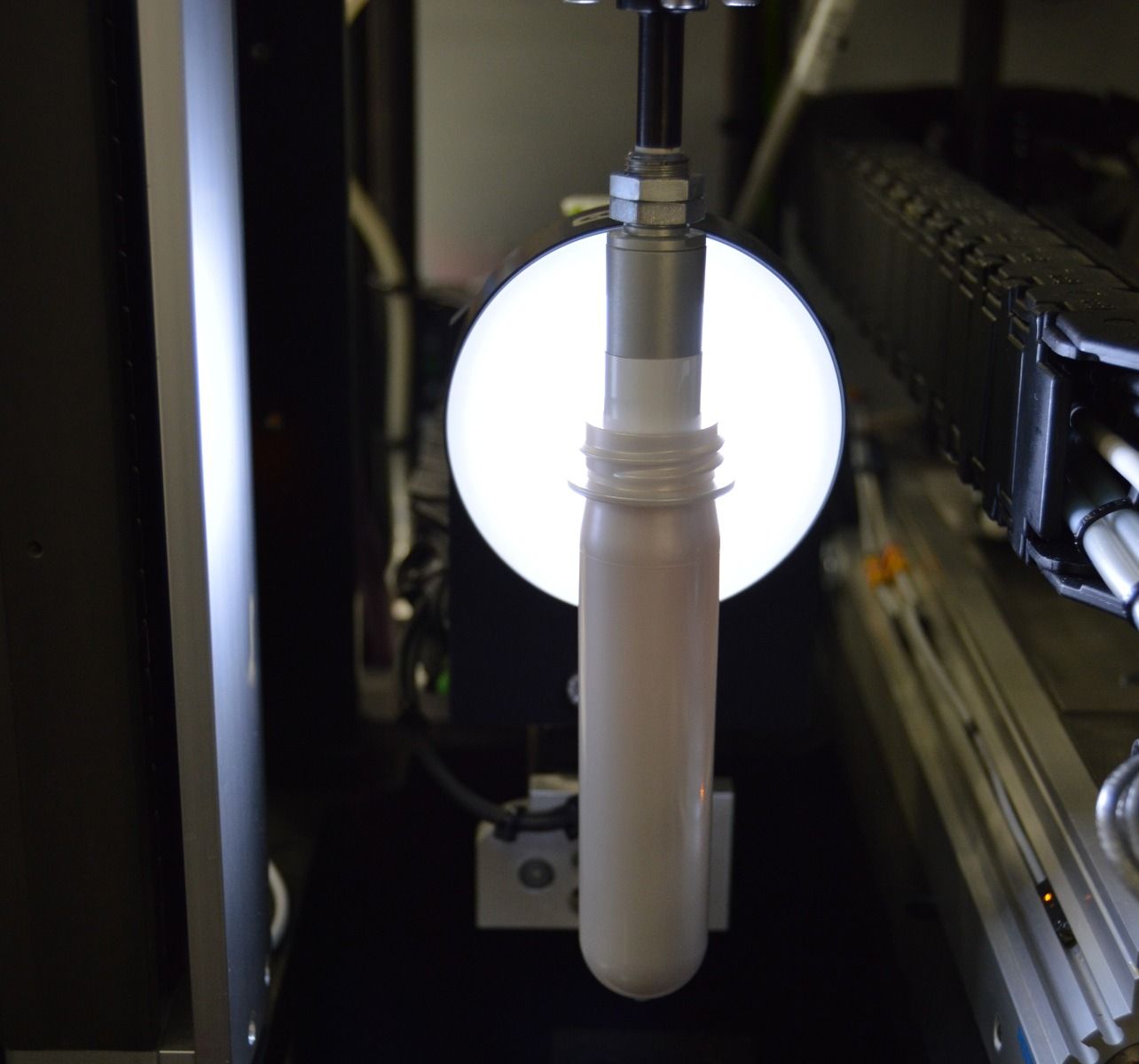

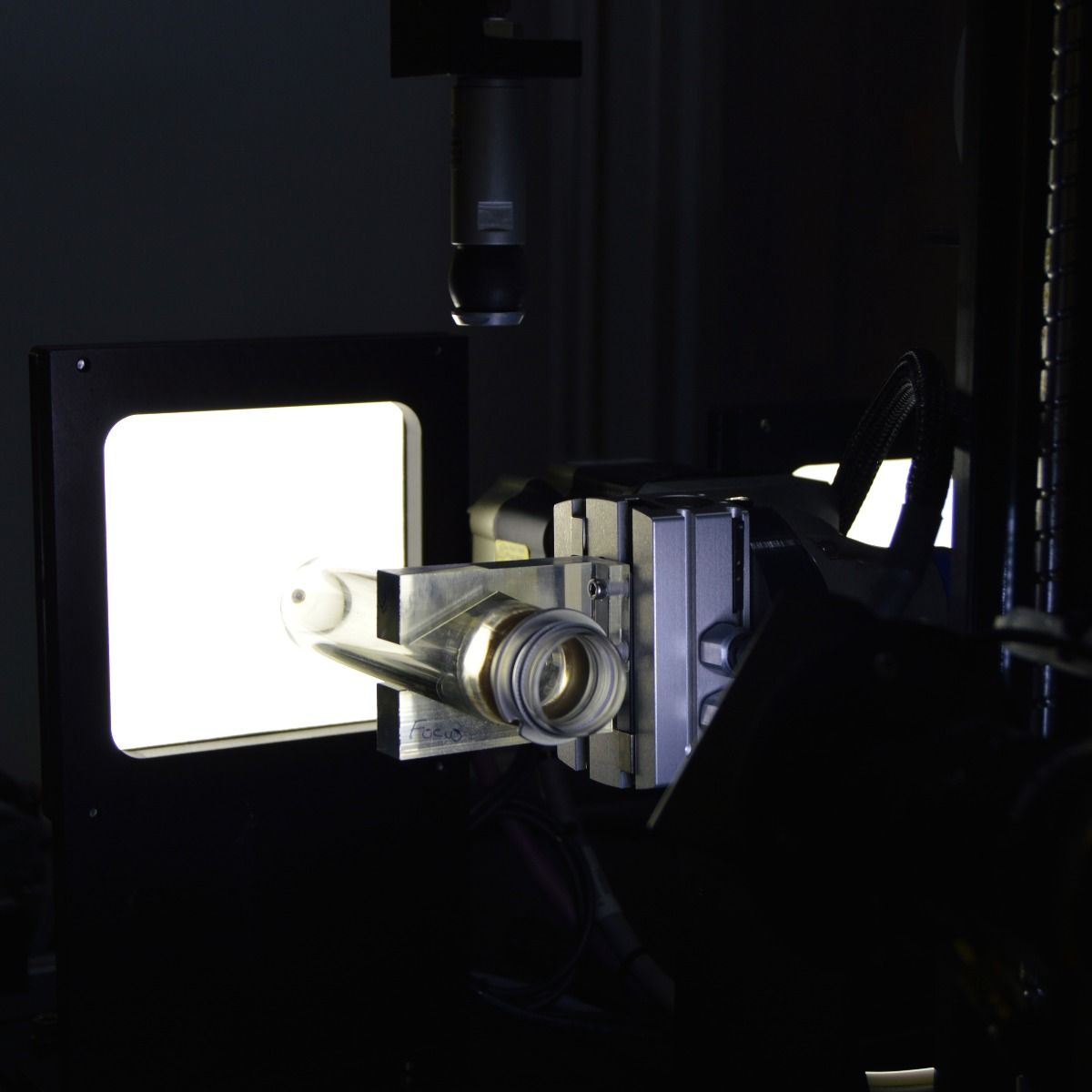

Using state-of-the-art optical technology and illumination the system can provide a wide variety of defect analysis for features such as Gate and Seal, Body Defects and Plastic Flow.

The UV and Colour Inspection quickly provides checks on UV transmission rates and Colour data against customer preform specification.

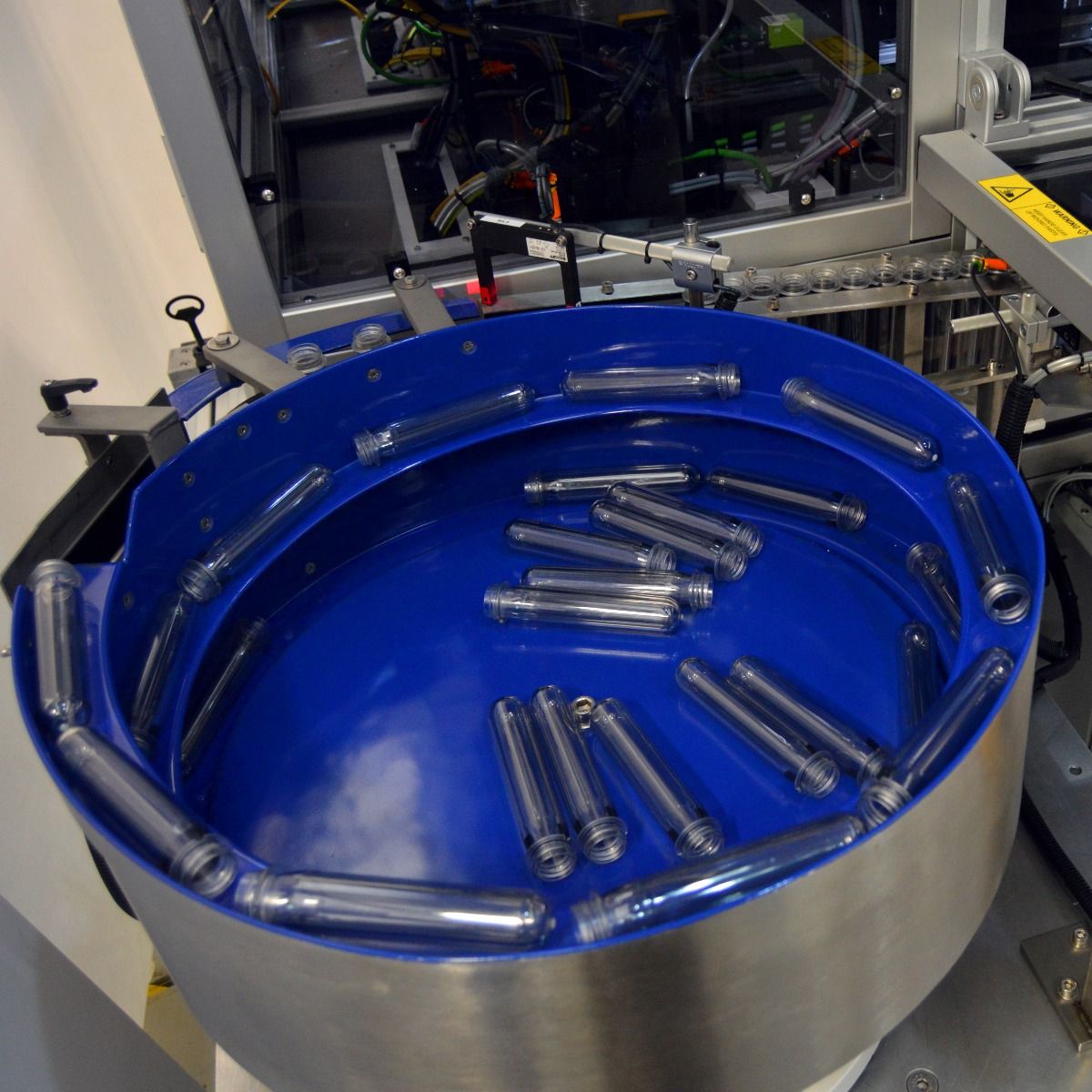

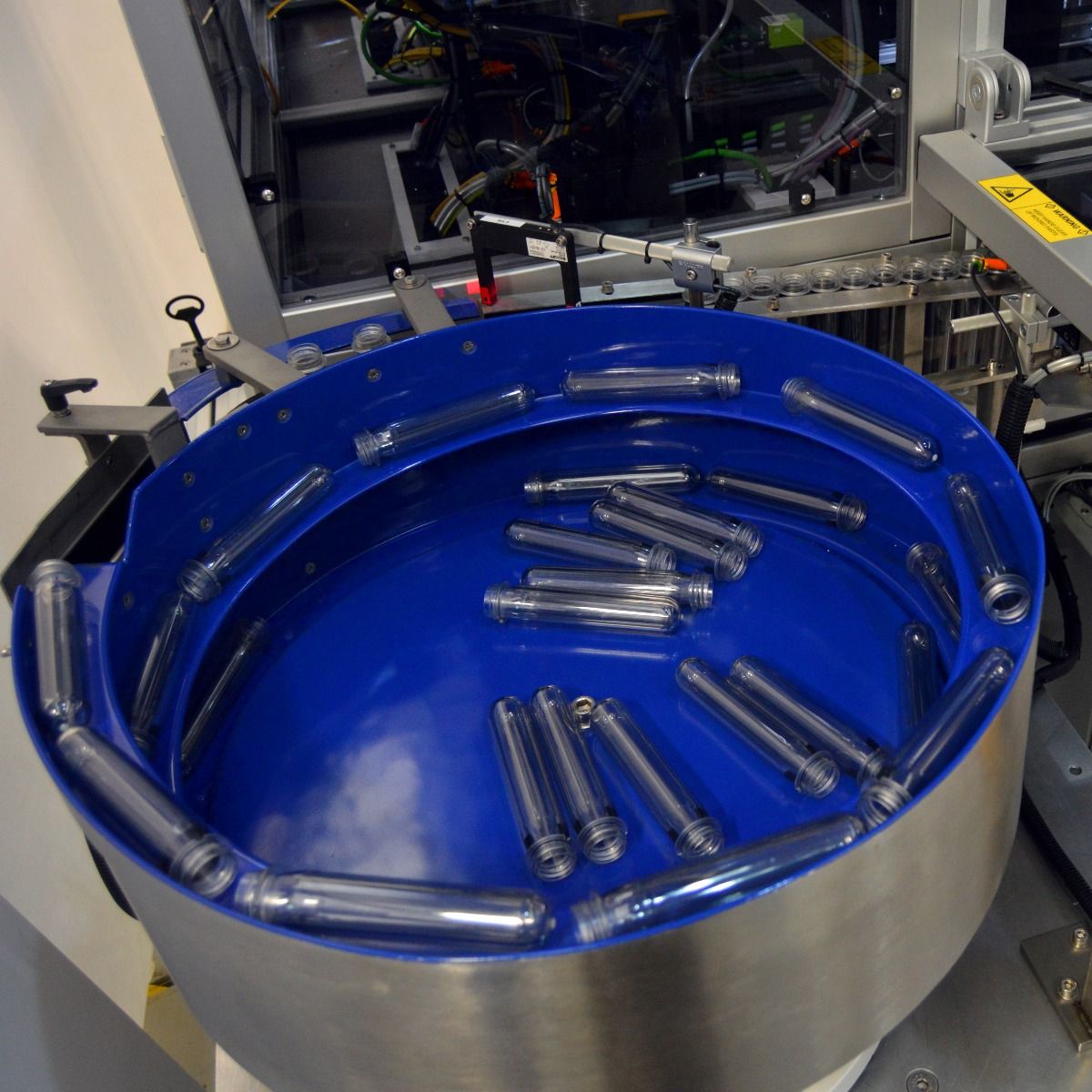

The loading bowl feeder, enables the operator to load full shots of preforms, with traceable measurement results provided by the Cavity Identification Module.

Technical Specification

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999