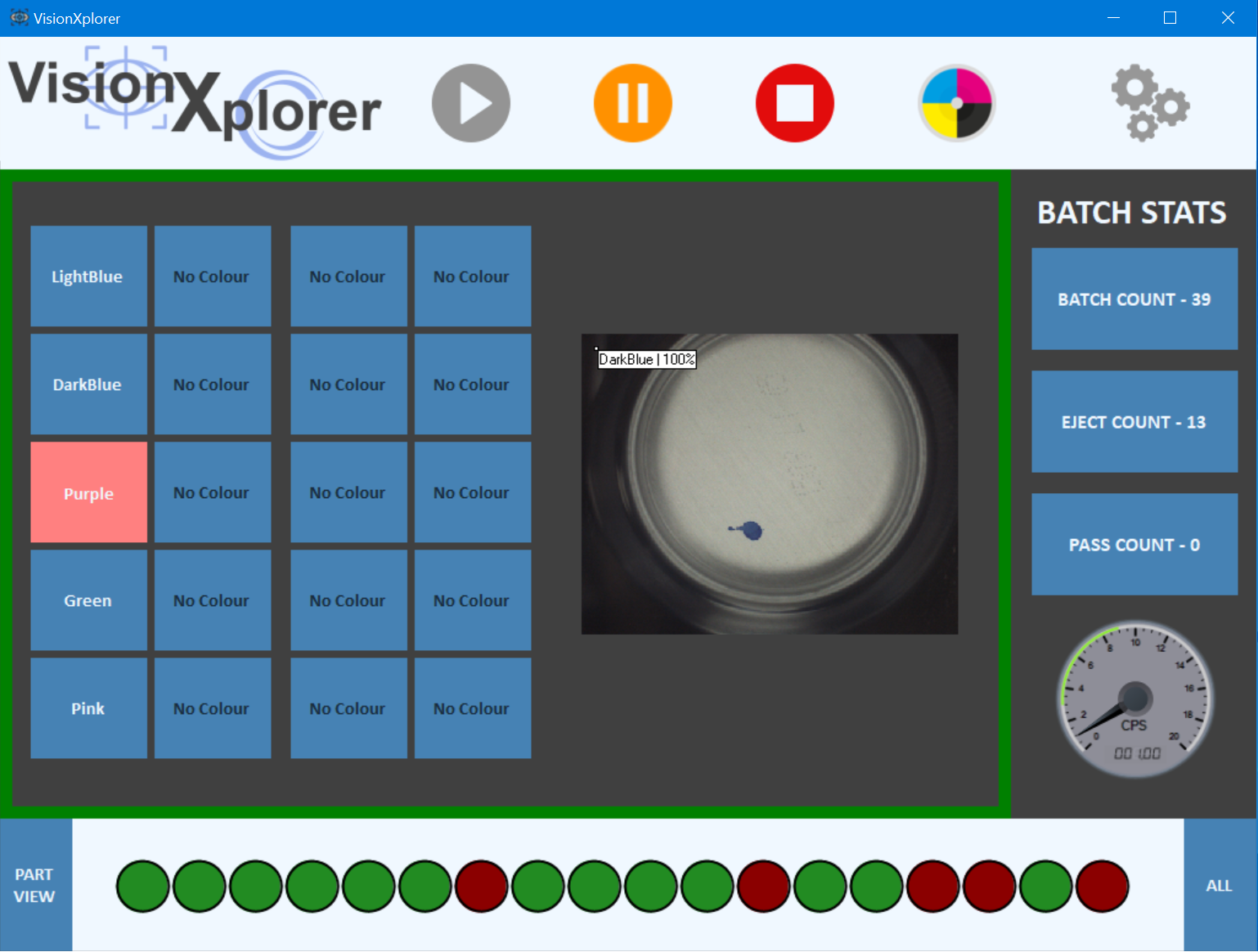

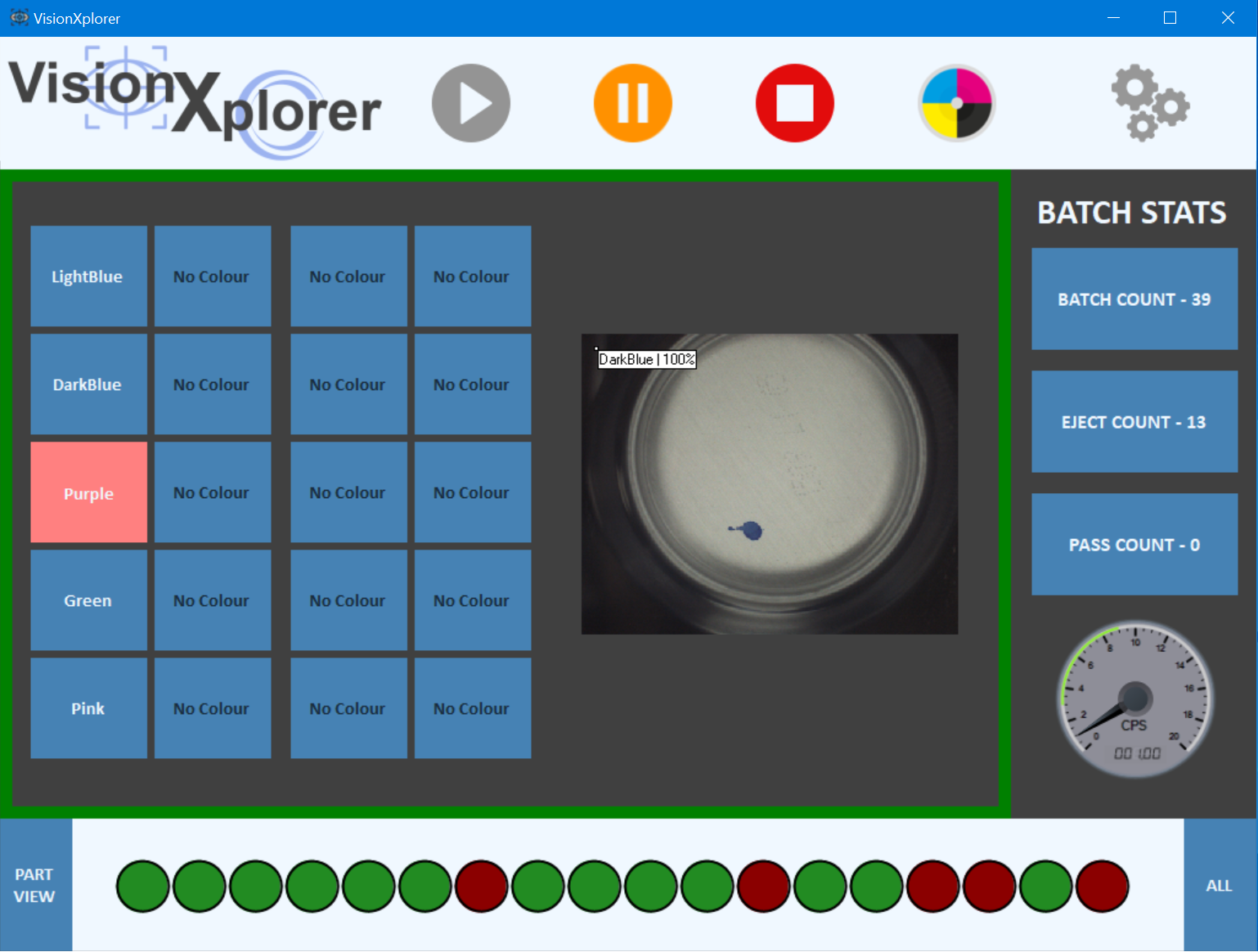

The Z701 Vision Sorting System has been developed specifically to meet customer end of line sorting requirements to facilitate sorting of HFI (Hold for Inspection) pallets to reduce manual work.

Torus Beverage Can Gauging

Measurement Features

Key Features

The Z701 integrates directly into an existing end of line sorter with minimal adjustments required. The system can be integrated into an existing or new sorter – Torus work closely with the customer’s chosen integrator to ensure a successful installation. A site survey is carried out by both parties to agree the suggested location for the integration.

The camera will be located on your existing sorting line

The Vision System can be positioned up to 10m away from the camera

The 2nd monitor can be positioned up to 10m away from the Vision System, enabling the user to measure results from elsewhere in the facility

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999