Torus Inspection Systems are used extensively within the Metal Packaging Industry for Dimensional and Destructive Testing under production conditions. Using specialised contact probe, laser and optical technologies, our automated can inspection systems offer a price/ performance ratio far in excess of other models. From can inspection equipment to can testing equipment, our systems offer unique and modular solutions to virtually any of today’s inspection requirements.

Torus Measurement Systems provide global solutions within the metal packaging industry for Quality assurance inspection testing under production conditions to create inspection equipment that meets the demands of your customers.

Torus offer a full range of inspection equipment, from manual, semi-automatic, automatic, to fully integrated in line turnkey solutions, improving quality, maximizing your process efficiency, and assisting in the reduction of manufacturing running costs.

Torus’ project team will work to develop the equipment to best suit your requirements utilising the latest contact and non-contact technology.

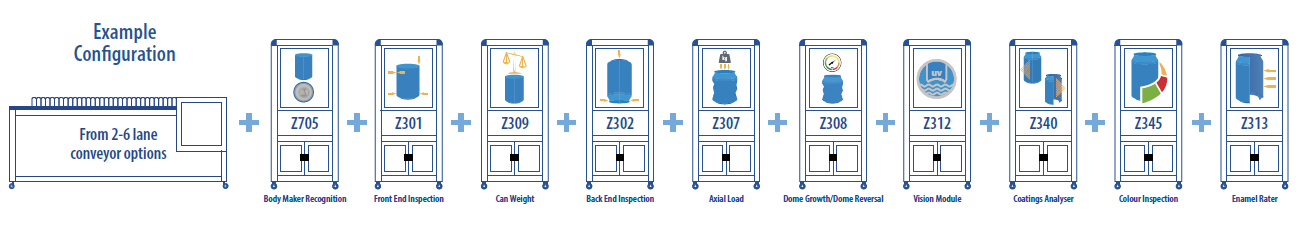

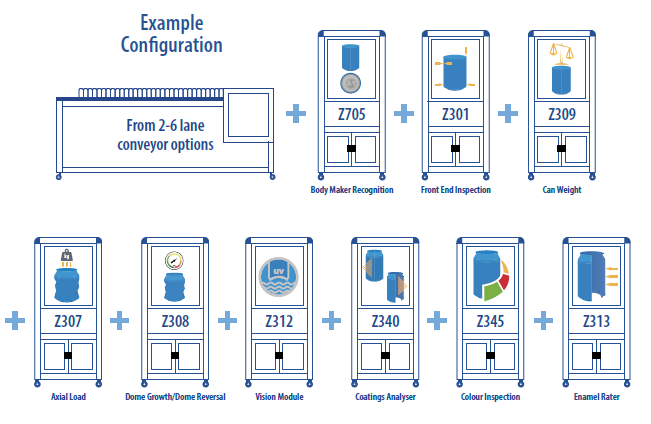

Our modular design approach provides flexibility by allowing our customers to configure individual measurement modules to best suit their needs ensuring the system is fit for purpose.

Torus gauges are industry 4.0 ready, future proofing your business and offering the ability to directly transfer live data to customer-specific networks and shop floor machinery allowing for instant analysis & monitoring, giving you complete confidence in your process control.

Our Modular Systems allow you to build a system to suit your measurement requirements

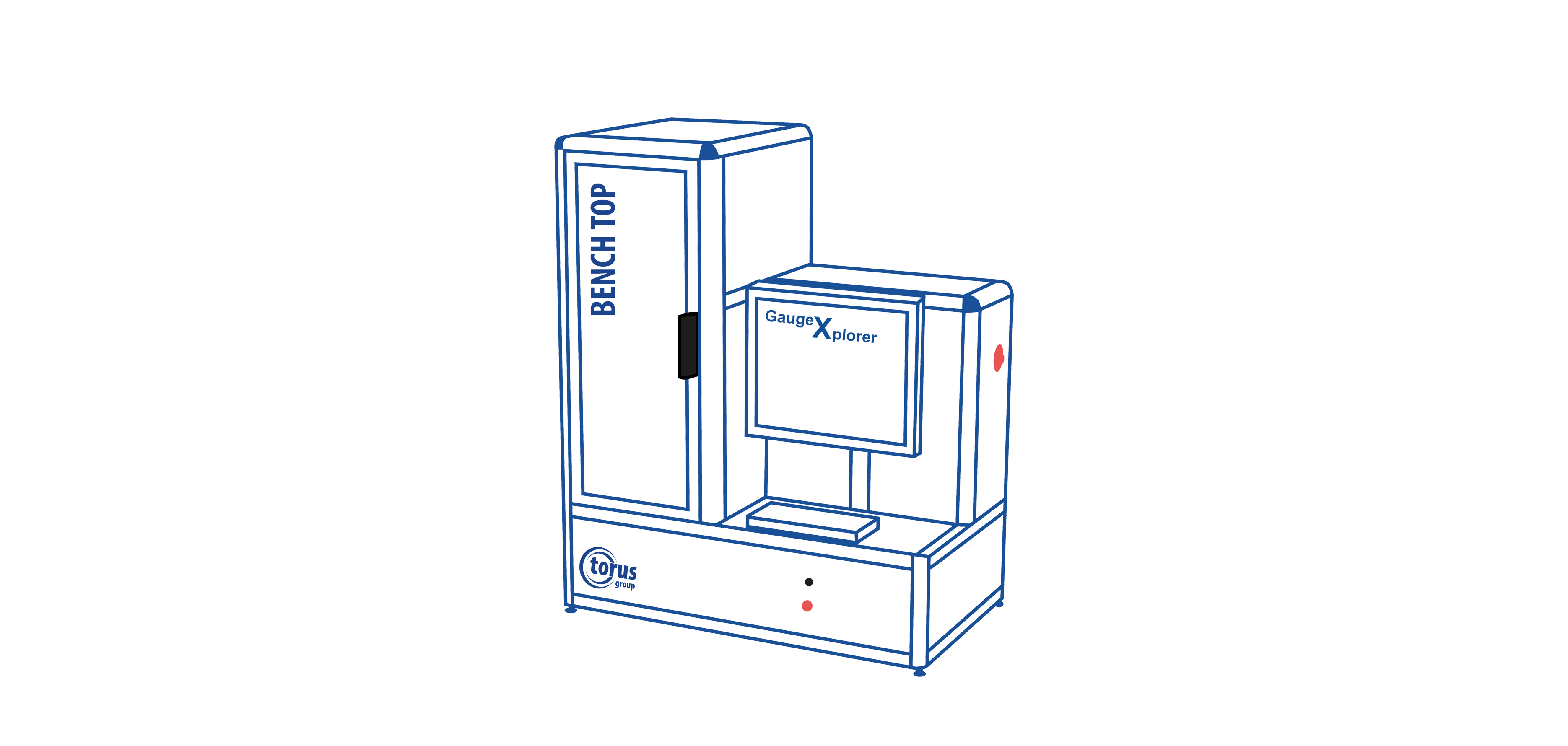

Manual Bench Top

Our manual bench top gauges are space saving and transportable making them a cost-effective addition to any laboratory.

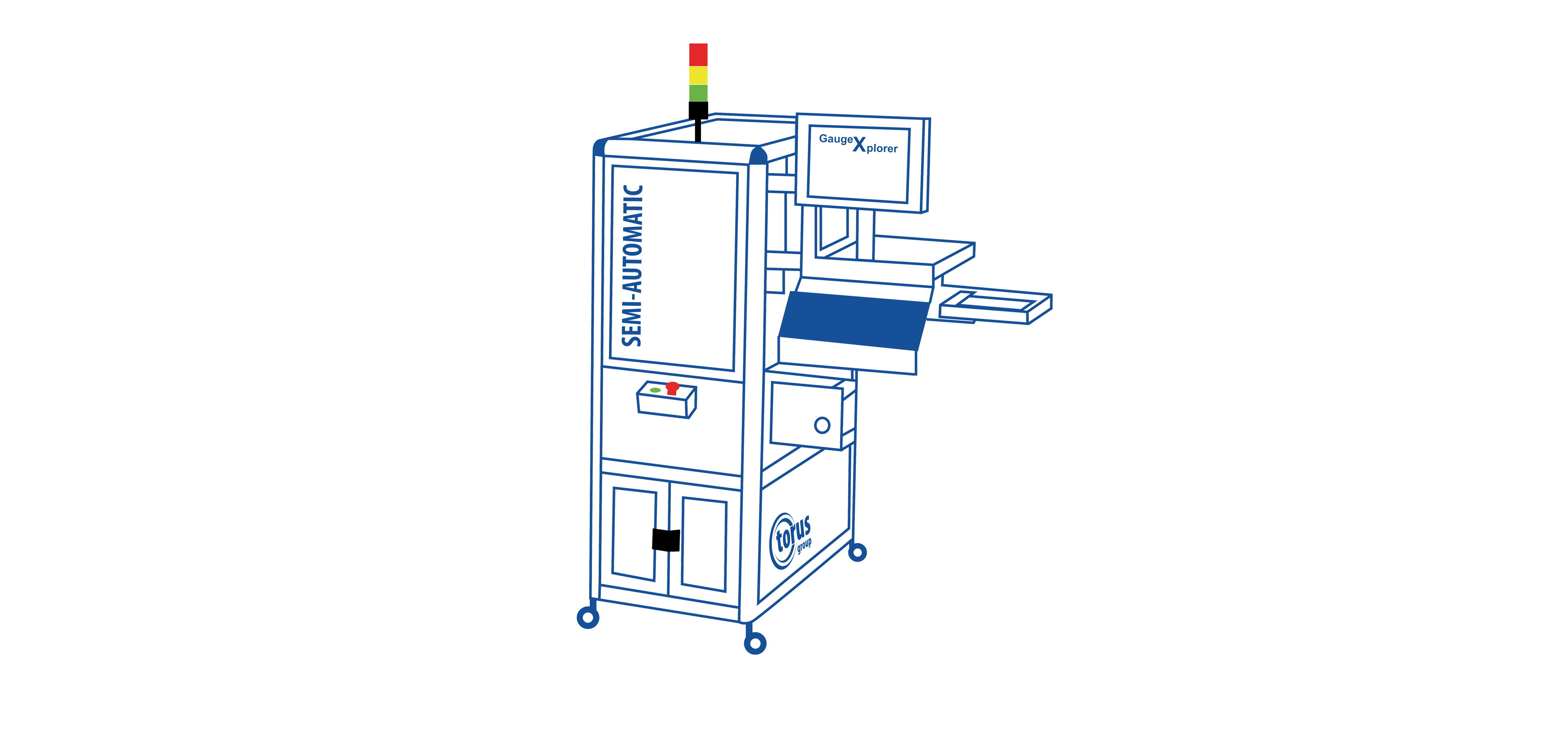

Semi-Automatic

Our semi-automatic systems are completely modular and fully upgradeable, meaning you can combine as many as needed to build your own system.

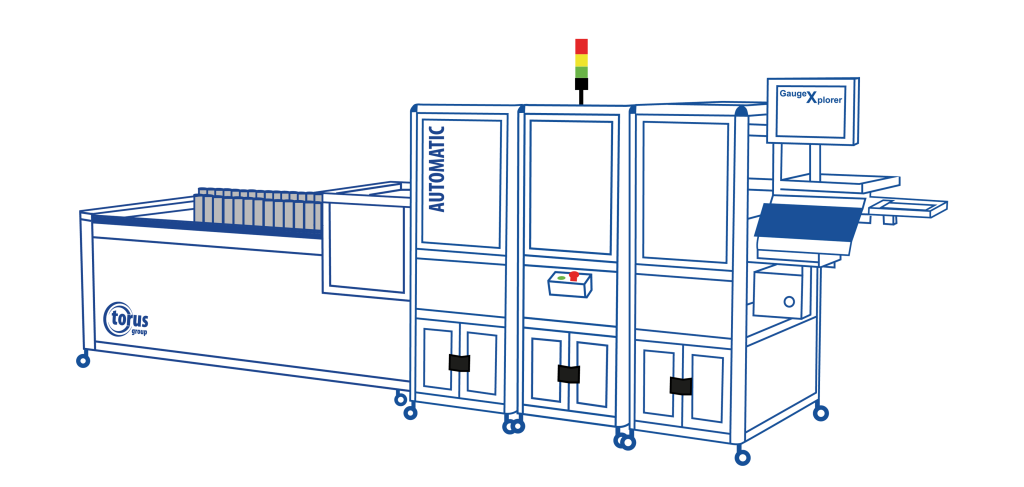

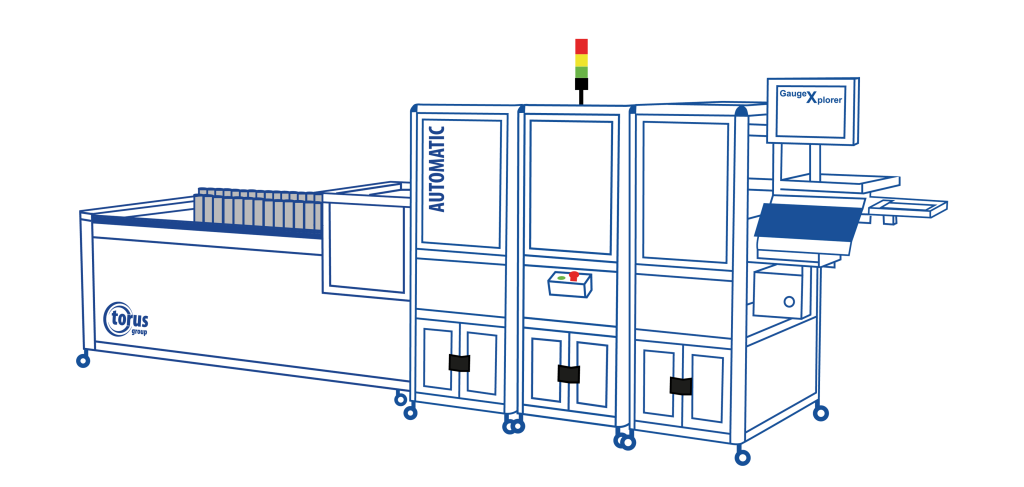

Automatic

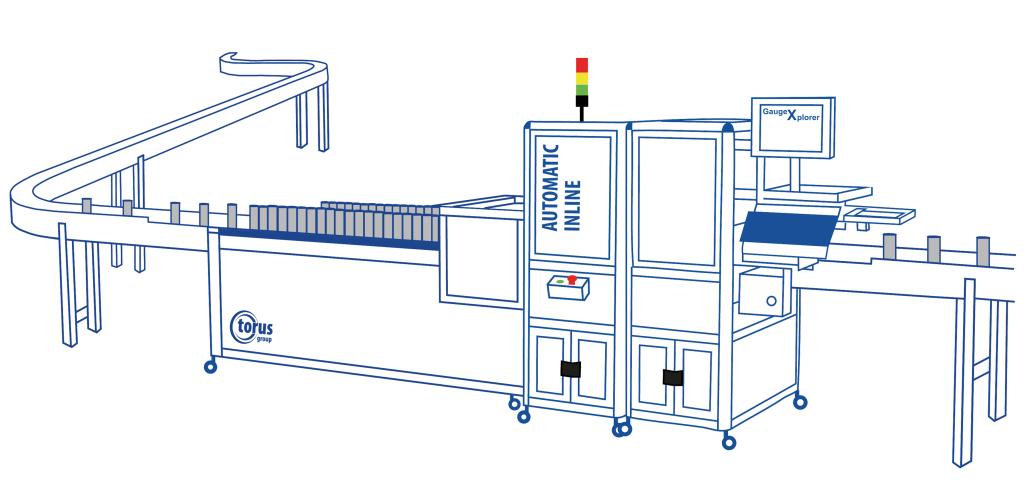

Our automatic systems can consist of several modules, building a bespoke measurement system with inline capability.

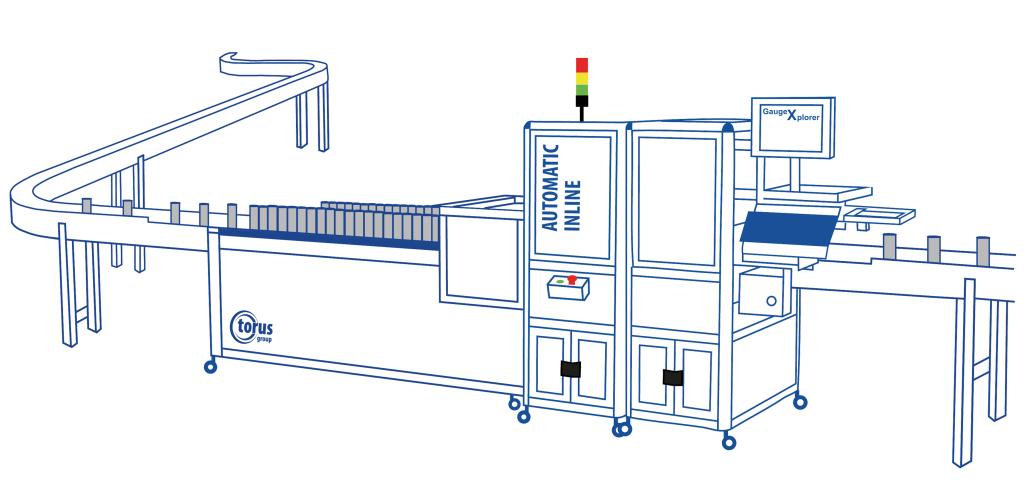

Inline

Our fully automatic inline solutions ensure you are completely covered – no matter what your set-up is.

Manual Bench Top

Our manual bench top gauges are space saving and transportable making them a cost-effective addition to any laboratory.

Semi-Automatic

Our semi-automatic systems are completely modular and fully upgradeable, meaning you can combine as many as needed to build your own system.

Automatic

Our automatic systems can consist of several modules, building a bespoke measurement system with inline capability.

Inline

Our fully automatic inline solutions ensure you are completely covered – no matter what your set-up is.

With over 30 years in the gauging industry and operations across the globe, our automated beverage can inspection systems offer solutions to virtually any of today’s metal packaging inspection requirements. Our modular systems have your beverage can inspection needs covered from start to finish.

Our Food Can Inspection systems offer modular flexibility by allowing customers to configure individual measuring stations and automated handling systems to best suit their specific application. Have a look at the video below to see how Torus’ food can inspection systems can fit in to your can making processes.

Our Shell and Ends Inspection gauges include our Z401 Shell Inspection System, Z403 Automatic Compound Weight and Placement Gauge, Z601 Automatic EOE Progression Gauge, Z603 Automatic Opening Force Gauge, Z604 Automatic Shell and End Enamel Rater, Z605 End Buckle and Burst Gauge and Z606 Automatic Score Gauge. Have a look at the video below to see how Torus’ shell and ends inspection systems can fit in to your can making processes.

Concluding our Metal Packaging Inspection Systems range is our modular Aerosol Inspection Systems, designed and built with flexibility in mind.

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999