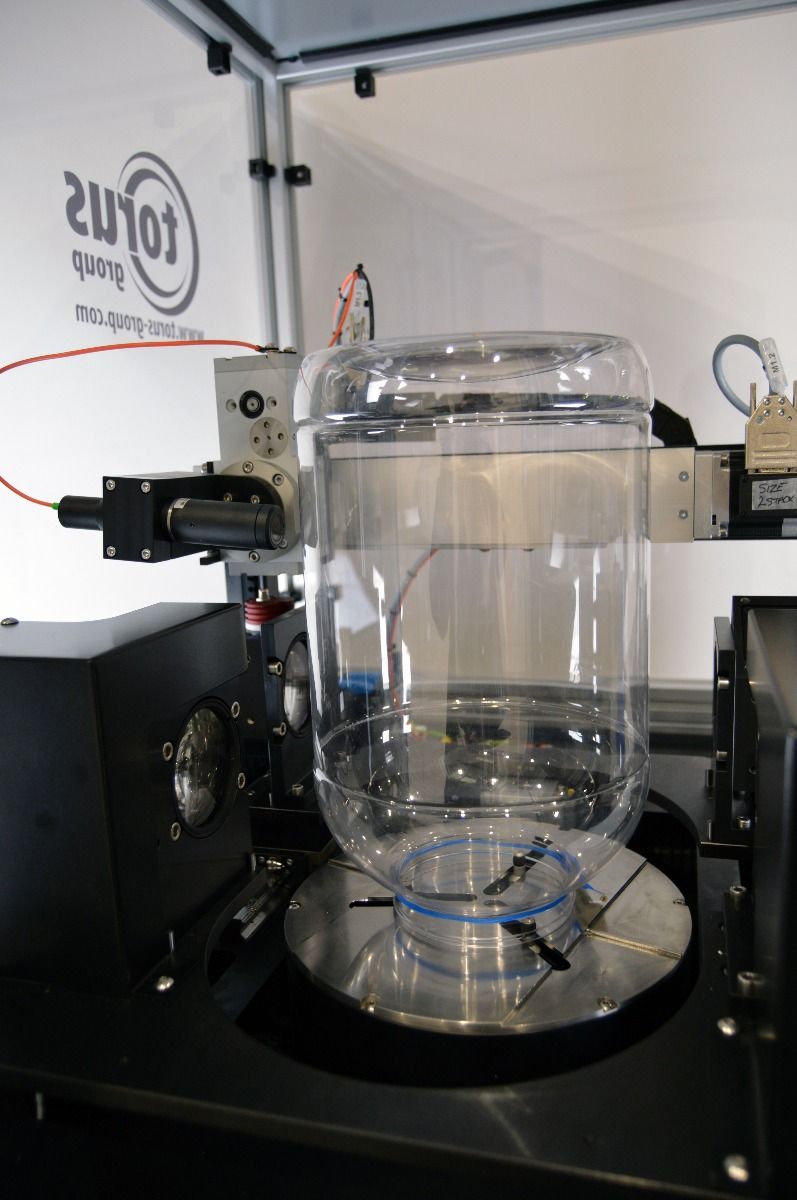

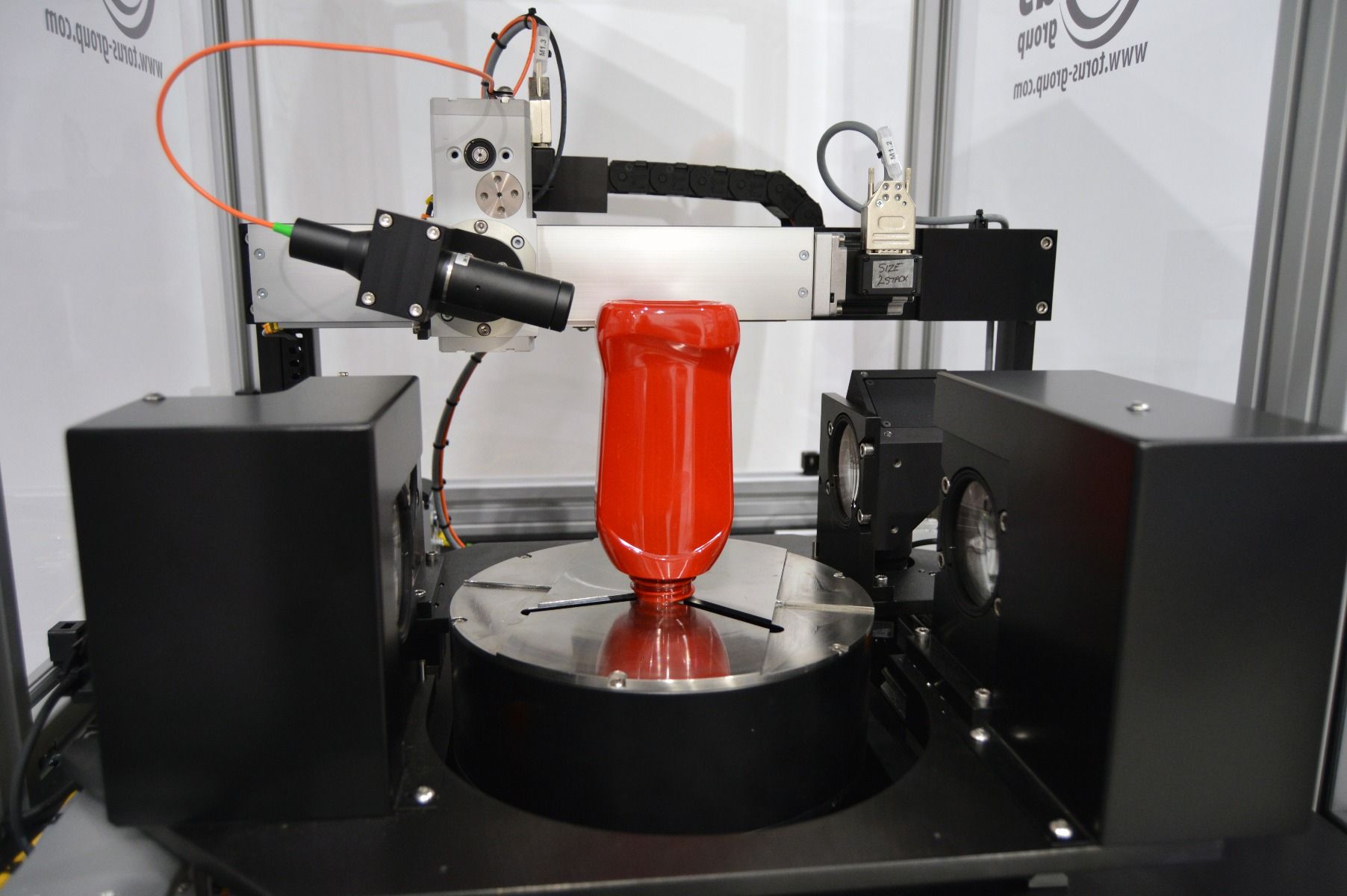

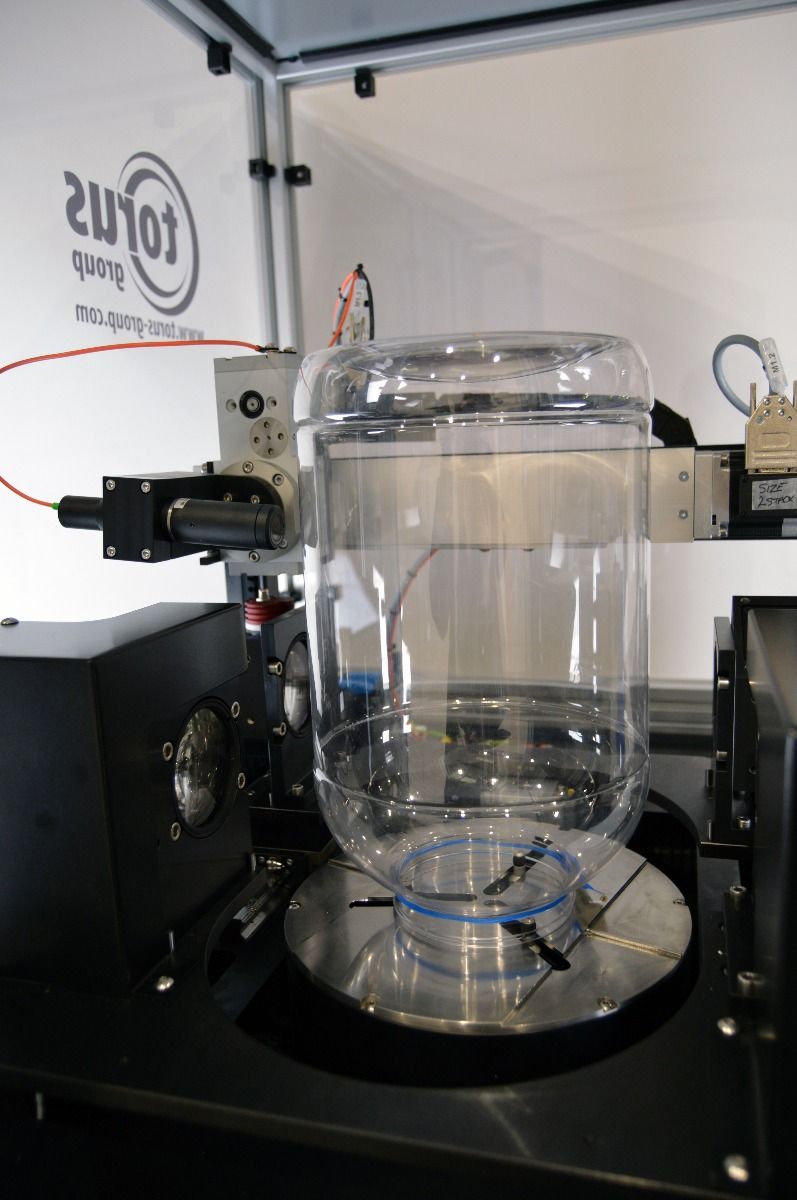

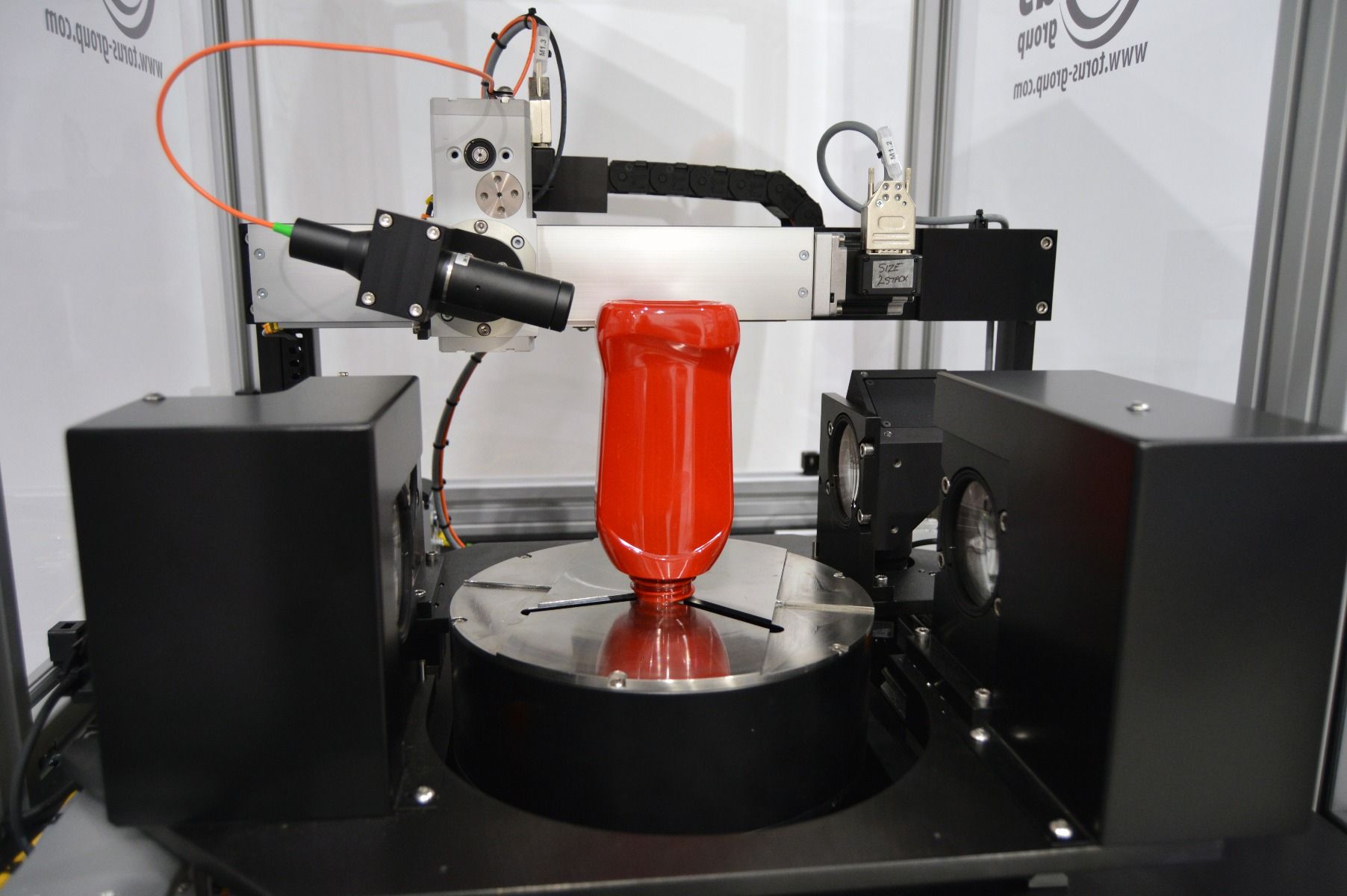

The 6-axis Torus TBT Gauge provides the ability to measure base & wall thickness with dimensional measurements in a single operation. This gauge has been designed with extended range to deal with the latest industry needs encompassing the scope to measure containers, jars and preforms as standard. Self centralising tooling delivers fast and repeatable container location, increasing throughput whilst achieving industry leading results. The latest confocal white light and optical technologies allow for unrivaled, non-contact measurements creating a new standard for plastic packaging quality control.

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

Reporting options such as standard CSV or Statistical Process Control (SPC).

Traceable to UKAS standards.

Measurement Features

Technical Specification

Thickness Sensor Options

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999