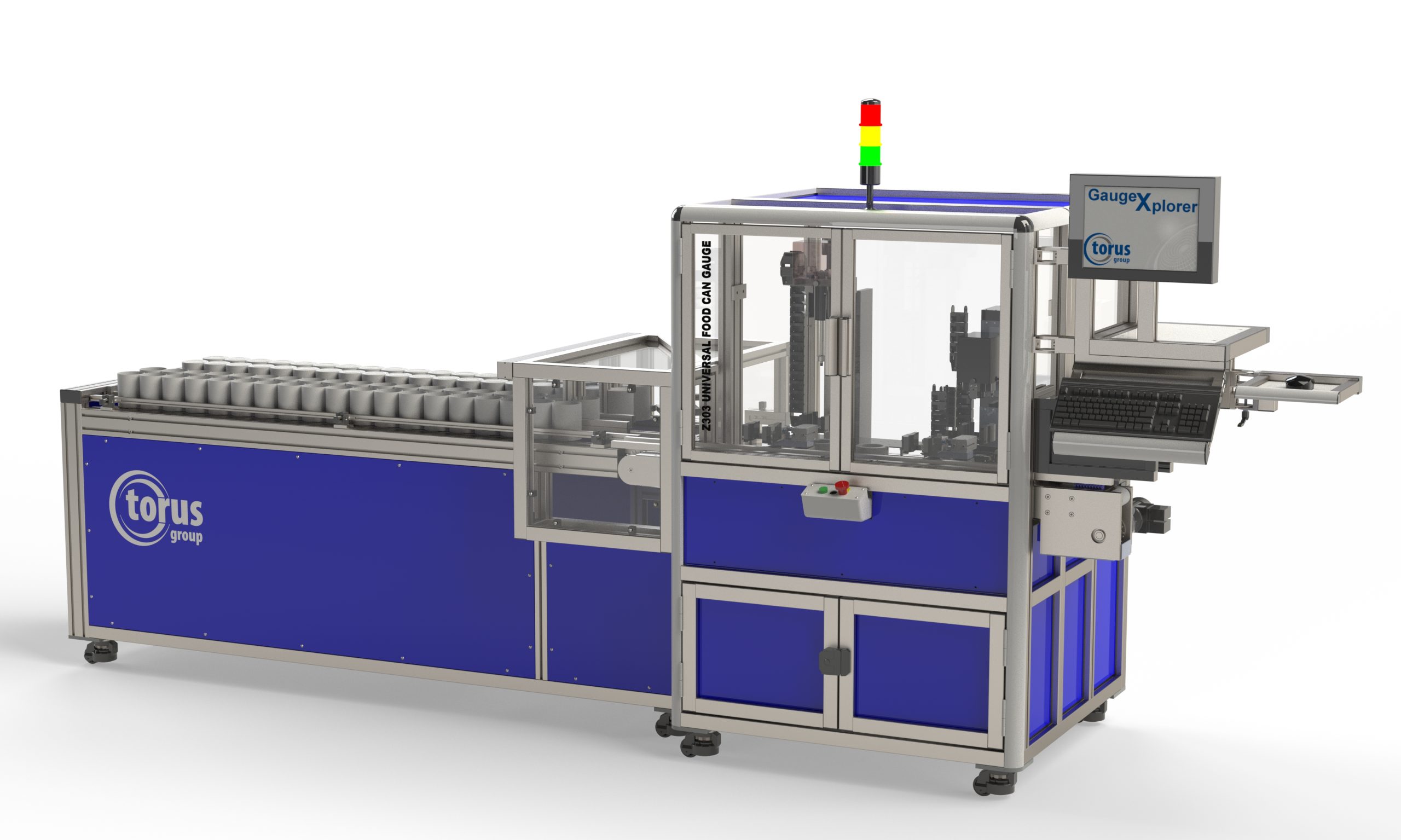

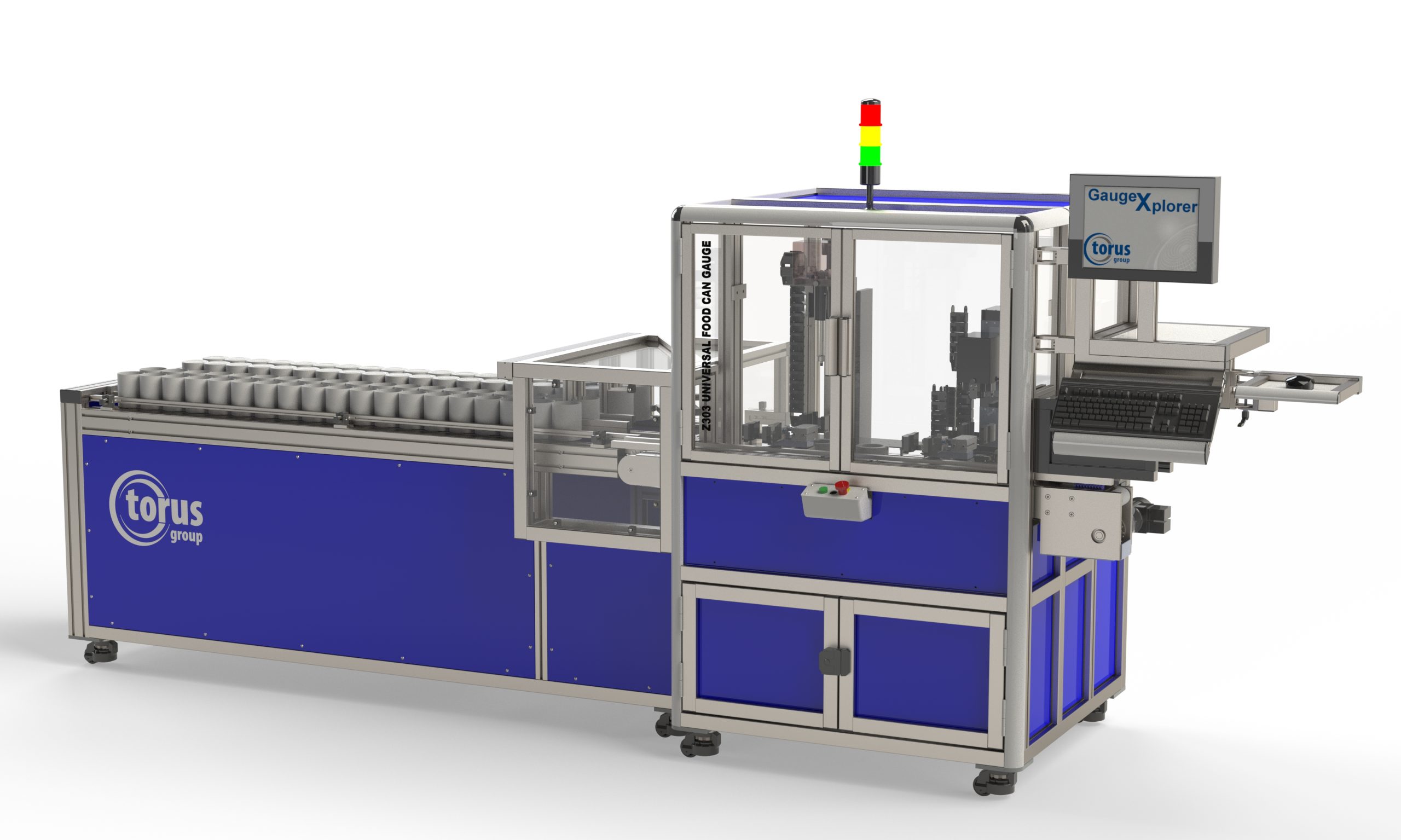

The gauge features fixed-top and mid-wall probe positions for multi-positional radial measurement, with a dedicated caliper to ensure the correct top and mid-wall thickness measurement position every time.

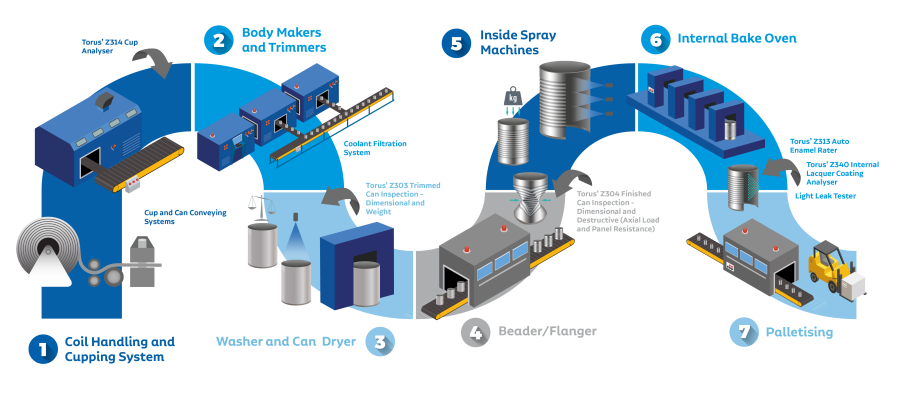

Torus Food Can Gauging

Measurement Features

Trimmed Can Features

- Mid Wall Thickness | 1-16 positions | Accuracy: +\- 0.001 mm

- Top Wall Thickness | 1-16 positions | Accuracy: +\- 0.001 mm

- Trimmed Can Height | 1-16 positions | Accuracy: +\- 0.010 mm

- Panel Depth | 1-16 positions | Accuracy: +\- 0.010 mm

- Countersink | 1-16 positions | Accuracy: +\- 0.025 mm

Finished Can Features

- Flanged Can Height | Accuracy: +/- 0.010 mm

- Finished Can Height | Accuracy: +/- 0.010 mm

- Flange Width | Accuracy: +/- 0.010 mm

- Bead Depth | Accuracy: +/- 0.010 mm

- Roll Bead Diameter | Accuracy: +/- 0.010 mm

- Roll Bead Position | Accuracy: +/- 0.025 mm

- Bead Symmetry | Accuracy: +/- 0.025 mm

- Panel Resist | Accuracy: +/- 0.5 PSI

Technical Specification

Trimmed Can Capabilities

- Can Range | Typical Range: Ø 211 – Ø 307 body diameters

- Can Materials | Aluminium/Steel

- Can Height Range | Typical Range: 87 – 210 mm

- Can Dome Depth Range | Typical Range: 9 – 13 mm

- Can Wall Thickness Range | Typical Range: 0 – 1 mm

- Can Body Diameter Range | Typical Range: Ø 202 – Ø 307 body diameters

Finished Can Capabilities

- Can Range | Typical Range: Ø 202 – Ø 307 body diameters

- Can Materials | Aluminium/Steel

- Can Height Range | Typical Range: 87 – 210 mm

- Can Flange Width Range | Typical Range: 1.5 – 2.5 mm

- Can Internal Neck Diameter Range | Typical Range: Ø 200 – Ø 209 body diameters

- Speed and accuracy

- Confidence in your production process

- Modular concept to cater for future upgrades

- Cost-effective upgrade path for additional modules to be added

- Fully automated, removing operator bias

- Trimmed and finished can inspection in one cabinet saves operator time, resource and space