Article written by Festo – original article can be found here

Torus offers a range of custom-designed automated inspection and testing systems that enable customers to control high-speed processes, reduce costs, and maintain quality in demanding environments. TQ-Lab is a total quality-testing station for plastic packaging, typically used for soft drinks, health supplements, cosmetics, and domestic cleaning products.

Expanding horizons

Plastic packaging requires precision measurement of aspects such as material thickness, outer body and neck physical dimensions, and load testing for crushing and pressure.

The TQ-Lab can undertake all the necessary tests in a single system. Once batches of containers are placed onto the turnaround conveyor, the operator simply selects the relevant program and walks away.

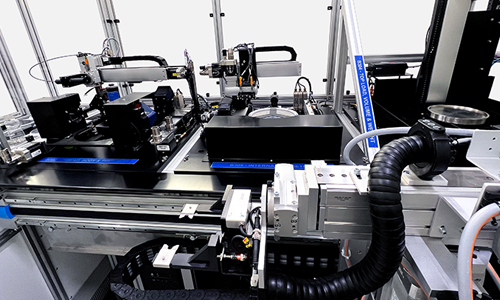

A bespoke vision system locates the position of the neck and an intelligence force feedback gripper and multi-axis pick-and-place system transfers the product from the conveyor between measurement modules. The system is fully customisable, so customers can select the Torus test modules that suit their particular requirements or budgets. Controlled via a single interface, TQ-Lab delivers reliable data to the network with no operator influence.

Its development is a major diversification for Torus. Traditionally, the company has focused on developing test stations for metal packaging, but TQ-Lab extends its expertise to the plastics packaging sector.

“We knew that our in-house expertise would enable us to transfer our testing technology from metal to plastics packaging,” explains Brian Wilson, Engineering Director at Torus.

“However, the handling complexities involved in offering a total testing solution in a single system was a real challenge.”

Accurate handling and repeatability were key to delivering the customer benefits that Torus envisaged for TQ-Lab. These included reduced time and labour costs, the potential to collect a large amount of measurement data, and a reduced footprint to save valuable floor space.

Torus investigated the option of sourcing components to build the handling system itself, but there were issues with compatibility and reliability using multiple suppliers. It also considered the option of using an ‘off-the-shelf’ robot solution and modifying it to suit.

However, this involved considerable design modifications and specialist automation skills that lay outside its core expertise. It recognised the need for an automation expert to work alongside it to optimise the system design.

“Festo had been a valued supplier of automation components, such as electric drives, handling components and valve terminals, to Torus for many years, but this was the first time we decided to tap into their design support services,” says Wilson.

“It was the best decision we could have made. Festo engineers enabled Torus to focus on their area of expertise, so the whole system benefited.”

Handling with care

The final TQ-Lab was developed over 12 months, and Festo was involved from an early stage. Chandra Patel, Business Development Manager at Festo, explains: “We were able to speed up design lead-in times quite significantly: for example, by using our extensive software tools and experience to identify the best components for the handling system specification.

“The final design helped to simplify the handling system into a single integrated solution, instead of multiple bespoke parts from separate suppliers. Using the recently introduced Festo ELCC cantilever axis, we were able to replace the original custom-built vertical module with a technically neat and commercially attractive single part.”

“The highly technical specification and complexities of movement also made it crucial to test that the design would work in principle before building out the handling system. Our dedicated sizing and simulation software enabled us to test different configurations and proved to Torus that the final design would deliver the desired performance, in terms of accuracy and repeatability.”

The automation expertise available from Festo enabled Torus to reach a final design more quickly and delivered a fully optimised solution. Festo then built and delivered the complete handling solution for installation in the TQ-Lab.

Festo has also made it easier for Torus to order the handling system in the future by assigning it a single order number, which automatically generates a comprehensive list of all the necessary components. This streamlines purchasing and stores, while still supporting any repair or replacement needs. Festo also has a global network of service centres that enables Torus to offer its customers local support with commissioning and any troubleshooting.

Total package

Festo’s handling solution delivers the accuracy and adaptability to customer requirements that Torus wanted to achieve. It is also future-proofed, allowing reprogramming to suit changes in packaging design.

Festo’s complementary automation expertise and online software tools further improved the design and development of the TQ-Lab, significantly reducing the component selection and prototyping phase.

Brian Wilson concludes: “Festo were there all the way, from early concept discussions, through component selection and system design, testing to commissioning, to fine-tuning and completion. With their support, we have delivered a unique automated testing solution at least six months earlier than predicted – giving us and our customers a real competitive advantage.”