With over three decades of expertise in the food, beverage, and aerosol industries, our focus on metal packaging defines our mission. Rooted in a shared passion for innovation and customer satisfaction, our team of over 100 employees is dedicated to advancing our infrastructure to serve both our customers and employees better.

Central to our commitment is our world-class R&D department, continually pushing boundaries to develop new technologies and enhance existing ones. Our expanding infrastructure includes dedicated service and technical support teams strategically located worldwide to provide prompt assistance to our customers.

Darren Hawkings, Torus’ Metal Packaging Sales Manager talks about one of Torus’ latest innovations.

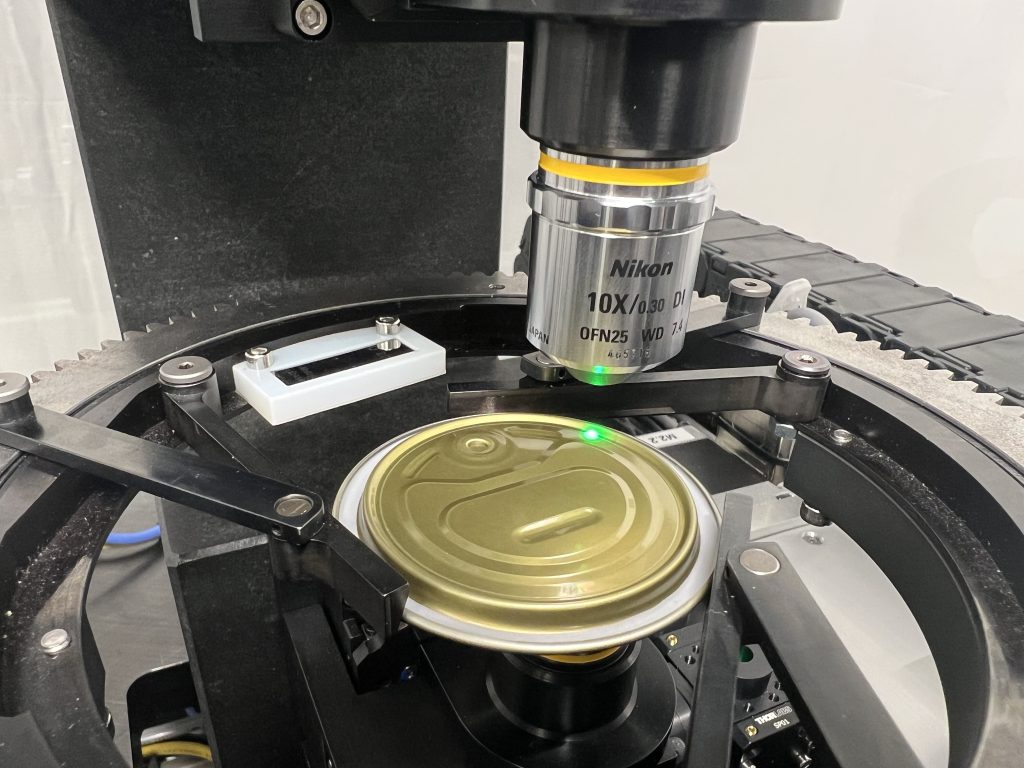

“One of our recent breakthroughs is the Torus Z606 Score Gauge, revolutionising the industry with its automated solution for measuring score residual on beverage and food ends. Eliminating operator bias, this innovative system offers complete user configurability, allowing for precise analysis tailored to specific requirements.

Powered by white light scanning interferometry, the Z606 employs a cutting-edge sensor design to optimise score residual measurement. Utilising interferometry optics and a high-resolution voice coil positioning slide, it scans the end’s surface, generating a detailed point cloud of up to 2.3 million data points. This comprehensive data set enables precise measurement of score path and residual thickness.

The Z606’s loader system accommodates up to 8 stacks of ends per cycle, facilitating efficient processing of multiple sizes without requiring change parts. Its innovative handling system ensures universal compatibility with most end sizes, streamlining operations.

Additionally, the integration of machine vision enables seamless end orientation detection, enhancing usability for operators. With measurement times under 30 seconds per position, the Z606 provides end makers with vital data to optimise their score process and prevent faulty ends from entering production.”

Learn more about our Z606 Score Gauge here.