Introducing Torus’ Z704 RemoteXplorer, offering remote visual global support from our head office

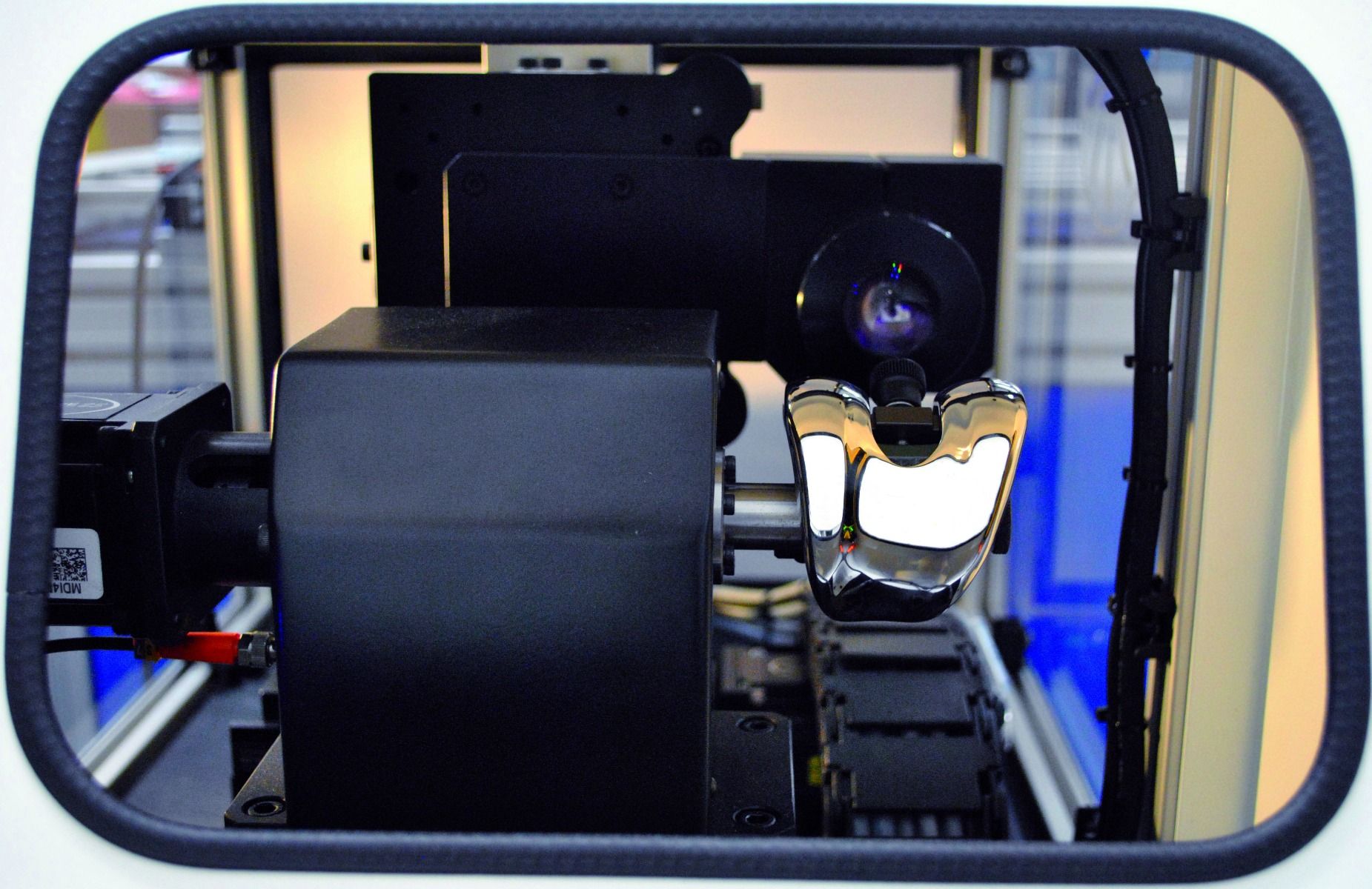

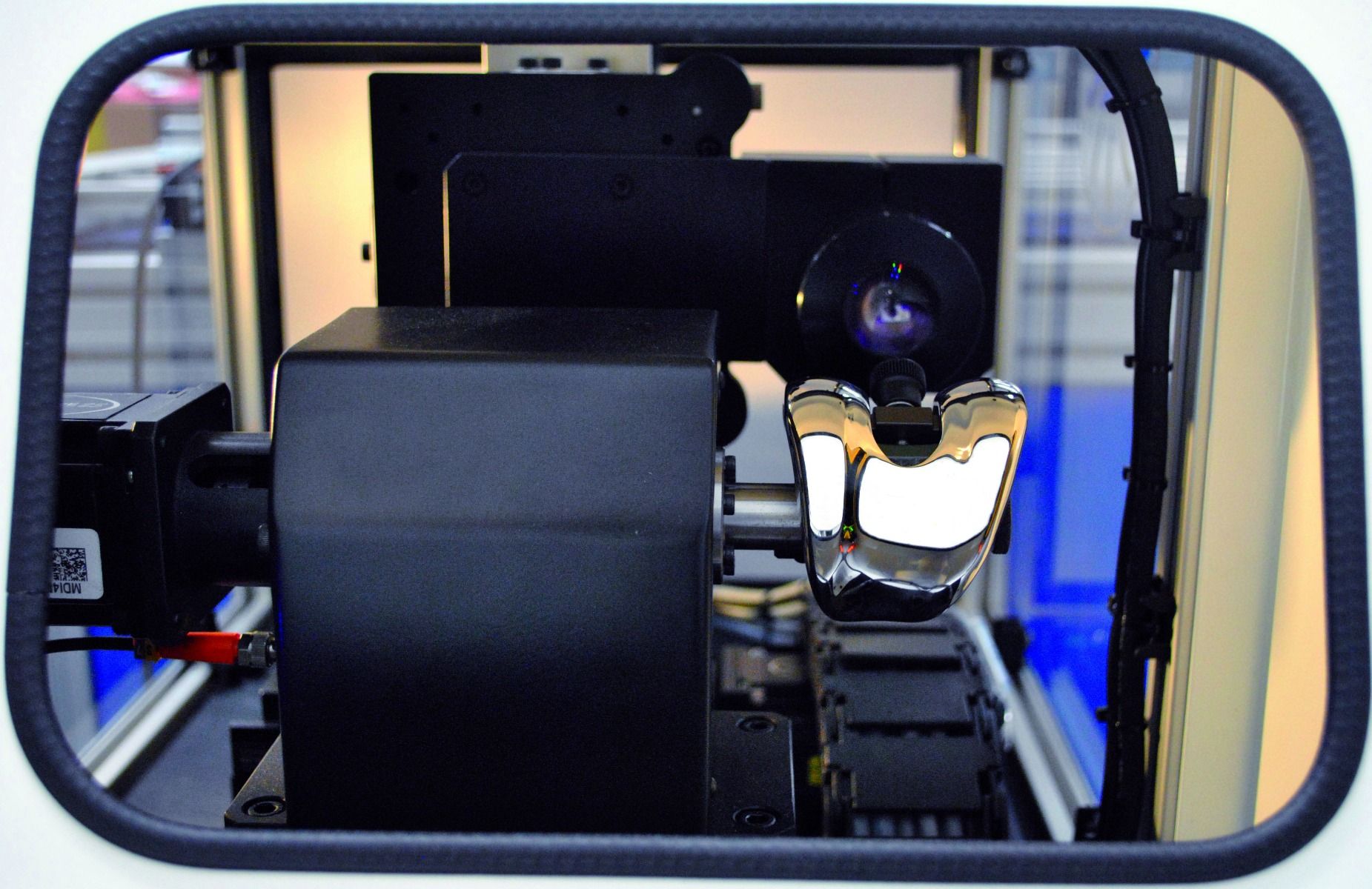

Remote support has been available for many years via Torus’ global helpdesk team, but only now can ‘eyes on’ support be offered via a new extension of Torus’ traditional GaugeXplorer software. RemoteXplorer, with the permission of customers, the gauges can now be monitored visually using RemoteXplorer’s newly developed pan and tilt camera system and software package.

How can we help you?

The Torus surface profiler measurement system utilises state-of-the-art confocal technology for rapid non-contact inspection of surface profiles on orthopaedic femoral knees, eliminating the need for handheld and subjective profile gauges and comparators

The system is designed for operational use on the shop floor therefore giving the machine tool operator a quick and repeatable measurement without having to go in to the inspection lab.

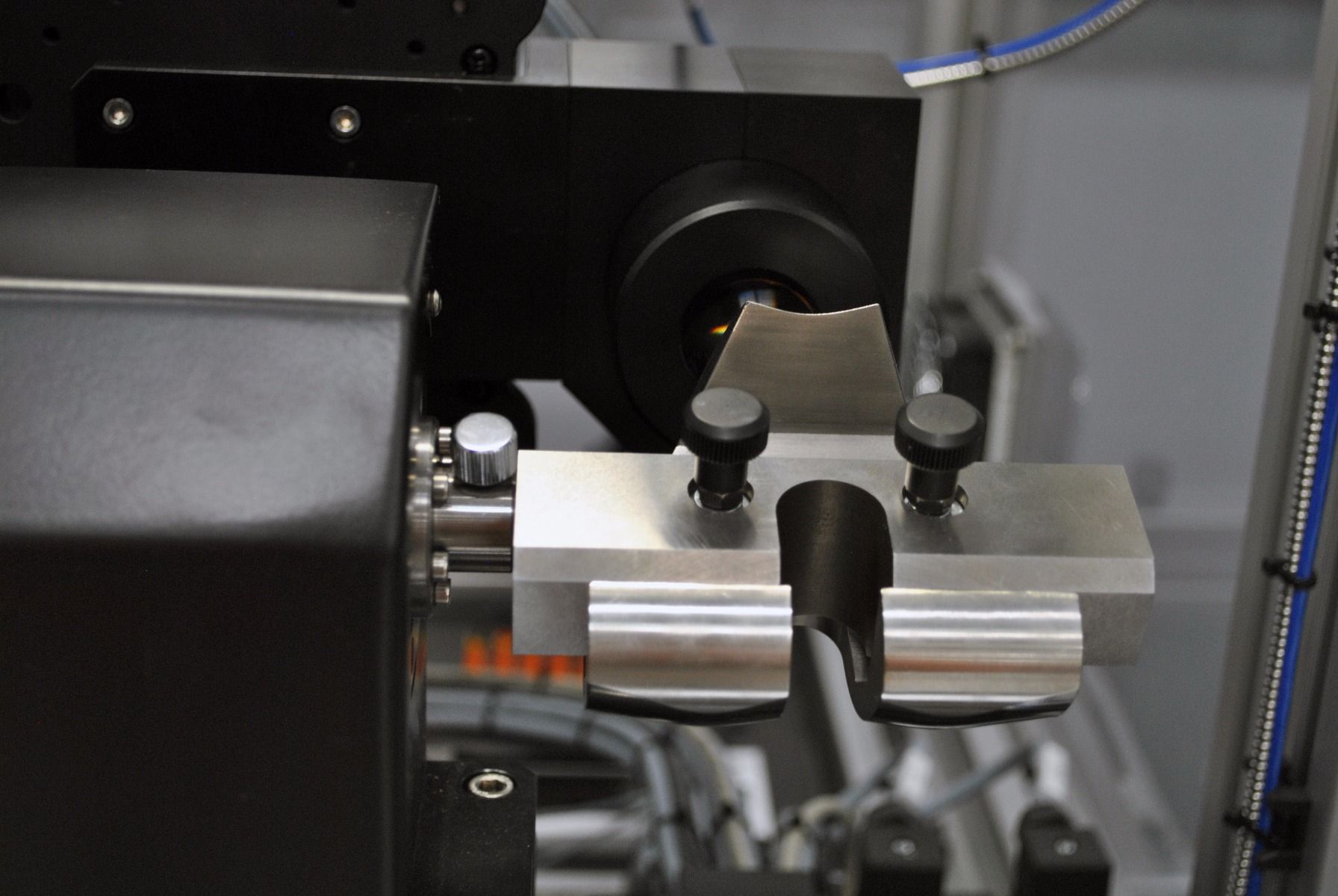

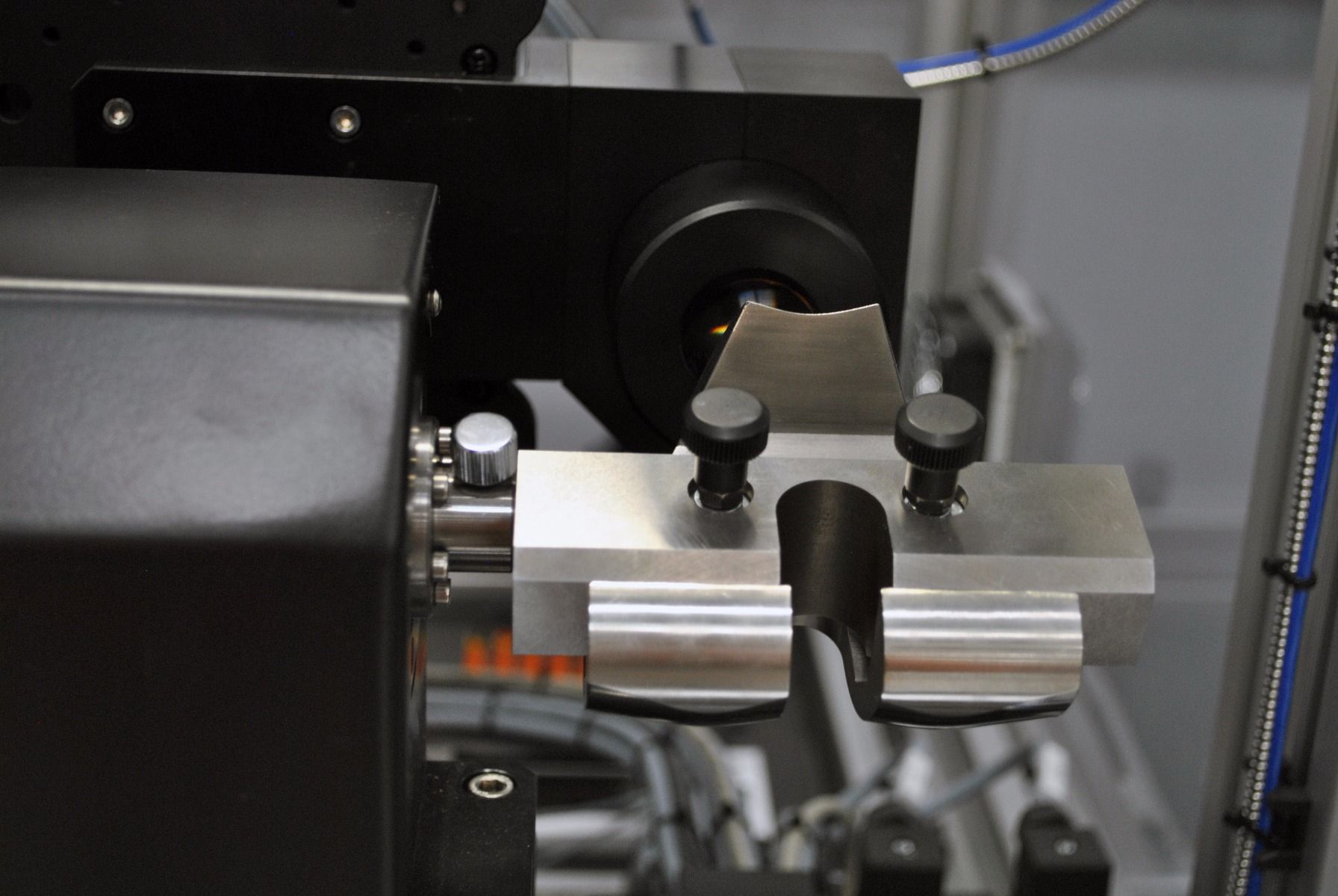

Polychromatic white light is focused onto the target surface by a multi-lens optical system. The lenses are arranged so that the white light is dispersed into monochromatic light by controlled chromatic aberration. Specific distance to the target is assigned to each wavelength which is exactly focused on the target is used for measurement.

This unique measuring principle enables displacements and distances to be measured with high precision and extreme spatial resolution. Cast, finished and highly polished surfaces can be measured without the requirement for surface preparation or machine adjustment.

Since the emitter and receiver are arranged in a single axis, shadowing is avoided, in contrast to conventional triangulation sensors.

The 4-axis motion control system is driven by high accuracy micro-stepping motors giving positional feedback, providing high resolution and high speed with stability and reliability.

Measurement Features

Feature

Technical Specification

Capabilities

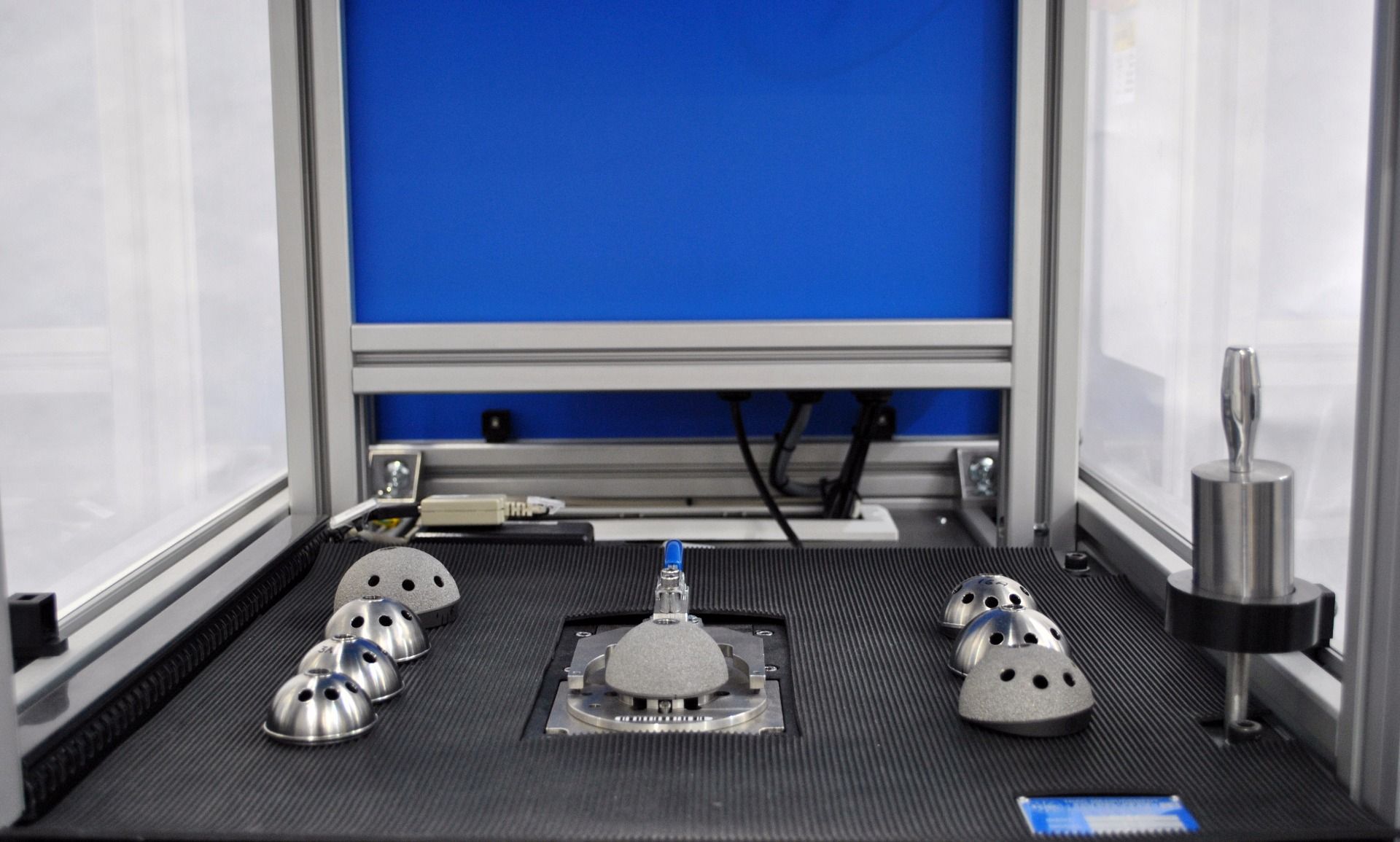

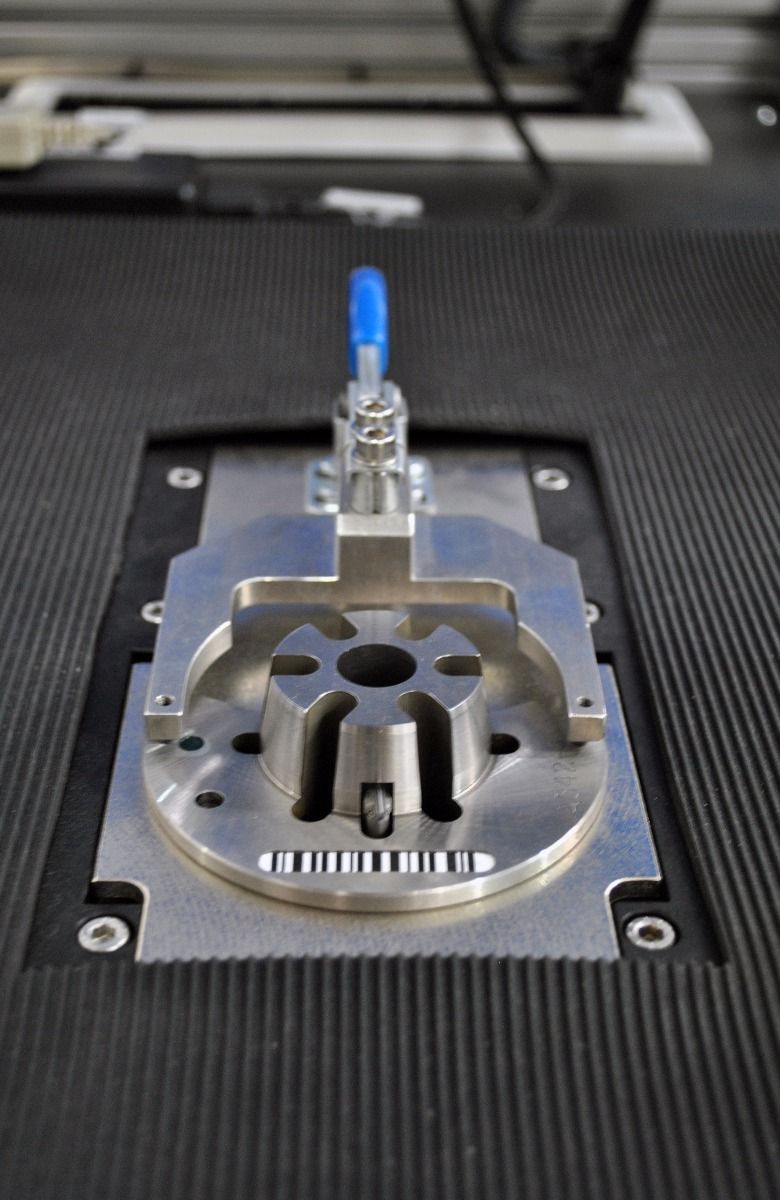

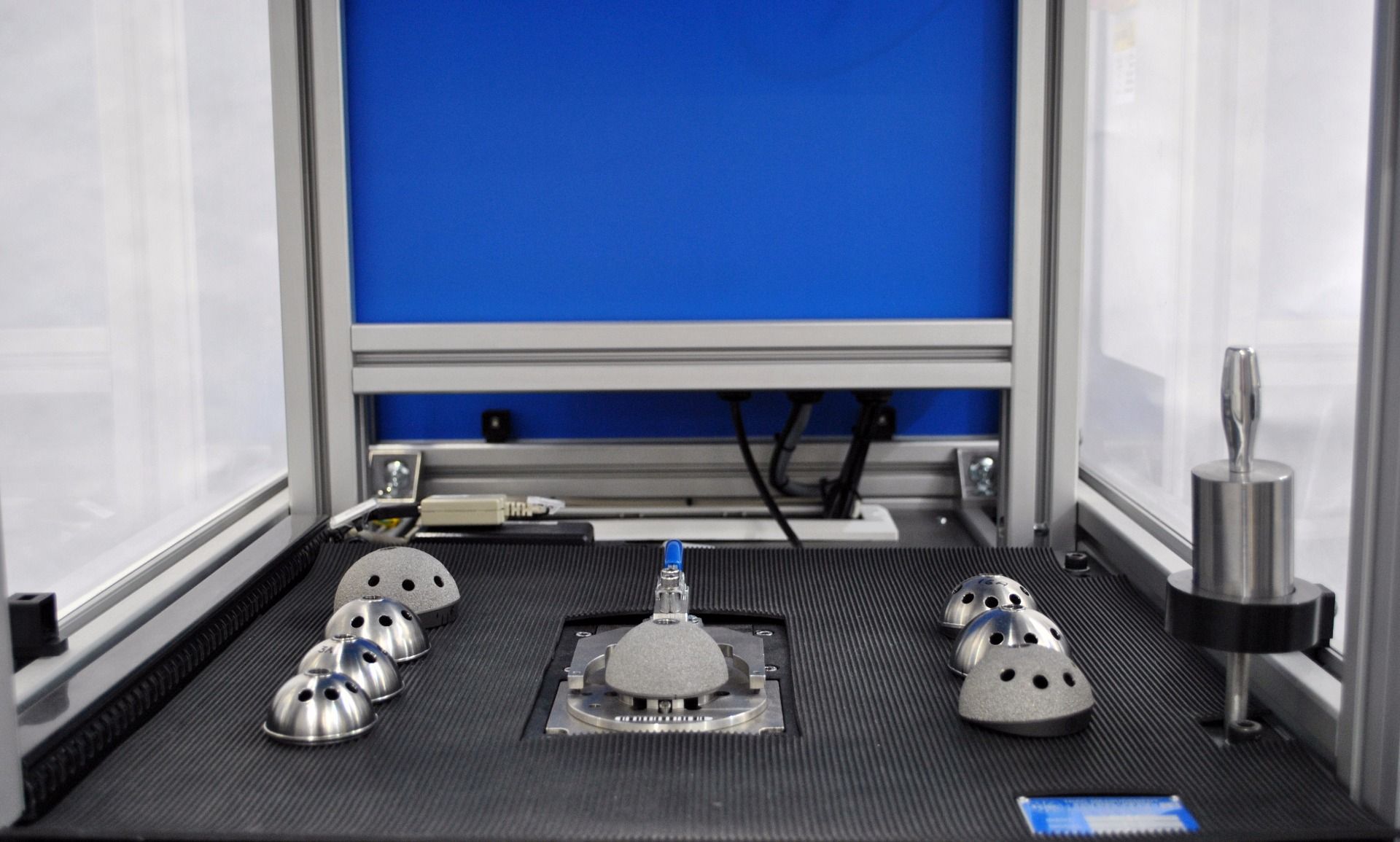

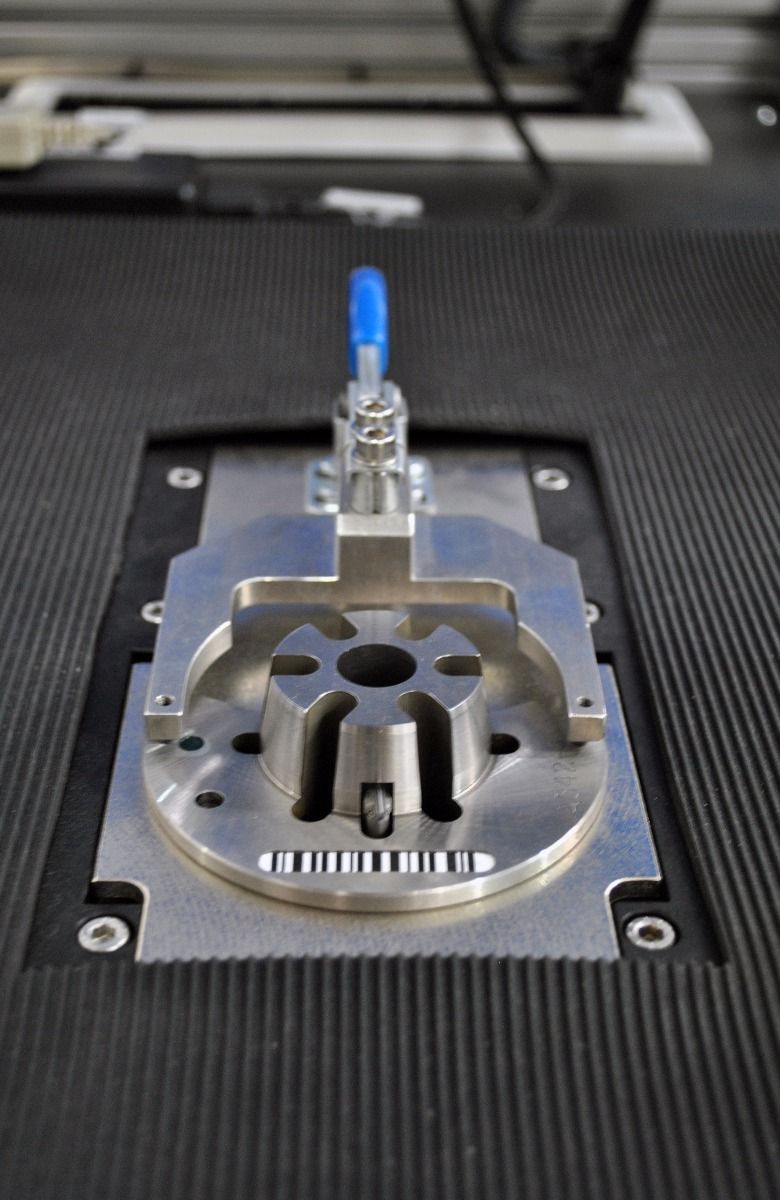

Torus’ A542 Actabular Cup Gauge gives critical measurement information on a variety of measurement features

Torus’ Floor Standing Acetabular Cup Gauge is designed specifically for Orthopaedic Hip manufacturers who need control their Acetabular Cups quickly, accurately and beside the machine tool. The gauge can accommodate the full range of Acetabular Cups and gives critical measurement information on inferred mouth diameter, internal taper angle, taper straightness and an accurate indication of rounds.

To operate, simply scan the batch card with a barcode reader and the software will automatically select the relevant component type from the menu and the powerful Windows software will prompt you to load the specific Acetabular Cup.

Important trace information can also be attributed, to ensure easy analysis and comparison to assist in process control.

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999